Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Mountainous and High-Temperature Climate Adaptation

Haalbare toleranties en maatnauwkeurigheid:

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s High-Heat, High-Gradient Routes

Pakistan’s electrification is moving beyond city-center pilots into the steep, hot, and harsh operating corridors that define real mobility economics—from Islamabad’s foothills to the salt-laden Karachi coast and the dust belts around Lahore and Faisalabad’s cement and staal clusters. In these environments, range and uptime depend on how confidently a drivetrain holds torque on long grades at 40–50 °C ambient, how cleanly it manages regeneration on extended descents, and how robustly it resists dust, humidity, and corrosion. Silicon carbide (SiC) technology—when paired with double-sided cooling, low-inductance packaging, anti-clog thermal hardware, and hill-optimized control algorithms—unlocks high efficiency, stable thermal behavior, and durable reliability exactly where conventional silicon platforms struggle.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than 10 years of SiC customization and supports 19+ enterprises with full-cycle solutions. From R‑SiC, SSiC, RBSiC, and SiSiC materials to automotive-grade devices, double-sided-cooled modules, busbars, shared-cooling structures, sealing/coating systems, and accelerated validation, Sicarbtech delivers turnkey technology transfer and factory establishment. For Pakistan, this means localized packaging and testing, faster spares, and consistent quality backed by data—translating into better PKR economics and dependable fleet uptime in mountainous and high-temperature conditions.

Industry Challenges and Pain Points: The Reality of Heat, Altitude, and Harsh Terrain

The operating envelope in Pakistan’s high-temperature seasons is unforgiving. Ambient temperatures regularly hit 40–50 °C, pushing junction temperatures toward device limits if thermal paths are long or fouled. On long slopes, drivetrains spend extended time at low speed and high torque, where copper loss dominates and switching stress spikes during frequent start–stop on grades and switchbacks. In thin air at higher altitudes, convective heat transfer falls, so air-cooled systems lose margin. If cold plates scale, corrode, or cavitate due to poor channel design or coolant quality, liquid-cooled stacks also degrade. The result is early derating, audible fan noise spikes, and driver complaints when torque fades before the climb is done.

Environmental contamination makes matters worse. Cement and road dust clog fin stacks, elevating pressure drop and reducing airflow. Monsoon rains add water and mud ingress risks; detergents from wash-downs attack poorly selected coatings. Along coastal and saline-alkali routes, salt mist accelerates galvanic corrosion on aluminum and copper, undermining busbar joints and heat exchanger integrity. Conventional single-sided cooling with commodity interface materials often exhibits pump-out and voiding under vibration and thermal cycling, raising junction-to-case thermal resistance and creating hotspots that shorten device life.

Electromagnetic behavior also shifts under heavy load. Long cable runs and high regeneration currents on descents can excite oscillations if busbars and return paths are not symmetric and low-inductance. Overshoot and ringing during torque transitions stress devices and can trigger protections, especially when combined with moisture and contamination that alter insulation behavior. In textile mills and steel facilities, poor EMC discipline invites interference with drives and PLCs, creating unplanned downtime.

Commercially, the costs stack quickly. Frequent derating reduces daily mileage, forcing more vehicles or schedule slack to hit targets. Maintenance windows lengthen when clogged fins or corroded cold plates demand attention, while imported spare module turnarounds inflate downtime. Certification delays carry penalties as tenders increasingly reference IEC 60747 (device characteristics), IEC 60068 (damp heat, salt spray, dust, vibration, shock), and EMC expectations similar to IEC 61800‑3 for adjustable speed systems. ISO 7637 disturbance immunity applies for onboard interfaces, and ISO 9001/IATF 16949 governance is frequently requested for supplier qualification. As Dr. H. Rehman, an industrial power electronics advisor, notes, “Uptime on long grades is a thermal and control problem first, a battery problem second—proof of endurance is now a prerequisite, not a promise.” [Source: Regional Power Electronics Workshop, 2024]

In contrast, SiC with engineered packaging and control changes the trajectory. Double-sided cooling shortens thermal paths and spreads heat, high-conductivity interfaces resist pump-out, and anti-clog fins or corrosion-resistant cold plates sustain cooling with simple, low-pressure wash routines. Low-inductance busbars and active damping reduce overshoot and ringing, while hill-optimized control strategies coordinate torque and regeneration with temperature and altitude to keep power flowing without damaging components.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Mountainous and High-Temperature Adaptation

