Siliciumcarbide hoogspanningsmodules voor middenspanningsomvormers, tractie en netgekoppelde systemen

Haalbare toleranties en maatnauwkeurigheid:

Productoverzicht en relevantie voor de markt in 2025

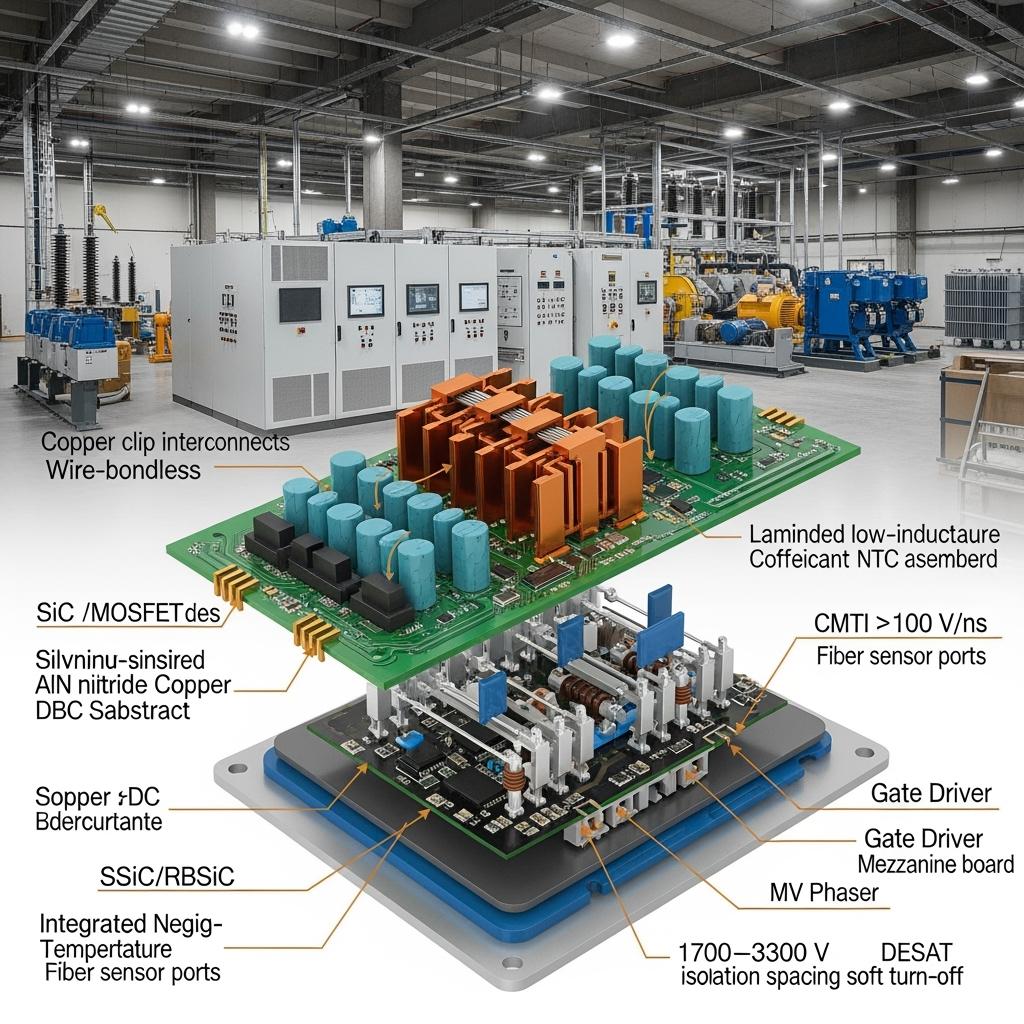

Silicon carbide (SiC) high-voltage power modules enable compact, efficient, and robust conversion at kilovolt-class DC-link voltages for medium-voltage (MV) drives, traction inverters, and grid-tied converters. Leveraging 1200–3300 V SiC MOSFETs and diodes in advanced packages with AlN/Si3N4 DBC, silver-sinter die attach, and low-inductance busbars, these modules deliver high switching frequency, lower losses, and high-temperature operation compared with traditional IGBTs.

For Pakistan’s textile, cement, and staal industries—and the country’s evolving rail/transit and renewable grid integration—SiC HV modules address critical needs:

- Higher efficiency reduces power and cooling costs in 24/7 industrial lines and data-critical facilities.

