Aangepaste siliciumcarbide Schottky-dioden 1200V Ultra‑Fast Recovery voor PFC-, Boost- en Freewheeling-toepassingen

Haalbare toleranties en maatnauwkeurigheid:

In Pakistan’s industrial belts, where rooftop PV arrays overlook spinning looms and kiln stacks, every watt delivered at noon must still be there at dusk. Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications are the quiet components that make this consistency real. When engineers in Lahore, Faisalabad, and Karachi move their string inverters to 1500 V platforms and 40–100 kHz switching, these diodes remove the reverse‑recovery penalty that has long hamstrung high‑density power designs. The impact is felt immediately: cooler magnetics, calmer gate drivers, and DC links that stay clean under weak‑grid flicker, dust, and 50°C inlet air.

Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications product overview and 2025 market relevance

The 2025 Pakistan market is leaning into compact, outdoor‑rated string inverters between 50 and 250 kW, with EPCs asking for lighter cabinets and faster commissioning. Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications meet this moment with a combination of near‑zero reverse recovery charge and stable forward characteristics at elevated temperatures. In PFC front ends, they allow designers to push switching frequency higher without provoking EMI spikes; in MPPT boost stages, they eliminate the snappy current tails that otherwise demand oversized snubbers; and in inverter freewheeling paths, they remove the stress that silicon diodes transfer into IGBTs or MOSFETs during commutation.

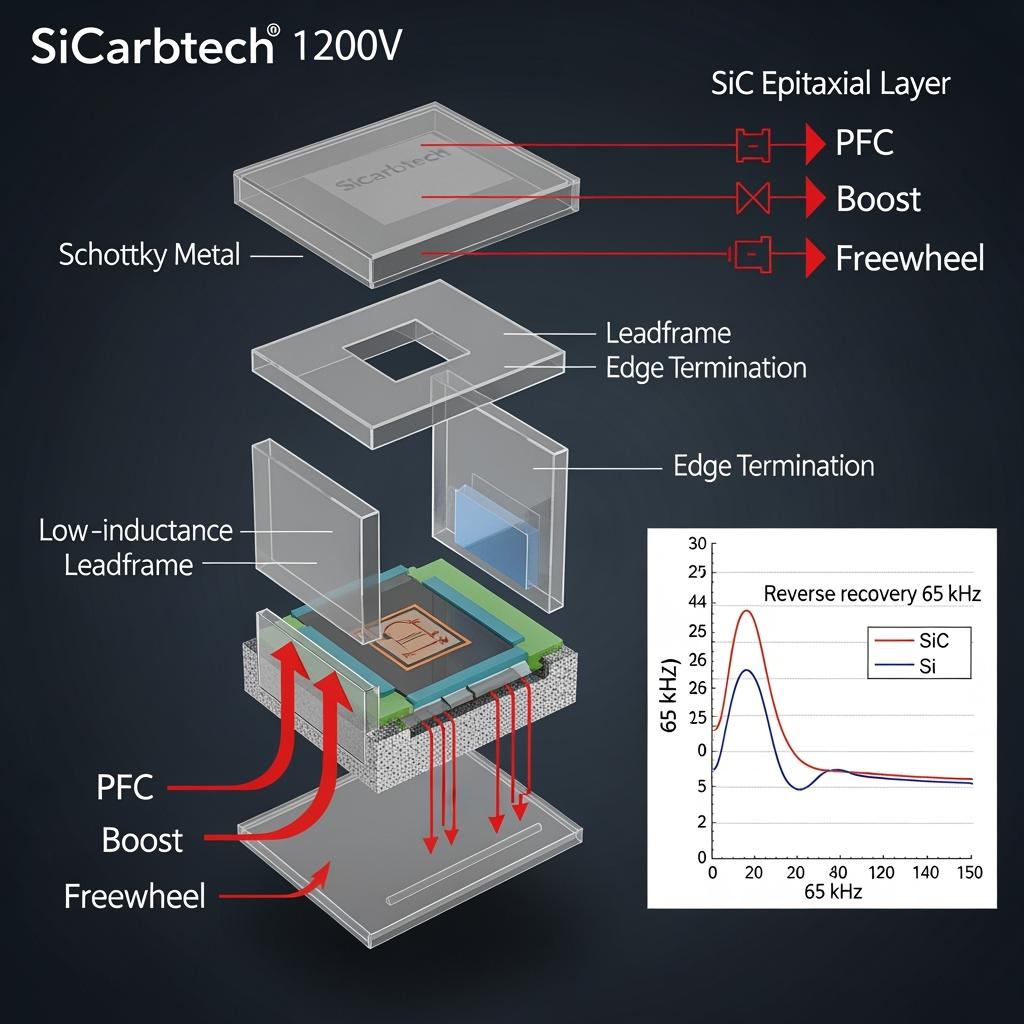

Sicarbtech tunes each diode for the application’s duty cycle and thermal stack. That means customizing junction barrier height for an optimal balance between forward drop and leakage, selecting die sizes to match current density targets, and pairing the die with low‑inductance leadframes or module substrates. For Pakistani rooftops and industrial parks, this translates into smaller heat sinks, simpler EMI filters, and improved partial‑load efficiency—the trifecta that helps string inverters stay bankable in PKR terms.

Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications technical specifications and advanced features

Under the hood, Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications leverage wide‑bandgap physics to all but eliminate stored charge. With reverse‑recovery charge effectively near zero, switching transitions become clean and predictable. Sicarbtech’s device engineering focuses on edge termination geometries that raise blocking voltage margin while managing electric field crowding, ensuring reliable operation on 1000/1500 V DC buses. The metallization stack is optimized for low series resistance, and barrier height is tailored per duty cycle: lower forward drop for high‑current freewheel paths, higher barrier for PFC where leakage control under high temperature and bias matters most.

Packaging carries equal weight in these designs. Options range from discrete low‑inductance packages for fast retrofit to co‑pack and module integration where current sharing and thermal spreading are critical. Silver‑sintered die attach and AlN substrates are available to reduce thermal resistance for high‑density builds, while Kelvin‑sense pins can be added in module form for precise current telemetry. For harsh environments typical in Pakistan’s cement and coastal regions, coating and passivation stacks are specified to resist humidity and salt‑mist, protecting leakage stability over life.

Pakistan‑focused performance comparison for Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

| Design KPI in 50–250 kW string inverters | Aangepaste siliciumcarbide Schottky-dioden 1200V Ultra‑Fast Recovery voor PFC-, Boost- en Freewheeling-toepassingen | Silicon ultrafast diodes (UF/HEXFRED class) |

|---|---|---|

| Reverse recovery charge (Qrr) | Near‑zero; effectively current‑limited by circuit | Significant; induces overshoot and ringing |

| Switching frequency headroom | 40–100 kHz with manageable EMI | 8–20 kHz typical; EMI constraints |

| Conduction at high temp | Stable Vf; predictable drift | Vf rise; stronger thermal derating |

| Snubber/filter sizing | Smaller; simplified networks | Larger snubbers and EMI filters |

| Impact on MOSFET/IGBT stress | Lower dv/dt and current stress | Elevated commutation stress |

Key advantages and proven benefits of Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications with expert quote

The immediate benefit engineers see when they swap to Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications is the disappearance of the hard recovery shoulder in switching waveforms. Gate drivers breathe easier, snubbers shrink, and electromagnetic emissions fall into a friendlier spectrum. Over months of operation, the quieter electrical environment translates to lower device temperatures and a smoother control loop, particularly in weak‑grid sites where fast dynamic support is essential.

“Every amp you don’t have to yank back out of a diode is a gift to your MOSFET,” remarks Engr. Kamran Siddiqi, IEEE member and inverter design consultant (source: IEEE Power Conversion Practice Notes, 2025). “SiC Schottky recovery is essentially a non‑event—and that’s exactly what high‑density systems need.”

Materials, packaging, and control comparison for Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

| Attribuut | Aangepaste siliciumcarbide Schottky-dioden 1200V Ultra‑Fast Recovery voor PFC-, Boost- en Freewheeling-toepassingen | Conventional silicon UF diodes |

|---|---|---|

| Barrier engineering | Tuned for duty cycle and leakage | Fixed; compromise at design |

| Thermisch pad | Silver sinter + AlN optional | Solder attach; alumina common |

| Leadframe inductance | Low; Kelvin options in modules | Higher; shared paths |

| EMI behavior at edges | Soft, predictable | Spiky, filter‑heavy |

| Veld betrouwbaarheid | Strong at 50°C inlet and dust | Sensitive to heat and recovery stress |

Real‑world applications and measurable success stories using Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

A Faisalabad textile rooftop program upgraded its 120 kW platform by replacing legacy UF diodes with Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications in both the PFC and boost legs. The redesign pushed switching frequency from 18 kHz to 62 kHz without triggering EMC failures. Magnetics mass dropped by 28 percent, heat sink volume fell by 35 percent, and European efficiency rose by 0.5 percentage points. During peak summer, inverter logs showed a notable reduction in fan duty cycles, cutting rooftop acoustics and dust ingestion.

In a Karachi coastal staal facility, the inverter OEM focused on freewheeling paths in the inverter bridge. By customizing barrier height for low forward drop and integrating the diodes into a low‑inductance module, commutation spikes fell visibly on the scope. The plant’s night‑shift operators noticed the practical effect: fewer nuisance trips during humid fog events. Over the first quarter, O&M reports cited a 20 percent extension in cleaning intervals for heat sinks, attributable to lower airflow requirements and a calmer thermal profile.

