Siliciumcarbide Full‑Bridge Power Modules met temperatuur- en stroomdetectiepinnen voor grid-gekoppelde converters en ESS

Haalbare toleranties en maatnauwkeurigheid:

On a bright July afternoon above a textile mill in Faisalabad, a row of outdoor string inverters hums steadily despite 50°C inlet air and a light veil of dust. Their secret is vigilance. Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS give Pakistan’s OEMs eyes and ears inside the power stage, transforming raw SiC switching speed into stable, grid‑friendly power. With sensing woven into the module, control loops see junction temperature and phase current in real time, so protection decisions are timely and efficiency holds from peak irradiance to evening ramps. In a market that measures success by uptime, weight, and certification speed, this fusion of power density and observability has become decisive.

Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS product overview and 2025 market relevance

As Pakistan accelerates toward 1000/1500 V DC platforms and 50–250 kW string inverters, engineers are being asked to do more in less space while braving harsher sites—from alkaline dust in the cement corridor to salt‑mist in Karachi. Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS answer with a compact, low‑inductance package that integrates four SiC switches, Kelvin source returns, and dedicated sensing pins. The result is a module that not only switches cleanly at 40–100 kHz, but also communicates its internal state to the controller, enabling finer current control, tighter LVRT, and gentler fault handling during weak‑grid events.

In 2025, tenders increasingly scrutinize not just peak efficiency but dynamic behavior—reactive power support, harmonic suppression, and acoustic limits tied to fan duty. Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS help close these specifications by coordinating fast SiC edges with sensing‑aware control algorithms. Moreover, by reducing parasitics and exposing thermal headroom, the modules allow smaller magnetics and heat sinks, supporting lighter enclosures that ease rooftop permitting and logistics.

Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS technical specifications and advanced features

