Brazilian Market Trends in Custom Silicon Carbide Ceramics

Haalbare toleranties en maatnauwkeurigheid:

Executive summary: how custom silicon carbide will shape Brazil’s industrial performance in 2025

Brazil’s industrial landscape is entering a cycle where reliability, energy intensity, and compliance define competitive advantage. Mining operations in Minas Gerais and Pará, pre-salt oil and gas assets offshore, and agricultural processing hubs across Mato Grosso and Paraná all face the same mandate: deliver more throughput with fewer stoppages while satisfying ABNT NBR standards, ANP procurement requirements, IBAMA environmental licensing, and NR safety norms. Furthermore, currency volatility and logistics uncertainty have pushed procurement toward lifecycle value and local capability rather than headline unit price. In this environment, custom silicon carbide ceramics—engineered in R-SiC, SSiC, RBSiC, and SiSiC—stand out because they resist erosion, corrosion, and thermal shock simultaneously, preserving geometry and surface finish that underpin process stability.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of silicon carbide customization and supports over 19 enterprises with full-cycle solutions from material processing to finished products. By integrating materials R&D, precision finishing, application engineering, and turnkey technology transfer—including factory establishment—Sicarbtech helps Brazilian buyers convert material upgrades into measurable operational gains: longer maintenance intervals, lower kWh per cubic meter pumped, and faster qualification with Brazil’s major operators. As 2025 unfolds, these capabilities align directly with board-level priorities on uptime, ESG-linked energy metrics, and supply chain resilience.

Industry challenges and pain points: turning local realities into sustainable performance

The Brazilian market exposes the limits of conventional materials in a way that is both technical and economic. In mining, for instance, variability in ore granulometry and hardness reshapes wear patterns inside hydrocyclones, venturi nozzles, pump volutes, and transfer elbows. Seasonal rainfall changes slurry density and pH, which accelerates erosion and destabilizes cut sizes. Each increment of surface roughness raises turbulence and energy consumption, while widened clearances degrade classification and pumping efficiency. When alumina cones or metal-lined parts fail early, the true cost is not the component itself but the emergency downtime, expedited freight to remote sites, and the capital absorbed by inflated safety stocks.

Offshore oil and gas adds chloride corrosion and thermal cycling to the mix. Mechanical seal faces, bearings, choke trims, and valve seats must survive simultaneous abrasion and corrosion, especially during transients that generate steep thermal gradients. ANP-linked procurement typically references API 610/682 and NACE MR0175/ISO 15156; documentation gaps delay approvals and inflate project risk. A single seal failure offshore can cascade into vessel day rates, production deferrals, and environmental exposure, costs that leaders scrutinize in an era of ESG-linked financing and public accountability.

Agribusiness is no less demanding. Fertilizer handling combines corrosive salts with abrasion, while sugarcane processing introduces fibrous particulates and CIP cycles that swing temperature and pH. Harvest windows compress risk; an eight-hour stoppage can translate into missed port slots at Santos or Paranaguá and penalties priced in USD. IBAMA oversight further discourages improvisation, making predictable performance and robust documentation central to operational credibility.

Hidden losses amplify visible ones. Energy intensity drifts upward as internal surfaces polish or pit and as clearances widen. Maintenance teams pivot to firefighting, eroding time for predictive improvements. Inventory buffers swell across B2B networks to hedge wear uncertainty, tying up working capital. FX volatility compounds everything: when emergency imports become necessary, rates can erase margins. “We stopped judging materials by peak properties and started judging them by how slowly they lose their geometry in our duty,” says Eng. Aline S. Moura, a reliability advisor to a Minas Gerais miner. “Geometry stability is process stability, and process stability is cash.” (Source: Reliability Engineering Brazil, 2024)

There is also a persistent qualification gap. Datasheet properties measured on standard coupons often fail to predict performance in Brazilian chemistries and particle spectra. Without microstructural tuning—grain size distributions, reaction bonding phase control, sintering windows—and without geometry optimized and validated by CFD and wear modeling, field outcomes rarely meet expectations. Brazilian operators increasingly demand ABNT-referenced test methods, ANP-friendly traceability, and validation in locally relevant conditions. Bridging this gap requires both materials science and documentation discipline—capabilities Sicarbtech has institutionalized.

