Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 DC Fast-Charging and Industrial Power Playbook

Haalbare toleranties en maatnauwkeurigheid:

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Charging and Industrial Sectors

Pakistan’s electrification of two-wheelers, three-wheelers, and light commercial vehicles is accelerating alongside modernization across textile, cement, and steel plants. The convergence of nighttime clustered charging, volatile grid conditions, and harsh environments—heat, dust, and coastal humidity—has exposed the limits of conventional silicon power electronics. In 2025, silicon carbide (SiC) sits at the center of high-efficiency DC fast-charging modules and rugged industrial power systems. By enabling higher switching frequencies, high junction temperatures, and low loss operation, SiC delivers smaller, cooler, and more reliable equipment that reduces operating costs and shortens payback.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s SiC manufacturing hub, within the Chinese Academy of Sciences (Weifang) Innovation Park. With more than a decade of SiC customization and 19+ enterprise collaborations, Sicarbtech provides full-cycle solutions spanning materials (R-SiC, SSiC, RBSiC, SiSiC), devices and modules, drive and control, thermal stacks, magnetics, and reliability screening. For Pakistan, Sicarbtech’s turnkey technology transfer and factory establishment services unlock local packaging, verification, and maintenance—cutting lead times, elevating uptime, and building domestic capacity for scale.

Industry Challenges and Pain Points: The Reality of DC Fast-Charging and Heavy Industry in Pakistan

The first constraint is power quality. Urban and peri-urban charging sites typically feed from distribution networks that experience voltage sags, dips, and phase imbalance. During nighttime and midday peaks, clustered charging can drive significant harmonic injection and feeder stress. For charger-side power modules, the consequence is frequent protection trips, thermal stress from repeated restarts, and lower station throughput. Vehicle-side receiving modules on two- and three-wheelers often face low-voltage, high-current bursts where cable inductance and contact resistance amplify transients, raising the risk of overvoltage and EMI noncompliance.

Heat and environment compound these electrical stresses. Summer ambient temperatures often exceed 40 °C; in Karachi and coastal belts, salt mist and humidity accelerate corrosion, while cement and steel corridors add dust and abrasive particulates. Conventional silicon modules, with higher reverse-recovery and switching losses, require larger magnetics and heatsinks and still exhibit early derating under elevated temperature. Inside charging cabinets, forced-air systems run harder and louder, yet cabinet hotspots persist, degrading electrolytics and accelerating failure. Maintenance then becomes a cost center, with technicians chasing intermittent faults in contactors, filter banks, or thermal interfaces that lose performance in dust-laden air.

There is also a business dimension. Site owners shoulder high energy and HVAC costs; every point of efficiency matters in PKR-denominated bills. Long payback periods and utilization volatility discourage expansion, especially when downtime spikes during summer peaks. Meanwhile, fleet operators expect dependable fast-charging for predictable route planning. For industrial users—textile mills with variable-speed drives, cement plants with kiln-adjacent electronics, and steel rolling lines—voltage disturbances, airborne contaminants, and thermal cycling contribute to nuisance trips and capex-protective overdesign.

Regulatory expectations are tightening. While Pakistan aligns with international frameworks, tenders increasingly reference IEC 61000 series for EMC, IEC 61800-3 for adjustable speed systems, IEC 60747 for device characteristics, IEC 60068 for environmental testing, and ISO 7637 for automotive electrical disturbances. Developers must demonstrate power factor near unity, controlled total harmonic distortion (THD), surge resilience, and insulation robustness. As Dr. H. Rehman, a power systems advisor, puts it, “Grid-friendly, high-efficiency equipment earns better financing terms and site approvals; it’s no longer optional—it’s the price of admission.” [Source: Regional Power Electronics Forum proceedings, 2024]

In short, Pakistan’s charging ecosystem and industrial plants demand compact, heat-tolerant, and grid-resilient power modules. The solution must pair device physics with packaging, control, and environmental hardening. Silicon carbide answers these needs with high-voltage capability, low loss at high frequency, and temperature robustness—especially when integrated into low-inductance, double-sided-cooled packages with active clamping and predictive monitoring.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech DC Fast-Charging Modules Built for Pakistan

Sicarbtech’s portfolio for DC fast-charging spans both charger-side power modules and vehicle-side receiving units. At the core are automotive-grade SiC power modules in 1200 V and 1700 V classes, configured as half-bridge or bridge-leg elements for scalable topologies. The AC front-end benefits from high-frequency, SiC-based totem-pole power factor correction that delivers ≥0.99 power factor at rated load and maintains high performance under partial load. Downstream isolated DC stages employ phase-shift full-bridge or three-level architectures to balance efficiency, switching stress, and control complexity.

