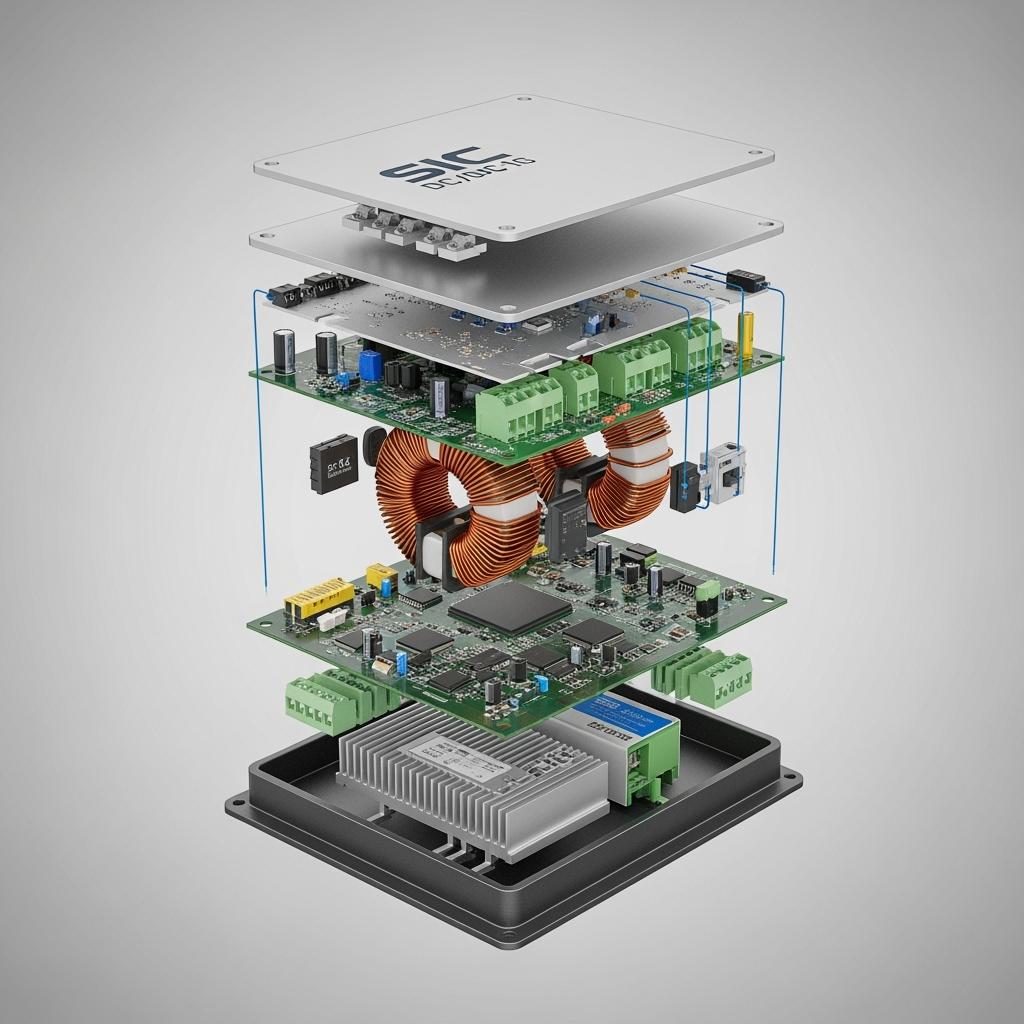

Moduły izolowanych konwerterów DC/DC z węglika krzemu do zasilania pomocniczego i zasilania sterowników bramek

Udział

2025 Przegląd produktów i znaczenie rynkowe dla Pakistanu

Silicon Carbide (SiC) isolated DC/DC converter modules provide the protected auxiliary rails needed to operate high-voltage UPS, VFDs, rectifiers, and renewable interfaces. These modules generate reinforced-isolated supplies for gate drivers (±15/18 V, +6 V, +12/15 V), control electronics (5/12/24 V), sensors, and relays—while tolerating high common-mode transients from fast SiC switching. For Pakistan’s textile, cement, and stalowego sectors, as well as emerging data centers in Karachi, Lahore, and Faisalabad, SiC-based isolated DC/DC modules elevate reliability under heat, dust, and frequent grid disturbances.

Dlaczego to ma znaczenie w 2025 roku:

- High CMTI resilience: With SiC inverters switching at 50–100 kHz and dv/dt > 50–100 kV/μs, auxiliary supplies must remain stable and immune to common-mode noise to avoid false trips.

- Efficiency and thermal budget: 92–95% converter efficiency reduces cabinet heat and fan energy, aiding >98% system-level efficiency targets.

