Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Cement Kiln Cooler Discharge Zones and Ventilation Ducts

Udział

Pakistan’s cement industry is entering 2025 with an uncompromising brief: cut energy per ton, extend campaign life, and protect crews—while coping with volatile fuels, variable raw mixes, and supply chain uncertainty. Nowhere do these pressures collide more intensely than in the kiln cooler discharge zone and ventilation ducts, where high-temperature clinker, gas–solid two-phase scouring, and alkali–sulfur–chlorine cycling attack conventional linings from every direction. Industrial silicon carbide (SiC) offers a clean technical break. With high hardness, high thermal conductivity, low thermal expansion, and corrosion resistance, SiC wear systems tame grooving, spalling, fouling, and pressure-drop creep, transforming maintenance from reactive firefighting into planned reliability. Sicarbtech—located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of advanced SiC customization, full-cycle manufacturing, and turnkey technology transfer to help Pakistani plants localize capability and control outcomes.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters for Pakistan’s Coolers

Cement kiln coolers in Pakistan increasingly face larger clinker, hotter discharge, and higher alternative fuel ratios that swing alkali–sulfur–chlorine chemistry. In this environment, high-alumina and metallic-aggregate wear systems often erode quickly, oxidize, or foul, driving pressure drops and unplanned stoppages. Silicon carbide flips those tendencies. Its high hardness and dense microstructure resist impact and sliding abrasion from clinker particles. Its thermal conductivity drains heat and reduces gradients, while low expansion limits stress accumulation and crack propagation. With engineered low-wettability surfaces, SiC also shrugs off dust adhesion and clinker bonding, preserving flow cross-section and ventilation efficiency.

Sicarbtech integrates “material formulation + composite structure design + densification process + surface engineering + prefabrication and onsite installation + inspection and O&M” into one cohesive program. Moreover, through technology transfer, Pakistani partners can bring classification, mixing, prefabrication, and eventually reaction sintering in-country, compressing lead times and buffering exchange-rate risk. The result is not only longer life and steadier airflow, but a repeatable, auditable method for procurement and operations teams to bank on.

Industry Challenges and Pain Points: The Reality in Pakistan’s Cooler Discharge and Ducting

Stand at the discharge hood during a peak run and the failure mechanics unfold in real time. Oversized, high-temperature clinker lands with kinetic force, then grinds and slides across the working face; simultaneously, alkali- and sulfur-laden dust-laden gas scours ventilation ducts at high velocity, especially at elbows and inlets where re-attachment accelerates wear. With every start, stop, and load swing, thermal gradients spike and recede, prying open microcracks in materials with higher expansion or weak connectivity. If chemistry turns aggressive, penetration reactions loosen the microstructure, while dust bonding and clinker adhesion seed build-ups that restrict cross-section and inflate pressure drop. Ventilation efficiency slips, cooling performance deteriorates, and operators see the effects as hotter clinker out, higher fan currents, and a noisier control room.

Pakistan’s operating context intensifies these risks. Plants run both legacy and modern lines, often pairing different grate cooler designs across a site. Alternative fuels are rising to contain energy costs, bringing wider volatility in ash chemistry and alkali–sulfur–chlorine cycling. Maintenance teams must work around monsoon humidity that complicates bake-out and venting; anchors and interfaces suffer fatigue as thermal and mechanical shocks accumulate. Supply-side uncertainty lingers as well: high-performance wear systems are not broadly available locally, so import buffers tie up working capital, and FX moves turn routine reorders into budget debates.

“The fastest way to lose a week’s production is a lining surprise in the discharge zone or an elbow that thins faster than expected,” a Karachi-based maintenance head remarked during a 2024 review. “When pressure-drop curves steepen, fan energy climbs, and we start planning for cleanouts instead of throughput.” Industry advisors echo the physics. “In gas–solid scouring zones, it’s two levers: conductivity to quench gradients, and connectivity control to block penetration,” notes a regional refractory consultant, citing established refractory and wear-corrosion handbooks. “Without both, you trade impact resistance for oxidation or vice versa—and neither trade ends well.”

