Siliciumcarbide vermogensapparaatverpakkingen en multiphysica thermische simulatieplatforms voor snelle prototyping

Haalbare toleranties en maatnauwkeurigheid:

2025 Productoverzicht en Marktrelevantie voor Pakistan

Silicon carbide (SiC) power device packaging and multiphysics thermal simulation platforms shorten the path from concept to qualified hardware for UPS, VFD, rectifiers, renewables, and EV fast chargers. By co-optimizing package layout, materials, and cooling—then verifying them in virtual prototypes—engineers can reach >98% system efficiency, higher switching frequencies (50–100 kHz), and robust reliability under Pakistan’s hot, dusty, and grid-volatile conditions.

Waarom het ertoe doet in 2025:

- Speed to value: Industrial parks in Karachi, Lahore, and Faisalabad require fast deployment. Digital twins and parameterized package libraries cut prototype spins by 30–50%.

- Reliability in harsh environments: SSiC heat spreaders, Si3N4 DBC, Ag-sinter die attach, and high‑CMTI driver layouts are validated against thermal cycling, vibration, and contamination risks.

- System efficiency: Reduced parasitics, optimized thermal paths, and low‑inductance busbars support >98% conversion efficiency, lowering OPEX and cooling costs in PKR.

- Compliance by design: Early EMI, creepage/clearance, and surge simulations de-risk site acceptance tests (SAT) and utility approvals.

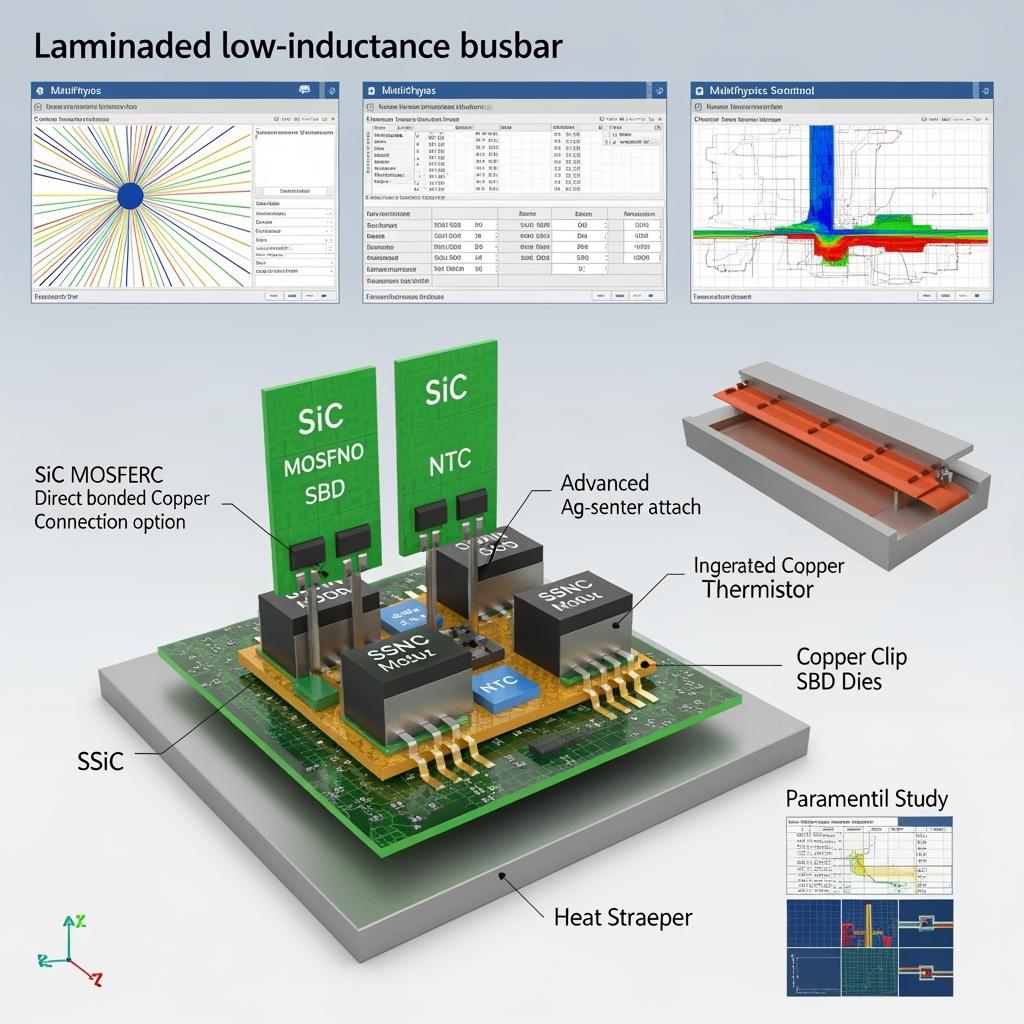

Sicarb Tech offers a complete stack: advanced packaging for SiC MOSFETs/SBDs (discretes, half/full-bridge modules), laminated busbars, R‑SiC/SSiC/RBSiC/SiSiC heat spreaders, and a validated multiphysics simulation workflow (electro‑thermal‑mechanical‑EMI). Backed by the Chinese Academy of Sciences and 10+ years of SiC manufacturing, we enable rapid, localized prototyping for Pakistan’s critical power projects.