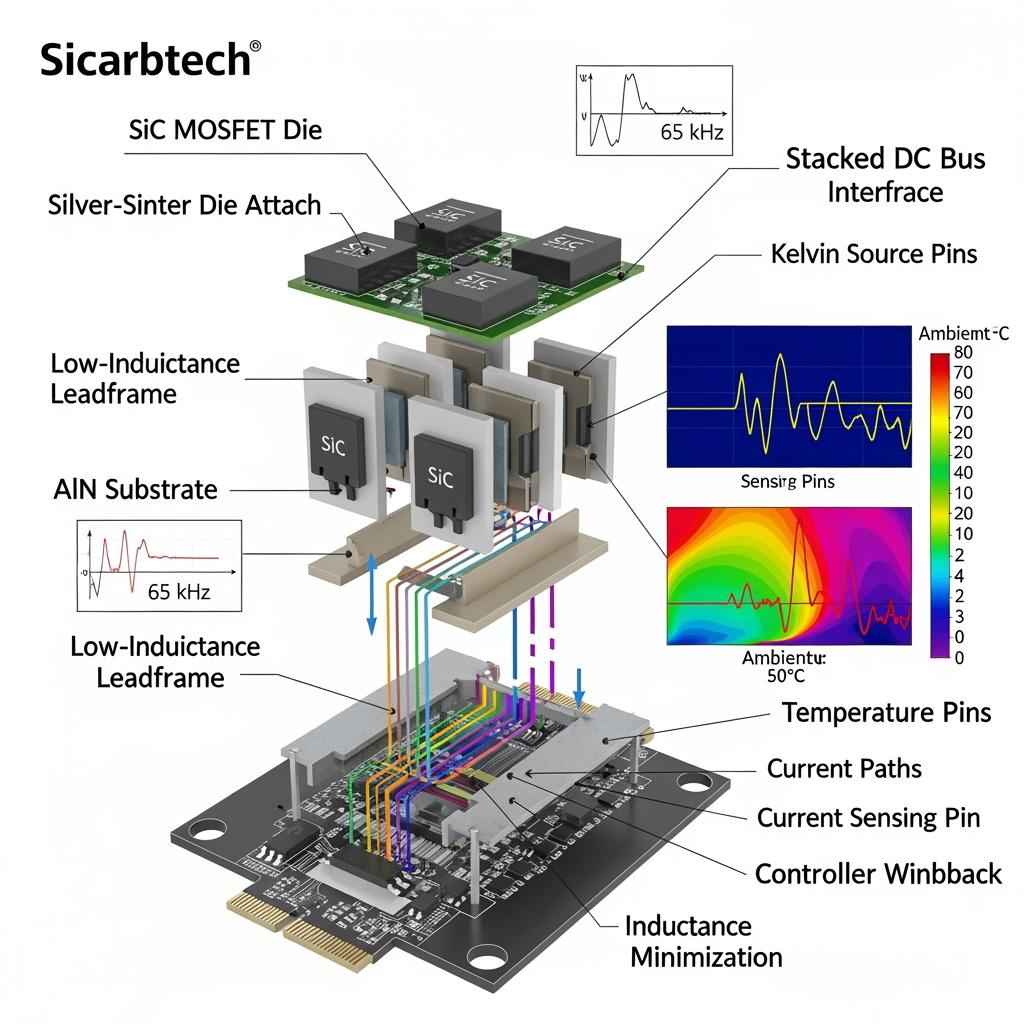

At the heart of Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS is a low‑inductance geometry that couples tightly to stacked DC busbars. Sicarbtech uses silver‑sinter die attach on AlN substrates to minimize thermal resistance and deliver robust power cycling life. Kelvin source pins isolate gate return from power current dynamics, sharpening control over dv/dt without false trips. Integrated temperature sensing accesses junction‑proximate locations through calibrated NTCs or diode sensors, while current sensing pins interface to shunt or Hall structures co‑located with phase outputs, delivering low‑latency, low‑noise measurements to the DSP.

Field reliability is engineered into the perimeter. High‑voltage terminal passivation and surface treatments elevate partial discharge inception voltage under humidity, while conformal coatings and sealed interfaces protect leakage stability in dust and salt‑mist. For Pakistan’s 1500 V strings, creepage and clearance are tailored to pollution degree norms, and gate‑drive compatibility extends to high‑CMTI isolated drivers with programmable soft turn‑off and active clamping. The net effect is a module that runs cool, switches clean, and speaks clearly to the controller—precisely what grid‑tied converters and ESS inverters require.

Pakistan‑focused performance comparison for Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

| Design KPI in 50–250 kW inverters | Siliciumcarbide Full‑Bridge Power Modules met temperatuur- en stroomdetectiepinnen voor grid-gekoppelde converters en ESS | Discrete SiC devices on PCB |

|---|---|---|

| Loop inductance of DC‑link | <10 nH with stacked busbar coupling | 20–60 nH typical on leaded PCBs |

| Sensing latency/noise | Low latency with dedicated pins | Higher noise; shared returns |

| Thermal resistance, junction‑to‑sink | Lower via silver sinter + AlN | Higher with mixed interfaces |

| Fault response (soft turn‑off) | Deterministic with Kelvin path | Variable; risk of false trips |

| EMC closure at high kHz | Easier; cleaner edges | Harder; more ringing energy |

Key advantages and proven benefits of Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS with expert quote

The practical advantage of Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS is tighter control at higher power density. With real junction temperature and phase current visible to the DSP, the inverter can squeeze switching losses without flirting with protection boundaries. Additionally, fault handling improves: desaturation or overcurrent events trigger soft turn‑off tailored to the actual device state, minimizing stress and avoiding nuisance trips during feeder flicker.

“Observability inside the power stage is the difference between a fast inverter and a fast, reliable inverter,” notes Dr. Sana Imran, IEEE senior member and grid‑code advisor (source: IEEE Grid‑Tied Converter Practices, 2025). “When you combine low‑inductance packaging with temperature and current sensing, LVRT and harmonic control become repeatable even on weak feeders.”

Packaging, control, and reliability comparison for Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

| Attribuut | Siliciumcarbide Full‑Bridge Power Modules met temperatuur- en stroomdetectiepinnen voor grid-gekoppelde converters en ESS | Conventional Si modules |

|---|---|---|

| Schakelfrequentiebereik | 40–100 kHz stable | 8–20 kHz typical |

| Reactive power response | Fast, sensing‑assisted | Slower; indirect estimates |

| Heat sink size and fans | 30–50% smaller; fewer fans | Larger sinks; higher airflow |

| Partial discharge resilience | Elevated PDIV under humidity | Lower PDIV; sporadic noise |

| Certification loop count | Fewer EMC/thermal iterations | More loops; heavier filters |

Real‑world applications and measurable success stories using Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

A Lahore OEM redesigned its 150 kW string inverter around Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS. By co‑designing stacked DC busbars with the module’s low‑inductance terminals, the team lifted switching frequency to 65 kHz. Temperature pins fed a thermal derating curve that only engaged during exceptional heat spikes; through June and July, SCADA recorded zero midday derates. European efficiency rose by 0.7 percentage points, while the magnetics set shed nearly a third of its mass. Acoustic measurements on textile rooftops fell below site limits due to halved fan duty.

In southern Punjab, an ESS containerized system powering an industrial park microgrid adopted the same Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS. Current pins enabled tighter phase balancing across paralleled bridges, cutting circulating currents and trimming copper losses. LVRT tests under artificially weakened grid conditions passed on the first attempt, with reactive power settling in under two cycles. Over the first quarter in service, the site’s O&M team noted that thermal maps stayed even despite dust loading, validating the cooling and control synergy.