- Compact MV converters help retrofit space-constrained MCC rooms and containerized substations.

- Fast, high-fidelity control improves power quality, supporting NTDC Grid Code objectives.

- Elevated ambient temperatures (40–45°C) and dusty conditions require packaging and thermal systems built for reliability.

Sicarb Tech offers configurable 1200 V, 1700 V, 2400 V, and 3300 V module families for multi-level topologies (NPC/TNPC/ANPC) and 2-level traction inverters, with integrated gate drive options and diagnostics-ready sensing paths.

Technische specificaties en geavanceerde functies

Representative module capabilities (customizable by application):

- Voltage and current classes

- 1200 V, 1700 V, 2400 V, 3300 V SiC MOSFET/diode modules

- Continuous current per module: 200–1200 A (thermal and cooling dependent)

- Surge and short-circuit robustness coordinated with protection

- Topologies and switching

- 2-level for traction/utility; 3-level NPC/TNPC/ANPC for MV drives and STATCOM/PV

- Switching frequency: 5–50 kHz typical (higher possible in lower-voltage stacks)

- dv/dt control via adjustable gate resistance and integrated Miller clamp

- Losses and thermal performance

- Conduction loss: low RDS(on) SiC dies optimized for high-current density

- Switching loss: significantly lower than IGBTs; soft recovery diodes

- Thermal: AlN/Si3N4 DBC, silver-sinter die attach, SSiC baseplates; liquid or high-performance air cooling

- Target RθJC per switch position: 0.05–0.15 K/W (design dependent)

- Isolation and safety

- Creepage/clearance per IEC 60664 for 3.3 kV-class operation

- Partial discharge screening at module level for long-cable MV applications

- Detectie en bescherming

- Embedded NTC/RTD; optional fiber Bragg sensors for advanced thermal mapping

- DESAT-kortsluitdetectie (<2 µs), soft turn-off, UVLO, OCP/OVP/OTP

- Insulation monitoring and leakage trending when used with Sicarb gate-driver suite

- Interfaces en naleving

- Compatible with isolated gate drivers (CMTI ≥100 V/ns) and digital control platforms

- Standards alignment: IEC 61800 (MV drives), IEC 62477-1 (power converters), IEC 62109 (PV), IEC 61000 EMC; PEC practices and NTDC Grid Code ready

Geavanceerde functies van Sicarb Tech:

- Draad-loze koperen clip-verbindingen voor duurzaamheid bij vermogenscycli

- Gelamineerde busbars en Kelvin-bronverbindingen voor ultralage inductie

- Optionele intelligente modulevariant met geïntegreerde drivers en fouttelemetrie

Efficiency, Density, and Reliability Gains for MV and Grid-Tied Systems

| Hoogrendements MV-conversie voor de industriële en netbehoeften van Pakistan | SiC hoogspanningsvermogensmodules (Sicarb Tech) | Siliconen IGBT MV-modules |

|---|---|---|

| Gewogen efficiëntie bij nominaal vermogen | >98% haalbaar in multi-level | 94–96% typisch |

| Schakelfrequentiecapaciteit | Hoger (5–50 kHz) maakt kleinere magnetische componenten mogelijk | Lager (1–5 kHz) |

| Thermische speling en omgevingsbestendigheid | Bruikbaar tot 175°C Tj met robuuste behuizing | Lagere Tj-capaciteit, vermindering bij hitte |

| Vermogensdichtheid (converter-niveau) | >10 kW/L haalbaar in veel ontwerpen | Groter voor hetzelfde vermogen |

| Dynamische respons en controle | Hoge bandbreedte, lagere THD | Langzamere respons, hogere rimpel |

Belangrijkste voordelen en bewezen voordelen

- Stap-verandering in efficiëntie en footprint: 5–8% systeemefficiëntieverbetering; tot 30–35% volumevermindering ten opzichte van siliconen basislijnen, waardoor CAPEX en OPEX worden verlaagd.

- MV-klare betrouwbaarheid: Zilver-sinter-aansluiting, AlN/Si3N4 DBC en SSiC-grondplaten overleven zware thermische cycli en trillingen in cement- en staalfabrieken.

- Netconforme golfvormen: Hogere schakelfrequentie en multi-level controle verminderen THD, waardoor filtervereisten en transformatorbelasting worden verlicht.

