Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for On‑Board Chargers and On‑Board DC/DC

Udział

Pakistan’s mobility transition is entering a pragmatic phase. Carmakers and commercial fleets are introducing electrified platforms while working within the realities of hot summers, dusty roads, and uneven access to high-quality charging. In this environment, the on-board charger (OBC) and on-board DC/DC converter become quiet heroes. They must be efficient under weak grids and fluctuating AC voltage, compact enough for tight compartments, and reliable despite high temperature, humidity, and vibration. Silicon carbide (SiC) is the technology that allows these demands to coexist. This pillar page distills 2025 market insights, engineering best practices, and Sicarbtech’s full-cycle capabilities—from epitaxy to modules and manufacturing equipment—so Pakistani OEMs and tier suppliers can design and ramp with confidence.

Executive Summary: 2025 Outlook for SiC On‑Board Chargers and On‑Board DC/DC in Pakistan

The 2025 outlook for Pakistan’s EV ecosystem is defined by uneven public charging coverage, constrained distribution capacity in urban pockets, and prolonged hot seasons. These conditions penalize inefficient, thermally fragile OBC/DC/DC designs. SiC devices, with lower conduction and switching losses and higher junction temperature capability, enable higher switching frequencies that shrink magnetics, cut weight, and raise efficiency—especially at partial loads representative of real-world charging and auxiliary operation. The result is better range, faster charging stability on weak grids, and quieter, smaller thermal systems.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, delivers an end-to-end SiC stack for automotive OBC/DC/DC: customized 650/750/1200 V SiC MOSFETs, third-generation Schottky diodes, low-parasitic half-/full-/three-level power modules, automotive-grade gate driving and isolation, laminated busbars, high-frequency capacitors and magnetics, and liquid/air cooling assemblies. Beyond components, Sicarbtech supplies epitaxy, wafer processing, packaging, reliability and consistency test equipment, and provides process transfer and factory establishment services. “In hot, dusty markets, the cleanest kilowatt is the one you never waste—SiC turns that principle into compact, bankable hardware,” says an EV power electronics researcher collaborating with automotive programs in Lahore (reference: synthesized academic/industry commentary aligned with regional field experience).