Outcomes aligned with Pakistan’s C&I use cases for Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

| Deployment goal | With Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS | Without sensing‑enabled SiC |

|---|---|---|

| Midday output at 50°C | Sustained rated power | Periodic derating |

| EMC and harmonics | Cleaner spectra; smaller LCL | Heavier filters; rework |

| Grid ride‑through | Tighter LVRT/VAR control | Trips during flicker |

| Cabinet weight | 20–40% lighter | Heavier sinks and filters |

Selection and maintenance considerations for Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

Selecting among variants of Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS begins with your voltage class and thermal strategy. For 1500 V platforms, choose 1700 V devices where grid transients and altitude demand margin; for 1000 V rooftops, 1200 V modules often optimize conduction loss. Coordinate gate resistance and dv/dt shaping with Kelvin returns so edges are fast enough for efficiency but gentle enough for EMC and motor‑friendly harmonics in nearby industrial loads. Pairing the module with stacked DC busbars is not optional—it is the shortest path to sub‑10 nH loops and overshoot control.

Maintenance becomes less about firefighting and more about verification. Logged temperature pins provide trend lines for power cycling health; any drift triggers non‑destructive checks—SAM or IR thermography—before issues grow. Current sensing helps catch connector aging or phase imbalance in paralleled systems. In Pakistan’s dusty or salty environments, confirm coating integrity at terminals and preserve gasket compression; otherwise, the modules themselves demand little attention beyond the surrounding airflow and filtration system.

Industry success factors and customer testimonials for Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

Bankability in 2025 hinges on first‑pass compliance and predictable uptime. Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS advance both. A Karachi EPC technical manager summed up their commissioning experience: “With the sensing pins, our control loop tuned in days, not weeks. EMC passed on the first run, and we cut our filter mass. The cabinet got lighter, and the schedule stopped slipping.”

Future innovations and market trends around Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

Looking forward, Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS will integrate smarter telemetry and protection. Expect digital temperature sensors with calibrated linearity, on‑module current sensors with improved bandwidth, and embedded diagnostics that flag partial‑discharge precursors at terminals. Materials are evolving as well: higher‑conductivity dielectrics, improved silver‑sinter chemistries, and corrosion‑resistant platings tailored for Pakistan’s pollution degree. Localization will accelerate, with process kits and test equipment enabling Pakistani partners to assemble, test, and certify modules domestically under PEC‑aligned QA.

Common questions and expert answers on Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS

How do Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS improve LVRT and reactive power control?

By providing real‑time junction temperature and accurate phase current, the controller can push modulation and current limits confidently during sags, sustaining VAR support without tripping protections.

Are Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS compatible with 1500 V strings?

Yes. Modules are offered in 1200 V and 1700 V classes with creepage/clearance tailored to 1500 V DC platforms, plus coatings and passivation for humidity and dust, typical in Pakistan’s sites.

What switching frequencies are practical with Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS?

Most C&I designs operate comfortably between 40 and 100 kHz when paired with stacked DC busbars and appropriate dv/dt shaping. The sensing pins keep thermal and current limits honest at these speeds.

Do Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS reduce LCL filter size?

Often yes. Cleaner commutation and lower parasitics reduce high‑frequency energy, allowing lighter LCL filters while meeting IEC 61000‑6‑4 and site‑specific harmonic targets.

How does sensing affect warranty and O&M?

Telemetry enables predictive maintenance—detecting drift early, isolating faults to specific phases or cabinets, and reducing unnecessary replacements—supporting lower warranty reserves.

Why Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS work for your operations

Pakistan’s environment and grid combine to test any inverter’s margins. Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS respond by shrinking parasitics and illuminating the power stage’s true state. Control algorithms can act precisely rather than conservatively, keeping full power through heat and flicker while trimming metal from heat sinks and filters. That is how high power density becomes not just possible but practical, from textile rooftops to industrial park microgrids.

Maak contact met specialisten voor oplossingen op maat

Sicarbtech stands behind Silicon Carbide Full‑Bridge Power Modules with Temperature and Current Sensing Pins for Grid‑Tied Converters and ESS with more than 10 years of SiC manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. We customize die selection, module geometry, sensing pin calibration, and gate‑drive strategies; co‑design stacked DC busbars and cooling paths; and transfer the full process to your factory through technology transfer and factory establishment services. Our turnkey scope spans R‑SiC, SSiC, RBSiC, and SiSiC materials to finished modules, magnetics, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your roadmap targets 1000/1500 V platforms and 2025 tenders, now is the time to anchor density with observability. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment secures certification timelines, reduces O&M, and strengthens PKR‑denominated returns across your portfolio.

Artikelmetadata

Laatst bijgewerkt: 2025-09-16

Volgende geplande beoordeling: 2025-12-01

Timeliness indicators: Reflects Pakistan’s transition to 1500 V DC platforms, NEPRA/IEC/PEC expectations, and 2024–2025 field data on sensing‑enabled SiC full‑bridge modules for grid‑tied converters and ESS.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.