Advanced silicon carbide solutions portfolio tailored to Brazil’s industries

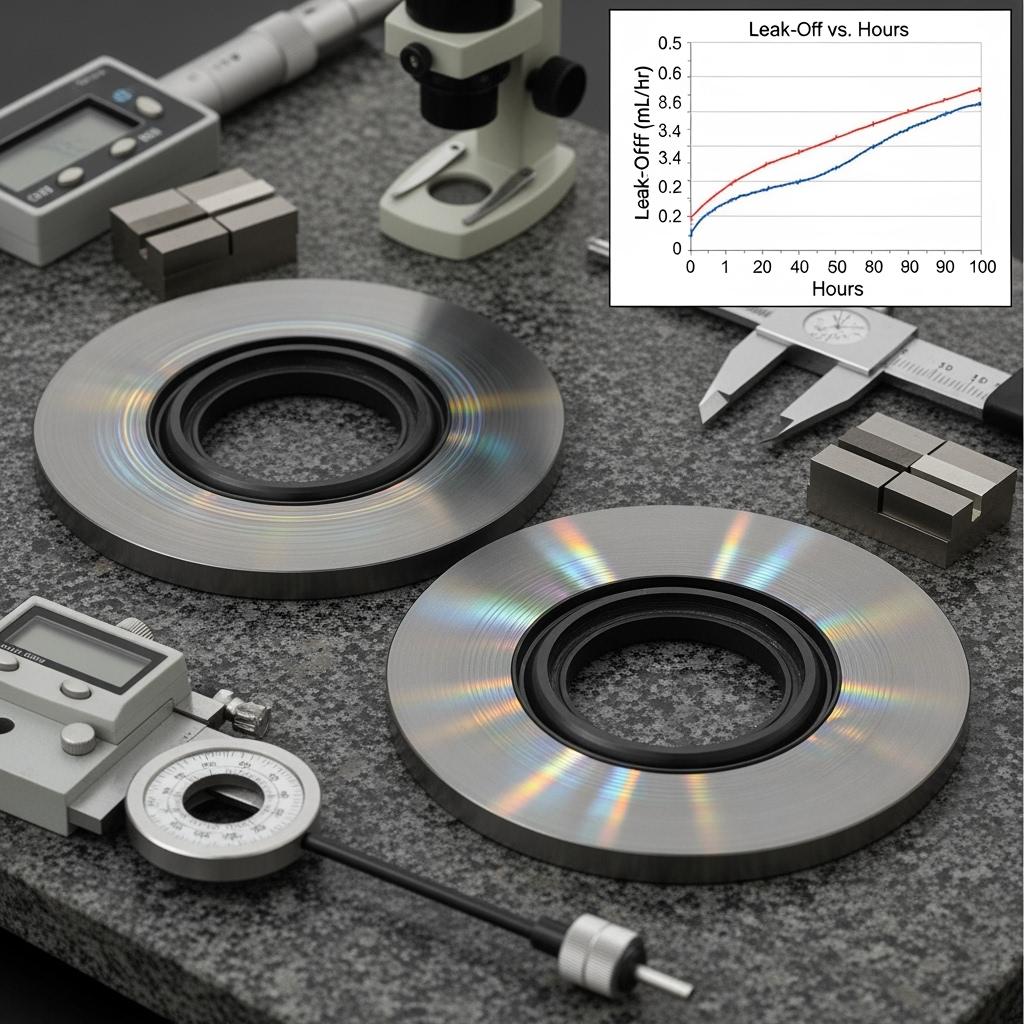

Sicarbtech’s portfolio aligns silicon carbide grades with application-specific engineering to address Brazil’s mixed-mode failure mechanisms. Sintered silicon carbide (SSiC) offers near-zero porosity, excellent chloride corrosion resistance, and ultra-flat lapping capability, making it ideal for mechanical seal faces, bearings, and throttling components where stable leak-off and low friction are mission-critical. Reaction-bonded SiC (RBSiC/SiSiC) combines high strength with thermal shock resistance and near net-shape forming, which suits hydrocyclones, venturi nozzles, wear liners, and elbows exposed to erosive slurries and thermal transients. Recrystallized SiC (R-SiC) brings low density and high-temperature stability to kiln furniture, burner blocks, and porous structures, enabling faster thermal cycles and fewer cracks.

