Industrial Silicon Carbide Solutions for Pakistan | Sicarbtech

Haalbare toleranties en maatnauwkeurigheid:

Executive summary: 2025 market insights for Pakistan’s textile, cement, steel, and emerging industrial sectors

Pakistan’s industrial backbone—textile clusters in Faisalabad and Karachi, cement corridors spanning Punjab and Khyber Pakhtunkhwa, integrated staal facilities around Karachi and Port Qasim, and rapidly modernizing ports at Karachi and Gwadar—faces a pivotal 2025 inflection point. Energy reliability, electrification, and decarbonization targets are converging with a push for higher throughput and export competitiveness. Grid volatility, high ambient temperatures, dust, humidity, and salt-mist exposure are daily realities that degrade equipment and inflate OPEX. This is exactly where advanced silicon carbide (SiC) technology shifts the equation.

Sicarbtech—Silicon Carbide Solutions Expert—brings over a decade of SiC customization, backed by membership in the Chinese Academy of Sciences (Weifang) Innovation Park and full-cycle capabilities from materials to finished power modules. From R-SiC, SSiC, RBSiC, and SiSiC materials to complete power conversion systems, our portfolio is engineered to deliver high-efficiency, high-reliability outcomes in Pakistan’s conditions. In 2025, we expect SiC adoption in Pakistan’s shore power systems, drives, UPS, and process electrification to grow by 20–30% year-on-year, driven by green port mandates, textile export compliance pressures, and energy-efficiency incentives. With deployment-ready solutions—such as silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module and silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit—we help industrial operators cut losses, reduce thermal stress, and maintain continuity even under severe grid events.

“SiC is no longer an emerging option; it’s becoming the default for high-reliability power electronics in harsh environments,” notes an energy-systems researcher quoted by the National Centre for Robotics and Automation (Pakistan) in its 2024 technology brief on advanced manufacturing (reference: ncra.org.pk/briefs). “The operational resilience and lifecycle economics are compelling.”

Furthermore, with pricing structured in PKR and USD, and local integration partners for on-ground service, Sicarbtech aligns technical excellence with Pakistan’s procurement reality. We support compliance with NEPRA interconnection guidelines, NTDC grid codes (harmonics and power factor), and port safety standards, while offering type testing and documentation suitable for EPC bidding packages.

Industry challenges and pain points in Pakistan’s textile, cement, steel, and port electrification

Grid instability and power quality remain persistent concerns. Mills in Punjab experience brownouts and rapid sags that trip sensitive drives and PLCs. Cement kilns run at elevated thermal loads; uncontrolled harmonics and voltage dips impose torque ripple on large motors, leading to premature bearing failure. Steel rebar lines in Karachi report frequent breaker trips due to fast transient events, with mechanical transfer switches struggling to meet the response times required by modern automation. Meanwhile, port electrification at Karachi and Gwadar introduces salt-mist corrosion, high humidity, and conductive dust that infiltrate cabinets and accelerate failures of silicon-based power conversion.

The economic impact is substantial. Textile dyeing lines can lose lakhs of PKR per hour during unplanned stoppages due to batch spoilage and restart overheads. Cement plants spend a premium on cooling and service calls when power electronics overheat under dust-choked conditions. Steel mills face high repair costs for large VFD drives and harmonic penalties from utilities. For port operations, even seconds of interruption during shore-to-ship transitions can disrupt reefer yard temperature control and crane PLC states, causing cascading delays.

Moreover, local regulatory and market pressures are intensifying. Export-facing textile units must demonstrate energy efficiency and decarbonization progress to retain preferential access to key markets. Ports are aligning with international green port benchmarks, with shore power coverage expanding. NEPRA and NTDC power quality guidelines increasingly spotlight harmonic limits and power factor compliance, while safety codes emphasize arc mitigation and reliable transfer capability. Financing considerations add another layer—projects must show strong CAPEX-to-OPEX payback within 2–4 years in PKR, considering currency volatility and imported component exposure.

