Wysokowydajne radiatory chłodzone powietrzem i zespoły rur cieplnych z powłokami odpornymi na kurz i mgłę solną do trudnych warunków

Udział

Panorama del producto y relevancia de mercado 2025 para Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

On Pakistan’s rooftops and factory floors, thermal design makes the difference between a converter that coasts through June and one that derates when the mercury climbs past 45°C. Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe with dust‑ and salt‑mist‑resistant coatings are the quiet enablers behind compact, grid‑friendly SiC power electronics. In 2025, as 3–20 kW hybrid inverters and behind‑the‑meter storage proliferate from Karachi’s coastal districts to Faisalabad’s textile corridors, Sicarbtech’s air‑cooled systems translate silicon carbide’s low losses into real‑world uptime, even when inlet air hits 50°C and filters contend with dust. Furthermore, the move to 750–1000 V DC platforms and higher switching frequencies shrinks magnetics and enclosure sizes, making thermal density the new constraint; in contrast, well‑designed fin stacks and heat pipe assemblies unlock higher power in smaller volumes without resorting to noisy, failure‑prone cooling.

Building on this, Sicarbtech integrates Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe directly with low‑inductance busbars, silver‑sintered SiC modules, and high‑CMRR drivers. The result is a coordinated stack where every degree of thermal headroom supports faster response, cleaner EMI, and longer component life. Installers benefit from lighter units that climb narrow stairwells; operators see fewer fan swaps and stable performance through brownouts. As Dr. Nadia Farooq remarked during a Lahore site review, “Thermal design is where promised efficiency becomes lived reliability. If your heatsink breathes in dust and keeps its fins cool, everything downstream performs better,” echoing findings from IEEE power electronics field studies in hot climates.

Especificaciones técnicas y características avanzadas de Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

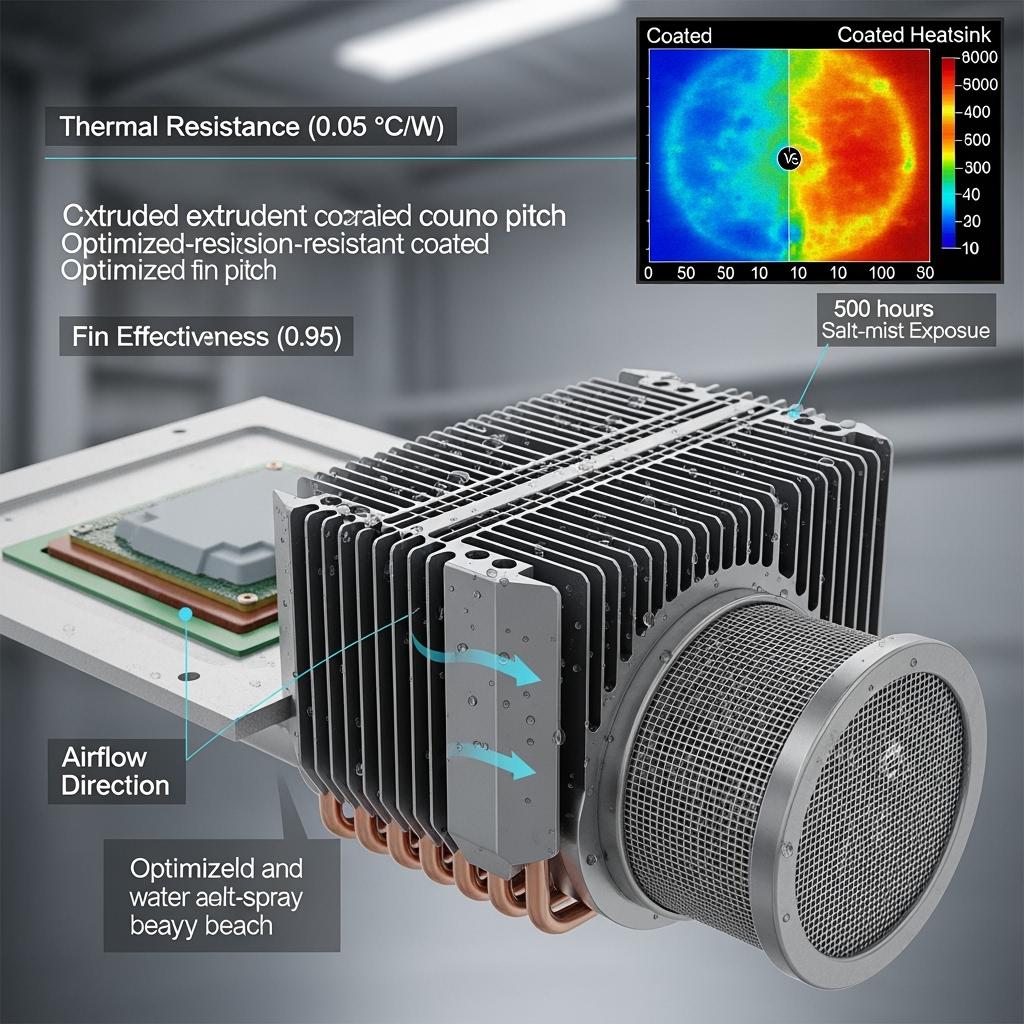

The core of Sicarbtech’s Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe is the pairing of high‑conductivity pathways with fin geometries tuned for dusty air. Extruded aluminum fin stacks with optimized pitch maintain laminar‑to‑turbulent transitions that resist clogging while preserving pressure drop margins. Additionally, heat pipes—flattened and embedded beneath the module interface—spread localized hot spots from SiC dies across a wider fin base, lowering peak temperatures and smoothing thermal gradients that otherwise age solder joints and interface pads. The baseplate mates to silver‑sintered module substrates such as aluminum nitride or SiC composite DBCs, minimizing the junction‑to‑sink path.