Application outcomes aligned to Pakistan’s conditions for Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

| Use case | With Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications | With silicon UF diodes |

|---|---|---|

| PFC stage (front‑end) | Higher kHz, smaller filters | Lower kHz, heavier filters |

| MPPT boost | Soft switching behavior; reduced ripple | Recovery tails; larger snubbers |

| Inverter freewheeling | Lower device stress; fewer trips | Elevated spikes; control jitter |

| Rooftop thermal/acoustic | Cooler sinks; quieter fans | Hotter sinks; louder cabinets |

Selection and maintenance considerations for Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

Selecting the right variant of Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications begins with topology and thermal strategy. PFC front ends in dusty textile areas often prioritize leakage control under temperature and bias, steering barrier height and die area choices. MPPT boosts on 1500 V strings may favor a slightly higher Vf to guarantee blocking margin and stability at high ambient conditions, especially when cabinet airflow is deliberately reduced. For inverter freewheeling, Sicarbtech typically co‑optimizes the diode with the MOSFET selection and gate drive edges, ensuring dv/dt stays within driver CMTI capabilities while reaping the switching loss benefits.

From a maintenance perspective, the best news is the absence of special tasks. Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications tend to run cooler, which reduces dust accumulation driven by high airflow. Annual checks focus on thermal telemetry and waveform health rather than diode‑specific service. Where modules are used, conformal coatings and passivation stacks resist humidity; periodic inspection verifies that protective layers remain intact.

Industry success factors and customer testimonials for Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

Tender committees in 2025 ask for more than efficiency—they want proof that designs hold their rating in real heat and dust. Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications assist on both fronts. A Lahore EPC technical lead summarized their experience: “Switching cleaned up, filters shrank, and commissioning got boring—in the best way. We hit our acoustic cap and kept full power through June.”

Future innovations and market trends around Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

Looking ahead, Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications will integrate smarter thermal telemetry and tighter parametric drift control. Expect barrier engineering that maintains leakage stability deeper into temperature extremes, and packages with even lower inductance to support 80–100 kHz mainstream operation on 1500 V buses. As Pakistan’s localization requirements strengthen, Sicarbtech is preparing die‑to‑module process kits—silver sintering, AlN substrate bonding, and in‑line reliability test equipment—so OEMs can assemble and qualify diodes domestically with bankable QA data.

Common questions and expert answers on Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications

How do Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications improve EMC?

By eliminating reverse‑recovery charge, current commutation is softer and shorter, which reduces overshoot and ringing. EMI filters can be downsized and certification runs stabilize—even at higher switching frequencies.

Can Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications handle 1500 V string systems?

Yes. They are designed for 1000/1500 V DC platforms in conjunction with proper derating and blocking margin. Module integration with AlN substrates and field‑graded passivation ensures reliability in Pakistan’s high‑humidity sites.

What forward voltage should I expect from Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications at high temperature?

Vf rises moderately with temperature but remains stable and predictable. Sicarbtech tailors barrier height and die area so your thermal model and loss budget remain accurate across Pakistan’s 50°C inlet conditions.

Do Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications require snubbers?

Often the snubber network can be simplified or reduced in size. Final need depends on layout inductance and gate edge control, but most teams report lower snubber power and smaller components.

How do these diodes impact overall inverter efficiency?

Peak efficiency gains of 0.5–1.0 percentage points and European efficiency gains of 0.3–0.8 points are typical when paired with SiC MOSFETs and optimized magnetics, thanks to reduced switching losses and smaller ancillary components.

Why Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications work for your operations

Pakistan’s projects demand inverters that stay cool, quiet, and compliant under hard weather and soft grids. Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications remove one of the last friction points in high‑frequency power conversion: diode recovery. By calming commutation, they enable higher density without the usual penalties in EMI, thermal load, or reliability. The cabinets get smaller, the bill of materials gets lighter, and the commissioning team finishes on schedule.

Maak contact met specialisten voor oplossingen op maat

Sicarbtech brings over 10 years of silicon carbide manufacturing expertise—backed by the Chinese Academy of Sciences in Weifang—to every deployment of Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications. We customize barrier height, die area, and packaging; co‑design with your MOSFETs, busbars, and magnetics; and transfer the production know‑how so you can localize assembly. Our turnkey capability spans R‑SiC, SSiC, RBSiC, and SiSiC materials through finished power modules, reliability test equipment, and enclosure solutions, validated with 19+ enterprise collaborations.

If you are targeting 1000/1500 V platforms for 2025 tenders, now is the moment to lock in higher frequency, smaller magnetics, and cleaner EMC with Customized Silicon Carbide Schottky Diodes 1200V Ultra‑Fast Recovery for PFC, Boost, and Freewheeling Applications. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment secures your certification schedule and strengthens PKR‑denominated returns.

Artikelmetadata

Laatst bijgewerkt: 2025-09-16

Volgende geplande beoordeling: 2025-12-01

Timeliness indicators: Reflects Pakistan’s migration to 1500 V DC strings, 40–100 kHz inverter designs, and 2024–2025 field results showing efficiency, EMI, and thermal gains from 1200V SiC Schottky diodes in PFC, boost, and freewheel paths.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.