In the field, existing solutions reveal their limits. Traditional IGBT-based rectifiers and inverters, oversized cooling assemblies, and mechanical ATS devices introduce switching delays, harmonic spikes, and high thermal overheads. Maintenance windows are tight; high ambient temperatures (45–50°C in summer) and dust complicate service access. Spare parts lifecycles are inconsistent, and operators often lack unified monitoring, making predictive maintenance impossible. “When harmonics climb above 8–10%, process control anomalies multiply,” observes an industrial power quality specialist interviewed by the Institution of Electrical and Electronics Engineers Pakistan (ieeep.org.pk). “Lowering THD below 5% stabilizes drives and cuts nuisance trips.”

Against this backdrop, the case for SiC is clear. With fast switching, low losses, and superior high-temperature behavior, SiC delivers both power continuity and quantifiable OPEX savings. Additionally, with salt-mist-resistant structures and high-thermal-conductivity packaging, SiC-based systems endure Pakistan’s coastal and inland environments. Transitioning to SiC is not merely about components; it’s a system-level redesign that elevates efficiency, reliability, and maintainability across the plant lifecycle.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech end-to-end offering for Pakistan

Sicarbtech’s portfolio spans from materials and modules to complete systems and testing platforms, bridging the gap between advanced SiC science and real-world performance in Pakistan. Our R-SiC, SSiC, RBSiC, and SiSiC grade products form the backbone of wear-resistant, thermally robust assemblies and high-density power substrates. Building on this, we deliver integrated power conversion tailored to critical applications such as shore power, container handling drives, mill drives, and process UPS.