Compliance and safety considerations are not optional. Plants are increasingly asked for ISO 9001-aligned QA documents and PSQCA conformity in tenders; ISO 14001 goals put a premium on fewer interventions, lower waste, and energy discipline. Every extra maintenance hour at high temperature lifts risk and cost. Ultimately, the cooler’s lining strategy either stabilizes the plant’s heat and airflow or destabilizes it; there is little middle ground in Pakistan’s 2025 reality.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

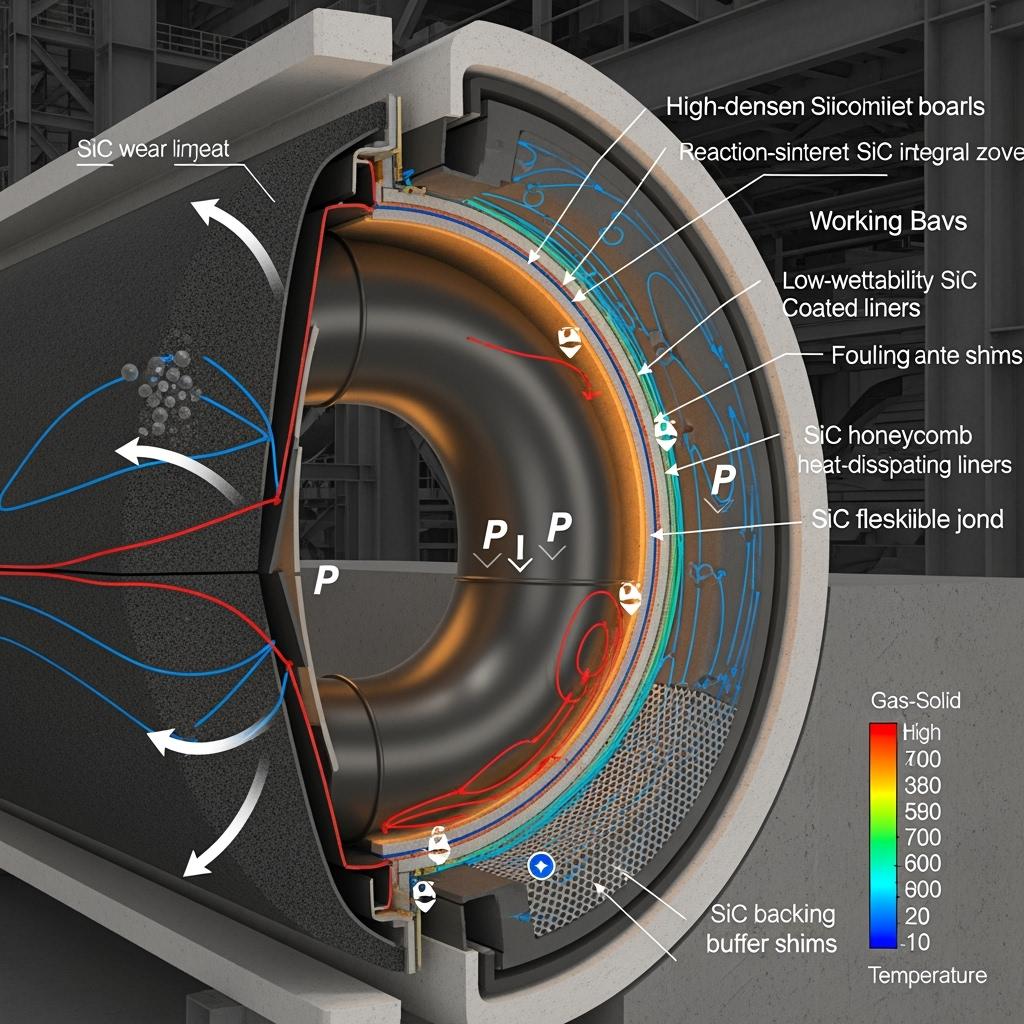

Sicarbtech’s SiC suite for coolers is built as a modular, field-proven system. High-density SiC wear liners anchor the discharge working face, with tuned grain bonding that resists cutting and rolling abrasion. Where clinker impact is extreme, SiC–carbon composite impact-resistant liners add toughness, with antioxidant packages stabilizing carbon phases in oxidizing streams. For ventilation elbows and inlets—the classic hot spots—reaction-sintered SiC integral elbow components deliver anti-scouring performance and dimensional stability under oxygen-rich, dusty flow.

