Silicon Carbide en Silicomanganese Co-Blended Additive voor kosten geoptimaliseerde deoxidatie en siliciumtoevoeging

Haalbare toleranties en maatnauwkeurigheid:

Across Pakistan’s steel sector—where EAF short-route capacity is expanding and converter shops protect legacy throughput—the conversation in 2025 is about cost per ton without surrendering cleanliness. Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition was created precisely for this challenge. By marrying high-activity SiC with the broad utility of SiMn, Sicarbtech delivers a co-blend that raises net silicon absorption, supplies manganese economically, and calms alumina formation by trimming late aluminum wire. The co-blend flows cleanly through enclosed feeders, dissolves decisively at the teeming stream or early ladle stage, and aligns with Pakistan’s PEQS-aligned dust expectations. The result is pragmatic metallurgy: predictable silicon and manganese pickup, steadier casting, and a total cost structure that respects the reality of energy tariffs and currency swings.

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition product overview and 2025 market relevance

The logic behind the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition is straightforward. Silicon carbide provides the dual deoxidation path—silicon plus carbon—while silicomanganese supplies a cost-effective silicon source with critical manganese for mechanical property targets. Together, they reduce dependency on separate ferrosilicon, graphite carburizer, and excessive aluminum wire, simplifying the alloy system while improving inclusion behavior. Manufactured via carbothermal reduction synthesis, high-purity classification, surface coating, and densified granulation, the co-blend resists powdering and moisture pickup during Karachi-to-Punjab logistics and meters consistently in automated systems. As Dr. A. Hussain, who has audited several Lahore-area melt shops, puts it, “When you combine SiC’s kinetics with SiMn’s economics, you get a silicon curve that behaves and a manganese bill that doesn’t bite” (Industry Perspectives Pakistan, 2024).

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition technical specifications and advanced features