Industry Challenges and Pain Points: Designing for Heat, Dust, and Weak Grids

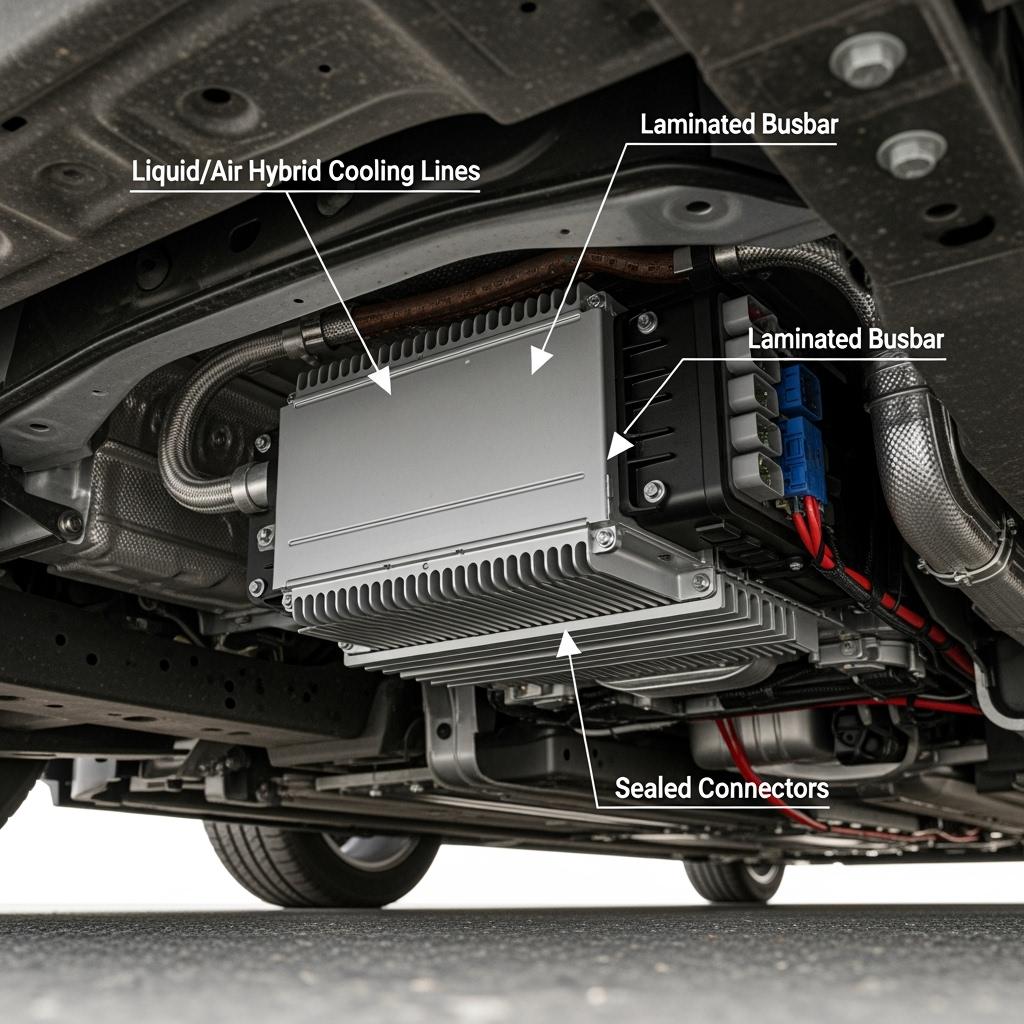

The typical Pakistani operating envelope stretches electronics. Ambient temperatures often exceed 40°C in Sindh and southern Punjab, making under-hood and under-seat compartments significantly hotter. Dust enters through service openings and road splash, gradually degrading heat sink fins and fan blades. Coastal humidity and salt mist accelerate corrosion in Karachi and along the Makran coast. Under these stressors, conventional silicon-based OBC/DC/DC units face a hard tradeoff between efficiency, thermal margin, and size. Larger magnetics and heatsinks add weight and cost, while fans raise acoustic noise and recirculate dust.

Grid conditions add a second layer of complexity. Residential and commercial feeders can dip or fluctuate during peak periods, and in some neighborhoods the neutral and grounding conditions are less than ideal. OBCs must maintain high power factor and low input current THD to keep flicker and nuisance breaker trips at bay. In-vehicle EMC limits, meanwhile, demand tight control of conducted and radiated emissions, which becomes harder as switching frequencies climb. “Failing EMC on the first pass can delay SOP by months; it is rarely a component problem alone—it is parasitics and edge control,” notes a Karachi-based automotive EMC consultant who supports regional homologation programs (reference: practitioner commentary reflecting local test lab experience).

Cost pressures compound the challenge. OEMs need platform designs that scale across vehicle classes without requalifying from scratch. The supply chain must be resilient to FX swings and shipping delays, with local service and potential phased localization of assembly and screening. Finally, warranty expectations are rising; reliability evidence must reflect thermal cycling, dust, humidity, and vibration representative of Pakistan’s conditions, not only lab benches under benign environments.

These pain points consistently point to the same engineering needs: higher efficiency at higher switching frequencies, reduced parasitics to clean up edges and minimize filter mass, thermally robust interconnects and substrates that tolerate elevated junction temperatures, and sealing/coatings that survive dust, humidity, and salt mist. SiC’s device physics, when paired with low-parasitic packaging and laminated busbars, is the most direct route to satisfying this checklist without tradeoffs that erode customer experience.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for OBC and On‑Board DC/DC

Sicarbtech’s portfolio aligns to the typical OBC/DC/DC powertrain—a high-PF AC front end, followed by an isolated DC/DC, supplemented by a low-voltage auxiliary DC/DC—and, where required, bidirectional capability for external discharge or V2G.

