Siliciumcarbide hoogfrequente geïsoleerde laad-/ontlaad- en DC-busregelunit voor batterijgekoppelde UPS en microgrid-stabiliteit

Haalbare toleranties en maatnauwkeurigheid:

Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability product overview and 2025 market relevance

In Karachi’s humid sea air and Gwadar’s expanding terminals, the difference between a smooth shift and an interrupted one often comes down to how gracefully the DC bus behaves when loads surge and feeders wobble. The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability was designed precisely for that moment. Conceived by Sicarbtech as part of a vertically integrated SiC ecosystem—from crystal growth and epitaxy through device fabrication, module packaging, and system-level validation—the unit provides galvanically isolated, bidirectional energy flow between battery banks and the UPS DC bus while regulating voltage with high bandwidth and low ripple. In practical terms, it keeps cranes lifting, reefers cooling, and dispatch systems stable when the grid sags or sources transfer, turning potential disturbances into quiet non-events.

By 2025, Pakistan’s ports and adjacent textile, cement, and staal industries are demanding both resilience and efficiency. Moreover, shore power must now function as a microgrid cornerstone during grid anomalies, coordinating with active front ends, static transfer switches, and inverter stacks. The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability delivers high-frequency operation—typically 50–150 kHz—through SiC devices and high-permeability planar magnetics, shrinking filters and reducing thermal burdens. The result is a compact, salt-mist-hardened module that keeps the DC bus within tight bounds while charging or discharging batteries at high efficiency, aligning with NTDC expectations for power quality and the operational realities of monsoon seasons.

Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability technical specifications and coordinated control features

The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability centers on a bidirectional isolated topology—most often a phase-shifted full-bridge or hybrid LLC—driven by SiC switches with low conduction and switching losses. Operating at 50–150 kHz, it achieves high power density and minimal output ripple, supporting UPS DC buses in the 600–1200 V range with module-level insulation ratings verified to 1200–1700 V for transient resilience. Interleaved phases reduce ripple current into batteries, protecting cell health and thermal stability, while planar transformers and coupled inductors reduce copper losses and stray fields within compact footprints.

A digital control platform—DSP plus FPGA fabric—executes model-based control for tight DC-bus regulation, smooth charge/discharge transitions, and precise current sharing across paralleled units. The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability coordinates with Sicarbtech’s silicon carbide three-level high-efficiency rectifier and active front-end power unit to absorb or inject real power as the grid shifts, maintaining PF near unity and minimizing THD. It also aligns with the silicon carbide seamless on/off-grid transfer control board and digital controller, pre-biasing the bus and reserving inverter headroom before a static transfer, so transfers complete invisibly. Protection spans fast overcurrent detection, soft-start sequencing, battery-side isolation checks, pre-charge coordination, and comprehensive thermal supervision.

Environmental hardening is non-negotiable: conformal coating, corrosion-resistant bus bars and heat spreaders, and sealed airflow with hydrophobic filters are validated in salt-fog and humidity cycling representative of Karachi and Gwadar. Telemetry—charge power, bus voltage, battery current, thermal margins, and efficiency—streams via fiber or industrial Ethernet to Sicarbtech’s monitoring stack, enabling predictive maintenance, SOH/SOC-informed dispatch, and audit-ready records for FAT/SAT.

Power density and stability comparison with the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

| DC Microgrid KPI at Pakistani Terminals | Siliciumcarbide hoogfrequente geïsoleerde laad-/ontlaad- en DC-busregelunit voor batterijgekoppelde UPS en microgrid-stabiliteit | Silicon-based Low-Frequency Isolated Converters |

|---|---|---|

| Switching frequency and magnetics size | 50–150 kHz; compact planar magnetics | 5–20 kHz; bulky transformers/inductors |

| End-to-end efficiency at rated power | 96.5–98% typical with SiC | 92–95% typisch |

| DC bus regulation bandwidth | Fast; sub-millisecond transients | Slower; larger droop under step loads |

| Ripple current into battery | Low due to interleaving and filtering | Higher; greater cell stress |

| Cabinet thermal/acoustic profile | Lower fan duty; quieter operation | Higher airflow; audible hum |

