Novel SiC Processing for Enhanced Advantages

Share

Novel SiC Processing for Enhanced Advantages

In today’s rapidly evolving industrial landscape, the demand for advanced materials capable of withstanding extreme conditions is at an all-time high. Among these, Silicon Carbide (SiC) stands out as a material of unparalleled performance, critical for industries ranging from semiconductors and automotive to aerospace and renewable energy. Its exceptional properties, including superior hardness, high thermal conductivity, chemical inertness, and excellent high-temperature strength, make it the material of choice for components facing the most demanding operational environments. However, unlocking the full potential of SiC often requires novel processing techniques to achieve the precise specifications and enhanced advantages that modern applications demand. This blog post delves into the world of custom silicon carbide products, exploring the latest in processing advancements and how they are transforming various industrial sectors.

What are Custom Silicon Carbide Products and Why are They Essential?

Custom silicon carbide products are engineered components meticulously designed and manufactured to meet the exact specifications of a particular application. Unlike off-the-shelf solutions, custom SiC parts offer tailored performance, optimized geometries, and specific material compositions to address unique challenges. This bespoke approach is essential because standard materials often fall short in environments characterized by:

- Extreme Temperatures: SiC maintains its mechanical integrity and electrical properties at temperatures exceeding 1,500°C.

- Abrasive Wear: Its exceptional hardness, second only to diamond, provides outstanding resistance to wear and erosion.

- Corrosive Chemicals: SiC exhibits remarkable inertness to a wide range of acids, bases, and aggressive chemicals.

- High Electrical Fields: Critical for power electronics, SiC offers high breakdown voltage and low switching losses.

- Thermal Shock: Excellent thermal shock resistance ensures durability under rapid temperature fluctuations.

For engineers, procurement managers, and technical buyers in industries like semiconductors, automotive, aerospace, power electronics, and industrial manufacturing, custom SiC components are not just an option, but a necessity for achieving breakthrough performance, extending product lifespan, and ensuring operational reliability.

Main Applications of Silicon Carbide Across Industries

The versatility of silicon carbide allows it to be deployed across a broad spectrum of critical applications. Novel SiC processing techniques further expand its utility, enabling the creation of components that push the boundaries of what’s possible.

- Semiconductor Manufacturing: SiC is vital for high-temperature furnace components, wafer carriers, and process tubes, ensuring purity and stability in critical production steps.

- Automotive Industry: Power electronics in electric vehicles (EVs) and hybrid vehicles heavily rely on SiC for inverters, on-board chargers, and DC-DC converters, leading to smaller, more efficient, and lighter systems.

- Aerospace and Defense: Used in lightweight, high-strength structural components, heat exchangers, missile radomes, and brake systems, where extreme temperatures and harsh environments are commonplace.

- Power Electronics: SiC power devices are revolutionizing grids, industrial motor drives, and renewable energy systems by offering higher efficiency, faster switching speeds, and reduced system complexity.

- Renewable Energy: Essential for solar inverters and wind turbine converters, enhancing efficiency and reliability in energy conversion.

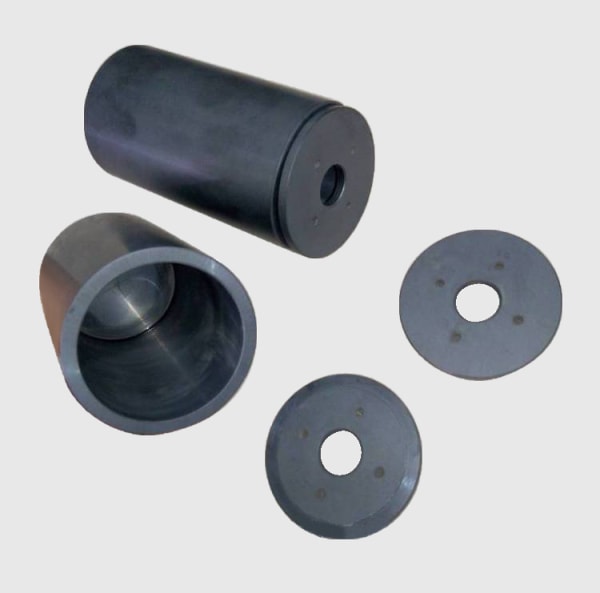

- Metallurgy and High-Temperature Processing: SiC refractories, kiln furniture, and crucibles withstand extreme heat and corrosive molten metals.

- Chemical Processing: Components like pump seals, valve parts, and heat exchanger tubes benefit from SiC’s exceptional chemical resistance.

