Siliciumcarbide fijn poeder voor pneumatische injectie met bijpassende lansen en silo's voor gesloten voeding

Haalbare toleranties en maatnauwkeurigheid:

In Pakistan’s fast-modernizing melt shops, the move from manual alloying to enclosed, automated systems is rewriting the playbook for cost, cleanliness, and safety. Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding sits at the center of that shift. Sicarbtech engineered this integrated material-and-equipment solution so that fine SiC powder delivers immediate deoxidation and silicon addition directly into the metal bath, while sealed silos, metering units, and purpose-designed lances keep dust contained and dosing precise. The combination suits EAF bath conditioning, BOF/convertor trim control, and selective ladle interventions, especially when higher scrap ratios and tight KPIs demand steady absorption, lower total oxygen, and calmer casting behavior.

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding product overview and 2025 market relevance

The 2025 context in Pakistan is clear: energy tariffs bite, alloy imports swing with currency moves, and continuous casting lines demand more predictable metallurgy to keep sequence lengths stable. Against that backdrop, Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding delivers value on three fronts. First, the powder’s high reaction activity, originating from carbothermal reduction and fine classification, allows rapid oxygen control without sacrificing silicon pickup. Second, enclosed feeding removes much of the dust and variability that come with open additions, aligning with PEQS and internal EHS commitments. Third, integrating matching lances and silos creates a closed loop between oxygen activity signals and feed rates, turning deoxidation from a manual art into a measured science. As Engr. R. Khan, a Lahore-based metallurgist, notes, “When alloying becomes a closed, metered circuit, you don’t just reduce dust—you reduce guesswork” (Metallurgy Pakistan Review, 2024).

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding technical specifications and advanced features