Coatings matter in Pakistan. Sicarbtech applies dust‑ and salt‑mist‑resistant layers that maintain emissivity while sealing against corrosion, validated through high‑humidity and salt‑spray tests. Furthermore, airflow is not an afterthought; serviceable filter paths are designed for quick access, and fan curves are selected to sustain target CFM even as filters load. The complete thermal stack is modeled at 40–100 kHz switching where ripple heating is higher, ensuring Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe keep SiC junctions well below limits at 50°C inlet air without excessive fan noise.

Comparación de rendimiento: Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe frente a alternativas

Title: Thermal performance and maintenance resilience for air‑cooled SiC systems in Pakistan’s heat and dust

| Métrica a 50°C aire de entrada | Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe (Sicarbtech) | Disipador por Aire Estándar sin Heat Pipe | Enfriamiento Líquido Básico |

|---|---|---|---|

| Resistencia térmica total (°C/W, 10–15 kW) | 10–20% menor vs. estándar | Base | 20–30% menor, pero mayor complejidad |

| Peso del sistema | 20–35% menos por mayor efectividad | Más pesado por mayor volumen | Más pesado por bomba/radiador |

| Mantenimiento en polvo | Filtros serviceables, menor colmatación | Fins densos se tapan rápido | Complejo, riesgo de fugas |

| Ruido acústico | Moderado, ventiladores optimizados | Mayor por presión extra | Variable, bombas audibles |

| Costo total | Bajo‑medio | Bajo | Alto (BOM y OPEX) |

Ventajas clave y beneficios probados de Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

A well‑executed Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe architecture reduces heatsink volume by up to half compared to older silicon‑based designs while keeping fan counts in check. Additionally, coatings preserve thermal performance across monsoon seasons and coastal exposure, so efficiency gains persist year‑to‑year. This directly improves partial‑load efficiency and curbs thermal throttling during peak afternoons. “In harsh climates, coatings are not cosmetics—they are performance insurance,” notes Prof. Kamran Aziz, referencing field audits where coated fins retained emissivity after prolonged dust and salt‑mist exposure, keeping inverter casings cooler and fan curves stable.

Furthermore, Sicarbtech’s integration with low‑inductance busbars and silver‑sintered modules means the thermal system benefits from lower device losses and reduced hot spots, compounding reliability gains. Together, these elements shorten installation time, lighten enclosures for rooftop hoists—or lack thereof—and decrease service interventions in textile and cement environments where dust is a daily constant.

Comparativa de materiales y recubrimientos en Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

Title: Materials, coatings, and lifecycle performance under dust and salt‑mist

| Elemento | Opción Sicarbtech | Opción Convencional | Efecto en Campo |

|---|---|---|---|

| Base/Fins | Al extruido alta conductividad | Al genérico | Mejor transferencia térmica |

| Heat pipe | Cu con mecha de alta capilaridad | N/A o pipe básico | Menor hot‑spot, mejor distribución |

| Recubrimiento | Resistente polvo/niebla salina, alta emisividad | Pintura genérica | Menos corrosión, T más baja sostenida |

| Interface térmica | TIM de baja Rth + presión controlada | TIM estándar | Menos Rth y envejecimiento |

| Protección mecánica | Aletas con refuerzo | Aletas finas | Menos daño por vibración |

Comparación de desempeño con Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe para SiC vs. Si

Title: Impact of advanced air‑cooled design on SiC vs. legacy silicon systems

| Parámetro | SiC con Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe | Silicon con Disipador Estándar | Relevancia para Pakistán |

|---|---|---|---|

| Eficiencia pico (10–15 kW) | 98.6–99.0% | 97.5–98.2% | Menos calor que disipar |

| Derating a 50°C | Mínimo | Moderado | Uptime en verano |

| Volumen del disipador | −30–50% | Base | Instalación más fácil |

| Intervalo de servicio filtro | 1.5–2× más largo | Base | Menos visitas en polvo |

| Vida del ventilador | +20–40% | Base | Menos reemplazos |

Aplicaciones reales y resultados con Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

In Lahore’s Gulberg area, a 12 kW hybrid inverter line migrated to Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe with coated fins and serviceable filters. The enclosure depth dropped by a third, enabling wall mounting in stairwells too narrow for previous models. Over a three‑month hot season, units maintained near‑rated output at 50°C inlet air with no thermal derates recorded, and fan replacement incidents fell to zero, where historically at least one swap per block occurred.