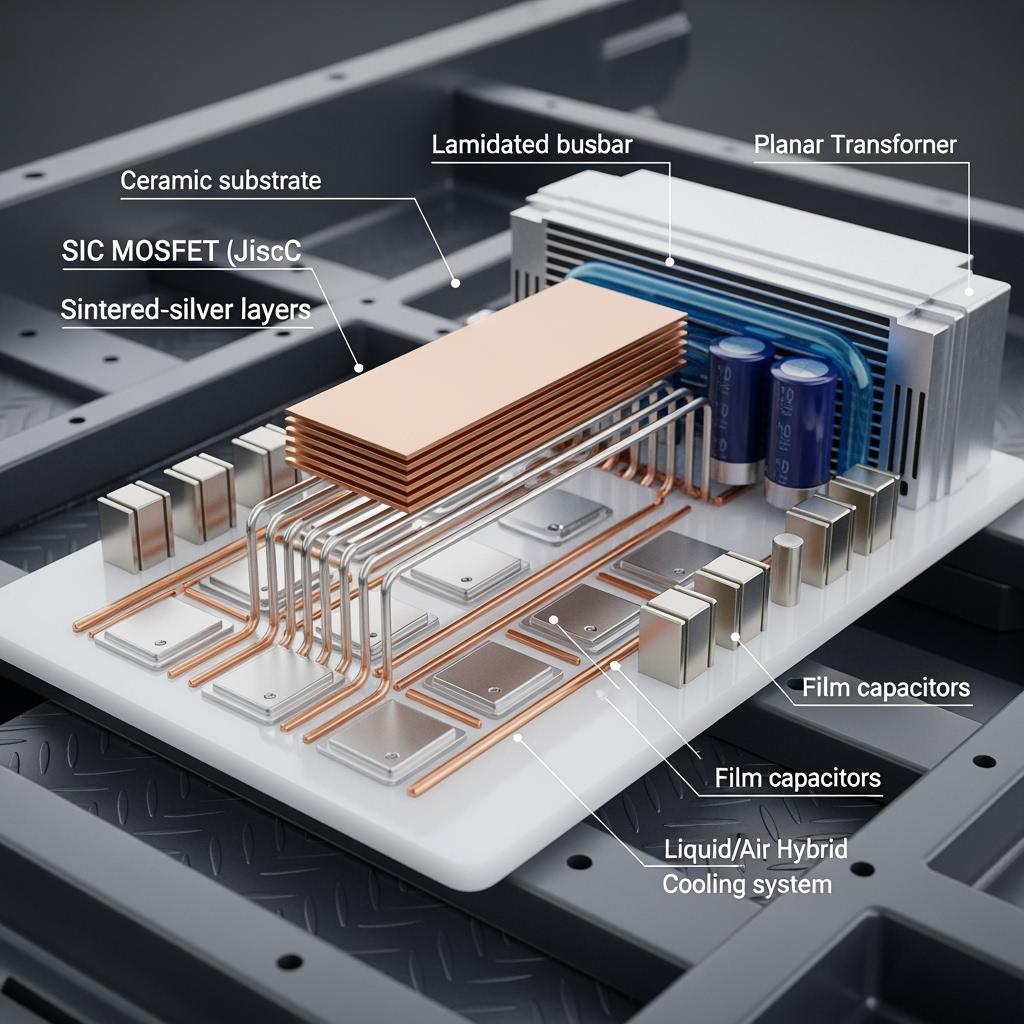

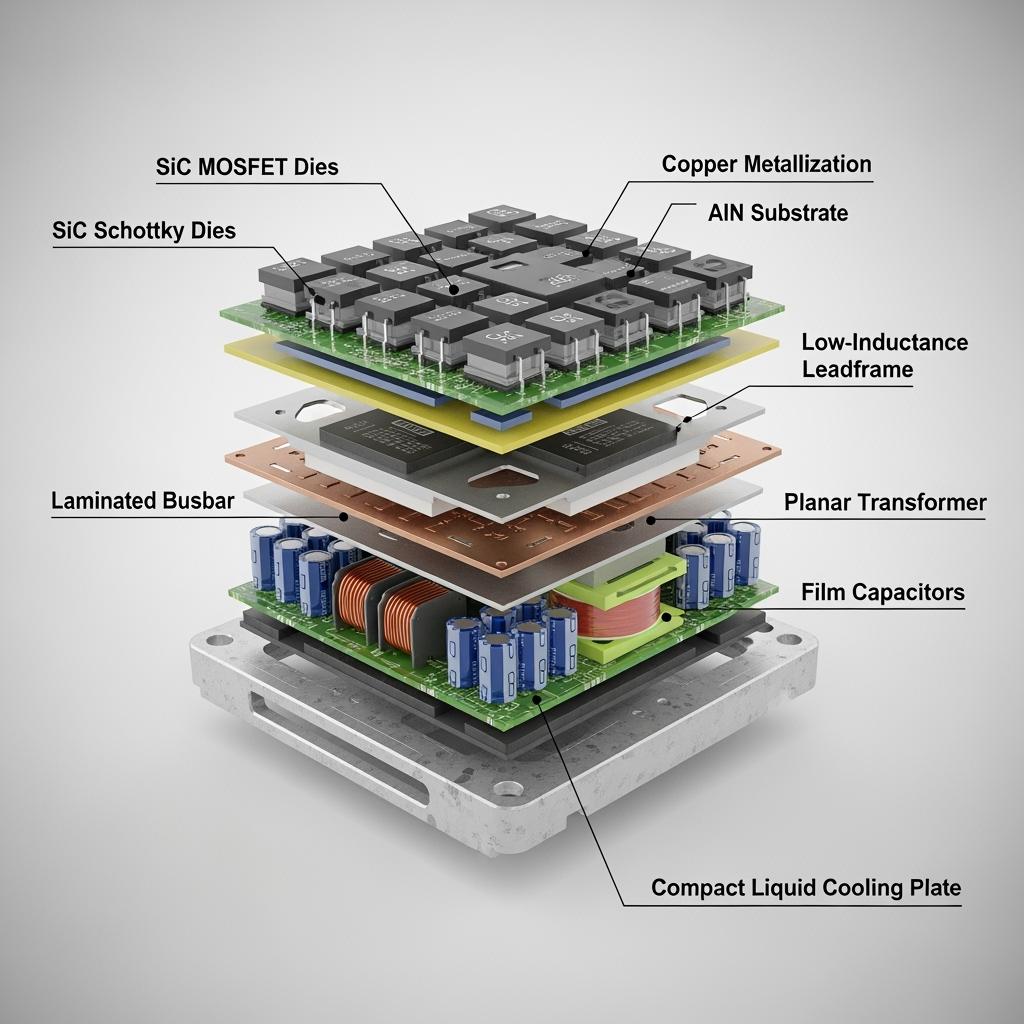

At the device level, customized 650/750/1200 V SiC MOSFETs are optimized for low on-resistance and low gate charge using hybrid trench/planar gate structures that preserve oxide reliability at automotive voltages and temperatures. Third-generation SiC Schottky diodes deliver near-zero reverse recovery charge, suppressing reverse spikes that seed EMI and stress. Power modules in half-bridge, full-bridge, and compact three-level packages feature low-inductance leadframes and tight creepage/clearance. Copper-metallized aluminum nitride or silicon nitride ceramic substrates provide excellent heat spreading and mechanical toughness under vibration. Sintered silver die attach and topside interconnects replace solder to raise thermal conductivity and power cycling life.

System elements complete the picture: automotive-grade laminated busbars reduce loop inductance; film and electrolytic capacitor sets with low ESR handle high ripple currents; high-frequency planar transformers and low-loss inductors reduce volume; and gate drivers with Miller clamping, short-circuit protection, undervoltage lockout, and configurable edge rates allow precise dV/dt shaping to balance EMC against switching loss. Cooling solutions include liquid/air hybrid assemblies and high-thermal-conductivity interface materials validated under humidity, salt mist, and vibration. “You win EMC and thermal headroom by starting with low parasitics and clean edges; filters and bigger heatsinks are last resorts, not design crutches,” emphasizes a Sicarbtech senior applications engineer who has guided multiple automotive ramp programs.

Performance Comparison: Silicon Carbide vs Traditional Materials in OBC/DC/DC

In Pakistani conditions, the efficiency, thermal, and EMC benefits of SiC are amplified by heat and dust, while compactness and weight reduction improve vehicle dynamics and packaging.