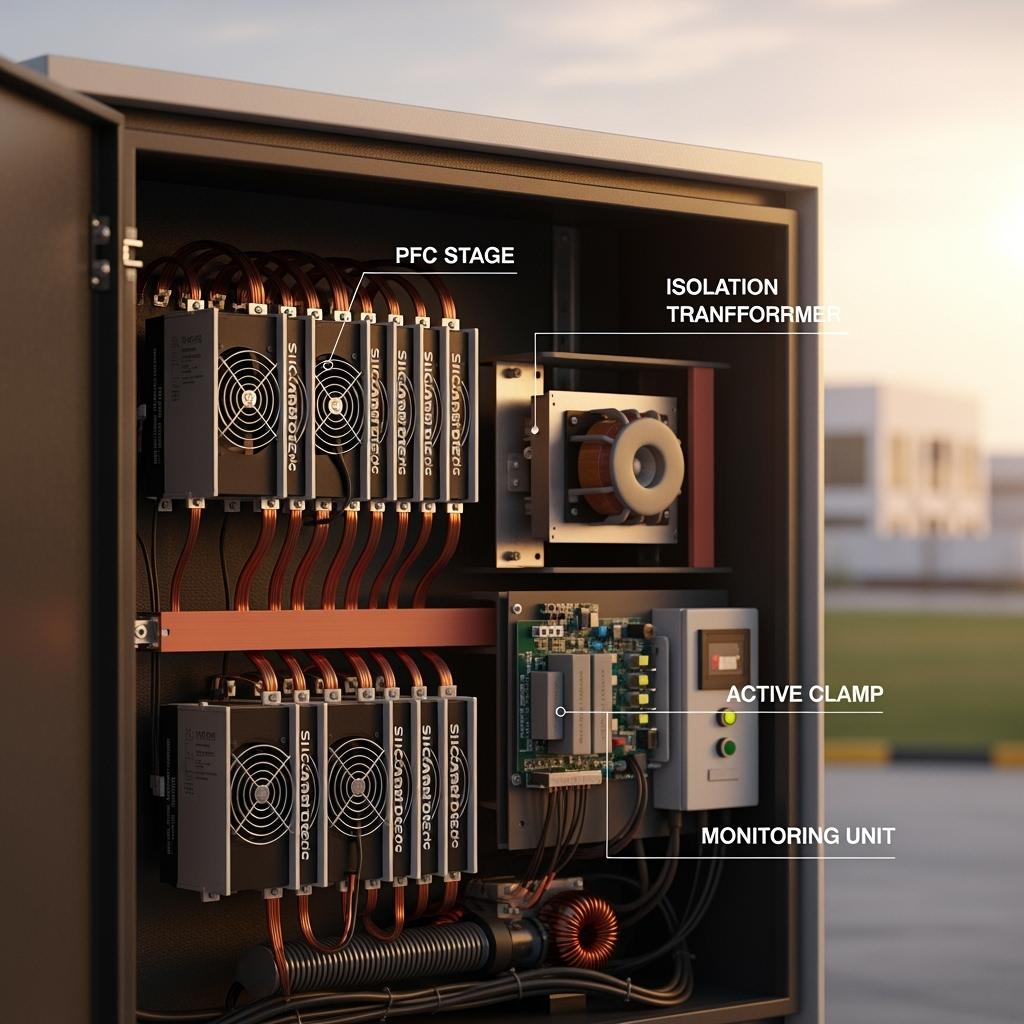

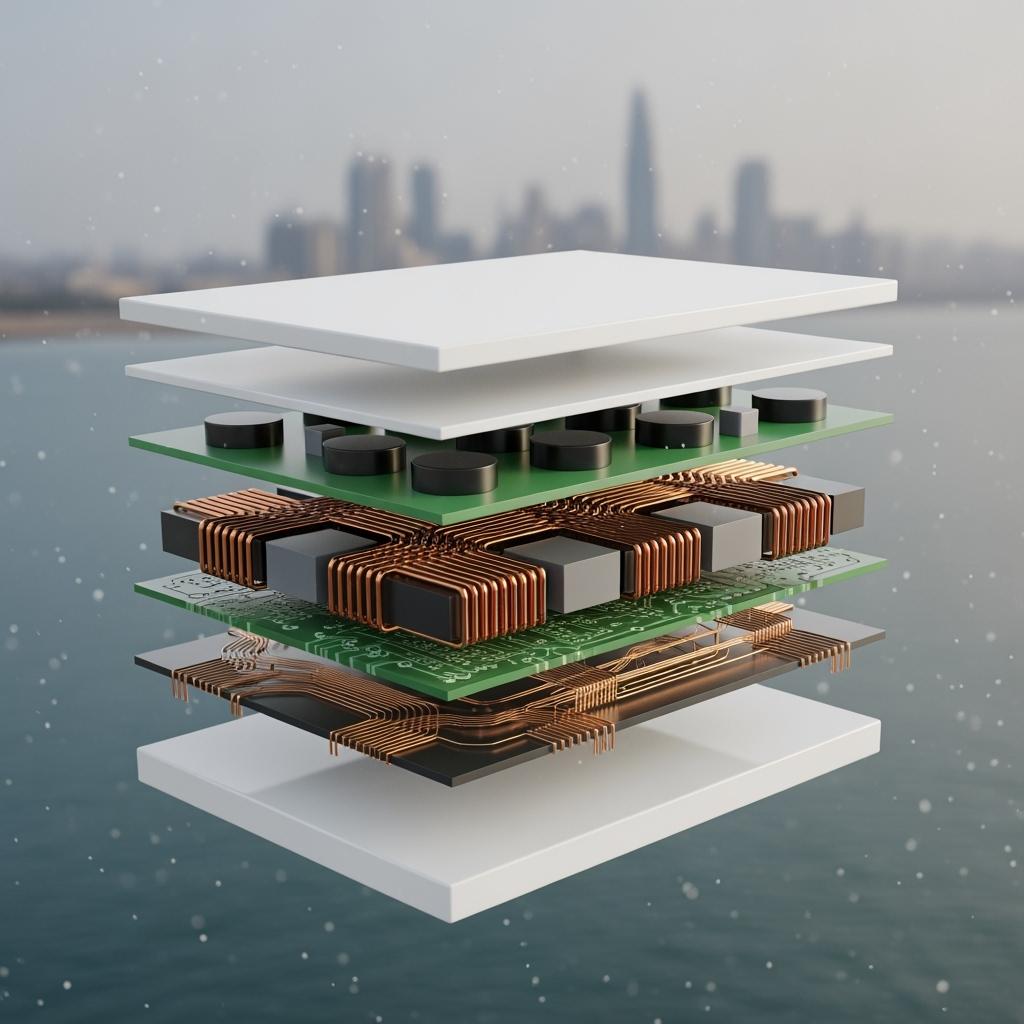

Thermally, low-inductance, double-sided cooling packages with high-thermal-conductivity ceramic substrates spread heat effectively, which is critical for high altitude or high ambient temperatures common in the north and during heat waves nationwide. Gate driver boards integrate soft turn-off and active clamping to suppress DC bus surges caused by cable parasitics, while fast desaturation detection protects against short circuits. Magnetics are co-designed with the switching stages to exploit higher frequencies, shrinking transformer and inductor volumes without compromising EMI.

Beyond the power path, Sicarbtech provides modular DC bus systems and copper–aluminum composite busbars to reduce eddy losses and manage thermal gradients. Environmental protection options—from conformal coating and potting to salt-mist-resistant hardware—extend lifecycle in dusty and coastal environments. Site controllers and protocol adapters ensure compatibility with local and regional charging standards, while edge computing units support remote O&M, health assessment, and data-driven maintenance scheduling. Most importantly, the same ecosystem includes localized packaging and production equipment—vacuum brazing, pressure sintering, power cycling rigs, and damp-heat/salt-spray chambers—so Pakistani partners can build, screen, and service modules domestically.