- LED Manufacturing: SiC substrates are used for growing GaN layers, crucial for high-brightness LEDs.

- Industrial Machinery: Wear parts, bearings, and nozzles made from SiC offer extended lifespan and reduced maintenance in abrasive environments.

- Telecommunications: High-frequency devices and power amplifiers leverage SiC for superior performance.

- Oil and Gas: Downhole tools and components exposed to abrasive slurries and corrosive fluids.

- Medical Devices: Precision components requiring biocompatibility and high wear resistance.

- Rail Transportation: Power converters for traction systems in trains.

- Nuclear Energy: Structural components in reactors due to high radiation resistance and thermal stability.

Why Choose Custom Silicon Carbide for Enhanced Advantages?

While standard SiC products offer significant advantages, custom solutions elevate performance to the next level. The ability to precisely control the material’s microstructure, purity, and geometry during novel processing enables superior outcomes.

Benefits of Customization:

- Optimized Thermal Resistance: Tailored compositions can offer even higher thermal stability for specific high-temperature applications.

- Enhanced Wear Resistance: Custom formulations and surface treatments can provide superior abrasion and erosion resistance.

- Exceptional Chemical Inertness: Specific SiC grades can be chosen or modified for enhanced resistance to particular corrosive agents.

- Precise Electrical Properties: Custom doping and processing can achieve desired electrical conductivity or insulating properties for advanced electronic devices.

- Complex Geometries: Novel processing techniques allow for the creation of intricate shapes and features impossible with conventional methods, optimizing performance and integration.

- Reduced Weight and Size: By optimizing design and material usage, custom SiC can contribute to lighter and more compact systems, especially critical in aerospace and automotive.

Recommended SiC Grades and Compositions

The performance of a SiC component is heavily influenced by its grade and composition. Novel processing allows for greater control over these factors, leading to optimized properties. Here are some commonly recommended types of SiC:

| SiC Grade/Type | Key Characteristics | Typical Applications |

|---|---|---|

| Reaction-Bonded SiC (RBSiC) | High strength, excellent wear resistance, good thermal shock resistance, near-net-shape capabilities. Contains free silicon. | Kiln furniture, mechanical seals, wear plates, nozzle inserts. |

| Sintered Alpha SiC (SSiC) | High purity, superior corrosion resistance, high strength, excellent thermal shock resistance, very hard. No free silicon. | Mechanical seals, pump components, ball valves, high-temperature structural parts, semiconductor equipment. |

| Nitride-Bonded SiC (NBSiC) | Good strength at high temperatures, good thermal shock resistance, moderate cost. | Refractory linings, furnace components, kiln furniture. |

| Chemical Vapor Deposited (CVD) SiC | Extremely high purity, theoretical density, isotropic properties, excellent surface finish. Thin coatings or complex shapes. | Semiconductor susceptors, optical components, mirror substrates, precision parts. |

| Siliconized Silicon Carbide (SiSiC) | Good strength, wear resistance, excellent thermal conductivity. Contains free silicon. | Wear parts, pump impellers, nozzles, heat exchangers. |

Design Considerations for SiC Products

Designing with silicon carbide requires a specialized understanding of its unique material properties. Novel SiC processing enables greater design flexibility, but fundamental principles remain crucial for successful outcomes.

Key Design Considerations:

- Geometry Limits: While advancements allow for more complex shapes, sharp corners, thin walls, and abrupt changes in cross-section should be avoided due to SiC’s inherent brittleness. Large radii are preferred.

- Wall Thickness Uniformity: Consistent wall thickness is vital for even thermal expansion and contraction, minimizing internal stresses during processing and operation.

- Stress Points: Identify potential stress concentration points during design, especially in areas subjected to high loads or thermal gradients. FEA (Finite Element Analysis) is highly recommended.

- Fastening and Joining: Consider how SiC components will be joined to other materials. Brazing, adhesive bonding, and mechanical fastening methods all have specific design implications.

- Machinability: While SiC is extremely hard, advanced machining techniques like diamond grinding, laser machining, and ultrasonic machining can create intricate features. Design for manufacturability (DFM) is key.

- Material Grade Selection: The specific SiC grade should be chosen based on the operating environment (temperature, chemical exposure, mechanical loads) and desired performance characteristics.

Tolerance, Surface Finish & Dimensional Accuracy

Achieving high precision in SiC components is critical for many advanced applications. Novel processing techniques, coupled with specialized finishing methods, allow for exceptional accuracy.