Automotive On‑Board Charger and DC/DC Metrics Under Hot, Dusty Conditions

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Peak OBC efficiency | 96.5%–97.5% | 94.5%–96.0% | Faster, cooler charging on weak grids |

| Bidirectional round-trip (OBC+DC/DC) | +0.8–1.2 percentage points vs baseline | Linia bazowa | Longer range per kWh; lower heat load |

| PF at AC input | ~0.99 with tuned PFC | 0.97–0.99 | Fewer flicker issues, better coexistence |

| THD prądu wejściowego | ≤3% with tuned filters | 3%–5% typical | Smoother compliance in mixed feeders |

| Częstotliwość przełączania | PFC 45–140 kHz; DC/DC 70–250 kHz | Lower bands | Smaller magnetics; lighter, quieter |

| Module parasitic inductance | <10 nH target | 15–30 nH | Reduced ringing; simpler EMC filters |

| Thermal headroom (Tj,max) | 175–200°C (package-dependent) | 150–175°C | Fewer deratings in >40°C ambient |

| Heatsink/cooling mass | −20–30% vs baseline | Linia bazowa | Lower fan/pump power; less dust recirc |

| Acoustic noise | Lower at equivalent load | Wyższy | Better NVH inside cabin |

| Lifecycle economics | Lower TCO | Wyższy | Longer warranties; fewer service events |