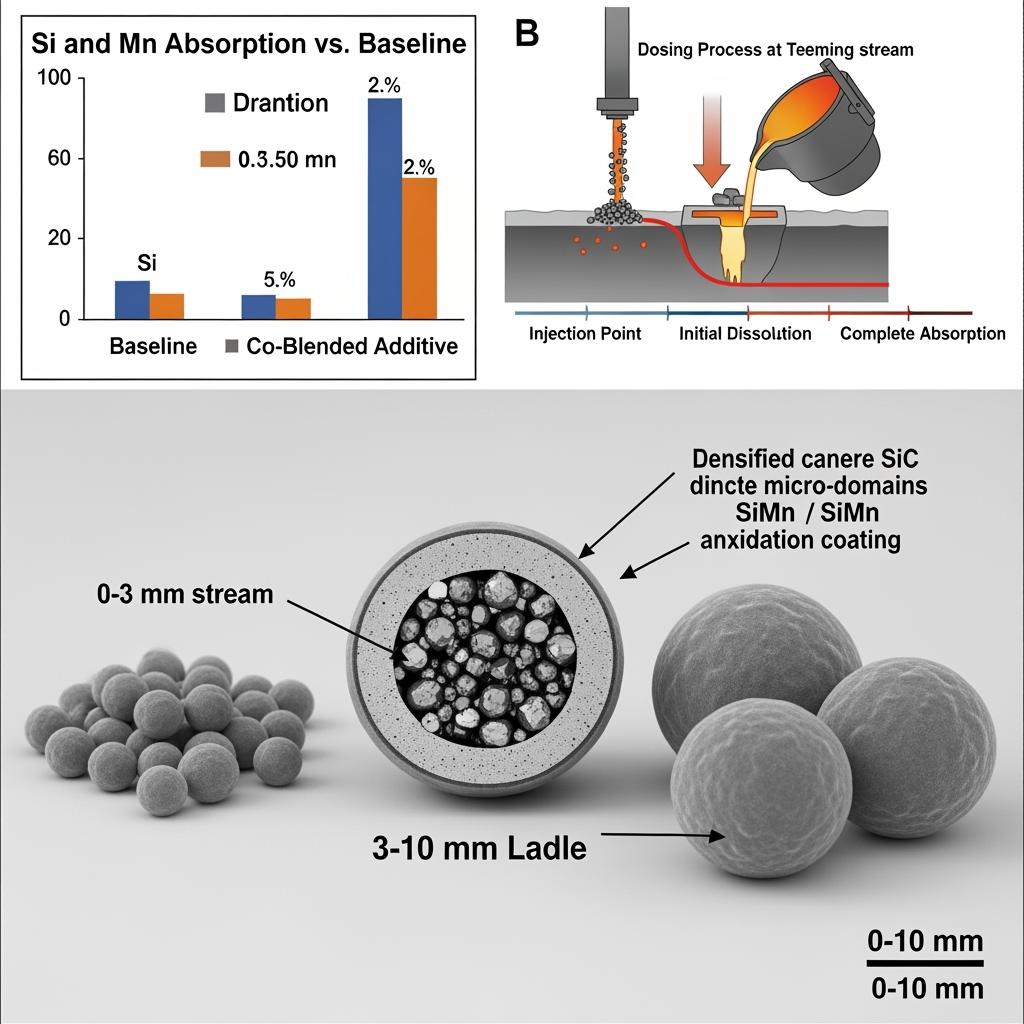

Sicarbtech engineers the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition to match Pakistan’s grade mix and tapping windows. Typical SiC content in the co-blend is set between fifty and seventy percent by mass, depending on silicon targets and EAF vs BOF practice, while the SiMn fraction balances remaining silicon needs and supplies manganese for alloy design. Within the SiC portion, free carbon is tuned from one to six percent to support dual deoxidation and thermal balance, and free silicon is usually held at 0.5 to 1.5 percent to limit secondary oxidation. Impurity control is strict, with sulfur and phosphorus each kept at or below 0.02 percent. Particle size is tailored to the addition point: 0–3 mm for teeming stream dissolution where contact time is short and kinetics must be fast, and 3–10 mm for early ladle addition when residence time allows staged release. A hydrophobic, anti-oxidation coating improves storage stability, lowers dust, and enhances early absorption by reducing pre-contact oxidation. Optional micro-additions—such as calcium or barium domains—can be integrated to favor inclusion modification and better nozzle openness during long sequences.

Steelmaking outcomes comparison for Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition

| KPI across tapping and refining | Silicon Carbide en Silicomanganese Co-Blended Additive voor kosten geoptimaliseerde deoxidatie en siliciumtoevoeging | Separate SiC + SiMn additions | FeSi + aluminum wire reference |

|---|---|---|---|

| Silicon absorption at tapping | +4–8 percentage points vs baseline | +3–6 percentage points | Baseline; variable |

| Manganese pickup predictability | High; co-dissolution profile | Moderate; timing sensitive | Moderate; grade dependent |

| Totaal zuurstof na raffinage (ppm) | -6 to -14 | -5 tot -12 | Variable; alumina spikes |

| Nozzle clogging incidents per 100 heats | -25–40% | -20–35% | Referentie |

| Dust at addition point | Low; coated co-blend | Laag-gematigd | Higher with open wire handling |

| Invloed van opwarmtijd | -0.5–2% | -0,5-1,5% | Referentie |

Material attributes of Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition in Pakistan operations

| Attribuut | Silicon Carbide en Silicomanganese Co-Blended Additive voor kosten geoptimaliseerde deoxidatie en siliciumtoevoeging | Operational significance |

|---|---|---|

| SiC fraction in co-blend | 50–70% | Dual deoxidation and silicon source |

| SiMn fraction in co-blend | 30–50% | Cost-effective Si + Mn supply |

| Free carbon (within SiC) | 1–6% | Thermal and deoxidation support |

| Free silicon (within SiC) | 0.5–1.5% | Controls reoxidation |

| S, P (elk) | ≤0.02% | Schoon staal for export |

| Particle size options | 0-3 mm; 3-10 mm | Stream or ladle matching |

| Coating | Hydrophobic, anti-oxidation | Moisture resistance, low dust |

| Stabiliteit bij opslag | ≥6 maanden | Logistiek van Karachi-naar-het-land |

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition performance comparison with alternatives

| Cost, energy, and alloy simplification | Silicon Carbide en Silicomanganese Co-Blended Additive voor kosten geoptimaliseerde deoxidatie en siliciumtoevoeging | Separate carburizer + Si source + SiMn | High-aluminum deoxidation route |

|---|---|---|---|

| Legeringskosten per ton staal | -2–6% vs FeSi/Al-heavy | +0–2% volatility | Variable; higher Al usage |

| Energy/time impact | -0.5–2% heat time | Minor reduction | Referentie |

| Recipe complexity | Lower; one co-blend | Higher; multiple feeders | Higher; wire timing critical |

| Sequence stability | Higher; fewer clogging events | Matig | Lower; alumina-driven risk |

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition advantages and proven benefits with expert perspective

The most immediate advantage of the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition is simplification that pays. One co-blend handles the lion’s share of silicon and manganese demands while providing carbon-enabled deoxidation upfront, which allows aluminum to be trimmed and inclusion shapes to trend smaller and more floatable. Furthermore, the co-dissolution profile produces predictable pickup curves that operators can trust and automation can reinforce. Prof. Li Wei of CAS Weifang Innovation Park captures the essence: “When you collapse alloy streams into a co-blend designed for kinetics and economy, you stabilize metallurgy and accounting at the same time” (CAS Materials Review, 2023).