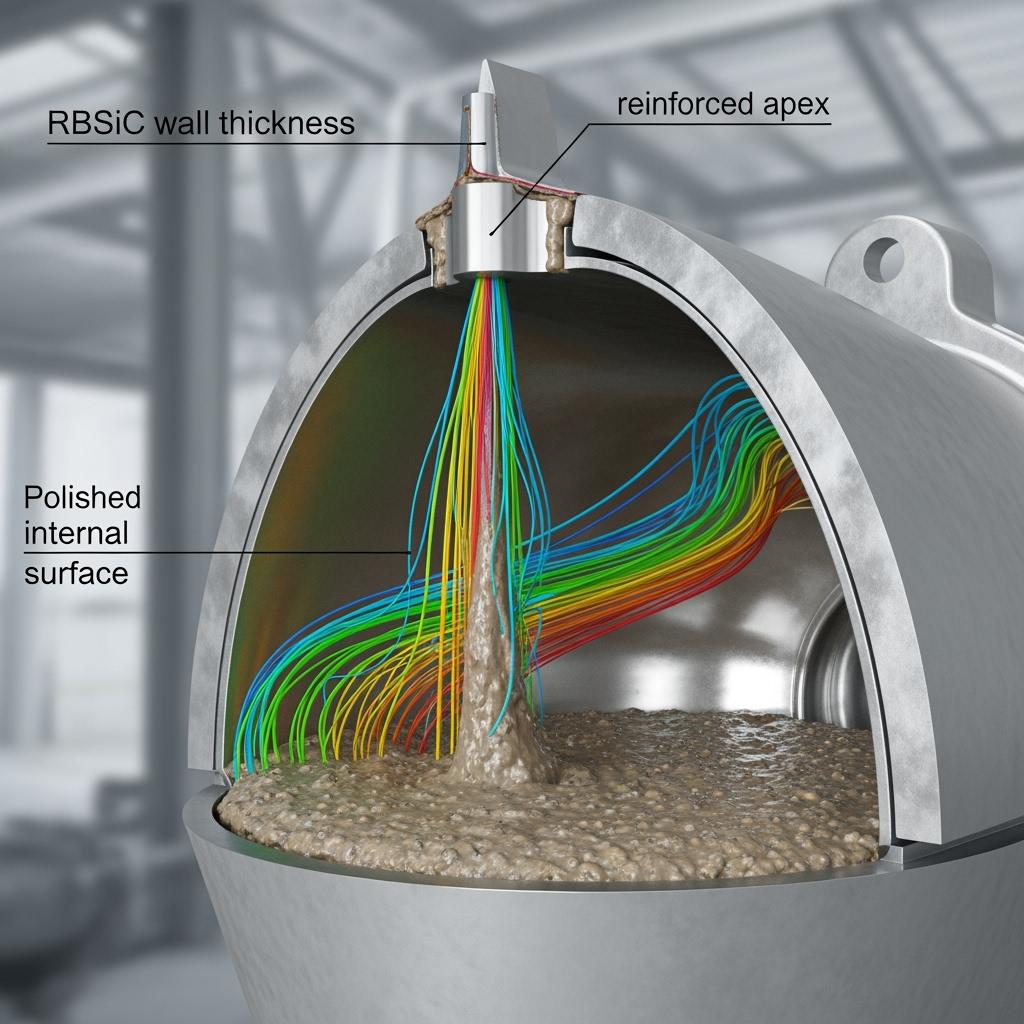

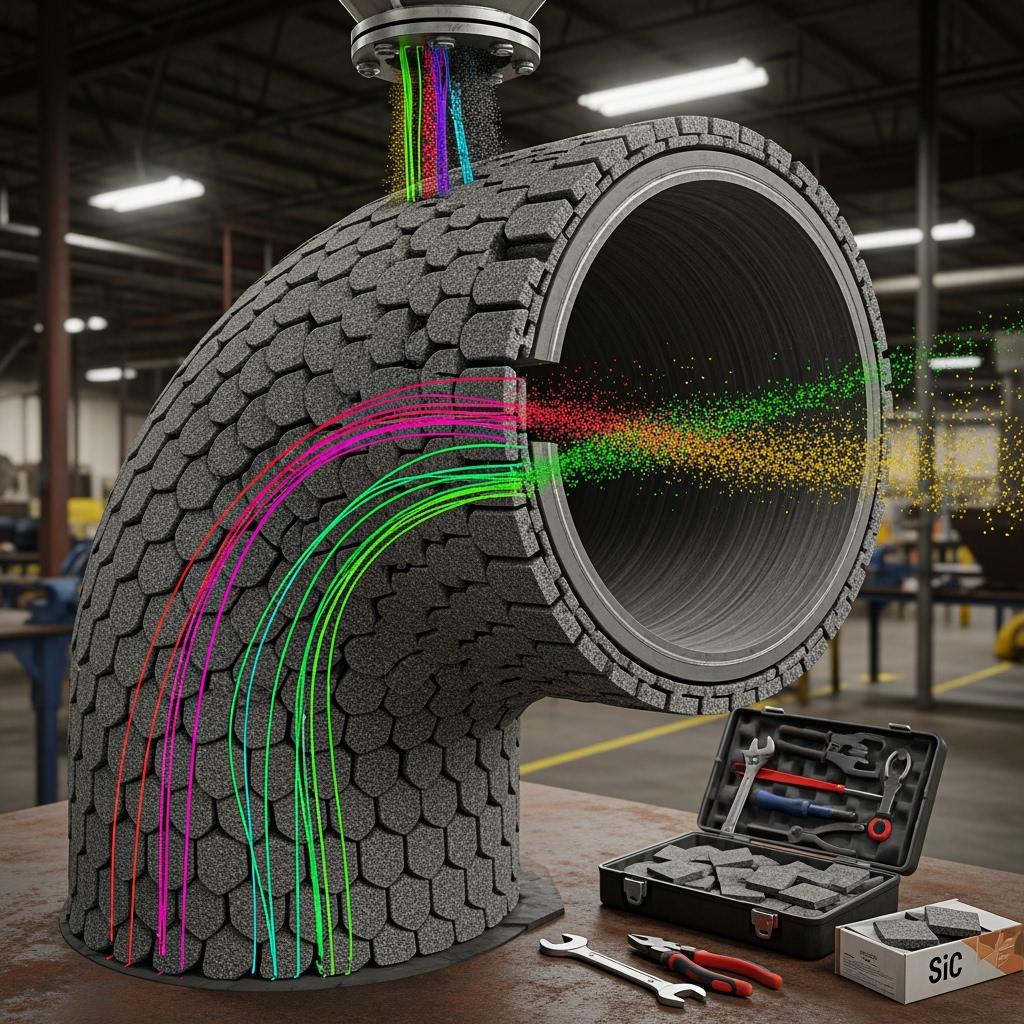

Design is collaborative and data-led. Hydrocyclone cones are reprofiled to dampen vortex instabilities, while apex and inlet geometries are reinforced to equalize wear without changing mounting envelopes. Seal faces are micro-lapped to optical flatness and paired with verified counterface materials, stabilizing leak-off under API 682 conditions. Wear tiles for fertilizer elbows are engineered with thickness gradients and overlaps tailored to site-specific velocity profiles, turning chaotic wear into predictable maintenance. Every component ships with ABNT-referenced tests, dimensional and NDT reports, and traceability formatted for ANP workflows, smoothing approvals and standardizing spares across multi-site portfolios.