Lifecycle economics and PKR-denominated outcomes from the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

| Operationele resultaten over vijf jaar | Siliciumcarbide hoogfrequente geïsoleerde laad-/ontlaad- en DC-busregelunit voor batterijgekoppelde UPS en microgrid-stabiliteit | Conventional Battery Couplers |

|---|---|---|

| Energy lost in conversion | 15–30% reduction vs. baseline | Higher steady losses |

| Battery life and SOH drift | Improved via low ripple and thermal margins | Faster aging from ripple/heat |

| Downtime linked to DC bus events | 40–60% fewer PQ alarms and trips | Frequent resets during sags |

| Cooling and maintenance | Lower fan runtime; predictive service | Higher fan hours; reactive service |

| Terugverdientijd | 24–36 maanden typisch | 48+ months, efficiency constrained |

System coordination enabled by the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

| Integratieaspect | Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability Implementation | Impact in Karachi/Gwadar-activiteiten |

|---|---|---|

| AFE interaction | Real-time DC voltage and power targets | PF ≥0.99 while smoothing grid sags |

| UPS inverter | Headroom management pre-transfer | Invisible <2 ms source swaps |

| Static transfer switch | Pre-bias and phase-ready support | No DC dips during STS actions |

| Batterijbeheer | SOC/SOH-aware current profiles | Longer battery life, safer operation |

| Milieuafdichting | Coatings, sealed airflow | Betrouwbaarheid door moessonseizoenen |

Key advantages and proven benefits of the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability with expert perspective

The defining benefit is calm under compound events. When a feeder sags during simultaneous hoists, the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability instantaneously supports the DC bus, while the AFE maintains grid harmony and the static transfer stands ready. As Dr. Adeel Moin, an industrial microgrid advisor contributing to port modernization programs, remarked during a 2025 briefing, “When the DC bus stops breathing hard, everything downstream becomes predictable—cranes, reefers, even operator morale” (industry workshop notes, Karachi). Predictable DC stability translates directly to fewer alarms, tighter schedules, and lower energy cost per move.

Real-world applications and measurable success using the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