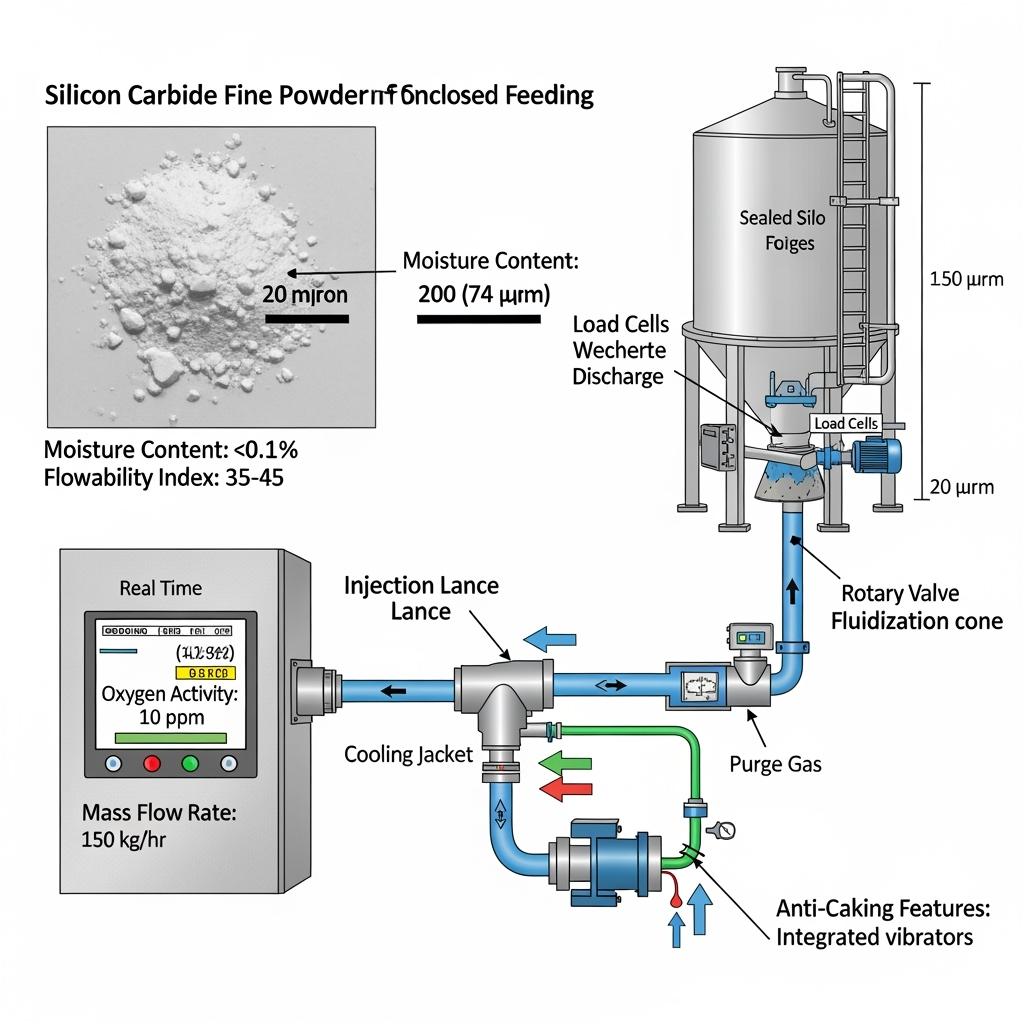

Sicarbtech tunes Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding so that powder chemistry and handling match the realities of Pakistan’s mills. Typical SiC content spans eighty-eight to ninety-six percent, supported by free carbon between one and six percent to reinforce dual deoxidation and thermal balance. Free silicon is usually calibrated at 0.5 to 1.5 percent, limiting secondary oxidation while preserving responsiveness. Impurities are kept tight—sulfur and phosphorus each at or below 0.02 percent—so that cleanliness targets for export-grade billets and flats are attainable. The particle size distribution centers below 200 mesh for entrainment and stable pneumatic flow, while surface conditioning and anti-caking agents defend against monsoon-related moisture uptake. The system includes sealed storage silos with fluidization pads, precision metering, and lances designed for thermal durability and optimized jetting so the powder penetrates turbulence and contacts liquid staal effectively.

Clean steel and process control comparison for Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding

| KPI and practice impact | Siliciumcarbide fijn poeder voor pneumatische injectie met bijpassende lansen en silo's voor gesloten voeding | Coated SiC granules via enclosed feeders | FeSi + aluminum wire (open handling) |

|---|---|---|---|

| Oxygen activity control (response time) | Rapid, real-time metered | Fast but stepwise | Variable, operator dependent |

| Silicon absorption predictability (σ) | Low variability with closed loop | Laag-gematigd | Moderate–high |

| Dust exposure at addition points | Very low; enclosed circuit | Laag | Higher; wire handling and open charge dust |

| Inclusion morphology outcome | Finer, more floatable inclusions | Improved, depends on dosing | Alumina spikes more frequent |

| Automation readiness | High; oxygen-linked dosing | High; timed dosing | Lower; manual interventions |

Material and equipment attributes of Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding

| Attribuut | Siliciumcarbide fijn poeder voor pneumatische injectie met bijpassende lansen en silo's voor gesloten voeding | Operationele betekenis in Pakistan |

|---|---|---|

| SiC content | 88–96% | Strong silicon source with carbon synergy |

| Free carbon | 1–6% | Dual deoxidation and thermal profile |

| Gratis silicium | 0.5–1.5% | Limits secondary oxidation |

| S, P (elk) | ≤0.02% | Clean steel compliance for exports |

| Particle size | <200 mesh | Stable pneumatic entrainment and delivery |

| Moisture and anti-caking | Engineered surface and flow aids | Humidity resilience across monsoon season |

| Matching lances | Cooled, optimized jet geometry | Penetration and mixing in turbulent baths |

| Sealed silos | Fluidized cones, load cells | Accurate, traceable dosing with low dust |

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding performance comparison with alternatives

| Cost, energy, and throughput metrics | Siliciumcarbide fijn poeder voor pneumatische injectie met bijpassende lansen en silo's voor gesloten voeding | Separate carburizer + silicon source | High-aluminum deoxidation route |

|---|---|---|---|

| Legeringskosten per ton staal | -1–5% vs reference | +0–2% volatility | Variable; higher Al usage |

| Invloed van opwarmtijd | -0.5–2% | Minor | Referentie |

| Temperature loss | -2 to -6°C | -1 to -3°C | 0 to -2°C |

| Sequence stability | Higher; fewer nozzle events | Matig | Lower; alumina clogging risk |

| EHS and housekeeping | Very low dust, enclosed | Higher with open charging | Wire feed dust, manual handling |

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding advantages and proven benefits with expert insight

The real power of Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding is control. By linking oxygen activity to a metering algorithm, the system dispenses SiC precisely when and where it is needed. Powder, unlike discrete granules, can be modulated in seconds, smoothing the oxygen curve and boosting silicon absorption without overshooting. Additionally, the enclosed path—silo to lance—minimizes dust and operator exposure, which EHS teams value as much as the metallurgical gains. Prof. Li Wei of the CAS Weifang Innovation Park summarizes it well: “Fine-powder injection turns deoxidation into a servo-controlled event, not a set piece—precision is the point” (CAS Materials Review, 2023). The outcome is measurable: fewer nozzle alarms, shorter refinings, and steadier product quality.

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding real-world applications and measurable success stories

At an EAF billet producer near Karachi, deploying Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding reduced total oxygen by eight ppm on average while raising silicon absorption by roughly five percentage points. Over a six-week period, nozzle clogging interventions dropped by thirty-five percent per hundred heats, and average heat time fell by close to one percent. The plant also reported simpler PEQS particulate compliance due to the fully enclosed path from silo to lance. In a converter shop in Punjab, the same solution was used for trim control during secondary metallurgy. By tying metering to real-time oxygen activity, the team trimmed aluminum wire by about ten percent and improved tundish stability across longer sequences, with SEM checks revealing smaller, more floatable inclusions.