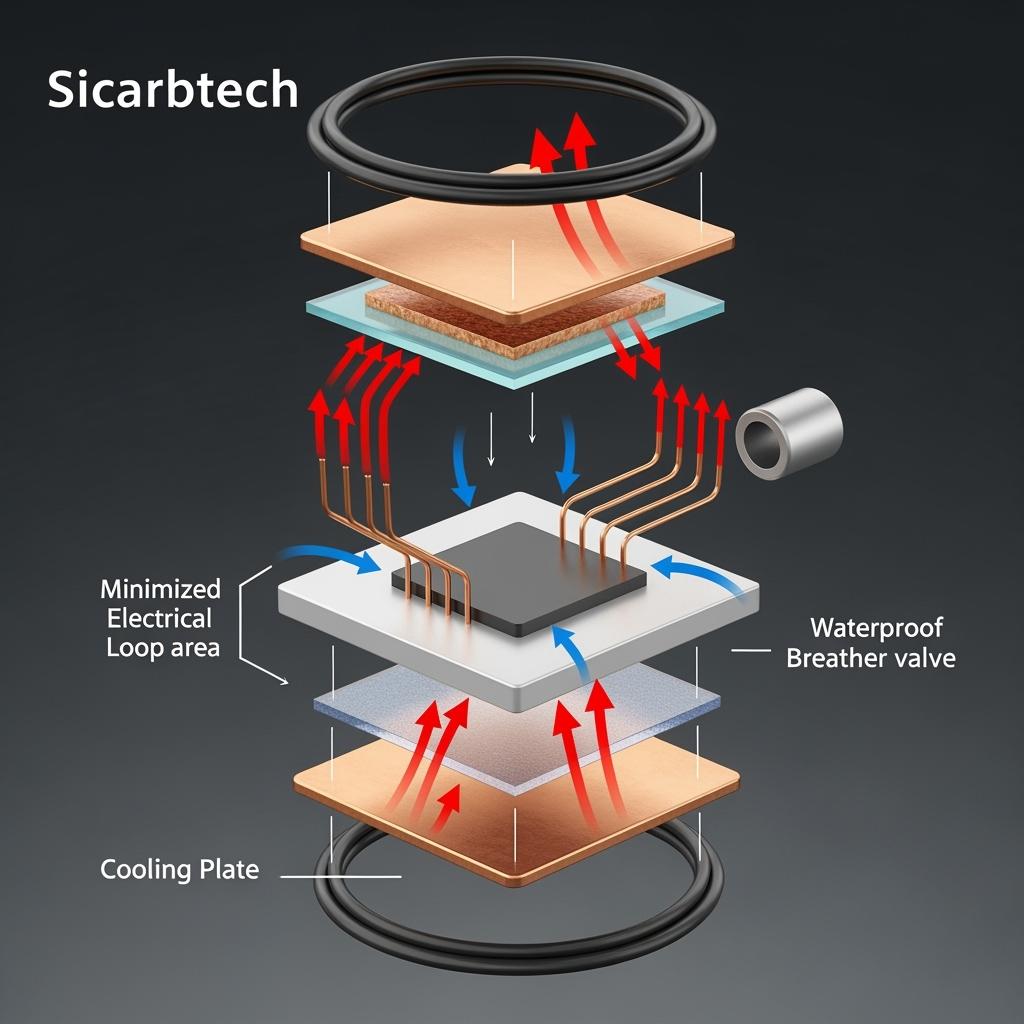

Sicarbtech’s portfolio is a coordinated stack from device to depot. Automotive-grade SiC MOSFETs and diodes at 650/1200 V populate low-inductance, double-sided-cooled modules on high-thermal-conductivity ceramic substrates. Pressure/laser sintered interfaces minimize voiding and fatigue, while symmetric busbars reduce loop area and EMI coupling. High-temperature phase-change pads and thermal gels are specified with controlled pressure and thickness windows to avoid pump-out and preserve junction-to-case performance over life.

Thermal mechanics are adapted to the environment. Anti-clog, high-throughput heatsinks with self-cleaning fin geometries sustain airflow in dusty corridors and clean with low-pressure water. Corrosion-resistant cold plates use optimized channel geometry to prevent scaling and cavitation, with materials and surface treatments matched to local coolant chemistry. Sealing and breathing balance via waterproof breather valves and standardized ring systems manage cavity pressure and humidity, preventing condensation without compromising ingress protection. Conformal coating with high-adhesion primers and selective potting protect against moisture, salt mist, and conductive dust.

