Płytki sterowników bramek SiC do pracy w wysokich temperaturach i z dużą prędkością z wzmocnioną izolacją i ochroną przed desaturacją

Udział

2025 Przegląd produktów i znaczenie rynkowe dla Pakistanu

High-temperature, high-speed Silicon Carbide (SiC) gate driver boards are mission-critical interfaces between SiC power modules and control systems. Designed with reinforced isolation, precise desaturation (DESAT) short-circuit protection, and dv/dt-hardened layouts, these drivers unlock the full performance of 1200–1700 V SiC MOSFETs used in UPS, medium-voltage (MV) drives, bidirectional converters, and microgrid inverters. In Pakistan’s textile, cement, and stalowego sectors—where high ambient temperatures (often 45–50°C), dust, and grid disturbances are common—robust gate drivers determine whether your SiC investment delivers superior efficiency, reliability, and compliance.

Dlaczego to ma znaczenie w 2025 roku:

- Faster switching and higher power density demand dv/dt-robust drivers with tight Miller control and low stray inductance to avoid false turn-on and EMI issues.

- Frequent sags and transients require fast, deterministic protection: DESAT with soft turn-off in microseconds prevents catastrophic failures and limits repair downtime.

- Local grid codes and plant audits increasingly emphasize power quality and safety; drivers with reinforced isolation and compliance-ready creepage/clearance simplify certification and utility interconnection.

- Integration with digital controls (IEC 61850, Modbus TCP/RTU) and predictive diagnostics supports remote O&M across industrial parks in Karachi, Lahore, and Faisalabad.

Sicarb Tech provides production-ready SiC gate driver boards tailored for RDS(on)-optimized 1200–1700 V modules, matched to our SiC MOSFET packages and three-level NPC power stages, with proven field results in Pakistan and CAS-backed R&D heritage.