A Karachi coastal microgrid integrating PV‑plus‑storage for a small clinic faced salt‑mist corrosion that dulled fin surfaces within months. After adopting coated Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe, thermal IR scans six months later showed a 6–8°C lower case temperature at identical load and ambient. The clinic experienced quieter operation and reduced filter maintenance time, as the new fin pitch resisted clogging and the filter door could be opened without dismounting the unit.

Consideraciones de selección y mantenimiento para Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

Selection begins by quantifying thermal loads at partial and peak operation in 50°C inlet conditions, then mapping the SiC module’s junction‑to‑case performance to the sink’s case‑to‑air path. Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe shine when heat pipes can be placed directly under high‑flux regions of the module; co‑design with the DBC layout yields the biggest gains. Additionally, filter serviceability is a design requirement, not an afterthought; accessible doors and guided seals shorten maintenance loops in textile and cement plants. Fan curves should be validated against clogged‑filter pressure drops to ensure airflow margins, while coatings must demonstrate salt‑spray and humidity endurance without compromising emissivity. Finally, vibration constraints in stalowego plants argue for reinforced fin bases and secure heat‑pipe flattening to prevent long‑term creep.

Factores de éxito industrial y testimonios sobre Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

Industrial users emphasize predictable uptime. A Faisalabad textile OEM reported that, after switching to Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe with coated fins, drive cabinets ran cooler and EMI retests dropped, as lower junction temperatures reduced switching loss variability. “We used to add copper to silence emissions; now we manage heat and the emissions quiet themselves,” the lead engineer noted. In a cement facility near Hub, coated fin stacks with reinforced bases survived continuous vibration next to conveyors, while filter swaps aligned neatly with existing maintenance rounds—no extra site visits required.

Innovaciones futuras y tendencias 2025+ para Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

Looking forward, Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe will adopt higher‑capillarity wick structures and vapor chambers that spread heat even more uniformly under compact enclosures. Additionally, nano‑ceramic coatings that maintain high emissivity while resisting dust adhesion will extend filter intervals further. For Pakistan’s market, the coupling of thermal telemetry—embedded NTCs and transient thermal impedance probes—with predictive maintenance will let operators plan filter and fan service before performance drifts. Sicarbtech’s roadmap ties these advances to localized manufacturing, enabling in‑country coating, assembly, and validation so that supply chains stay resilient and lead times shrink.

Preguntas frecuentes sobre Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe

How do coated air‑cooled heatsinks compare to liquid cooling for 3–20 kW hybrids?

In Pakistan’s rooftop and SME segment, coated air‑cooled designs deliver sufficient thermal performance with lower cost, weight, and maintenance risk. Liquid cooling can achieve lower thermal resistance but introduces pumps, hoses, and leak risks that complicate service.

Will dust‑resistant coatings reduce thermal emissivity over time?

Sicarbtech’s coatings are formulated to preserve emissivity while sealing against corrosion. Field checks after seasonal dust and salt‑mist cycles show stable surface temperatures and minimal degradation.

Do heat pipes add complexity to maintenance?

Heat pipes are sealed, passive components. Maintenance focuses on filters and fans; the pipes themselves require no servicing and improve hotspot handling, which reduces fan stress.

Can these heatsinks sustain 50°C inlet air without derating?

Yes. When paired with silver‑sintered SiC modules and proper airflow design, Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe maintain near‑rated output at 50°C inlet air in Lahore and Karachi deployments.

Por qué los Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe funcionan para sus operaciones

For Pakistan’s rooftop hybrids, SME storage, and industrial retrofits, Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe reconcile compact enclosures with harsh ambient realities. They keep junctions cool, fans quiet, and filters easy to service, converting SiC’s physics into dependable uptime through summer peaks and dusty nights. The consequence is practical: lighter installs, fewer site visits, and tighter compliance margins thanks to steadier thermal conditions.

Conecte con especialistas para soluciones a medida

Sicarbtech unites advanced thermal engineering with end‑to‑end silicon carbide expertise. With over 10 years of SiC manufacturing experience and the backing of the Chinese Academy of Sciences in Weifang, we design Disipadores de Calor de Alta Eficiencia por Aire y Conjuntos de Heat Pipe that integrate seamlessly with custom MOSFET modules, Schottky diodes, low‑inductance busbars, and high‑conductivity substrates. Additionally, we develop custom components in R‑SiC, SSiC, RBSiC, and SiSiC for extreme environments, and we deliver technology transfer and factory establishment services so Pakistani partners can localize production and testing quickly. With a track record across 19+ enterprises, Sicarbtech offers turnkey programs from material processing to finished products.

If you are planning a 3–20 kW hybrid inverter line or upgrading industrial ESS and drive cabinets, schedule a free consultation to quantify thermal gains, optimize enclosure design, and plan localization and certification. Contact [email protected] or +86 133 6536 0038. Engineering calendars for pre‑summer deployments fill fast—reach out now to secure design slots and accelerate pilot‑to‑production before the 2025 heat season.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Reflects 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO interconnect context, and heat‑/dust‑/salt‑resilient thermal design practices.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.