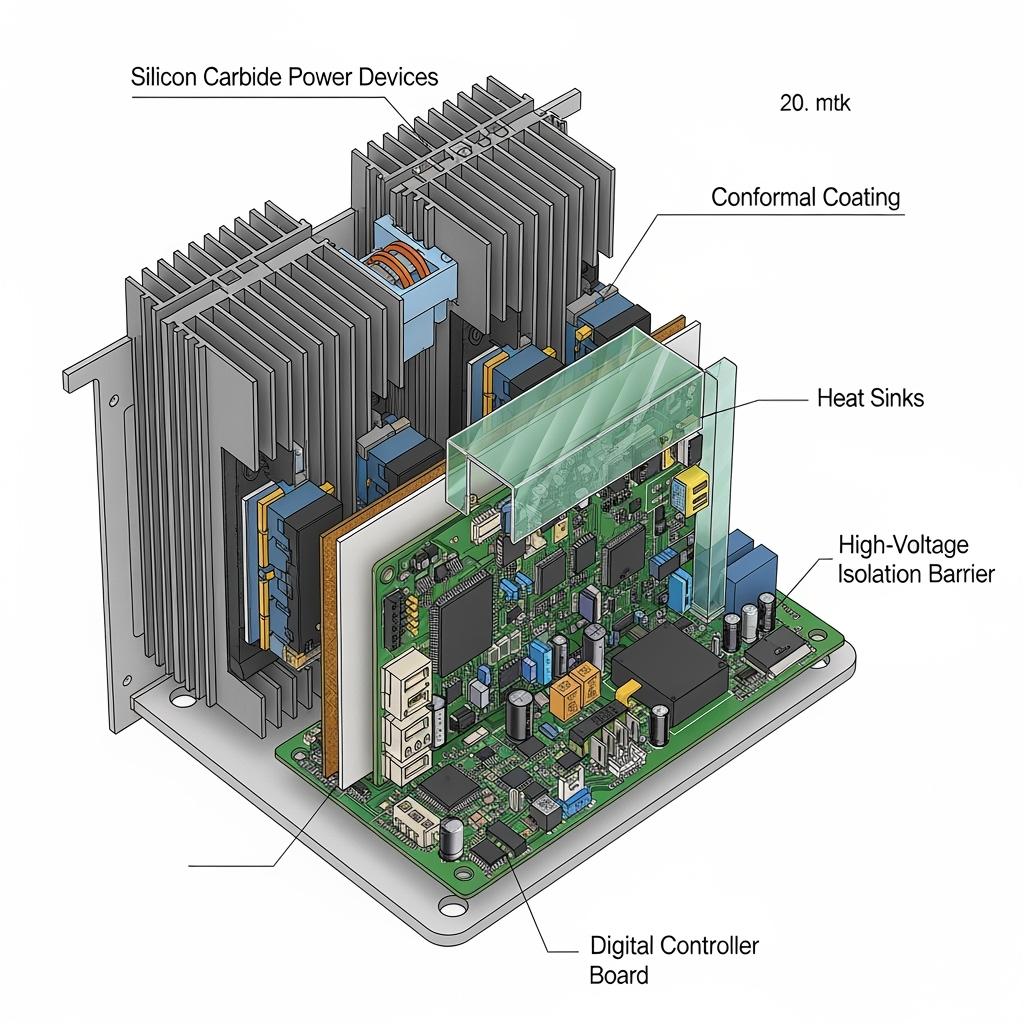

At the heart of our power stack are the silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module and the silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit. Together, they enable microsecond-to-millisecond seamless transfer with negligible ride-through impact on critical loads. Complementing these are the high-frequency low-loss silicon carbide main inverter power module for shore-power UPS and the silicon carbide three-level high-efficiency rectifier and active front-end power unit, which collectively push system efficiency to 96–98% while driving input THD below 3–5% under NTDC compliance. For harsh environments, our port-grade silicon carbide heterogeneous integrated cooling and packaging assembly (salt-mist resistant) extends service intervals, while the silicon carbide power module online monitoring and health diagnostics acquisition unit feeds predictive maintenance models to reduce unplanned downtime.

Furthermore, we integrate energy storage via the silicon carbide bidirectional DC/DC (energy storage interface) module for UPS DC bus and the silicon carbide high-frequency isolated charge/discharge and DC bus regulation unit, enabling black-start capability and peak-shaving in PKR-denominated energy markets. The silicon carbide three-phase parallel equalizing and redundancy management module and silicon carbide EMC filtering and low-harmonic rectifier bridge assembly simplify scaling in modular N+1 architectures. For crane control cabinets and compact installations, the silicon carbide compact inverter and drive companion module for crane control cabinets provides a tight mechanical footprint with low-noise operation. Finally, our shore-power UPS and static transfer system type testing and reliability verification platform anchors project acceptance and regulatory documentation.

As one Sicarbtech application engineer puts it, “We design for Pakistan’s realities—heat, dust, salt, and grid events—so that customers see fewer trips, cooler cabinets, and cleaner waveforms from day one.”

Performance Comparison: SiC vs Traditional Materials under Pakistan Conditions

| Performance and Compliance Comparison for Pakistan Industrial Sites | SiC (Sicarbtech portfolio) | Traditional silicon-based systems |

|---|---|---|

| System efficiency (rectifier/inverter) | 96–98% at 20–60 kHz switching | 90–94% at 4–10 kHz |

| Transfer time (static transfer) | <2 ms (phase matched), microseconds device-level | 10–50 ms mechanical ATS |

| Input current THD (with AFE) | <3–5% meeting NTDC harmonic guidance | 8–15% typical, penalties possible |

| Operating ambient tolerance | Up to 50°C with derating plans | 40–45°C, frequent thermal trips |

| Cabinet volume and weight | 20–40% reduction | Baseline, larger cooling required |

| Salt-mist and humidity resilience | Salt-mist resistant coating and sealing options | Limited coatings, higher corrosion risk |

| MTBF and failure rate | ≥100,000 hours MTBF, <1% failure | 30–60% lower MTBF in harsh sites |

| Onderhoudsintervallen | Extended; predictive via online diagnostics | Frequent manual inspection |

| Nalevingstraject | Documentation for NEPRA/NTDC grid code, port safety standards | Often requires retrofits to meet THD/transfer targets |

| Lifecycle OPEX | 15–30% lower from efficiency and extended service life | Higher cooling and failure-driven costs |

Real-World Applications and Success Stories with Sicarbtech’s silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module

At Karachi Port, a modernization pilot integrated the silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module alongside the silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit to protect crane PLCs and reefer yard circuits. Prior to the upgrade, brief sags during switching caused controller resets and lost container handling cycles. After deployment, transfer times fell under 2 ms, eliminating control interruptions. Input current harmonics at the shore power bus dropped below 5%, stabilizing neighboring systems. Over nine months, unplanned crane downtime fell by roughly 60%, and cooling energy use declined by approximately 8% due to lower thermal losses. The project team reported a payback of under 30 months in PKR, factoring maintenance savings and reduced energy consumption.