- Snellere dynamische prestaties: Snelle koppel- en vermogensregeling voor tractie- en industriële aandrijvingen, waardoor de processtabiliteit wordt verbeterd.

Expertcitaat:

“SiC-modules van 1,7–3,3 kV maken multi-level converters mogelijk met ongekende efficiëntie en controlebandbreedte, waardoor MV-aandrijvingen en netwerktoepassingen worden getransformeerd.” — IEEE Power Electronics Magazine, Medium-Voltage Converters with Wide-Bandgap Devices, 2024

Praktijktoepassingen en meetbare succesverhalen

- MV-ventilatoraandrijving voor cementfabriek (Punjab):

- 3-level ANPC-aandrijffase met behulp van 1700 V SiC-modules met vloeistofkoeling.

- Resultaten: ~6,8% energiebesparing ten opzichte van IGBT-retrofit; THD aan motorklemmen verbeterd; positieve-druk-kast verminderde stofintreding; minder EMI-alarmen.

- MV-pomp aandrijving voor staal hulpapparatuur (Karachi):

- 2-level SiC tractie-grade modules aangepast voor industrieel gebruik.

- Prestaties: 4–6% efficiëntiewinst; kast footprint met 25% verminderd; onderhoudsintervallen verlengd als gevolg van lagere thermische belasting.

- Netgekoppelde PV-omvormer (industriegebied Sindh):

- 1500 Vdc PV-fase met 1700 V SiC-modules; LCL-filter verkleind.

- Resultaat: CEC-gewogen efficiëntie 98,0%; reactief vermogen ondersteuning verbeterd; incidenten met transformatorverwarming verminderd.

【Afbeelding prompt: gedetailleerde technische beschrijving】 Gesplitste scène: 1) 3-level ANPC-faselijn met behulp van 1700 V SiC-modules met dv/dt-annotaties; 2) Vloeistofgekoelde koude plaat met stroomkanalen onder SSiC-grondplaat; 3) Netgekoppelde kast met kleiner LCL-filter en efficiëntiecurve. Inclusief labels voor RDS(on), schakelfrequentie en PD-screening. Fotorealistisch, 4K.

Overwegingen voor selectie en onderhoud

- Spannings- en topologiekeuze

- 1700 V voor 1000–1500 Vdc-verbindingen; 2400/3300 V voor hogere DC-bussen of trapsgewijze H-brug MV-aandrijvingen.

- Kies NPC/ANPC voor MV-aandrijvingen om de belasting van het apparaat en de filtergroottes te verminderen; 2-level voor tractie-eenvoud waar van toepassing.

- Thermisch en koeling

- Model worst-case 45°C omgeving; selecteer vloeistofkoeling boven ~250 kW per kast of op locaties op grote hoogte.

- Valideer grondplaatvlakheid en TIM-toepassing; controleer de kwaliteit van het koelmiddel om corrosie en vervuiling te voorkomen.

- EMI en isolatie

- Handhaaf kruipweg/speling per IEC 60664; implementeer dv/dt-filters voor lange motorkabels.

- PD-testen op module- en assemblageniveau om de isolatierobustheid te garanderen.

- Gate-aansturing en -bescherming

- Hoge-CMTI-isolatoren, DESAT-drempels gecoördineerd met module SOA, negatieve gate-bias voor betrouwbare uitschakeling.

- Foutloggen en soft turn-off om overspanning tijdens kortsluitingen te beperken.

- Servicepraktijken

- Conditiegebaseerd onderhoud met behulp van thermische en schakelspanningslogs.

- Koppelverificatie voor busbar-verbindingen; geplande koelmiddel-/filtercontroles.

Succesfactoren in de industrie en getuigenissen van klanten

- Succesfactoren:

- Front-end netwerkstudie (harmonischen, flikkering) en transformatorbeoordeling

- Thermisch en luchtstroomontwerp gevalideerd in pilotprojecten in de piekzomer

- Training over MV-veiligheid, PD-bewustzijn en dv/dt-beheer

- Reservemodule- en driverstrategie voor snelle vervanging

- Getuigenis (Electrical Superintendent, grote cementproducent):

- “SiC MV-modules leverden de efficiëntieverhoging die we nodig hadden. De kleinere filter- en koelerkasten hebben het onderhoud aanzienlijk vereenvoudigd.”