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding selection and maintenance considerations

Selecting the right variant of Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding begins with your furnace profile and sensor infrastructure. If your EAF exhibits rapid oxygen swings during flat bath periods, prioritize a formulation with moderate free carbon and low free silicon so the control loop can respond without risking reoxidation. Plants focusing on sequence length and nozzle openness can consider calcium-containing micro-additions to promote inclusion modification, provided flux chemistry and slag basicity are coordinated. Maintenance focuses on keeping flow consistent: ensure silo fluidization pads are calibrated, purge gas is dry, and lance tips remain free of buildup. Regular flowability tests and moisture checks by batch preserve dosing accuracy, particularly through monsoon humidity cycles. Matching lance geometry to bath depth and turbulence further improves penetration and mixing, reinforcing the absorption advantage that makes this approach compelling.

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding industry success factors and customer testimonials

Where results shine most, the Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding is treated as a system. Plants integrate sensor signals, verify silo mass via load cells, and track feed curves against oxygen activity and temperature. A QA superintendent from a North Region caster remarked after adoption that radio chatter about the nozzle “went quiet,” a shop-floor way of saying stability returned. Moreover, operators appreciated the reduction in manual handling and housekeeping, shifting attention to process improvements rather than firefighting.

Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding future innovations and market trends

As Pakistan’s mills drive toward higher automation and cleaner casting through 2025–2027, the trajectory points to tighter integration of materials, equipment, and data. Sicarbtech is advancing Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding with coatings that stabilize flow under humidity, AI-informed dosing algorithms in the controller, and lance designs that manage thermal shock during long campaigns. Technology transfer programs are also expanding so that powder synthesis, classification, and silo-lance systems can be set up locally, shrinking lead times and enabling rapid iteration of powder PSD and coating recipes based on actual heat data.

Veelgestelde vragen en antwoorden van experts

How does Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding improve silicon absorption versus granules?

By metering continuously and responding to oxygen activity in real time, Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding keeps Si available precisely when needed, reducing oxidation losses and improving net absorption.

Will Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding help reduce aluminum wire usage?

Yes. Taking on a larger share of initial and mid-heat deoxidation, Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding allows aluminum wire to be trimmed or reserved for final corrections, which also reduces alumina inclusion load.

What particle size should we choose for Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding?

For pneumatic injection, a distribution centered below 200 mesh is standard to ensure stable entrainment and transport. Sicarbtech can tighten the PSD to match your air velocity, line geometry, and lance design.

How is dust controlled with Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding?

The system employs sealed silos with fluidized cones, enclosed rotary valves, dry purge gas, and cooled lances. This closed path keeps airborne particulate low and simplifies PEQS reporting.

How does Sicarbtech assure lot consistency for Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding?

Each batch is validated for SiC content, free carbon and silicon, PSD, moisture, flowability, and coating performance under Sicarbtech’s in-situ quality monitoring and traceability system, with results tied to batch and shipment IDs.

Why Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding works for your operations

Because control beats correction. Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding turns deoxidation and silicon addition into a closed-loop, data-led action that is as much about stability as it is about chemistry. In Pakistan’s mills—where scrap variability and energy costs pressure every heat—this approach delivers predictable absorption, fewer inclusion surprises, and quieter casters, all while reducing dust and manual handling.

Maak contact met specialisten voor oplossingen op maat

Sicarbtech supports Silicon Carbide Fine Powder for Pneumatic Injection with Matching Lances and Silos for Enclosed Feeding with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. Beyond premium powders, we deliver complete systems: sealed silos with metering, engineered lances, integration with oxygen activity and temperature signals, and Level 2 data hooks. We also develop custom R-SiC, SSiC, RBSiC, and SiSiC materials and provide technology transfer and factory establishment services to localize powder synthesis, classification, granulation, and coating in Pakistan. With turnkey solutions proven across nineteen-plus enterprises, Sicarbtech will design a no-cost pilot with clear KPIs—lower alloy cost per ton, reduced total oxygen, and longer sequence stability—so you can scale with confidence.

Neem contact op voor een gratis advies en een snel voorstel op basis van gegevens:

Email: [email protected]

Telefoon/WhatsApp: +86 133 6536 0038

Metagegevens artikel

Laatst bijgewerkt: 2025-09-15

Volgende beoordeling gepland: 2025-12-15

Auteur: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, and flats)

Timeliness note: Content aligned to 2025 automation trends, PEQS-aligned dust control, and closed-loop pneumatic injection deployments

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.