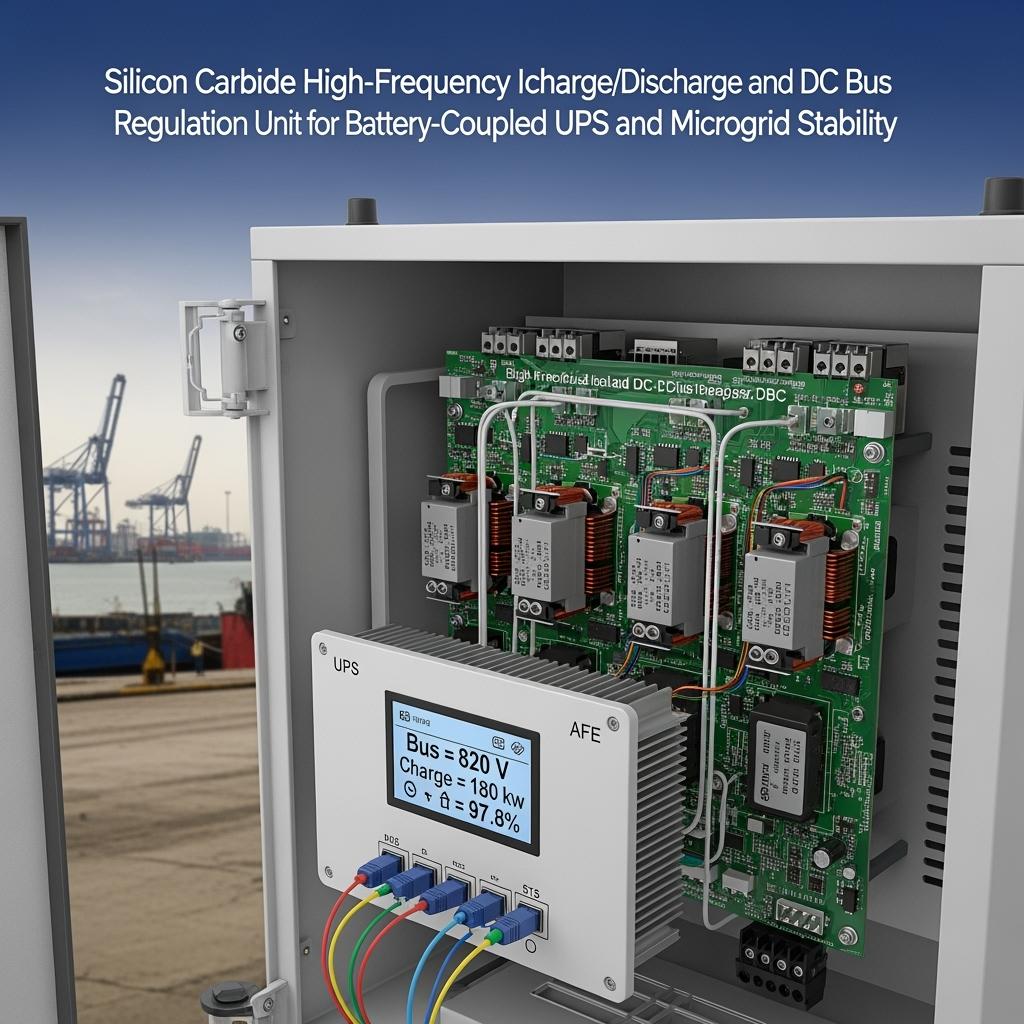

In a Karachi reefer yard retrofit, adding the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability between the battery bank and an 820 V DC bus reduced bus droop during compressor clusters from 6% to less than 2%. Over six months, PQ-related reefer alarms fell by 43%, while cabinet fan duty dropped by 20%, contributing to quieter operation and lower energy overhead. Battery thermal spread narrowed by 3–4°C during peak cycles, which the site’s analytics linked to improved SOH retention.

At a Gwadar STS crane pier, simultaneous hoist events previously triggered minor DC dips that stalled auxiliary drives and occasionally forced operator resets. With the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability delivering 200 kW of rapid discharge during lifts and absorbing regen during trolley decel, DC bus deviation stayed within ±1.5%. Commissioning closed four days early thanks to built‑in oscillography and harmonics reports, and the terminal reported a 5–7% reduction in energy per container move over the first quarter, driven by lower conversion losses and fewer restarts.

Selection and maintenance considerations for the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

Choosing the optimal configuration begins with the battery chemistry, desired C-rates, and the shore-power DC bus voltage. Sicarbtech engineers profile feeder impedance, AFE behavior, and load duty cycles to set current limits, soft-start ramps, and control bandwidths for the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability. Planar transformer turns ratios and interleaving counts are chosen to minimize ripple and avoid audible beat frequencies with nearby switching stages. For cabinet design, laminated busbars, short return paths, and shielded measurement leads keep EMI contained and phase measurement accurate. Maintenance is data-driven rather than calendar-based: the unit’s diagnostics track temperature margins, ripple metrics, and lifetime estimators tied to switching stress and thermal cycles. Firmware is versioned and validated on Sicarbtech’s Shore-Power UPS and Static Transfer System Type Testing and Reliability Verification Platform for Certification and FAT/SAT Validation, ensuring that field updates deliver measurable improvements without regression.