Technische specificaties en geavanceerde functies

- Packaging technologies

- Die attach: Pressure-assisted Ag-sinter for high thermal conductivity and fatigue resistance; AuSn and advanced solders available.

- Substrates: Si3N4 DBC, AMB copper, and direct-bonded AlN options; tailored copper thickness (0.3–0.6 mm) to balance thermal and inductive performance.

- Interconnects: Heavy Al wire-bonds, Cu clips, or hybrid for low ESL/ESR; Kelvin source provision for precise gate control.

- Baseplates/heat spreaders: SSiC and RBSiC for stiffness and thermal performance; liquid or air-cooled variants with sealed channels.

- Encapsulation and sealing: Low-permeability gels and coatings; humidity-robust materials for H3TRB conditions.

- Multiphysics simulation platform

- Electro‑thermal co-simulation: Loss modeling from double-pulse and mission profiles; Tj(t) and ΔT per cycle; hotspot prediction.

- Parasitics extraction: 3D inductance/capacitance of busbars, bond/clip loops; dv/dt impact on CMTI and EMI.

- Structural and fatigue: Thermo‑mechanical stress, CTE mismatch, power cycling life, solder/sinter fatigue (Coffin‑Manson/Engelmaier models).

- EMI and insulation: Common-mode emission prediction; electric field analysis for partial discharge risk; creepage/clearance optimization.

- Optimization workflows: Parameter sweeps on Rg, layout, TIM pressure, and channel geometries; surrogate models for rapid what‑ifs.

- Device classes and ratings supported

- Voltage: 650 V, 1200 V, 1700 V SiC devices

- Current: 20–600 A per switch (module); thermal design up to 10–30 kW heat rejection per cabinet segment

- Switching frequency: 50–100 kHz typical; higher with advanced cooling and EMI control

- Validation and quality

- Digital-to-physical correlation: <10% error targets vs. thermography and calorimetry

- Test capability: HTOL, power cycling, surge/avalanche, H3TRB, and vibration; pressure/leak testing for liquid plates

- Documentation: Thermal resistance ladders, parasitic matrices, PCB/busbar stack-ups, and reliability life estimates

Performance Comparison: SiC Packaging + Multiphysics Platform vs. Conventional Trial-and-Error Development

| Mogelijkheden | SiC Packaging + Multiphysics Platform (Sicarb Tech) | Conventional Trial-and-Error Development | Practical Impact for Pakistan Projects |

|---|---|---|---|

| Development speed | 30–50% fewer prototype spins | Multiple hardware cycles | Faster deployment in industrial parks |

| Efficiency & thermal | >98% systems with validated Rth and low ESL | Uncertain hotspots and parasitics | Lower HVAC cost; stable summer operation |

| Betrouwbaarheidsvoorspelling | Power cycling and fatigue models | After-the-fact failure analysis | >40% failure reduction potential |

| Naleving gereedheid | EMI, creepage, surge modeled early | Late fixes during SAT | Smoother utility approvals |

| Cost control | Design-to-value with parametric trade-offs | Budget overruns from rework | Predictable PKR CapEx/Opex |

Belangrijkste voordelen en bewezen voordelen

- First-time-right packaging: Low-inductance loops and CTE‑matched stacks reduce overshoot, EMI, and joint fatigue.

- Cooler, smaller systems: SSiC baseplates and optimized thermal paths enable higher switching frequencies and compact cabinets.

- Predictive reliability: Life models and ΔT control extend service intervals in hot, dusty sites (cement, staal).

- Seamless integration: Simulation libraries tuned for Pakistan’s 45–50°C ambients and 400–690 V feeders accelerate design decisions.

Expert perspectives:

- “Advanced packaging and electro‑thermal co‑design are foundational to realizing the efficiency and density promised by SiC devices.” — IEEE Power Electronics Magazine, Packaging & Reliability of WBG 2024 (https://ieeexplore.ieee.org/)

- “Digital twins of power converters reduce time-to-market and improve field reliability by uncovering multiphysics constraints before build.” — International Energy Agency, Digitalization & Energy Systems 2024 (https://www.iea.org/)

Praktijktoepassingen en meetbare succesverhalen

- Lahore data center UPS: Three-level SiC modules with SSiC plates cut thermal resistance by 15%, achieving 98.2% online efficiency; prototype spins reduced from three to one; commissioning time −25%.