Achievable Tolerances:

- As-fired/As-sintered: Typically for less critical dimensions, tolerances might be in the range of ±0.5% or ±0.005 inches, whichever is greater.

- Ground/Lapped: For high-precision applications, diamond grinding and lapping can achieve tolerances as tight as ±0.0001 to ±0.0005 inches (2.5 to 12.5 micrometers), depending on part size and complexity.

- Runout and Flatness: Can be controlled to very tight specifications, often in the micron range, for critical sealing or optical applications.

Surface Finish Options:

- As-fired/As-sintered: Typically results in a matte finish with a roughness of Ra 1.6-6.3 µm (63-250 µinch).

- Ground: Achieves a smoother finish, often Ra 0.4-0.8 µm (16-32 µinch).

- Lapped/Polished: For ultra-smooth surfaces, such as those required for seals, bearings, or optical components, finishes can be achieved down to Ra < 0.1 µm (< 4 µinch).

Dimensional accuracy is paramount in applications like semiconductor processing, where precise alignment and fit are non-negotiable. Custom SiC manufacturers leverage advanced metrology and quality control systems to ensure components meet stringent requirements.

Post-Processing Needs for Enhanced Performance

After initial fabrication, SiC components often undergo post-processing steps to refine their properties, enhance performance, or prepare them for assembly.

- Grinding: Precision diamond grinding is commonly used to achieve tight dimensional tolerances and improved surface finishes.

- Lapping and Polishing: Essential for critical sealing surfaces, optical components, and bearing surfaces to achieve extreme flatness and smoothness.

- Honing: Used for internal diameters to improve surface finish and dimensional accuracy.

- Brazing/Joining: SiC can be brazed to metals or other ceramics to create complex assemblies or hermetic seals for demanding applications.

- Coating: While SiC is inherently resistant, specific coatings (e.g., additional CVD SiC layers for ultra-purity in semiconductor applications or specialized wear-resistant coatings) can further enhance performance.

- Cleaning: Thorough cleaning is often required, especially for semiconductor and medical applications, to remove any contaminants.

Common Challenges and How to Overcome Them

Despite its superior properties, working with SiC presents certain challenges. Experienced custom SiC manufacturers have developed robust strategies to mitigate these issues.

Challenges:

- Brittleness: SiC is a hard but brittle material, making it susceptible to chipping or cracking under impact or excessive tensile stress.

- Machining Complexity: Its extreme hardness makes conventional machining difficult and expensive.

- Thermal Shock Sensitivity (though less than other ceramics): While good, extreme or repeated rapid thermal cycles can still cause issues in some designs.

- High Processing Temperatures: Sintering SiC requires very high temperatures, making the manufacturing process energy-intensive and requiring specialized equipment.

- Cost: The raw materials and specialized processing methods contribute to a higher cost compared to traditional engineering materials.

How to Overcome Them:

- Optimized Design: Employing DFM principles, stress analysis, and avoiding sharp corners minimizes stress concentrations.

- Advanced Machining: Utilizing diamond grinding, EDM, laser machining, and ultrasonic machining for precise and efficient fabrication.

- Controlled Processing: Careful control of heating and cooling rates during manufacturing to prevent thermal shock and ensure material integrity.

- Material Selection: Choosing the optimal SiC grade for the specific application’s thermal and mechanical demands.

- Expert Partnership: Collaborating with experienced SiC manufacturers who possess the specialized knowledge and equipment to handle these challenges.

How to Choose the Right SiC Supplier

Selecting the right supplier for custom silicon carbide products is a critical decision that directly impacts the success of your project. For technical buyers, procurement managers, and engineers, this choice goes beyond price.

When evaluating potential partners, consider the following:

- Technical Capabilities: Does the supplier have a deep understanding of SiC material science, processing techniques (sintering, reaction bonding, CVD), and advanced machining? Can they assist with design optimization and provide engineering support?

- Material Options: Do they offer a comprehensive range of SiC grades (SSiC, RBSiC, SiSiC, CVD SiC) to meet diverse application requirements?

- Quality Control and Certifications: Look for ISO certifications, stringent quality assurance processes, and a track record of consistent product quality.

- Experience and Track Record: A supplier with extensive experience in your industry (e.g., semiconductor, aerospace, automotive) will better understand your specific needs and challenges. Request case studies or references.

- Customization Expertise: Do they specialize in custom parts, or are they primarily an off-the-shelf provider? True customization requires specialized design, tooling, and manufacturing capabilities.

- R&D and Innovation: A forward-thinking supplier will invest in R&D, exploring novel SiC processing techniques to offer cutting-edge solutions.