Performance Comparison: Silicon Carbide vs Traditional Silicon in Pakistan’s Fast-Charging Conditions

Efficiency, Power Quality, and Thermal Behavior for DC Fast-Charging Sites

| Performance Aspect | Sicarbtech SiC Charging Modules | Conventional Silicon Charging Modules | Impact on Pakistan Sites |

|---|---|---|---|

| End-to-end efficiency (PFC + isolation) | 96%–98% peak | 93%–95% | Lower PKR energy and HVAC costs; less cabinet heat |

| Power factor at rated load | ≥0.99 | 0.96–0.98 | Fewer upstream trips on weak feeders during peaks |

| Ingangsstroom THD | 5%–8% achievable | 15%–25% | Reduced interference with neighboring loads |

| Power density (per cabinet volume) | +30% to +60% | Basislijn | Higher site throughput per square meter |

| Heatsink volume and fan speed | −30% to −50% | Basislijn | Quieter sites, fewer thermal failures in summer |

| High-temp derating at 40–50 °C | 20%–40% fewer events | Frequent | Stable charging under heat and dust |

The gains are not purely theoretical; they translate directly into shorter queues, more consistent constant-power phases, and reduced O&M visits, especially during the summer months when utilization and heat converge.

Real-World Applications and Success Stories Across Pakistan

In a Lahore logistics park, a charging site upgraded 30 kW bricks from conventional silicon to Sicarbtech 60 kW SiC modules with N-parallel scalability. The cabinet footprint fell by roughly 35% after magnetics and heatsinks were downsized, while measured station efficiency climbed to the 97% range. During evening peaks, the site maintained constant-power output longer at high ambient temperatures. Month-on-month, kilowatt-hour per session costs dropped, and station throughput improved, reducing queue lengths without additional bays.

Karachi’s coastal environment posed a different challenge. A business district fast-charging site struggled with corrosion and intermittent trips. Sicarbtech supplied SiC modules with conformal coating, potting in high-risk areas, and salt-mist-resistant hardware. Active clamping and low-inductance busbars tamed surge events associated with feeder flicker. Over the following summer, derating incidents fell by about 40%, and predictive maintenance based on junction temperature estimation and on-resistance drift flagged two modules for replacement ahead of failures—preventing peak-hour downtime.

On the vehicle side, several passenger three-wheeler fleets deployed compact SiC receiving units for on-route fast top-ups. The higher switching frequency permitted smaller inductors, fitting within constrained vehicle compartments. Combined with site-side improvements, typical top-up durations decreased by around 12%, which in turn expanded daily operational windows for drivers and stabilized earnings across routes.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

Sicarbtech’s SiC modules are designed around high-frequency operation to cut magnetic volume and improve transient response. Low-inductance packaging, combined with active clamping and soft turn-off, suppresses overvoltage and ringing even with long cable runs—common in retrofit environments. Double-sided cooling reduces junction-to-case thermal resistance, enabling sustained output at high ambient temperatures and altitude where air density and cooling performance decline.

From a compliance perspective, documentation and design targets align with IEC 60747 for devices, IEC 61000 and IEC 61800-3 for EMC of power systems, IEC 60068 for environmental testing (damp heat, salt spray, dust), and ISO 7637 for automotive electrical disturbances. For industrial tie-ins at textile, cement, and steel facilities, Sicarbtech maps mitigation strategies to harmonics and flicker management expectations commonly referenced in procurement. Local partners in Karachi and Lahore can coordinate third-party tests, accelerating tender readiness and easing access to green financing that rewards high efficiency and power quality. As Engr. M. Abbas, an industrial electrification consultant, remarks, “Sites that demonstrate low THD, near-unity PF, and robust surge handling consistently win approvals and better tariffs.” [Source: Industrial Power Quality Seminar, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge in Pakistan

Sicarbtech’s advantage is a deep, practice-backed transfer of capability. Leveraging its Chinese Academy of Sciences partnership, Sicarbtech has developed proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades—knowledge that matters both for rugged mechanical fixtures in dusty plants and for thermally resilient power module substrates. The technology transfer package is comprehensive. It includes process know-how—pressure-sintering profiles, vacuum brazing parameters, metallization stacks, bond-wire and busbar design rules, coating and potting recipes—and clear equipment specifications with vendor shortlists and acceptance tests.