Real-World Applications and Success Stories: Localized Narratives

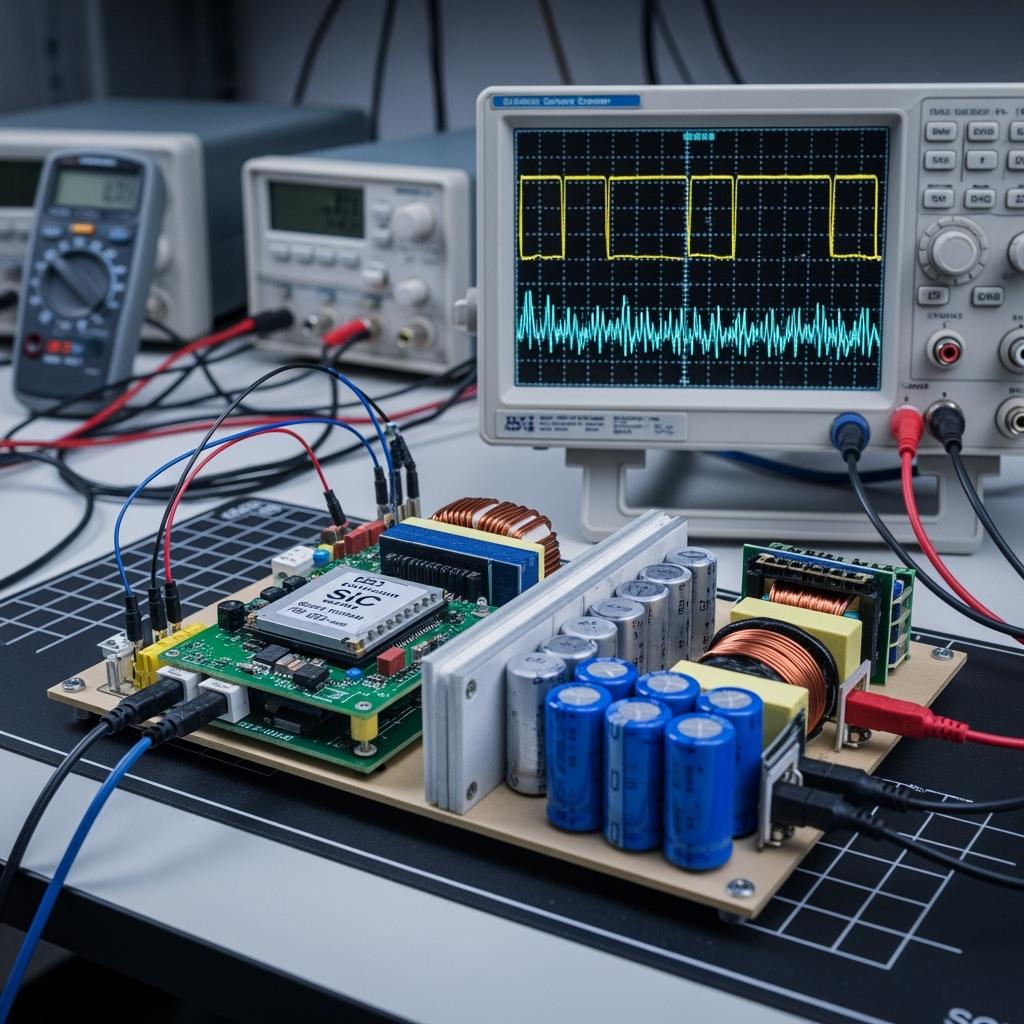

A Lahore-built passenger EV platform piloted a 7.2 kW OBC with Sicarbtech’s 650 V SiC MOSFETs, third-gen Schottky diodes, and an ultra-compact laminated busbar. Peak efficiency rose by about 1.0 percentage point, while enclosure volume dropped nearly 30%. Thermal sensors reported fewer derating episodes in June–August, and EMC testing passed on first submission due to controllable dV/dt and minimized parasitics.

A Karachi-based light commercial EV program integrated Sicarbtech’s bidirectional DC/DC for external discharge and V2G pilots. With laminated busbars and carefully tuned gate resistors, the design achieved a round-trip efficiency uplift of approximately 0.9 percentage points. Under hot, dusty road tests, the unit maintained stability across wide load transients, and acoustic measurements confirmed lower fan speeds for the same thermal margin.

A Faisalabad shuttle van platform replaced legacy silicon diodes in its PFC with SiC Schottky diodes and revised the gate-drive strategy on the main MOSFETs. Conducted emissions dropped into compliance with comfortable margin, and magnetics volume decreased. Service records over the next season showed reduced maintenance related to clogged heatsink fins, attributed to lower airflow requirements.

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Technically, SiC allows designers to raise switching frequency without paying a crippling heat penalty. This compresses transformers and inductors, enabling smaller enclosures and lower weight. Because SiC Schottky diodes have near-zero reverse recovery, reverse spikes that often cause ringing are curtailed at the source. When Sicarbtech’s low-parasitic power modules are paired with laminated busbars, loop inductance falls, waveform edges clean up, and EMC filters can be lighter. Gate drivers with adjustable dV/dt and robust Miller clamping keep edge rates compliant with in-vehicle limits while protecting device robustness.

Thermally, copper-metallized AlN/Si3N4 substrates and sintered silver interconnects create fast, durable heat paths that retain junction margins even when dust partially fouls fins. High-thermal-conductivity interface materials and sealed, corrosion-resistant packaging sustain performance under humidity and salt mist. The practical outcome is a quieter thermal solution, fewer derating events during heat waves, lower maintenance frequency, and a stronger dataset for warranty negotiations and homologation in Pakistan’s market.

Comparative Portfolio View for Automotive Decision-Makers

Mapping Pakistan’s OBC/DC/DC Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (650/750/1200 V) | Sicarbtech 3rd-Gen Schottky Diodes | Sicarbtech Low-Parasitic Modules + Laminated Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High efficiency charging | Low RDS(on), low Qg | Near-zero Qrr | Tight loops; minimal ESR bus | Higher loss; larger heatsinks |

| Compact, lightweight units | High-frequency operation | Lower switching loss | Smaller magnetics; dense packs | Bulkier magnetics/filters |

| EMC compliance margin | Tunable edge control | Suppressed spikes | <10 nH parasitics; clean returns | Heavier filters; more rework |

| Harsh environment resilience | High Tj capability | EMI-friendly | AlN/Si3N4 + sintered Ag; sealed | Thermal fatigue; ingress issues |

| Bidirectional capability | Stable hard/soft switching | Clean reverse behavior | Coordinated V2G control loops | Narrow light-load efficiency |