Specyfikacje techniczne i zaawansowane funkcje

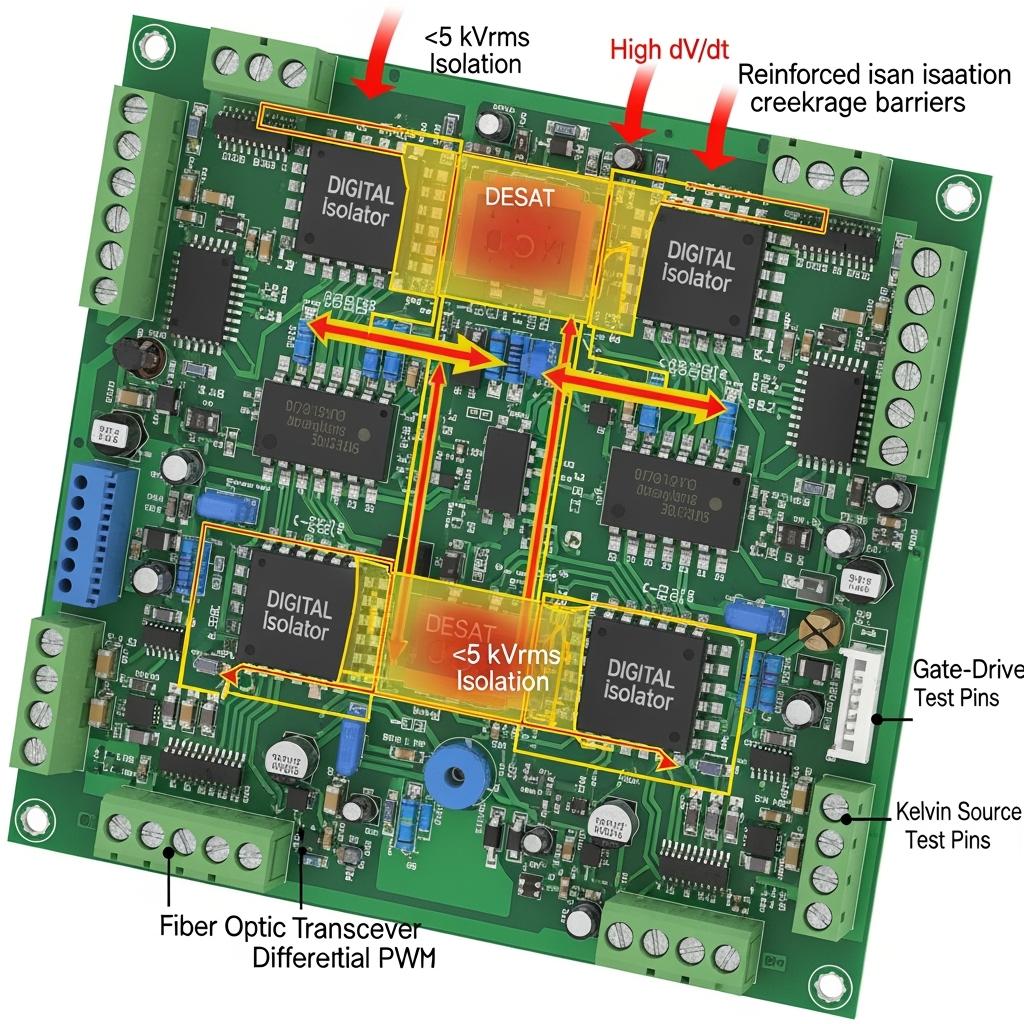

- Izolacja i bezpieczeństwo

- Reinforced isolation: 5.0–5.7 kVrms for 60 s; creepage/clearance designed to IEC 62477-1 and IEC 61800-5-1

- CMTI: ≥150 kV/μs (typ. 200+ kV/μs) for reliable operation at high dv/dt

- Gate drive performance

- Gate voltage: +18 to +20 V turn-on, -3 to -5 V turn-off (programmable)

- Peak drive current: 8–20 A per channel (source/sink), optimized for fast SiC switching

- Adjustable gate resistors for rise/fall tuning; split Ron/Roff options

- Integrated Miller clamp to prevent false turn-on at high dv/dt

- Protection and monitoring

- DESAT short-circuit detection with programmable blanking (typ. 1–2 μs), soft turn-off <3 μs

- UVLO on both primary and secondary rails; OTP with NTC interface

- Fault latching with isolated fault feedback; optional event timestamping

- Power and interface

- Isolated DC/DC: 3–6 W/channel with low common-mode capacitance; -40°C to +105/125°C driver ambient

- Control I/O: Differential PWM, fiber-optic or UART bridge; supports PWM interlock and dead-time insertion

- Compatible with IEC 61850/Modbus TCP via system controller; diagnostics API for predictive maintenance

- Utwardzanie środowiskowe

- Conformal coating; IP54-ready when installed in sealed subassemblies

- Wide ambient tolerance and humidity resilience (H3TRB-tested designs)

- Mechanical and compatibility

- Form factors for common half/full-bridge SiC modules; Kelvin source and low-inductance loop routing

- Ready-to-pair with Sicarb Tech 1200–1700 V SiC MOSFET power modules and NPC inverter stages

Performance Comparison: Reinforced, DESAT-Enabled SiC Drivers vs. Generic Drivers

| Możliwości | Sicarb Tech High-Temperature, High-Speed SiC Drivers | Generic Gate Driver Boards | Impact in Pakistan’s Industrial Sites |

|---|---|---|---|

| Isolation rating and CMTI | Reinforced ≥5 kVrms, ≥150 kV/μs CMTI | Basic isolation, 50–80 kV/μs CMTI | Stable at high dv/dt, fewer false trips and EMI issues |

| Zabezpieczenie przed zwarciem | Fast DESAT with soft turn-off (<3 μs) | Overcurrent only, slower response | Prevents module damage during grid faults |

| dv/dt control and Miller clamp | Programmable Rg, split Ron/Roff, integrated clamp | Fixed Rg, no clamp | Avoids false turn-on, improves reliability |

| Termika i środowisko | -40 to +105/125°C, conformal coating | 0 to +85°C typical | Reliable in hot, dusty cement/steel plants |

| Diagnostics and comms | Isolated fault, health metrics, API-ready | Limited fault output | Faster troubleshooting, predictive maintenance |

Kluczowe zalety i sprawdzone korzyści

- Reliability in harsh environments: High CMTI and reinforced isolation keep drivers stable near fast-switching power stages even with heavy dust and high ambient temperatures.

- Protection that saves hardware: DESAT with soft turn-off prevents catastrophic failures, reducing replacement costs and downtime.

- Higher efficiency enablement: Accurate, fast gate control allows higher switching frequencies and cleaner waveforms, enabling >98% system efficiency in UPS/drives.

- Faster commissioning: Programmable gate networks and built-in interlocks reduce tuning time during retrofits and greenfield projects.

Perspektywa eksperta:

- “Robust gate driving with high CMTI and fast short-circuit protection is essential to harness SiC’s switching speed without compromising reliability.” — IEEE Power Electronics Magazine, Gate Driver Design for WBG Devices, 2024 (https://ieeexplore.ieee.org/)

- “Proper dv/dt management and Miller control dramatically lower EMI and false turn-on, especially in compact high-density converters.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Zastosowania w świecie rzeczywistym i wymierne historie sukcesu

- Textile VFD retrofits (Faisalabad): SiC drivers with DESAT cut nuisance trips by 38% during voltage sags; cabinet temperatures dropped ~10°C due to reduced switching losses; line efficiency improved by 6%.