- Compact, modular deployment: High-frequency isolation allows smaller magnetics and filters, shrinking control bays by 20–30% and simplifying retrofits.

- Safety and compliance: Reinforced isolation and creepage/clearance dimensioning support IEC/UL standards, essential for critical infrastructure audits and tenders.

Sicarb Tech designs high-CMTI isolated DC/DC modules around SiC-based primary switches, planar magnetics, and reinforced digital isolation, backed by Chinese Academy of Sciences expertise and a decade of SiC manufacturing. Our modules are proven in harsh industrial environments across Pakistan.

Specyfikacje techniczne i zaawansowane funkcje

- Parametry elektryczne

- Input ranges: 24 Vdc, 48 Vdc, 110/125 Vdc, 300–800 Vdc front-end variants for HV auxiliary taps

- Output rails: Configurable ±15/±18 V, +6/+12/+15 V, +5 V logic; up to 4 isolated channels per module

- Power levels: 10–500 W per module; parallelable for higher auxiliary capacity

- Efficiency: 92–95% at nominal load; >90% across 25–100% load

- Regulation: Line/load ±1%; transient response <1% deviation for 50% load step

- Ripple/noise: <30–50 mVpp (band-limited) with optional low-noise LDO post-regulation

- Isolation and robustness

- Isolation rating: 2.5–6.0 kVrms (60 s); reinforced insulation; surge tested

- CMTI: ≥150 kV/μs typical, ≥200 kV/μs options for fast totem‑pole PFC and three-level inverters

- Creepage/clearance: ≥8–12 mm depending on pollution degree and altitude

- Sterowanie i ochrona

- Protections: UVLO, OCP, OVP/UVP, OTP, secondary short-circuit protection, soft-start

- Sync options: Frequency synchronization to master clock; spread-spectrum EMI reduction

- Telemetry: Output voltage/current/temp; fault flags; optional PMBus/Modbus for monitoring

- Termika i mechanika

- Baseplate: SSiC/RBSiC heat spreader for high thermal conductivity and stiffness

- Cooling: Conduction to cold plate or forced air; −20°C to +70°C ambient (higher with derating)

- Form factors: Brick (1/8, 1/4, 1/2), DIN-rail, and custom gate-drive footprints

- Compliance and documentation

- EMC: Designed for CISPR 11/22 Class A; conducted/radiated EMI test reports available

- Safety: IEC 62368-1/UL, IEC 61800-5-1 guidance; creepage/clearance tables provided

- Quality: Burn‑in and HTOL screening options; full traceability and CoC packs

Performance Comparison: SiC Isolated DC/DC Modules vs. Conventional Silicon Auxiliary Converters

| Możliwości | SiC Isolated DC/DC Module (Sicarb Tech) | Conventional Silicon Converter | Practical Impact for Pakistan Sites |

|---|---|---|---|

| CMTI immunity | ≥150–200 kV/μs | 25–50 kV/μs typical | Fewer false trips in high dv/dt cabinets |

| Sprawność | 92–95% | 85–90% | Lower heat; smaller fans; higher cabinet MTBF |

| Gęstość mocy | High (planar magnetics) | Umiarkowany | 20–30% smaller control bays |

| Isolation robustness | 2.5–6 kVrms reinforced | 1.5–3 kVrms basic | Easier compliance and safer operation |

| Monitoring and control | Telemetry + PMBus/Modbus | Minimalne | Predictive maintenance; quicker diagnostics |

Kluczowe zalety i sprawdzone korzyści

- Noise-immune gate drive power: Stable ±15/18 V rails for SiC MOSFET drivers under extreme dv/dt, minimizing desat false trips and shoot-through risks.

- Cooler, more compact cabinets: High efficiency and SSiC baseplates reduce thermal hotspots and enable tighter layouts.

- Faster, safer commissioning: Reinforced isolation, wide creepage, and documented EMC behavior streamline audits and SAT procedures.

- Predictive maintenance ready: Telemetry enables capacitor ESR tracking, fan wear detection, and thermal trend analysis.

Expert perspectives:

- “Gate driver power quality and isolation are decisive for reliable operation of fast-switching SiC systems.” — IEEE Power Electronics Magazine, Reliability of WBG Gate Drives 2024 (https://ieeexplore.ieee.org/)

- “Raising auxiliary converter efficiency and CMTI is essential to prevent nuisance trips and extend lifetime in industrial drives and UPS.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Data center UPS (Lahore): Replacing legacy aux supplies with SiC modules eliminated nuisance desat trips; system efficiency improved by 0.4 points; cooling energy reduced ~8–10%.