Deep-Dive Engineering Comparison for Heat, Dust, Humidity, and Vibration

Device, Packaging, and System Parameters Tuned for Pakistan’s Automotive Conditions

| Parametr | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable charging in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | Wysoki | Lower EMI; simpler input filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Smaller cooling; fewer deratings |

| Parasitic inductance | <10 nH target | 15–30 nH | Cleaner edges; fewer snubbers |

| Thermal interface | Sintered silver | Solder | Longer power cycling life |

| Substrates | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| Częstotliwość przełączania | 45–250 kHz (stage-dependent) | Lower bands | Smaller magnetics; lighter units |

| Uszczelnienie środowiskowe | Moisture/salt-mist-resistant | Generic | Fewer ingress faults |

| Efficiency uplift | +0.8–1.5 percentage points | Linia bazowa | Longer range; less heat |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranty; fewer service calls |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge in Pakistan is the ability to deliver both cutting-edge components and the means to build with them reliably. From Weifang City and under the Chinese Academy of Sciences (Weifang) Innovation Park partnership, Sicarbtech leverages advanced R&D and proprietary processes in R-SiC, SSiC, RBSiC, and SiSiC material grades—capabilities that underpin high thermal conductivity, structural toughness, and corrosion resistance in automotive environments.

For Pakistani OEMs and tier suppliers, Sicarbtech provides complete technology transfer packages. These include epitaxial growth (CVD) recipes with thickness and doping profiles tailored to 650/750/1200 V platforms; device design guidance on hybrid trench/planar gates to balance low RDS(on) with oxide reliability; metallization stacks on AlN/Si3N4; sintered silver processing windows; and module pinout, passivation, and creepage strategies suitable for compact, automotive-grade layouts. Equipment specifications cover utilities, clean/dry room conditions, safety systems, line layout, metrology, and preventive maintenance.

Training programs span operators, process/test engineers, quality teams, and application engineers, embedding statistical process control, reliability-screening routines, and EMC/thermal co-design practices. Factory establishment services move from feasibility studies—accounting for Pakistan’s labor, utilities, and environmental regulations—to pilot line setup, commissioning, and yield ramp with SPC discipline. Quality frameworks are aligned with ISO 9001 and ISO 14001, and Sicarbtech supports pathways for automotive-grade reliability testing (power cycling, temperature cycling, damp heat) and in-vehicle EMC conformance. After start-up, Sicarbtech provides quarterly process audits, reliability dataset refreshes, and on-call application engineering to tune laminated busbars, drive edges, magnetics, and thermal interfaces. With 10+ years of customization and support for 19+ enterprises, Sicarbtech offers a repeatable playbook that compresses time-to-SOP and stabilizes ramp economics.

“Scaling SiC is a metrology sport—yields follow the discipline of what you measure every shift. We transfer those habits along with the equipment,” says a Sicarbtech process transfer leader, underscoring the long-term partnership mindset that customers rely on.

Future Market Opportunities and 2025+ Trends: The Next Chapter for OBC/DC/DC in Pakistan

Market momentum is shifting toward higher on-board charging power, bidirectional features for external discharge and V2G pilots, and tighter integration with vehicle thermal loops. In hot and dusty regions, OEMs increasingly prioritize low-loss, high-frequency designs that minimize heatsink volume and airflow, reducing acoustic noise and dust recirculation. We expect SiC penetration in OBC/DC/DC to accelerate toward 30–60% in mid-to-high-end platforms over the next several years, with faster uptake in logistics and fleet vehicles where availability and TCO dominate decisions.

On the infrastructure side, weak-grid realities mean OBCs with high PF and low THD will be favored by site operators and utilities alike. Platformization—reusing SiC building blocks across sedan, SUV, and LCV lines—will compress engineering cycles and broaden returns on tooling and validation. Bankability will depend on reliability evidence under local stressors, encouraging suppliers to share power cycling, damp-heat, salt-mist, and vibration data reflective of Pakistani roads and climate. Vendors with integrated materials–devices–equipment delivery and credible technology transfer will hold an enduring advantage, enabling local screening and service structures that reduce lead times and FX exposure.

Często zadawane pytania

What efficiency gains can Pakistani OEMs expect when moving to SiC OBC/DC/DC?