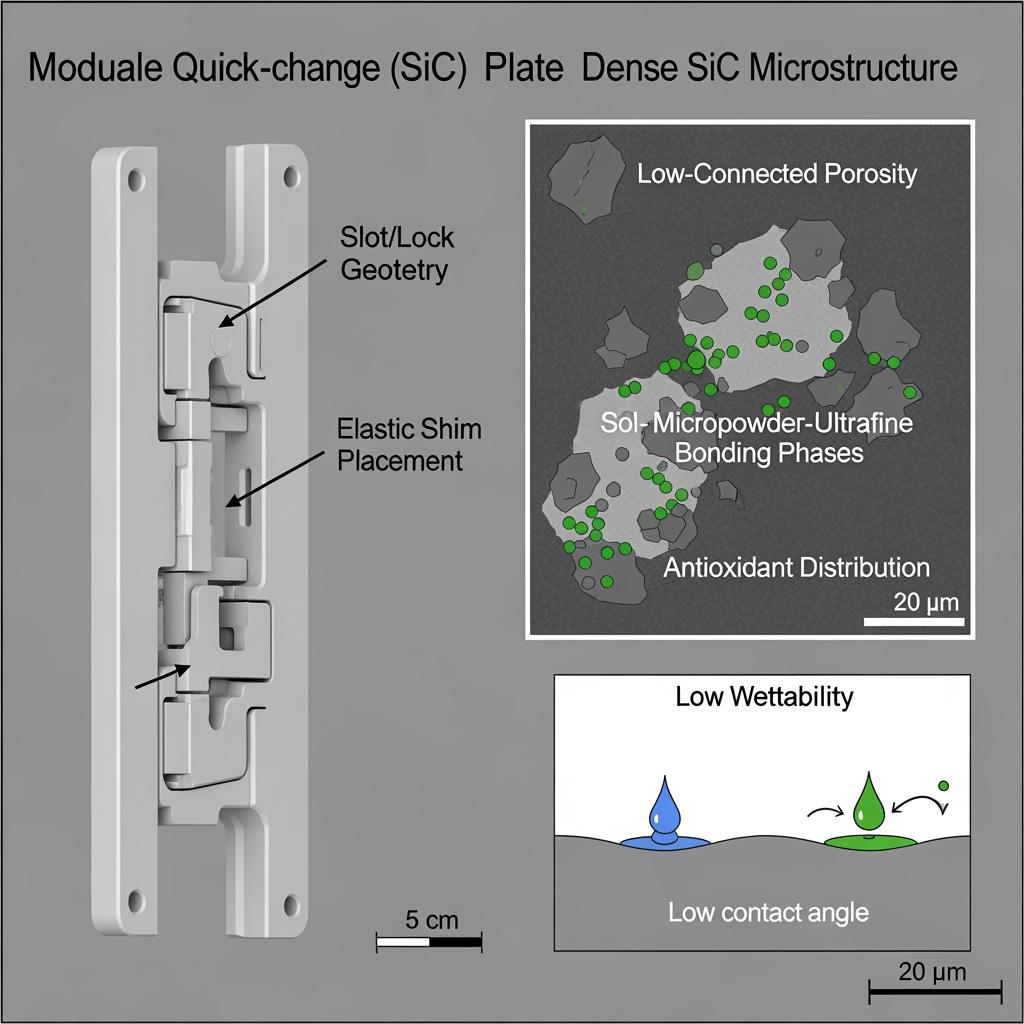

In fouling-prone sections, low-wettability, anti-fouling SiC coated liners slow adhesion and pressure-drop growth, while SiC honeycomb heat-dissipating liners shed weight and move heat laterally, flattening temperature peaks. High-thermal-conductivity SiC backing insulation composites protect shells and damp gradients, and ultra-low-cement SiC-bonded castables create resilient transition layers and fast-curing repairs. To keep maintenance windows tight, modular locking-type SiC quick-change plates and SiC wear gunning/patching mixes enable two-shift replacement and online patching. Flexible joints and buffer shims relieve expansion and impact stresses, reducing delamination and anchor fatigue. Under the hood, multi-graded SiC aggregates, micropowder activation packages, and anti-oxidation additives deliver low connected porosity and robust post-firing strength.

Sicarbtech pairs these materials with a localizable equipment backbone: reaction sintering and densification kilns, cold isostatic and die-press forming, intelligent mixing with vacuum vibration, precision classification and demagnetization, CNC cutting and grinding/polishing lines, and NDT plus dimensional inspection protocols. “The best liner is only as good as its curve,” a Sicarbtech process engineer says. “We transfer furnace curves, press parameters, surface prep protocols, and bake-out schedules that fit Karachi humidity and Lahore winters—so performance is consistent across seasons and shifts.”