Control and EMC are tuned for hills. Hill-climb and high-temperature optimization modules coordinate torque limits, pump speed, and field-weakening with estimated junction temperature and ambient conditions, including altitude adjustments for convective coefficients. Regenerative algorithms are tuned for long descents to maximize recovery without overvoltage or thermal runaway. Active bus management introduces damping and snubbing to suppress oscillations during heavy regeneration and long-cable runs. Isolated sensing kits remain stable in high humidity and temperature, and EMC filter assemblies address common-mode and differential-mode paths.

Validation and O&M close the loop. Online health monitoring estimates junction temperature, tracks interface thermal resistance trends, and measures leakage and corrosion indicators, enabling predictive maintenance. Accelerated testing covers power cycling, thermal shock, temperature–humidity cycling, vibration/shock, salt mist, dust, and rain to prove endurance. Technology transfer brings vacuum brazing, pressure sintering, pre-compliance EMC stations, and IEC 60068 environmental chambers into Pakistan, making localized screening and faster certification a reality.

High-Heat and Mountain Performance: SiC Versus Conventional Approaches

Continuous Power, Thermal Margin, and EMC Stability on Long Grades

| Attribuut | Sicarbtech SiC, Double-Sided Cooling, Hill-Optimized Control | Conventional Silicon, Single-Sided Cooling | Conventional Air-Cooled Heatsinks Without Anti-Clog Features | Operationele impact in Pakistan |

|---|---|---|---|---|

| System efficiency at high ambient | +2%–4% vs silicon | Basislijn | Lower at fouled airflow | Longer range and fewer charge stops |

| Junction temperature peak on long slopes | −5 to −12 °C | Higher peaks | Highest under fouling | Reduced derating and stress |

| Continuous output at 40–50 °C | +10%–20% | Frequent derates | Early derates | Stable climbing and payload |

| Regenerative energy recovery on long descents | +10%–25% | Limited by overvoltage/ripple | Often constrained | Better brake fade management |

| Cooling maintenance interval | 1.5×–2× longer | Basislijn | Short due to clogging | Lower OPEX and downtime |

| Overshoot/ringing during torque transitions | −15%–30% | Moderate to high | Hoog | Fewer trips, improved EMC |

By reducing thermal resistance and parasitics while optimizing control for hills and heat, Sicarbtech’s SiC architecture sustains power and improves drivability where it matters most.

Real-World Applications and Success Stories in Pakistan

A mountainous two-wheeler fleet north of Islamabad deployed double-sided-cooled SiC drives with anti-clog fin stacks and altitude-adaptive control. Data logs showed junction temperature peaks about 8 °C lower on sustained climbs, with high-temperature derating events dropping by roughly 30% year over year. Riders reported smoother torque at crawl speeds on hairpin sections, reducing rollback incidents.

In Faisalabad’s dust-heavy corridors, a light commercial platform adopted corrosion-resistant cold plates with anti-scaling channels and high-conductivity TIM. Continuous output at 45 °C ambient increased by approximately 15%, while cleaning intervals doubled thanks to low-pressure wash-compatible fins. Regenerative braking optimization improved energy recovery by around 12% on extended downhill delivery routes.

A coastal operator in Karachi integrated sealed breathing, high-adhesion conformal coating, and low-inductance busbars. Salt-mist-accelerated tests indicated a 2–4× increase in endurance before leakage thresholds were reached. EMC pre-compliance moved to first-pass success, shortening certification cycles and stabilizing deployment schedules during peak season.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

The SiC platform’s physics favor Pakistan’s conditions. Low conduction and switching losses at 10–60 kHz keep efficiency high under low-speed, high-torque operation, while double-sided cooling with high-k substrates and controlled TIM windows preserve thermal headroom at extreme ambient temperatures. Low-inductance busbars and symmetric loops diminish dv/dt stress, easing EMC constraints and reducing nuisance trips during steep-slope torque transitions and heavy regeneration.