The factory establishment pathway begins with feasibility studies, site layout, and utilities planning. Sicarbtech then guides line installation, commissioning, and pilot runs, followed by process capability validation and control plan setup aligned with ISO 9001 and IATF 16949 principles. Training programs cover operators, maintenance, and quality engineers, with special tracks on accelerated life testing (power cycling, HTRB/HTGB), failure analysis, and statistical process control. Post-launch, quarterly audits and yield-improvement sprints keep plants on the learning curve, while co-development of next-generation modules ensures product roadmaps reflect Pakistan’s evolving grid and usage profiles.

Results with 19+ enterprises show faster time-to-market, higher first-pass yields, and tangible reductions in field failure rates. For Pakistan, local packaging and screening mean spare parts in days, not months; it also means the freedom to tune designs for regional heat, dust, and voltage fluctuation without waiting for overseas engineering cycles. This is capability, not just product supply—and it is difficult for competitors to replicate quickly.

Comparative Design Choices and Localization Economics for DC Fast-Charging

Stage-by-Stage Design Comparison Optimized for Pakistan’s Distribution Networks

| Ontwerpfase | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Operational Outcome in Pakistan |

|---|---|---|---|

| AC Front-End | SiC totem-pole PFC at 20–50 kHz, PF ≥0.99 | Boost PFC with silicon diodes | Lower THD, fewer feeder trips in peak clusters |

| Isolation DC Stage | PSFB/three-level at 40–80 kHz | Lower-frequency bridge | Smaller transformer/inductor, higher partial-load efficiency |

| Packaging | Double-sided cooling, low-inductance busbar | Single-sided, higher L | Reduced overshoot, stable under cable parasitics |

| Bescherming | Soft turn-off + active clamp, fast desat | Basic protection | Graceful recovery after sags/outages |

| Monitoring | Tj estimation, Rds(on) drift, loss trend | Minimaal | Predictive maintenance and fewer sudden failures |

Localization and Lifecycle Value for Site Operators and OEMs

| Business Factor | With Sicarbtech Transfer | Import-Only Approach | Outcome for Pakistani Operations |

|---|---|---|---|

| Spare turnaround | Days–weeks (local screening) | Weeks–months | Higher uptime and service-level compliance |

| Compliance cycle | Guided plans with local labs | Trial-and-error | Faster approvals, lower lab rework costs |

| Voetafdruk van de kast | Co-designed thermal/magnetics | Overbuilt safety margins | More bays per site, lower rent and HVAC |

| O&M model | Remote monitoring, predictive service | Reactive repairs | Lower TCO in PKR and steadier cash flow |

| Capability growth | In-country process maturity | Supplier dependency | Stronger ecosystem and job creation |

Future Market Opportunities and 2025+ Trends: Why SiC Defines the Next Build-Out

The next wave of Pakistan’s charging build-out will emphasize higher utilization, smarter energy management, and rapid deployment. Sites will integrate staggered charging schedules, limited on-site storage, and rooftop solar where practical. Modules must maintain efficiency across partial loads, provide precise current sharing in parallel arrays, and ride through disturbances gracefully. SiC’s high-frequency operation enables tighter control loops and better power quality, supporting lower THD and near-unity PF, which in turn improves grid relationships and financing outcomes.

On the vehicle side, fast top-ups for two- and three-wheelers will expand, pushing the adoption of compact, high-current receiving units with robust surge handling and thermal resilience. Industrial corridors will continue replacing legacy drives and rectifiers with SiC-based systems to reduce energy use and improve reliability. In all cases, capability transfer is the force multiplier—accelerating domestic innovation cycles and embedding best practices in local teams. Sicarbtech’s integrated stack of devices, packaging, process, validation, and operations data is aligned with this trajectory, positioning partners to lead rather than follow.

Technical Specifications and Local Standards Alignment

Sicarbtech’s DC fast-charging modules target three-phase 380 V inputs at 45–65 Hz with tolerance for local deviations. DC outputs span 200–1000 V with per-module currents up to 300 A, and rated power blocks of 15–60 kW enable N-parallel systems beyond 240 kW. Peak efficiencies reach 96%–98% across PFC and isolation stages, with switching frequencies from 20–80 kHz depending on topology and rating. Operating junction temperatures up to 175 °C and optimized thermal resistance support sustained performance in 40–50 °C ambient conditions. Protection suites include overvoltage, undervoltage, overcurrent, overtemperature, short circuit, insulation monitoring, and surge/lightning protection. Environmental robustness is achieved through dust-proofing, moisture-proofing, salt-mist resistance, and sand-proof cabinet options for industrial corridors.