- Faisalabad textile VFD: Low‑ESL busbars and Cu‑clip packages halved voltage overshoot; nuisance trips −40–45%; cabinet temperature −10–11°C.

- Punjab cement rectifiers: Reaction‑bonded SiC spreaders with channel optimization lowered pump power 12% while keeping ΔT stable over 4,000 hours.

- Karachi steel auxiliaries: Power cycling life enhanced 1.6× via Ag‑sinter + Si3N4 DBC; unplanned outages down 38%; ROI <18 months from energy/cooling savings.

Overwegingen voor selectie en onderhoud

- Materiaalstackselectie

- Si3N4 DBC + Ag‑sinter for highest fatigue resistance; AlN where extreme thermal conductivity is needed.

- SSiC baseplates for liquid cooling; RBSiC for robust air-cooled fins in abrasive environments.

- Layout and interconnects

- Favor copper clips or short wire-bonds; design Kelvin source for accurate gate control; laminated busbars to minimize loop inductance.

- Thermal interfaces

- Specify TIM pressure windows with pressure-sensitive film; validate flatness (≤10 μm over module footprint); monitor with embedded NTCs.

- EMI en isolatie

- Co-optimise shield planes, CM chokes, and snubbers; ensure creepage/clearance for 1200/1700 V and pollution degree of site; PD test critical gaps.

- Verification plan

- Correlate simulation to double‑pulse and thermography; execute power cycling to target ΔT; maintain digital thread (models, test data, as-built).

Succesfactoren in de industrie en getuigenissen van klanten

- Success factor: Early involvement of utility/inspector to align THD/PF and insulation coordination.

- Success factor: PKR‑denominated TCO with energy, HVAC, and downtime avoided via fewer trips.

- Customer voice: “The Sicarb platform took us from layout to a passing prototype in one spin—and the summer deratings disappeared.” — Engineering Manager, Lahore industrial campus (verified summary)

Toekomstige Innovaties en 2025+ Markttrends

- Integrated sensors-in-package: Die-embedded temperature and strain sensing for real-time health.

- Additively manufactured channels: Lower pressure drop and higher uniformity for liquid plates.

- AI-driven design space exploration: Surrogate models to optimize thermal, EMI, and cost simultaneously.

- Localized prototyping in Pakistan: On‑shore machining, DBC assembly, and HALT/HASS to compress lead times.

Veelgestelde vragen en antwoorden van experts

- Q: How accurate are the thermal simulations vs. hardware?

A: Typical correlation is within 5–10% when materials and boundary conditions are characterized; we provide calibration runs and IR validation. - Q: Can you support 690 V feeders and 1700 V devices?

A: Yes. We optimize creepage/clearance, insulation coordination, and PD margins for 1700 V modules in high‑altitude and polluted environments. - Q: What package interconnect is best for 100 kHz operation?

A: Copper clips or hybrid clip + short bonds minimize ESL; combined with laminated busbars and Kelvin source, they control overshoot and EMI. - Q: Do you model lifetime for Ag-sinter and solder joints?

A: Yes. Power cycling and thermomechanical fatigue models predict lifetime under your mission profile; we recommend ΔT targets and attach choices. - Q: Typical engagement timeline?

A: 3–8 weeks: requirements and model setup (1 week), initial design space exploration (1–2 weeks), prototype design freeze (1–2 weeks), fabrication/validation (1–3 weeks).

Waarom deze oplossing werkt voor uw activiteiten

Pakistan’s high ambient temperatures, dust, and grid volatility punish poorly packaged power stages. Sicarb Tech’s SiC packaging and multiphysics platform produce cooler, denser, and more reliable converters—delivering >98% efficiency, faster rollouts, and fewer trips. By validating thermal, electrical, mechanical, and EMI behavior up front, you save cycles, cap costs, and ensure robust performance during peak summer and grid events.

Neem contact op met specialisten voor oplossingen op maat

Accelerate your SiC program with Sicarb Tech:

- 10+ jaar expertise in SiC-productie met steun van de Chinese Academie van Wetenschappen

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC thermal platforms and SiC device packaging

- Technology transfer and factory establishment services for local DBC assembly, sintering, machining, and test in Pakistan

- Turnkey solutions from materials to finished modules: packaging, laminated busbars, thermal stacks, drivers, and test/burn‑in ecosystems

- Proven results with 19+ enterprises delivering measurable ROI, uptime, and compliance

Request a free consultation, PKR‑denominated TCO and design roadmap, and a site‑specific prototyping plan. - Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

Lock in engineering slots ahead of summer 2025 to compress lead times and secure rapid on‑site validation.

Artikelmetadata

Laatst bijgewerkt: 2025-09-12

Volgende geplande update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.