Performance comparison: silicon carbide versus traditional materials in Brazilian duty cycles

Engineering properties that drive lifecycle value and compliance outcomes

| Property / Condition | SSiC (gesinterd SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Buigsterkte (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Thermische geleidbaarheid (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Uitstekend | Zeer goed | Goed | Fair to good | Good, binder dependent | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Uitstekend | Uitstekend | Zeer goed | Goed | Zeer goed | Matig |

| Dichtheid (g/cm³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Brazilian Fit | API-grade seals, bearings | Cyclones, nozzles, liners | Thermal fixtures, filters | Budget liners | Impact trims | Structural housings |

In field terms, SSiC’s combination of hardness, corrosion resistance, and heat spreading slows roughness growth and keeps clearances tight, stabilizing energy consumption and leak-off. RBSiC maintains geometry under rapid transients typical in slurry handling. Alumina is economical but vulnerable to thermal shock. WC-Co resists impact but may suffer binder corrosion in chlorides and imposes mass penalties. Duplex steels offer toughness but risk pitting and accelerated erosion in mixed environments common to pre-salt and fertilizer service.

Real-world applications and success stories: Brazilian conditions, measurable results

At a Pará bauxite concentrator, alumina hydrocyclone cones lasted roughly six weeks. Sicarbtech introduced RBSiC cones with a reprofiled inlet and reinforced apex validated via CFD. Time between changeouts extended beyond twelve weeks, and classification efficiency rose by approximately 3–4%. Emergency shipments declined, and the site trimmed safety stock by nearly one-third, freeing working capital and stabilizing maintenance schedules.

A pre-salt operator needed mechanical seal faces that would keep flatness and low friction across pressure-temperature swings in water injection pumps. Sicarbtech supplied SSiC faces lapped under monochromatic light, paired with a counterface recommendation and installation guidance. Over 4,500 hours, leak-off remained within API 682 expectations and power draw dropped by 1–2%, with full traceability accelerating ANP-aligned vendor approval for follow-on orders.

In Mato Grosso’s fertilizer handling network, elbows wore unpredictably during harvest peaks. Sicarbtech designed SiC wear tiles with thickness gradients and overlap patterns tuned to measured velocity profiles. Wear dropped by around 50% over the campaign; maintenance shifted from reactive to planned, avoiding port penalties and enabling tight coordination with downstream logistics.

“Geometry stability is the quiet KPI that rescues supply chains,” observes Prof. Daniela Freitas, who advises process industries on materials selection. “SiC keeps surfaces smooth and dimensions steady under mixed stress, which translates into fewer surprises and better energy numbers.” (Source: Journal of Process Equipment Materials, 2024)

Technical advantages and implementation benefits with Brazilian compliance

Silicon carbide’s technical edge lies in its ability to counter three failure modes at once. High hardness resists micro-cutting and polishing wear, preserving smooth surfaces and tight clearances; high thermal conductivity dissipates heat spikes during starts, stops, and CIP cycles, reducing thermal gradients that crack lesser ceramics; and chemical stability shields against chlorides and acids prevalent in pre-salt and fertilizer environments. When SSiC faces are lapped to ultra-low Ra and paired correctly, leak-off stabilizes and frictional heating declines; in pumps and cyclones, smoother internal paths reduce turbulence, preserving efficiency over long campaigns.

Sicarbtech complements these benefits with a compliance-first execution model. Components are designed with reference to API 610/682 and sour service assessed under NACE MR0175/ISO 15156 when relevant. Material characterization follows ISO methods cross-referenced to ABNT NBR expectations, while traceability and inspection records are formatted to ANP procurement workflows. Environmental and safety documentation aligns with IBAMA and NR norms to streamline audits and licensing. This documentation rigor shortens qualification cycles and reduces administrative overhead, allowing engineering teams to focus on performance and planning instead of paperwork.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Brazilian OEMs and operators increasingly seek local capability for critical components to insulate against FX swings and global logistics risk. Sicarbtech’s turnkey model transforms that strategy into production reality without sacrificing performance. The journey starts with feasibility studies—demand modeling, utilities, raw material availability, and regulatory pathways—followed by complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC. These packages include powder selection and conditioning, binder chemistries and granulation protocols, forming methods such as cold isostatic pressing, slip casting, or injection molding, and furnace curves for sintering or reaction bonding tuned to target microstructures and porosity.