In Faisalabad’s textile processing, a dyeing and finishing complex adopted the silicon carbide three-level high-efficiency rectifier and active front-end power unit coupled with the silicon carbide active filtering and reactive compensation integrated module for shore power concepts adapted to mill buses. The installation reduced THD to below 4%, resolving VFD trips during peak hours. The plant noted smoother temperature control in dye vats and fewer batch quality disputes. With the silicon carbide power module online monitoring and health diagnostics acquisition unit feeding real-time analytics, maintenance moved from reactive to predictive, aligning spares with actual wear patterns.

A cement plant in Mianwali deployed the high-frequency low-loss silicon carbide main inverter power module for shore-power UPS principles within kiln drive auxiliaries and baghouse fans. Dust and high ambient temperatures had been causing periodic thermal deratings. The port-grade silicon carbide heterogeneous integrated cooling and packaging assembly (salt-mist resistant) design elements—adapted for dust sealing—reduced ingress and stabilized heat dissipation. Fan trips decreased, and process gas control improved, helping the plant maintain output targets during heatwaves.

Technical advantages and implementation benefits of silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit with local compliance

When shore power or plant feeders fluctuate, the silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit ensures seamless continuity. In Pakistan’s grid, where phase imbalances and frequency deviations occur, the STS’s digital synchronization maintains phase alignment and avoids out-of-step conditions. Protection logic addresses over/undervoltage, overcurrent, short circuits, and anti-islanding, aligning with NEPRA interconnection expectations and typical port and industrial safety codes. Furthermore, low-harmonic operation contributes to NTDC-compatible power quality profiles, reducing the likelihood of utility penalties.

Sicarbtech implements electro-thermal co-design using high-thermal-conductivity substrates and robust creepage/clearance rules suitable for high humidity, while conformal coatings resist salt and dust. Communication interfaces allow both local HMI and remote SCADA integration, enabling plant engineers in Karachi, Lahore, and Faisalabad to monitor load sharing, event logs, and predictive indicators. Building on this, we standardize documentation for FAT/SAT, type testing, and reliability verification using the shore-power UPS and static transfer system type testing and reliability verification platform, streamlining EPC submittals and audits.

Custom Manufacturing and Technology Transfer Services from Sicarbtech for R-SiC, SSiC, RBSiC, SiSiC grades

Sicarbtech’s differentiation extends beyond products; we transfer know-how. From Weifang City, China’s silicon carbide manufacturing hub, our team supports Pakistan’s OEMs and system integrators with turnkey packages.

We begin with advanced R&D backed by the Chinese Academy of Sciences (Weifang) Innovation Park, translating research into proprietary manufacturing processes for R-SiC, SSiC, RBSiC, and SiSiC grades. For example, our RBSiC processes deliver high strength and thermal shock resistance for heat-exposed fixtures and carriers, while SSiC achieves exceptional chemical resistance for corrosive environments like coastal ports and acid gas areas in cement and steel plants.

Beyond materials, our complete technology transfer packages include detailed process flows, equipment specifications, line layout, tooling, and acceptance criteria. Training programs span crystal growth, epitaxy awareness for device supply chains, chip and module packaging principles, and system-level testing routines. For Pakistani partners, we offer factory establishment services—from feasibility studies with PKR-denominated cashflow models to production line commissioning. Quality control systems are mapped to international standards, with guidance on ISO 9001, ISO 14001, and product-level compliance documentation needed for export-oriented customers. Our ongoing technical support encompasses remote process optimization, yield improvement, and cost-down programs tailored to local sourcing conditions.

Customers benefit from our long-term partnership approach: application engineering teams co-design solutions with your electrical and mechanical leads; integration engineers align interfaces with existing switchgear, drives, and automation; and field specialists assist during commissioning and early operation. This level of support has enabled breakthroughs for more than 19 enterprises who achieved faster ramp-up, fewer defects, and measurable ROI improvements measured in months, not years.