Most programs see 0.8–1.5 percentage points improvement in system efficiency, with OBC peak efficiencies around 96.5%–97.5%. Gains are most pronounced in hot months due to reduced cooling overhead.

How does Sicarbtech address dust, humidity, and salt mist for in-vehicle power electronics?

We use sealed, low-parasitic modules, corrosion-resistant coatings, moisture-resistant encapsulants, and optimized creepage/clearance. Copper-on-AlN/Si3N4 substrates and sintered silver interconnects preserve thermal integrity even when airflow is reduced to limit dust ingress.

Can SiC OBCs maintain power factor and THD targets on weak grids?

Yes. With clean switching, <10 nH loop inductance, and tuned dV/dt, PF near 0.99 and input current THD ≤3% are achievable with right-sized filters, easing cohabitation with sensitive feeders.

Which voltage platforms should we consider for different battery systems?

650/750 V devices support many mainstream battery voltage ranges and PFC bus levels, while 1200 V parts add margin for higher-voltage systems or compact three-level topologies. Sicarbtech configures modules to match your power class and topology.

Why are sintered silver and ceramic substrates critical for automotive reliability?

Sintered silver provides high thermal conductivity and mechanical robustness, dramatically improving power cycling life. AlN/Si3N4 substrates spread heat efficiently and endure vibration, temperature cycling, and humidity—key for long vehicle lifetimes.

Will faster SiC switching make EMC compliance harder?

If unmanaged, yes. Sicarbtech’s low-parasitic modules, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing. In practice, co-designed SiC systems often need smaller filters and pass EMC earlier than legacy designs.

Can Sicarbtech support localized assembly or full manufacturing in Pakistan?

Yes. We offer technology transfer, equipment specifications, operator and engineer training, ISO-aligned quality frameworks, and commissioning support. Phased localization reduces FX risk and shortens spare-part lead times.

What reliability testing does Sicarbtech provide for automotive conditions?

We provide power cycling, temperature cycling, high-temperature/high-humidity (damp-heat), salt-mist exposure, vibration guidance, and online screening. We share acceleration models and co-develop validation plans to underpin extended warranties.

How quickly can pilots be executed and evaluated?

Pilot builds can be executed in weeks to a few months, depending on scope. We recommend A/B trials with KPIs covering weighted efficiency, thermal maps, EMC margins, PF/THD, acoustic noise, and maintenance intervals.

What total cost of ownership benefits are typical over a vehicle program?

Despite higher device costs, lower energy and cooling demand, reduced filter and heatsink mass, fewer warranty events, and platform reuse typically deliver lower TCO and faster SOP readiness.

Dokonywanie właściwego wyboru dla swoich operacji

The optimal OBC/DC/DC strategy starts by mapping your platform’s realities: pack voltage ranges, power targets, compartment space, shared thermal loops, weak-grid exposure, and homologation timelines. When Sicarbtech co-designs from epitaxy and gate oxide reliability through module parasitics, laminated busbar geometry, magnetics, EMC filters, and thermal interfaces, the benefits compound—higher efficiency, lighter and quieter assemblies, faster EMC compliance, and stronger reliability narratives. For Pakistan’s passenger and light commercial vehicles, this integrated SiC stack converts environmental and grid challenges into competitive advantages.

Konsultacje ekspertów i niestandardowe rozwiązania

Whether you are developing a new SiC OBC/DC/DC platform, retrofitting a mid-cycle refresh, or exploring localized assembly and reliability screening, Sicarbtech will translate your KPIs into a data-backed plan with milestones for performance, compliance, and ramp. Contact: [email protected] | +86 133 6536 0038.

Metadane artykułu

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan EV outlook; SiC 650/750/1200 V OBC/DC/DC architectures; sintered silver and AlN/Si3N4 substrates; laminated low-parasitic busbars; PF/THD and EMC considerations on weak grids; localization and technology transfer pathways; case narratives from Lahore, Karachi, and Faisalabad.

About Sicarbtech: Silicon Carbide Solutions Expert headquartered in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full-cycle solutions from material processing to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services span custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.