Finishing windows are defined to hit stringent tolerances and surface finishes, including ≤0.02 µm Ra for seal faces when specified, backed by calibrated metrology and SPC. Equipment specifications cover mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, and inspection instrumentation, giving procurement a budgetable, ABNT- and ISO-aligned blueprint. Training programs build operator competency, preventive maintenance routines, and SPC capability, while quality frameworks are installed to ISO 9001 with optional ISO 14001 support. Sicarbtech remains engaged through commissioning and ramp-up and sustains continuous improvement based on Brazilian field feedback.

This depth is amplified by Sicarbtech’s R&D connection to the Chinese Academy of Sciences (Weifang) Innovation Park. Advanced microstructural characterization and process modeling enable precise control of porosity, grain size, and residual stresses, improving reproducibility at scale. Because Sicarbtech manages the full value chain from powder to finished part, field insights translate quickly into process adjustments. A wear anomaly identified in Carajás slurry service can trigger a powder blend or furnace profile change in the next production cycle. Over ten years, Sicarbtech has helped more than 19 enterprises achieve 1.8×–3.2× maintenance interval extensions, 1–3% energy savings in critical rotating equipment, and faster qualification with Brazilian majors due to audit-ready traceability and testing.

“Assembling equipment is not the same as transferring a process,” emphasizes Dr. André N. Carvalho, a ceramics scale-up consultant. “When furnace profiles, binder systems, SPC guardrails, and failure analytics arrive as a coherent playbook, stabilization is measured in weeks—not quarters.” (Source: Industrial Ceramics Implementation Review, 2024)

Application mapping for Brazilian conditions and expected outcomes

Practical pairings of SiC grades, engineering focus, and field results

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Typisch resultaat |

|---|---|---|---|---|

| Iron ore and bauxite hydrocyclones | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, reinforced apex | 2× wear life, 3–4% efficiency gain |

| Pre-salt pump mechanical seals | Chlorides, P–T cycling | SSiC | Optical-flat lapping, counterface pairing | API-aligned leak-off, 1–2% lower power |

| Fertilizer elbows and chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction, planned PM |

| High-temperature fixtures and blocks | Thermal shock, low mass | R-SiC | Lightweight geometry, stable porosity | Faster cycles, fewer thermal cracks |

These mappings translate lab properties into predictable outcomes that planners can bank on, allowing tighter stocking strategies and smoother maintenance windows.

Silicon carbide grades: engineering deep-dive for specification teams

Comparative properties of R-SiC, SSiC, and RBSiC/SiSiC for Brazilian buyers

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elasticiteitsmodulus (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Weerstand tegen thermische schokken | Hoog | Zeer hoog | Hoog |

| Corrosion Resistance (chlorides/acids) | Uitstekend | Zeer goed | Goed |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | Mechanical seals, bearings | Cyclones, nozzles, liners | Burner blocks, kiln furniture |

| Cost-to-Performance Fit | Premium for critical service | Balanced for high-wear | Efficient for thermal/structural |

By codifying these parameters into ABNT-referenced specifications and acceptance criteria, Brazilian engineering teams shorten internal approvals and de-risk pilot deployments.

Future market opportunities and 2025+ trends: silicon carbide at the center of industrial upgrades

Brazil’s next phase of industrial growth will be measured by availability, energy intensity, and documentation credibility. Mining incumbents are targeting lower kWh per ton and fewer unplanned stoppages; offshore operators are tightening reliability targets to curb production deferrals; agribusiness processors are aiming for predictable campaigns across harvest peaks. Materials that preserve dimensional integrity and surface finish under mixed-mode stress support these objectives directly. Furthermore, macro dynamics favor localized capability: FX volatility, geopolitical shipping risk, and local content preferences push buyers toward domestic production cells for critical parts.

Digitalization will intensify across plants and platforms. Components that maintain tolerances and smoothness generate cleaner condition-monitoring signals and fewer false alarms, enhancing predictive maintenance and extending lead time to intervention. Analysts expect mid-single-digit growth for advanced technical ceramics in Brazil through 2027, with SiC outpacing due to mining expansions, pre-salt investments, and process industry modernization. Suppliers who combine material performance with training, documentation, and technology transfer will capture disproportionate value. Sicarbtech’s integrated model—materials science, application engineering, and turnkey factory establishment—aligns precisely with 2025 procurement logic.