Toekomstige innovaties en markttrends

- Vooruitzichten 2025–2027:

- 3300 V+ SiC met dubbelzijdige koeling en draad-loze stacks voor hogere stroomdichtheid

- Digitale twins en ingebedde sensoren voor levensduurvoorspelling en adaptieve vermindering

- 200 mm SiC-wafelaanname verlaagt de kosten; regionale assemblagepartnerschappen in Zuid-Azië

- Uitbreiding van STATCOM- en netvormende omvormertoepassingen met SiC voor stabiliteit en inertienabootsing

Industrieel perspectief:

“Medium-voltage conversie verschuift snel naar wide-bandgap halfgeleiders om een hogere efficiëntie en controleerbaarheid te bereiken met kleinere passieve componenten.” — IEA Technology Perspectives 2024, hoofdstuk Power Electronics

Veelgestelde vragen en antwoorden van experts

- Zijn SiC MV-modules drop-in vervangingen voor IGBT's?

- Niet direct. De controlestrategie, dv/dt en gate-aandrijving moeten worden aangepast. Mechanische footprints kunnen echter compatibel worden gemaakt, waardoor retrofits worden vereenvoudigd.

- Welke koelmethode wordt aanbevolen boven 1 MW?

- Vloeistofkoeling met corrosiegecontroleerde lussen wordt aanbevolen; controleer de debieten en plaat ΔP versus pompcapaciteit.

- Hoe beheert u dv/dt met legacy-motoren?

- Pas RG en Miller-klem aan; voeg dv/dt- of sinusfilters toe voor lange kabelloop; zorg voor isolatiecoördinatie per IEC 60034-17/-25.

- Welke efficiëntie kunnen we verwachten in MV-aandrijvingen?

- Toepassingsafhankelijk, maar >98% converterfase-efficiëntie is haalbaar in multi-level topologieën met SiC.

- Hoe wordt de isolatiebetrouwbaarheid gewaarborgd?

- PD-screening bij relevante spanningen, lay-out met versterkte kruipweg/speling en kwaliteits-TIM's/pakkingen om contaminatiepaden te voorkomen.

Waarom deze oplossing werkt voor uw activiteiten

SiC hoogspanningsvermogensmodules combineren lage schakel-/geleidingsverliezen met robuuste behuizing om compacte, efficiënte MV-converters, tractie-aandrijvingen en netgekoppelde systemen te leveren die zijn afgestemd op de hitte, het stof en de netwerkvariabiliteit van Pakistan. Het resultaat is meetbare energiebesparingen, kleinere filters en kasten, verbeterde stroomkwaliteit en langere onderhoudsintervallen — cruciale voordelen voor cementovens, staal hulpapparatuur, textiellijnen en hernieuwbare verbindingen.

Neem contact op met specialisten voor oplossingen op maat

Verbeter uw MV- en netwerkprojecten met Sicarb Tech:

- 10+ jaar expertise in SiC-productie met steun van de Chinese Academie van Wetenschappen

- Aangepaste productontwikkeling over R-SiC, SSiC, RBSiC en SiSiC materialen met geavanceerde modulebehuizing

- Technologieoverdracht en fabrieksoprichtingsdiensten voor gelokaliseerde waardecreatie

- Kant-en-klare levering van materialen tot afgewerkte MV-modules, inclusief gate-drivers, busbars en compliance-ondersteuning

- Bewezen resultaten met 19+ ondernemingen; snelle prototyping, PD-testen en pilot-implementaties

Ontvang een gratis MV-converter haalbaarheidsstudie en ROI-analyse voor uw fabriek of netgekoppeld project.

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

Reserveer Q4 2025 engineering- en productiesleuven om doorlooptijden te garanderen voor stilstandperioden en inbedrijfstellingsschema's.

Artikelmetadata

- Laatst bijgewerkt: 2025-09-11

- Volgende geplande beoordeling: 2025-12-15

- Auteur: Sicarb Tech Application Engineering Team

- Contact: [email protected] | +86 133 6536 0038

- Standaarden focus: IEC 61800 (MV), IEC 62477-1, IEC 62109, IEC 61000, IEC 60664; afgestemd op PEC-praktijken en NTDC Grid Code-kwaliteitscriteria

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.