Compliance mapping references IEC 60747 (devices), IEC 61000 and IEC 61800-3 (EMC), IEC 60068 (environment), ISO 7637 (automotive disturbances), and applicable safety clearances and creepage distances. Sicarbtech assists with documentation and third-party validation through local labs, easing inclusion in public and campus project shortlists and supporting financing that weighs efficiency and power quality.

Veelgestelde vragen

What power levels suit Pakistan’s charging sites today?

Most urban and peri-urban locations benefit from standardized 15, 30, and 60 kW modules that can be paralleled to meet site-specific throughput. This approach balances scalability with serviceability and simplifies spares.

How much efficiency gain can we expect, and how does it affect OPEX?

Moving from 93%–95% to 96%–98% peak efficiency lowers energy and HVAC costs, especially during hot months. For high-utilization sites, the PKR savings add up quickly and shorten payback periods.

Will SiC modules handle grid sags, surges, and phase imbalance?

Yes. Active clamping, soft turn-off, and low-inductance packaging reduce overvoltage and ringing during disturbances. Control strategies maintain high PF and low THD, minimizing upstream breaker trips.

How do these modules perform in heat, dust, and coastal humidity?

Double-sided cooling and high-thermal-conductivity substrates sustain output at elevated temperatures. Conformal coating, potting, and corrosion-resistant hardware pass IEC 60068 damp-heat and salt-spray profiles, lowering leakage and improving longevity.

Can Sicarbtech support localized manufacturing and faster spares?

Sicarbtech provides technology transfer, equipment specifications, training, and reliability screening protocols. Local packaging and verification reduce turnaround from months to days or weeks and build domestic capability.

What about EMC compliance and harmonics for tenders?

SiC totem-pole PFC and co-optimized filters achieve PF ≥0.99 with input current THD in the 5%–8% range, easing IEC 61800-3 expectations. Sicarbtech supports test plans and lab coordination in Karachi and Lahore.

How do parallel systems share current and maintain reliability?

Active current sharing and redundancy management allow hot-swapping and scalable capacity. Fault isolation limits the impact of a failed module, improving availability and simplifying maintenance.

Are these solutions relevant to textile, cement, and steel plants?

Yes. Beyond charging, SiC-based rectifiers and drives reduce losses and heat, and SiSiC/RBSiC fixtures and protections resist dust, abrasion, and thermal shock. The combined approach improves uptime and lowers energy intensity.

What integration timeline is typical from design to pilot?

With Sicarbtech’s modular kits and engineering support, many teams move from schematic to pilot within 8–12 weeks, depending on cabinet design and EMC iteration cycles.

How does predictive maintenance work in practice?

Module telemetry estimates junction temperature, tracks on-resistance drift and switching loss trends, and correlates with grid events. Alerts prompt planned service before failures, cutting unplanned downtime by around 30% in field reports.

De juiste keuze maken voor uw activiteiten

In Pakistan’s heat, dust, and dynamic grid, the winning formula is efficiency with resilience. Sicarbtech’s SiC modules deliver higher power density, lower losses, and robust disturbance handling, while the turnkey transfer of processes, testing, and training establishes local capability that outlasts any single product cycle. Whether you are scaling fast-charging sites or upgrading industrial power electronics, partnering with Sicarbtech means measurable gains—higher throughput, lower OPEX in PKR, shorter payback, and dependable uptime.

Deskundig advies en oplossingen op maat krijgen

Collaborate with Sicarbtech to specify the right 15/30/60 kW modules, define parallel architectures, and engineer thermal and EMC strategies tailored to Pakistan’s conditions. Explore technology transfer and factory establishment to localize packaging and screening, ensuring rapid service and a resilient supply chain.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“High efficiency wins the spreadsheet, but localized capability wins the year—through uptime, service speed, and trust.” — Sicarbtech Applications Team

Artikelmetadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook for DC fast-charging and industrial corridors; aligns with IEC 60747, IEC 61000/61800-3, ISO 7637, IEC 60068; includes Sicarbtech’s current portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.