Comparative Technical Performance for Cooler Discharge and Ventilation Ducts

| Technical performance in cooler discharge/ventilation zones | Silicon Carbide Systems (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Clay Liners | Metallic-Aggregate Wear Plates |

|---|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | 2.2–2.8 | 2.6–3.0 |

| Apparent porosity (%) | 6–14 (dense parts ≤ 6) | 15–25 | 12–20 (rises with oxidation) |

| Thermal conductivity at RT (W/m·K) | 20–55 | 3–7 | 8–15 (declines as metal oxidizes) |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | 60–150 | 80–160 |

| Flexural strength at RT (MPa) | 14–35 | 8–20 | 10–25 |

| Thermal shock (1000°C water quench) | ≥ 30–60 | 10–20 | 10–25 |

| Alkali/oxidation resistance | High; low connectivity | Umiarkowany | Weak at high O2; scale spalling |

| Wear under impact/abrasion | Excellent; hardened working face | Moderate; groove formation | Good early; degrades with oxidation |

| Fouling/adhesion tendency | Low with SiC anti-fouling coating | Wyższy | Moderate; increases over time |

In Pakistani conditions—hot clinker, aggressive gas chemistry, and dusty two-phase flow—SiC’s conductivity, hardness, and corrosion resistance converge to slow every major failure mode, buying back airflow stability, cooler efficiency, and safety margin.

Real-World Applications and Success Stories in Pakistan

A central Punjab producer faced 6–8 month change-out cycles in the discharge zone plus chronic erosion at two ventilation elbows. Sicarbtech engineered a solution using high-density SiC wear liners at the discharge working face, low-wettability SiC coatings on fouling-prone plates, reaction-sintered SiC integral elbows at the worst bends, and modular locking quick-change plates around the impact zone. Transition layers used ultra-low-cement SiC-bonded castable; shell hot spots were treated with high-conductivity SiC backing boards. The site adopted Sicarbtech’s substrate prep, vacuum vibration compaction, and humidity-adjusted bake-out curves. Over the next campaign, discharge liner life increased to 14–16 months, elbow life nearly doubled, pressure-drop growth rate fell by about 32%, and annual repair events dropped by roughly 48%. Refractory consumption per ton of clinker eased by about 20%, while unplanned downtime dropped by approximately 27%.

In Sindh, a plant with high alternative-fuel ratios reported anchor fatigue and delamination in a dust-laden ventilation branch. The upgrade added SiC honeycomb heat-dissipating liners to reduce weight and spread heat, flexible joints and elastic shims to buffer expansion, and a SiC wear gunning mix for online patching. Vibration and pressure-drop trends flattened, and maintenance intervals aligned with planned shutdowns rather than emergency calls. As one production manager noted, “When the fan amperage stops drifting upward, you know the lining is finally working for you—not against you.”

Zalety techniczne i korzyści z wdrożenia z lokalną zgodnością

Silicon carbide’s physical properties align with cooler KPIs. High hardness reduces cutting and grinding wear from clinker; high thermal conductivity lowers gradients that drive spalling, while low expansion limits stress accumulation. Dense, low-connectivity pores and grain-boundary purification impede penetration and oxidation, preserving strength. Low-wettability surface engineering slows fouling and pressure-drop creep, translating into steadier airflow and lower fan energy.

From a compliance lens, fewer interventions and lower energy intensity support ISO 14001 goals. Sicarbtech’s documentation aligns with ISO 9001 and supports PSQCA conformity for Pakistani tenders, incorporating SPC on density, porosity, CCS/MOR, thermal shock, adhesion, and dimensional control. SOPs—substrate prep, vacuum vibration, moisture/venting control, staged bake-out, and adhesion checks—integrate with CMMS for auditable, repeatable execution. Practically, that means fewer high-temperature tasks, a safer shop, and budget predictability despite fuel and FX swings.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s edge is converting high-performance materials into a controllable local capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary manufacturing routes for R-SiC, SSiC, RBSiC, and SiSiC, and we transfer them through staged, de-risked programs.

We begin with feasibility and plant layout tailored to Pakistani utilities, labor, and throughput targets. Equipment specifications include reaction sintering and high-temperature densification kilns; cold isostatic and die presses for uniform green bodies; precision classification and demagnetization for stable purity and PSD; and intelligent mixing with vacuum vibration for rheology control. CNC cutting and grinding/polishing lines deliver fit and surface quality; NDT and coordinate metrology enforce traceability and quarantine drift.