Industry success factors and customer testimonials around the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

Terminals that realize consistent gains treat the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability as the DC bus’s governor, not just a battery coupler. Coordinated setpoints across AFE, UPS inverter, static transfer, and the regulation unit yield a shore microgrid that behaves like a single, disciplined machine. As a Karachi terminal electrical supervisor noted after a phased rollout, “Our DC bus used to tell us when the grid was unhappy. Now it barely whispers.” That quiet is the sound of throughput protected by design rather than luck.

Future innovations and market trends linked to the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

The trajectory points toward predictive DC orchestration. The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability is evolving to incorporate workload-aware dispatch that pre-positions battery power for scheduled lifts or reefer surges. Next-generation SiC switches and gate drivers will push switching frequencies higher without efficiency penalties, further shrinking magnetics and improving transient response. Adaptive control will adjust ripple targets and current limits with temperature and SOH conditions, stretching battery life while maintaining stability. Cyber-secure telemetry and standardized NTDC-aligned compliance packs will reduce audit friction, and digital twins will enable lab rehearsal of complex commissioning sequences before a single cable is landed on the pier.

Common questions and expert answers about the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

How does the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability stabilize the DC bus during grid sags?

It delivers rapid, bidirectional power to hold bus voltage within tight limits, coordinating with the AFE and UPS so the DC bus neither collapses nor spikes when sources transfer or loads surge.

What efficiencies can be expected from the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability?

Typical end-to-end efficiency ranges from about 96.5% to 98% at rated conditions, thanks to SiC switching at 50–150 kHz and optimized planar magnetics.

Is the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability compatible with different battery chemistries?

Yes. Control profiles accommodate lithium-iron phosphate, NMC, and advanced lead systems with chemistry-appropriate current limits, ramp rates, and temperature safeguards.

How does the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability perform in Karachi’s salt-mist environment?

Port-grade conformal coatings, sealed airflow with hydrophobic filters, and corrosion-resistant hardware are validated in salt-fog and humidity cycling to ensure long-term reliability.

What commissioning tools accompany the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability?

The unit integrates with Sicarbtech’s verification platform to provide scripted FAT/SAT, built-in oscillography, harmonics and ripple reports, and secure configuration fingerprints for audit trails.

Why the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability works for your operations

Ports and connected industries demand continuity that feels effortless. The Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability provides that by turning batteries into an intelligent, fast-acting buffer while keeping the DC bus disciplined under stress. In Pakistan’s hot, humid, salt-laden reality, it converts variability into predictability, lowers conversion losses, and protects assets—from cables to compressors to crane drives—through calmer electrical behavior.

Connect with specialists for custom solutions on the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability

Sicarbtech brings more than 10 years of silicon carbide manufacturing expertise, backed by the Chinese Academy of Sciences. We engineer custom solutions across R-SiC, SSiC, RBSiC, and SiSiC, and we deliver technology transfer and factory establishment services that include feasibility studies, equipment selection, workforce training, quality systems, and commissioning. Our turnkey scope spans material processing to finished power electronics—AFEs, UPS stacks, battery regulation units, and the verification platforms that prove performance—validated across 19+ enterprises.

Engage our team for a free consultation. We will analyze your feeder and load profiles, battery chemistry, and compliance targets; then size and configure the Silicon Carbide High-Frequency Isolated Charge/Discharge and DC Bus Regulation Unit for Battery-Coupled UPS and Microgrid Stability to your site. We will model PKR-denominated ROI from avoided downtime and improved efficiency, and schedule FAT/SAT to compress timelines ahead of peak season.

Contact Sicarbtech: [email protected] | +86 133 6536 0038. Reserve production slots now to lock in DC bus stability and microgrid resilience for 2025 and beyond.

Artikelmetadata

Laatst bijgewerkt: 2025-09-15

Volgende geplande beoordeling: 2026-01-15

Timeliness note: Reflects 2025 Pakistan port electrification priorities, NTDC-aligned power quality practices, and Sicarbtech’s latest SiC battery-coupled DC regulation advancements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.