- Supply Chain Reliability: For B2B buyers, consistent supply and on-time delivery are crucial. Assess their production capacity and logistical capabilities.

- Customer Service: A responsive and knowledgeable sales and technical support team is invaluable throughout the project lifecycle.

Cost Drivers and Lead Time Considerations

Understanding the factors that influence the cost and lead time of custom SiC products is essential for effective project planning and budgeting.

Cost Drivers:

- Material Grade: High-purity grades like SSiC or CVD SiC generally cost more than RBSiC or NBSiC due to more complex processing.

- Part Complexity: Intricate geometries, tight tolerances, and fine features significantly increase manufacturing costs due to specialized machining and longer processing times.

- Volume: As with most manufactured goods, higher production volumes typically lead to lower per-unit costs due to economies of scale.

- Post-Processing Requirements: Extensive grinding, lapping, polishing, or specialized coatings add to the overall cost.

- Design and Engineering Support: If the supplier provides significant design, FEA, or prototyping services, these will be factored into the price.

- Tooling Costs: For new designs, non-recurring engineering (NRE) costs for tooling (molds, fixtures) can be a significant upfront investment.

Lead Time Considerations:

- Design and Prototyping: This phase can range from a few weeks to several months, depending on complexity and iterative design cycles.

- Tooling Fabrication: Production of molds and fixtures can take several weeks.

- Material Availability: While SiC raw materials are generally available, specific purities or forms might have lead times.

- Manufacturing Process: The SiC manufacturing process itself (sintering, reaction bonding) involves lengthy high-temperature cycles and precise control.

- Post-Processing: Grinding, lapping, and other finishing steps can add significant time, especially for high-precision parts.

- Supplier Backlog: The current workload of the chosen supplier will impact lead times. Discuss this upfront.

Frequently Asked Questions (FAQ)

Here are some common questions we encounter regarding custom silicon carbide products:

Q1: What is the typical lifespan of a custom SiC component in a high-temperature application?

A1: The lifespan of a custom SiC component in high-temperature applications can vary significantly based on the specific SiC grade, the exact operating temperature, thermal cycling frequency, mechanical loads, and the presence of corrosive agents. However, SiC is known for its exceptional longevity in such environments, often outlasting metallic or other ceramic alternatives by many times. For instance, in a well-designed application, a SiC kiln furniture component can last for years, where traditional materials might fail in months. Our engineering team can provide more specific estimates based on your detailed application parameters.

Q2: Can custom SiC components be repaired or recycled?

A2: Due to the extreme hardness and chemical inertness of SiC, repairing damaged components is generally not feasible or cost-effective. Small chips might be re-ground in some cases, but structural failures typically require replacement. While SiC itself is a stable compound, recycling SiC components in the traditional sense (like metals) is challenging due to its high melting point and chemical stability. However, efforts are ongoing in research to develop methods for reclaiming valuable SiC materials from waste streams, particularly from grinding slurries and used SiC wafers.

Q3: How does SiC compare to other advanced ceramics like Alumina or Zirconia for wear resistance?

A3: Silicon carbide generally offers superior wear resistance compared to both Alumina ($Al_2O_3$) and Zirconia ($ZrO_2$), especially in abrasive environments. SiC’s extreme hardness (Mohs 9-9.5) and high modulus of elasticity provide excellent resistance to scratching, erosion, and sliding wear. While Alumina is a good general-purpose ceramic with decent wear properties, and Zirconia offers excellent toughness, SiC typically outperforms them in applications requiring extreme wear resistance under high loads or in abrasive slurries. For specific comparisons and material selection guidance, our technical team can provide detailed data.

Conclusion

Custom silicon carbide products are at the forefront of material innovation, offering unparalleled performance for the most demanding industrial environments. Through novel SiC processing techniques, engineers and technical buyers can unlock bespoke solutions that provide enhanced thermal resistance, superior wear resistance, exceptional chemical inertness, and precise electrical properties. From high-purity semiconductor components to robust aerospace parts and efficient power electronics, the value proposition of custom SiC is clear: extended operational life, improved system efficiency, and breakthrough performance. Partnering with a knowledgeable and experienced custom SiC manufacturer, like Sicarb Tech, is essential to leverage these advantages and ensure the success of your critical projects. We are dedicated to providing higher-quality, cost-competitive custom silicon carbide components and even offer technology transfer for clients looking to establish their own SiC manufacturing capabilities. Embrace the power of custom silicon carbide and propel your innovations to new heights.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.