Quality systems are built-in: ISO 9001-aligned QC with SPC on bulk density, apparent porosity, CCS/MOR, thermal shock, adhesion, and dimensional checks; ISO 14001 environmental practices; and safety SOPs aligned with ISO 45001 principles. We train operators and supervisors in furnace curves, press parameters, substrate prep, spraying/gunning techniques, moisture and venting control, and seasonal bake-out adjustments. Commissioning includes on-floor curve tuning and supervised installations at the discharge zone and elbows. After start-up, Sicarbtech provides remote monitoring, quarterly audits, and formulation/geometry iteration tied to site KPIs—pressure-drop growth, vibration and airflow stability, shell temperature, and repair frequency.

Across 19+ enterprise collaborations, this “materials + equipment + process + training” stack has shortened lead times from months to weeks and reduced inventory buffers while raising batch consistency. As a Sicarbtech technical director frames it, “Owning the recipe is only half the battle. When Pakistani teams own the curves, the joints, and the checks, liner life stops being a guess—and becomes a schedule.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for cooler discharge/ventilation linings | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Verify via ISO/ASTM equivalents; SPC by batch and season |

| Apparent porosity (%) | 6–14 (dense parts ≤ 6) | Correlate with permeability and oxidation cup tests |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | ISO 10059/ASTM C133 equivalents; coupon traceability |

| Flexural strength at RT (MPa) | 14–35 | Bend tests with soak logs and location mapping |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check with start–stop/load-swing history |

| Max service temperature (°C) | 1450–1650 | Confirm vs local gas chemistry and O2 potential |

| Thermal conductivity (W/m·K) | 20–55 | Validate by IR thermography on trial sections |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre-/post-exposure |

| Surface contact angle (relative) | 10–30% better than oxide systems | Track vs pressure-drop growth and fouling maps |

Operational Outcomes Comparison That Drive Energy, Uptime, and Safety

| Outcomes critical to Pakistani cooler operations | SiC Wear Liners + Anti-Fouling Coating + R-SiC Elbows + Quick-Change Modules | High-Alumina/Clay or Metallic Baselines |

|---|---|---|

| Discharge liner life | +50–150% (extreme impact >2×) | Baseline; rapid groove wear |

| Elbow/duct life | +60–120% | Variable; oxidation/fouling issues |

| Pressure-drop growth | −20–40% vs baseline | Faster growth; early cleanouts |

| Airflow stability | +10–25% improvement | Drift with fouling and wear |

| Thermal shock/spalling events | −40–70% | Higher under cyclic loads |

| Nieplanowane przestoje | −20–40% | Elevated; reactive maintenance |

| Safety exposure at heat | Reduced via longer intervals | Higher; frequent hot tasks |

| Czas realizacji i ekspozycja na FX | Localizable via tech transfer | Import-dependent; volatile costs |

Innovation That Matters: From Microstructure Tuning to Modular Agility

Sicarbtech focuses innovation where the cooler demands it most. Functionally graded structures place a high-SiC, high-hardness working face over a low-modulus transition layer and insulating backing to distribute loads and mitigate delamination. Composite bonding—sol, micropowder, and ultrafine powder—raises post-firing strength while lowering connected porosity, slowing penetration and oxidation. Low-wettability, anti-fouling coatings and microtexturing reduce adhesion, stabilizing flow area and pressure drop. Geometry optimization—filleted transitions, guide ribs, and integral elbow forms—tempers vortex scouring. Finally, modular locking and anchoring systems with elastic shims build thermal tolerance and compress replacement time into short, predictable windows.

Future Market Opportunities and 2025+ Trends in Pakistan

Three forces will govern adoption. First, alternative fuels and energy constraints make airflow stability and low pressure-drop growth mission-critical, pushing plants toward high-conductivity, low-fouling SiC systems. Second, localization will accelerate to reduce FX exposure and lead-time risk; most sites will start with mixing/classification and prefab, then add reaction sintering as volumes grow. Third, data-driven maintenance will standardize: plants will correlate pressure-drop curves, vibration and airflow maps, and shell/liner temperatures with materials and installation parameters to tighten control and elongate intervals.

On scale, a 5,000–8,000 t/d line typically consumes 100–250 tons of discharge and ventilation SiC wear systems annually, depending on clinker size, fuels, and operating regime. Across Pakistan’s expansions and retrofits, annual demand plausibly reaches several thousand tons; including prefabs, coatings, equipment, and services, the market extends into the tens to hundreds of millions of Pakistani Rupees. Providers who prove raw material stability, densification and dimensional control, responsive onsite service, and fast delivery will hold durable positions. Sicarbtech’s integrated model is structured to deliver precisely those capabilities.