Compliance is engineered-in. Device behavior aligns with IEC 60747, while environmental validation follows IEC 60068 for damp heat, salt spray, dust, vibration, and shock. EMC behavior is designed toward expectations similar to IEC 61800‑3 for adjustable speed systems, and ISO 7637 informs disturbance immunity for onboard interfaces. Insulation design addresses creepage and clearance for high pollution classes, and leakage/partial-discharge behavior is verified. As Engr. M. Abbas, an electrification consultant, observes, “When altitude and heat are explicit in the design checklist—and the logs back it up—approvals shift from debate to documentation.” [Source: Industrial Power Quality Seminar, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Mountain and Heat Readiness

Sicarbtech’s competitive advantage is transferring capability, not just hardware. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC into thermally resilient substrates and corrosion-aware assemblies that stand up to Pakistan’s dust, heat, and salt.

The technology transfer package includes process recipes for pressure/laser sintering profiles, vacuum brazing atmospheres and flux control, metallization/passivation stacks, and busbar/bond geometries for low inductance. Gate-drive tuning covers soft turn-off and active clamping tailored to steep-slope transients. Equipment specifications span sintering presses, vacuum furnaces, bonding machines (wire/ribbon), inline electrical testers, power cycling rigs with junction temperature estimation, HTRB/HTGB, EMC pre-compliance stations, and IEC 60068 environmental chambers—each delivered with acceptance tests, calibration procedures, and vetted vendor lists.

Training and QA build sustainable performance: operator certification, failure analysis workflows, SPC-driven yield optimization, and PPAP-like control plans aligned with ISO 9001 and IATF 16949 principles. Factory establishment services cover feasibility, utilities, line installation and commissioning, pilot runs, parameter locking, and capability validation. Post-SOP, Sicarbtech provides quarterly audits, yield sprints, and roadmap co-development to reflect Pakistan’s gradients, ambient profiles, and cleaning practices.

Across 19+ enterprise collaborations, operators achieve shorter time-to-market, higher first-pass yield, and lower field failure rates. In Pakistan, localized packaging and screening compress spare lead times to days–weeks, stabilize uptime during peak seasons, and seed domestic skills that compound into a durable competitive advantage.

Comparative Engineering Choices and Lifecycle Economics

Thermal, Control, and Packaging Choices for Long Slopes and High Heat

| Design Area | Sicarbtech Mountain/Heat Best Practice | Conventional Choice | Practical Outcome in Pakistan |

|---|---|---|---|

| Cooling stack | Double-sided cooling, high-k substrates, controlled TIM windows | Single-sided, grease TIM | Lower Tj, fewer derates at 40–50 °C |

| Thermal hardware | Anti-clog fins, corrosion-resistant cold plates | Generic fins, untreated channels | Longer cleaning interval, stable flow |

| Packaging & busbars | Low-inductance, symmetric loops, shielding | Long leads, asymmetry | Less ringing/overshoot, better EMC |

| Control strategy | Altitude/temperature-adaptive derating; regen optimization | Fixed limits, generic regen | Sustained climbing, higher recovery |

| Milieuafdichting | Breather-balanced, high-adhesion coatings | Rigid seals, basic coat | Less condensation/corrosion |

Localization and Total Cost of Ownership on Mountain Routes

| Business Factor | With Sicarbtech Localization & Tech Transfer | Import-Only Approach | Outcome for Fleets and OEMs |

|---|---|---|---|

| Spare and repair lead time | Days–weeks via local screening | Weeks–months | Higher uptime, fewer canceled trips |

| Maintenance OPEX | 50%–100% longer cleaning intervals | Frequent service | Lower PKR OPEX, better availability |

| Certification and tenders | Pre-compliance logs and environmental evidence | Late-stage surprises | Faster approvals, predictable rollout |

| Energy and brake wear | +2%–4% efficiency, +10%–25% regen | Lower efficiency, limited regen | Lower PKR/km, safer descents |

| Ecosystem and skills | In-country QA/process maturity | Vendor dependency | Resilient supply and talent base |

Future Market Opportunities and 2025+ Trends: Designing for Heat, Height, and Data

Pakistan’s 2025+ electrification will emphasize performance on grades, thermal resilience in heat waves, and data-anchored reliability. Procurement will ask for altitude-aware derating curves, measured regen shares on long descents, and cleaning intervals validated by dust-chamber tests. ESG-linked financing will weigh endurance logs and predictive maintenance efficacy. Technically, we expect double-sided cooling and anti-clog fins to become baseline, while corrosion-resistant cold plates and breather-balanced sealing define the top tier. Active bus damping and low-inductance packaging will be standard for safe regeneration on long cables. Sicarbtech’s integrated stack—devices, packaging, control, validation, and technology transfer—aligns with these trajectories, enabling Pakistani partners to lead on uptime and lifecycle cost where competitive pressure is highest.