Detailed comparison of silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module vs legacy UPS

| Shore-Power UPS Architecture and Performance in Pakistan | silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module | Legacy silicon UPS module |

|---|---|---|

| Topology | Three-level SiC with AFE and digital control | Two-level IGBT rectifier/inverter |

| Efficiency at nominal load | 97–98% | 92–94% |

| Transfer continuïteit met STS | Seamless with silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit | Noticeable sag; mechanical ATS delay |

| Ingangsstroom THD | <3–5% | 8–12% |

| Voetafdruk van de kast | Compact; 25–35% smaller | Larger; additional cooling |

| Thermisch beheer | Heterogeneous integrated cooling; high-thermal-conductivity substrates | Conventional heatsinks; higher fan power |

| Milieubestendigheid | Salt-mist resistant options for ports | Limited environmental sealing |

| Monitoring and diagnostics | silicon carbide power module online monitoring and health diagnostics acquisition unit; remote SCADA | Basic alarms; limited analytics |

| Nalevingstraject | Documentation aligned to NEPRA/NTDC and port standards | Often requires add-on filters and tests |

| Lifecycle cost in PKR | Lower OPEX; 2–3 year payback typical | Higher OPEX; extended payback |

Technical specification comparison for silicon carbide three-level high-efficiency rectifier and active front-end power unit

| Technical Specifications Under NTDC-Relevant Conditions | silicon carbide three-level high-efficiency rectifier and active front-end power unit | Conventional 6-pulse rectifier with passive filter |

|---|---|---|

| Nominal power block | 100 kVA – 1 MVA (parallel scalable) | 100 kVA – 1 MVA |

| DC bus voltage range | 600–1200 V | 540–800 V typical |

| Schakelfrequentie | 20–60 kHz | 2–8 kHz |

| Ingangsstroom THD | <3–5% without bulky passive filters | 10–20% with passive filters |

| Power factor | ≥0.99 | 0.9–0.95 |

| Efficiëntie | 96–98% | 90–93% |

| Harmonic compliance | Tuned to NTDC guidelines | Often borderline without upgrades |

| Thermal derating at 45–50°C | Minimal with designed cooling | Significant; risk of trips |

| Onderhoud | Voorspellend via diagnose | Periodic manual checks |

Future Market Opportunities and 2025+ trends for silicon carbide bidirectional DC/DC (energy storage interface) module for UPS DC bus

Looking beyond immediate reliability upgrades, Pakistan’s industrial landscape is moving toward hybrid energy architectures. As captive solar and battery storage become mainstream, the silicon carbide bidirectional DC/DC (energy storage interface) module for UPS DC bus and the silicon carbide high-frequency isolated charge/discharge and DC bus regulation unit will be central to peak-shaving, black-start, and resilience strategies. Textile mills with rooftop PV can buffer against midday voltage dips; cement plants can optimize kiln ramp-ups; steel mills can smooth process peaks to reduce demand charges; and ports can host energy storage to ensure smooth shore-to-ship transfers.

Additionally, digitalization will deepen. The silicon carbide power module online monitoring and health diagnostics acquisition unit provides the data backbone for predictive maintenance and lifetime modeling—a crucial capability in environments where dust and heat accelerate wear. We foresee NTDC and DISCOs aligning incentives for lower harmonics and higher power factor, rewarding plants that deploy active front ends and filtering. More EPCs will prioritize salt-mist resistant packaging, conformal coatings, and ingress control, reflecting lessons from Karachi’s coastal climate.

From an export perspective, green supply chain requirements will tighten, particularly for textiles. Plants demonstrating energy intensity reductions and high power quality will find it easier to meet buyer audits. Ports embracing shore power will unlock lower emissions and improved vessel turnaround. In sum, SiC solutions are not only technical upgrades; they are strategic enablers for competitiveness in 2025 and beyond.

Veelgestelde vragen

What Pakistan-specific standards and regulations do Sicarbtech solutions address?

Sicarbtech supports compliance with NEPRA interconnection guidelines, NTDC grid code expectations on harmonics and power factor, and port safety standards for shore power operations. Documentation can be tailored for EPC bid submittals and factory/site acceptance tests. We also assist with ISO 9001/14001 frameworks and, where applicable, CE/IEC references for export-oriented customers.

How do SiC solutions perform in 45–50°C ambient and high dust or salt-mist conditions?