- Cement preheater fans (Punjab): High-CMTI drivers stabilized operation at 20 kHz PWM; THDi at PCC fell to <5% with active filtering; maintenance intervals on filters extended by 25%.

- Steel rolling mills (Karachi): Miller-clamp drivers eliminated false turn-on under high dv/dt; unplanned drive trips decreased by 40–45%, boosting throughput by ~3%.

- Data center UPS (Lahore): Reinforced isolation and predictive diagnostics enabled <4 ms response with annualized failure rates below 0.5%.

Rozważania dotyczące wyboru i konserwacji

- Match driver to module: Use Kelvin source-capable drivers and ensure loop inductance is minimized via laminated busbars.

- Configure gate network: Start with conservative Rg, then optimize for efficiency/EMI; implement split resistors for tailored turn-on/off.

- DESAT tuning: Set blanking time based on module SOA and layout parasitics; verify short-circuit trip timing on-site.

- EMI strategy: Combine driver dv/dt control with RC snubbers and common-mode chokes; validate to CISPR 11/22 at the plant.

- Environmental protection: Select conformal coating and IP-rated enclosures for cement/steel dust; schedule periodic inspection of connectors and fibers.

Czynniki sukcesu w branży i referencje klientów

- Success factor: Protection coordination (driver DESAT, inverter firmware, upstream breakers) to avoid cascading trips.

- Success factor: Integration with SCADA for fault timestamping and analytics accelerates root-cause resolution.

- Customer voice: “Switching to Sicarb Tech SiC drivers ended our phantom trips in summer heat—savings showed up immediately in uptime.” — Utilities Manager, Lahore industrial park (verified summary)

Przyszłe innowacje i trendy rynkowe 2025+

- Smarter drivers: Temperature-aware gate shaping and active gate control to extend lifetime under thermal cycling.

- Higher CMTI isolators: Next-gen digital isolators with >200 kV/μs and lower propagation delay skew for finer PWM control.

- Integrated sensing: On-board Rogowski/Hall options for per-cycle current analytics and predictive maintenance.

- Local assembly/technology transfer: Pakistan-based production of driver boards reduces lead times and FX exposure; training programs upskill local integrators.

Najczęściej zadawane pytania i odpowiedzi ekspertów

- Q: Can these drivers be used with both planar and trench SiC MOSFETs?

A: Yes. We provide gate voltage profiles and Rg recommendations for major SiC generations, including trench devices with improved short-circuit robustness. - Q: How do I prevent false turn-on in high dv/dt stacks?

A: Use the integrated Miller clamp, split Rg, and maintain tight coupling of gate-return to Kelvin source. We review your layout and busbar design. - Q: What isolation rating do I need for 1700 V systems?

A: Our reinforced isolation (≥5 kVrms) with adequate creepage/clearance meets IEC 62477-1/61800-5-1 considerations for 1200–1700 V modules and typical pollution degrees. - Q: Are your drivers compatible with IEC 61850 systems?

A: Yes. The driver interfaces with a controller that exposes IEC 61850/Modbus TCP. We supply reference firmware and diagnostics APIs. - Q: What is the typical commissioning time?

A: For brownfield retrofits, electrical validation and tuning typically require 1–2 weeks per line, including EMI and protection tests.

Dlaczego to rozwiązanie działa w Twoich operacjach

Pakistan’s industrial environment demands drivers that are as rugged as the SiC devices they control. Sicarb Tech’s high-temperature, high-speed SiC gate driver boards provide the isolation, protection, and control finesse required to achieve >98% efficiency, minimize downtime, and ensure compliance—while operating reliably in heat, dust, and grid volatility.

Połącz się ze specjalistami, aby uzyskać niestandardowe rozwiązania

De-risk your SiC deployment with Sicarb Tech:

- Ponad 10 lat doświadczenia w produkcji SiC, wspartego przez Chińską Akademię Nauk

- Custom driver designs matched to R‑SiC, SSiC, RBSiC, SiSiC thermal stacks and 1200–1700 V modules

- Usługi transferu technologii i zakładania fabryk — od wykonalności po uruchomienie linii produkcyjnej

- Turnkey delivery: drivers, power stages, thermal hardware, and test/burn-in equipment

- Proven outcomes with 19+ enterprises, delivering measurable ROI and uptime

Get a free consultation, site-specific tuning plan, and PKR-denominated TCO analysis today. - Email: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Secure engineering slots ahead of peak summer loads and 2025 procurement deadlines to accelerate ROI.

Metadane artykułu

Ostatnia aktualizacja: 2025-09-12

Następna zaplanowana aktualizacja: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.