Extended Technical Specifications and Local Standards Alignment

The adaptation platform covers 48–120 V DC buses for two-/three-wheelers and extends to 400–800 V for light commercial vehicles. Power ranges span 2–10 kW and 10–60 kW respectively, with switching frequencies from 10–60 kHz selected to balance losses, acoustics, and thermal limits. Device junction temperature capability reaches up to 175 °C; double-sided cooling and high-k substrates minimize junction-to-case resistance. Environmental protections include dust, moisture, salt mist, rain, and chemical exposure; vibration and shock robustness suits mountainous roads.

Monitoring captures junction temperature estimates, interface thermal resistance trends, leakage current, and corrosion indicators, feeding predictive maintenance. Documentation maps to IEC 60747 (devices) and IEC 60068 (environmental tests), with EMC expectations similar to IEC 61800‑3 and ISO 7637 applied where onboard interfaces apply. Sicarbtech coordinates pre-compliance with Karachi and Lahore labs, providing parameter traces and thermal histories for tender and financing packages.

Veelgestelde vragen

How much performance gain should we expect on long grades in high heat?

Typical deployments see 5–12 °C lower junction temperature peaks and 10%–20% higher continuous output at 40–50 °C ambient, with 2%–4% system efficiency gains versus conventional silicon platforms.

Will altitude and thin air compromise cooling?

Air-side performance drops with reduced density, but double-sided cooling, higher-k substrates, and control that adjusts pump/fan speeds and torque limits maintain safe junction temperatures. Altitude-aware derating curves are part of the configuration.

Can regeneration be safely increased on long descents without overvoltage issues?

Yes. Active bus damping, low-inductance busbars, and regen-optimized control typically improve recovered energy by 10%–25% while containing ripple and overshoot.

How often will anti-clog fins and cold plates need cleaning in dusty corridors?

Anti-clog fin geometries and anti-scaling channels support low-pressure wash routines, extending cleaning intervals by 50%–100% depending on duty and dust load.

What local standards and tests are supported for tender submissions?

Designs align with IEC 60747 and IEC 60068 (damp heat, salt-spray, dust, vibration, shock), with EMC engineered toward expectations similar to IEC 61800‑3 and ISO 7637 as needed. Pre-compliance with Karachi and Lahore labs is included.

Can the same hardware platform cover scooters, rickshaws, and light commercial vans?

Yes. The platform is modular across voltage classes and power levels, with parameterized control for torque, regen, and thermal management to suit different weights and routes.

How do you detect interface and sealing degradation before failures?

Online models estimate interface thermal resistance from temperature–power relationships, while leakage and corrosion indicators provide early warnings to schedule maintenance before faults.

What is a realistic design-to-pilot timeline with local screening?

With standardized modules and validation kits, pilots typically launch in 8–12 weeks, followed by local environmental and EMC pre-compliance to de-risk formal certification.

How much can localization reduce downtime and cost?

Local packaging and screening compress spare lead times to days–weeks, reduce warranty rework through consistent screening, and lower OPEX via longer cleaning intervals and fewer derates.

What ongoing support does Sicarbtech provide after SOP?

Quarterly audits, yield sprints, and co-developed updates to packaging, busbars, and control recipes tuned to Pakistan’s gradients, dust, and ambient conditions—plus rapid failure analysis and process feedback.

De juiste keuze maken voor uw activiteiten

Where heat, altitude, and dust define reality, performance is a system property. Sicarbtech’s SiC-based mountain and high-temperature adaptation joins double-sided cooling, low-inductance packaging, anti-clog thermal hardware, and altitude- and heat-aware control into a cohesive solution. With local manufacturing, screening, and data-backed validation, fleets and OEMs convert engineering into uptime, safer descents, and better PKR per kilometer—year after year.

Deskundig advies en oplossingen op maat krijgen

Partner with Sicarbtech to specify device ratings, packaging geometry, busbar design, and thermal hardware for your gradients and climate. Implement hill-optimized control and regeneration strategies, then localize packaging, screening, and pre-compliance to scale confidently across Pakistan’s mountainous and high-temperature routes.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency wins the datasheet; endurance wins the mountain; localization wins the season.” — Sicarbtech Applications Team

Artikelmetadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, ISO 7637, and EMC expectations similar to IEC 61800‑3; integrates Sicarbtech’s SiC mountain/heat adaptation portfolio, technology transfer, and local validation capabilities.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.