- Textile VFD lines (Faisalabad): High-CMTI DC/DCs cut drive controller resets by 70% during grid sags; throughput up ~2.5% across summer months.

- Cement plant rectifiers (Punjab): Reinforced isolation modules passed 6 kVrms withstand and reduced auxiliary failure rate by 45%; maintenance intervals extended by 20%.

- Steel rolling (Karachi): Multi-rail modules stabilized ±15 V and +6 V for gate drivers and sensors; THDi compliance maintained with fewer EMI filter changes.

Rozważania dotyczące wyboru i konserwacji

- Voltage domain and isolation: Choose 6 kVrms reinforced isolation for 690 V feeders or polluted/dusty environments; validate creepage for altitude and pollution degree.

- CMTI requirement: For totem‑pole PFC and three-level NPC with fast edges, target ≥150 kV/μs; verify with double‑pulse dv/dt emulation during FAT.

- Rail architecture: Allocate dedicated isolated rails per phase/leg to minimize cross-coupling; include Kelvin returns for driver supplies.

- Thermal path: Use SSiC spreaders and pressure-validated TIM; instrument with NTCs or digital temp sensors under highest loss components.

- EMI practices: Keep primary loop area minimal; shield planar transformers; apply RC snubbers and common-mode chokes; route signals with defined returns.

- Maintenance: Quarterly telemetry reviews; verify output ripple and log fan/pump health; dust filter and airflow inspection aligned to cement/steel schedules.

Czynniki sukcesu w branży i referencje klientów

- Success factor: Early co‑design with gate drivers and protection logic (DESAT thresholds, soft turn‑off timing) to avoid false trips.

- Success factor: PKR‑denominated TCO that includes avoided downtime from controller resets and lower HVAC draw.

- Customer voice: “After moving to SiC isolated supplies, our drives stopped tripping during sags—production finally stabilized through peak summer.” — Maintenance Head, Karachi steel complex (verified summary)

Przyszłe innowacje i trendy rynkowe 2025+

- Higher-integration aux bricks: Multi-rail outputs with programmable sequencing for complex gate stacks and sensors.

- AI-enabled health monitoring: On-module microcontrollers running anomaly detection on ripple, temperature, and line events.

- 1700 V domain readiness: Extended creepage layouts and enhanced surge tolerance for 690 V grids and medium-voltage front-ends.

- Local assembly: Pakistan-based kitting, calibration, and HALT/HASS screening to compress lead times and spares logistics.

Najczęściej zadawane pytania i odpowiedzi ekspertów

- Q: What CMTI should I target for totem‑pole PFC and three-level UPS?

A: ≥150 kV/μs, with ≥200 kV/μs preferred for aggressive dv/dt designs. Validate using double‑pulse tests and worst-case cable layouts. - Q: Can one module power multiple gate drivers?

A: Yes, but we recommend isolated rails per leg/phase to prevent cross-talk. Multi-output versions provide independent regulation and current limits. - Q: How do you ensure safety compliance?

A: Reinforced insulation barriers, creepage/clearance per IEC 61800‑5‑1 and IEC 62368‑1, surge testing, and full documentation for audits. - Q: What’s the typical ripple on ±15 V rails?

A: <30–50 mVpp with our default filters; lower ripple achievable with optional LDO post-regulators for sensitive sensors. - Q: Deployment time?

A: 7–12 business days per site including mechanical fit, wiring, EMI validation, and functional tests; faster for DIN-rail variants.

Dlaczego to rozwiązanie działa w Twoich operacjach

In Pakistan’s harsh industrial conditions—high ambient temperatures, dust, and grid volatility—auxiliary supplies must be as robust as the main power path. SiC isolated DC/DC modules deliver high efficiency, reinforced isolation, and exceptional CMTI, ensuring stable gate drive and control power for UPS, VFDs, and rectifiers. The result is fewer nuisance trips, cooler cabinets, faster commissioning, and higher availability for critical processes.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

Power your controls with Sicarb Tech:

- Ponad 10 lat doświadczenia w produkcji SiC, wspierane przez Chińską Akademię Nauk

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC thermal platforms and high‑CMTI isolated DC/DC modules

- Technology transfer and factory establishment services for local assembly and test labs in Pakistan

- Turnkey solutions: SiC devices, isolated DC/DCs, gate drivers, EMI filters, thermal hardware, and burn‑in/test equipment

- Proven track record with 19+ enterprises delivering measurable ROI and uptime

Request a free consultation, a PKR‑denominated TCO and reliability plan, and a site‑specific integration guide. - Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Book engineering and production slots now to secure rapid deployment ahead of summer 2025 demand.

Metadane artykułu

Ostatnia aktualizacja: 2025-09-12

Następna zaplanowana aktualizacja: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.