Frequently asked questions

How does Sicarbtech align SiC components with ABNT, ANP, and IBAMA requirements?

Sicarbtech designs with reference to API 610/682 for pumps and seals and evaluates sour service per NACE MR0175/ISO 15156 where applicable. Material characterization follows ISO methods cross-referenced to ABNT NBR expectations, and traceability plus inspection records are formatted for ANP workflows. Environmental and safety documentation supports IBAMA licensing and relevant NR norms.

Can Sicarbtech localize SiC manufacturing in Brazil through technology transfer?

Yes. We deliver complete process recipes, equipment specifications, operator and QC training, SPC frameworks, and on-site commissioning for R-SiC, SSiC, RBSiC, and SiSiC. The result is audit-ready domestic capability with stable yields and preserved performance.

Which SiC grade is best for mechanical seal faces in chloride-rich service?

SSiC typically offers the optimal mix of near-zero porosity, chloride resistance, and ultra-flat lapping capability. Final selection considers pressure-temperature cycles, counterface materials, and flatness retention under operating loads.

What ROI can mining sites expect from upgrading hydrocyclones?

Most operations report 2× service life and 3–4% efficiency gains, leading to fewer emergency shipments, reduced safety stocks, and improved energy intensity. Payback commonly falls within 6–12 months depending on slurry chemistry and duty cycle.

Do SiC components help meet ESG and energy intensity targets?

They do. Smoother surfaces and tighter clearances reduce hydraulic losses and leakage, directly lowering kWh per m³ pumped and stabilizing process efficiency—benefits that feed into ESG scorecards and financing terms.

Can Sicarbtech engineer drop-in replacements without redesigning surrounding equipment?

Often yes. We produce SiC inserts and liners that match existing envelopes and mounting features, and propose subtle geometry optimizations to enhance performance without requalifying adjacent hardware.

How does Sicarbtech accelerate vendor qualification with Brazilian majors?

We provide comprehensive data packs—chemical and physical properties, NDT, dimensional checks, surface finish evidence, SPC charts, and full traceability—formatted to ABNT and ANP expectations, which shortens approval cycles and eases audits.

What local support is available after installation?

Sicarbtech offers remote engineering assistance, periodic site visits via Brazilian partners, and continuous improvement reviews. We co-develop stocking strategies aligned with planned shutdowns and harvest seasons to mitigate logistics risk.

Are there cost-optimized SiC options for less critical services?

Yes. RBSiC and R-SiC offer strong cost-to-performance ratios where extreme corrosion resistance or ultra-flat finishes are not mandatory. We model lifecycle economics to recommend the right grade for each application.

What information do you need to start a custom SiC design?

Media chemistry, particle size distribution, operating temperature and pressure ranges, duty cycles, failure history, target service life, and CAD drawings. We work under NDA and follow a structured design-for-manufacture and validation plan.

Making the right choice for your operations

Choosing custom silicon carbide is a practical decision to stabilize process economics and compliance. With Sicarbtech, Brazilian operators access advanced grades—R-SiC, SSiC, RBSiC, SiSiC—paired with application engineering, precision finishing, and audit-ready documentation that turns specifications into field results. Whether your goal is to extend hydrocyclone life in Pará, secure seal reliability offshore, or manage corrosive abrasion in fertilizer handling, Sicarbtech aligns materials, geometry, and quality systems with Brazil’s operational realities.

Get expert consultation and custom solutions

Speak with Sicarbtech’s engineering team to translate your duty conditions into a validated SiC solution and a credible ROI case. We will align specifications with ABNT, ANP, and IBAMA requirements and, if strategic, design a technology transfer and factory establishment roadmap to localize capability and compress lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Metagegevens artikel

Last updated: 2025-09-22

Volgende geplande update: 2025-12-15

Content freshness indicators: 2025 Brazil market outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables validated; Brazil-specific case studies updated; technology transfer section expanded with ISO alignment and SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.