As a South Asia-focused cement technologist summarized in a 2025 briefing, “When pressure-drop lines flatten and elbow thickness stops surprising you, materials strategy is paying for itself—and SiC is usually the hinge.”

Często zadawane pytania

Which Sicarbtech SiC products should we prioritize for the discharge zone and ventilation ducts?

Start with high-density SiC wear liners for the discharge working face and reaction-sintered SiC integral elbows at high-scour bends. Add low-wettability SiC coatings in fouling-prone areas, and deploy SiC honeycomb heat-dissipating liners where weight and temperature spikes coincide. Use ultra-low-cement SiC-bonded castable for transition layers and SiC gunning/patching mixes for fast online repairs.

How much improvement can we expect in life and pressure-drop stability?

Typical outcomes are 50–150% longer life in the discharge zone and 60–120% at elbows, with pressure-drop growth reduced by 20–40% and airflow stability improved by 10–25%. Plants often report 20–40% fewer unplanned interventions once quick-change modules and coatings are standardized.

Can Sicarbtech help localize production to reduce lead times and FX risk?

Yes. We deliver complete technology transfer: process recipes, equipment specifications, plant layouts, operator training, ISO 9001/14001-aligned QA frameworks, safety SOPs aligned with ISO 45001 principles, and commissioning. Most partners begin with mixing/classification/prefab and spraying/gunning capability, then add reaction sintering as volumes justify.

How do SiC systems handle alkali–sulfur–chlorine cycling and oxidizing gas?

Dense, low-connected porosity and antioxidant-enhanced bonding limit oxidation-induced porosity growth. Low-wettability coatings reduce adhesion and bridging in fouling-prone zones, while high conductivity limits gradient-driven cracking during load swings.

What installation practices are critical to avoid early spalling and delamination?

Surface preparation and roughness control, vacuum vibration compaction, moisture and venting management, and staged bake-out curves tailored to ambient humidity are decisive. Flexible joints and elastic shims manage expansion mismatch; adhesion tests and dimensional checks verify quality before return-to-service.

What KPIs should we track to verify benefits and guide optimization?

Track pressure-drop trends, airflow maps, fan current, discharge temperature, shell and liner temperatures, vibration signatures, repair frequency, and refractory consumption per ton. Correlate these with fuel mix, clinker size distribution, and maintenance actions.

Are SiC–carbon composite liners safe in oxidizing environments?

Yes, when used selectively in extreme impact areas and paired with antioxidant packages and appropriate backing/transition layers. The broader field can remain SiC-dominant to maximize oxidation resistance.

How fast can modular quick-change plates be replaced?

With standardized locking geometries and pre-staged modules, critical replacements are routinely completed within one to two shifts, assuming disciplined bake-out and inspection protocols.

What documentation supports Pakistani tenders and audits?

We provide ISO 9001-aligned QC documentation, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity packs, and SPC dashboards covering density, porosity, CCS/MOR, thermal shock, adhesion, and dimensional checks.

What is a sensible roadmap to full local capability?

Phase 1: classification/mixing, prefab assembly, coatings, and spraying/gunning. Phase 2: cold isostatic/die pressing and densification kilns for select parts. Phase 3: reaction sintering lines for dense modules. Sicarbtech aligns CAPEX, staffing, training, QA gates, and commissioning to your targets.

Dokonywanie właściwego wyboru dla swoich operacji

If your discharge zone is dictating your shutdowns and your ventilation elbows are dictating your fan energy, materials are managing you—not the other way round. Silicon carbide resets that balance. With higher hardness, higher conductivity, and lower wettability, SiC linings resist the quartet of failure modes—impact, abrasion, oxidation, and fouling—while modular designs put time back in your maintenance windows. Sicarbtech’s integrated approach—materials, composite structures, densification, prefabrication, installation playbooks, and localizable manufacturing—turns a technical upgrade into predictable availability and safer, cheaper tons.

Konsultacje ekspertów i niestandardowe rozwiązania

Share your operating window—clinker size and discharge temperature, airflow and pressure-drop curves, fuel chemistry, start–stop cadence, and failure maps—and Sicarbtech will engineer a tailored SiC package with modeled life gains, coating strategies, geometry optimizations, and staged bake-out profiles. If localization is a priority, we will map a phased technology transfer plan to fit your CAPEX and timeline.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Metadane artykułu

Last updated: 2025-09-19

Następna planowana aktualizacja: 2026-01-15

Content freshness indicators: 2025 Pakistan cement market outlook validated; technical ranges aligned with current field data; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.