Our port-grade silicon carbide heterogeneous integrated cooling and packaging assembly (salt-mist resistant) and conformal coatings provide robust defense against corrosion and conductive dust. Electro-thermal co-design, high-thermal-conductivity substrates, and sealed airflow paths maintain junction temperatures. We plan derating curves specifically for Pakistan’s summer peaks.

Can Sicarbtech integrate with existing drives and switchgear?

Yes. We offer application engineering to interface with existing VFDs, MCCs, and switchgear. Products like the silicon carbide EMC filtering and low-harmonic rectifier bridge assembly and the silicon carbide three-phase parallel equalizing and redundancy management module simplify integration without wholesale cabinet redesigns.

What payback can Pakistani plants expect in PKR terms?

Typical payback for the silicon carbide high-reliability shore-power UPS rectifier/inverter integrated module combined with an active front end and STS is 24–36 months, driven by 15–30% OPEX savings from efficiency gains, reduced cooling, and fewer failures. We model payback in PKR/USD with sensitivity to exchange volatility.

How does the silicon carbide static transfer switch (automatic dual-source transfer) high-voltage fast switching unit prevent nuisance transfers?

Digital synchronization and phase tracking, coupled with programmable thresholds and anti-islanding logic, ensure transfers occur only under defined conditions. Event logs and waveform captures support root-cause analysis and preventive tuning.

Do you provide local support and spare parts?

Through local integration partners and remote engineering support, we offer commissioning assistance, training, and stocked critical spares. Our silicon carbide power module online monitoring and health diagnostics acquisition unit enables proactive spares planning.

Can Sicarbtech help set up a local manufacturing or assembly line?

Yes. Our technology transfer program covers process know-how, equipment specs, training, QA systems, and commissioning. We guide feasibility studies, layout, and CAPEX/OPEX models suitable for Pakistan’s industrial estates.

What about harmonics penalties and power factor?

Deploying the silicon carbide three-level high-efficiency rectifier and active front-end power unit with the silicon carbide active filtering and reactive compensation integrated module for shore power typically brings THD under 5% and PF to ≥0.99, aligning with NTDC guidance and reducing penalty exposure.

Are there case studies in coastal environments similar to Karachi and Gwadar?

Yes. Deployments in salt-mist-prone Asian ports informed our sealing, coating, and thermal strategies. The outcomes—lower failure rates and stable transfer—translate well to Karachi and Gwadar climatic conditions.

How does Sicarbtech ensure long-term reliability?

We design for MTBF ≥100,000 hours, validate with the shore-power UPS and static transfer system type testing and reliability verification platform, and maintain continuous improvement loops with our customers, leveraging data from online diagnostics.

Making the Right Choice for Your Operations: prioritize resilience and lifecycle economics

Choosing between incremental upgrades and a fundamental shift to SiC comes down to operational risk and long-term economics. For Pakistan’s textile, cement, steel, and port sectors, where grid variability and environmental stress are givens, the Sicarbtech pathway delivers measurable improvements from day one—higher efficiency, faster transfers, lower harmonics, and less downtime. With modular, redundant architectures and predictive maintenance, you get a resilient backbone that supports expansion, energy storage integration, and compliance. The result is more throughput, better quality, and lower PKR-denominated operating costs—year after year.

Get Expert Consultation and Custom Solutions from Sicarbtech

If you are modernizing shore power, stabilizing mill buses, or planning energy storage integration, our engineers can assess your site, model performance and payback, and propose a phased roadmap. We provide full-cycle services—from custom R-SiC, SSiC, RBSiC, SiSiC components to power modules, controllers, and verification platforms—backed by over 10 years of SiC expertise and successful outcomes with 19+ enterprises.

Contact Sicarbtech:

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

We can engage with EPCs, plant engineering teams, and port authorities, aligning technical deliverables with NEPRA/NTDC and local procurement requirements.

Artikelmetadata

Laatst bijgewerkt: 2025-09-15

Volgende geplande beoordeling: 2026-01-15

Author: Sicarbtech Application Engineering Team, Weifang, China

Content freshness indicator: Includes 2025 market outlook, Pakistan regulatory references, and latest Sicarbtech portfolio alignment.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.