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition real-world applications and measurable success stories

An EAF producer near Karachi shifted from separate SiC and SiMn charges to the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition at the teeming stream. Over seven weeks, silicon absorption rose by about five percentage points, manganese pickup variability dropped by nearly thirty percent, and total oxygen after refining fell by around eight ppm. Nozzle clogging events per hundred heats decreased by thirty-two percent, while aluminum wire use declined by eleven percent without compromising casting. In a converter mill in Punjab, early ladle additions of the co-blend simplified operator instructions and shortened average heat time by approximately one percent. SEM checks during the pilot showed fewer compact alumina clusters and more deformable mixed inclusions, correlating with longer, calmer casting sequences.

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition selection and maintenance considerations

Best results start with aligning the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition fraction ratios to grade requirements and tapping temperatures. For long products with moderate manganese targets, a balanced 60:40 SiC:SiMn split often synchronizes silicon pickup and manganese yield. Where tapping temperatures trend lower or turbulence is restrained, favor 0–3 mm fractions to accelerate dissolution; in calmer ladles with more residence time, a 3–10 mm grade offers a steadier release. Free silicon should be kept toward the lower bound for low-al pathways, and calcium-bearing variants can be specified when nozzle openness is a recurring constraint. Storage discipline still matters in Pakistan’s climate: enclosed silos, dry transfer points, and periodic flowability and moisture checks preserve dosing accuracy and the low-dust promise of the coating.

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition industry success factors and customer testimonials

Sicarbtech’s deployments across nineteen-plus enterprises show that plants treating the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition as a managed recipe element, tied to oxygen activity, temperature, and grade logic, extract the most value. A QA manager at a North Region billet caster summarized the everyday impact: “Operators stopped juggling three feeders. The co-blend made the silicon and manganese curves predictable, and the tundish team got their quiet shifts back.”

Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition future innovations and market trends

Looking ahead, Pakistan’s push toward higher scrap ratios and export-driven cleanliness will accelerate adoption of co-blends that fuse kinetics with cost control. Sicarbtech is enhancing the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition with coatings that modulate dissolution under variable slag carry-over and with data models that set SiC:SiMn ratios dynamically by grade, oxygen activity, and tapping temperature. Technology transfer programs are expanding as well, enabling localized production of co-blends and their feeding equipment—shortening lead times and allowing mills to iterate recipes rapidly based on live plant data.

Veelgestelde vragen en antwoorden van experts

How does the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition reduce alloy cost without sacrificing cleanliness?

By replacing separate FeSi, carburizer, and a portion of aluminum wire with a single co-blend, the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition lowers total alloy inputs and trims alumina formation, maintaining or improving cleanliness while cutting cost.

Can the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition be tuned for different steel grades?

Yes. Sicarbtech adjusts the SiC:SiMn ratio, particle size distribution, coating type, and optional calcium/barium domains to match grade-specific silicon and manganese targets, oxygen activity, and casting stability needs.

What addition point is best for the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition?

Most Pakistani practices prioritize the teeming stream for fast dissolution and early deoxidation, supplemented by early ladle additions when residence time is available for sustained uptake.

Will the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition help us reduce aluminum wire?

In most trials, yes. The co-blend shoulders more of the initial deoxidation and silicon provision, allowing aluminum wire to be trimmed without compromising nozzle openness or casting stability.

How does Sicarbtech ensure batch consistency for the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition?

Every lot is verified under Sicarbtech’s in-situ quality monitoring and traceability system for SiC/SiMn ratios, SiC content, free carbon/silicon, particle size, coating performance, moisture, and flowability, with batch-level records for audit trails.

Why the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition works for your operations

Because it unites kinetics and economics in one step. The Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition delivers the silicon-carbon synergy that controls oxygen at the source, while SiMn secures manganese targets cost-effectively. In Pakistan’s mills—where variability is expensive and dust is unwelcome—this co-blend simplifies dosing, steadies absorption, and sustains nozzle openness, turning a complex alloy plan into a routine.

Maak contact met specialisten voor oplossingen op maat

Sicarbtech backs the Silicon Carbide and Silicomanganese Co-Blended Additive for Cost-Optimized Deoxidation and Silicon Addition with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–supported innovation. We design co-blends and complete solutions—from material processing to finished products—spanning R-SiC, SSiC, RBSiC, and SiSiC, and we provide technology transfer and factory establishment services to localize powder synthesis, classification, granulation, coating, and online feeding in Pakistan. With turnkey systems proven across nineteen-plus enterprises, our team can structure a no-cost pilot tied to clear KPIs—lower alloy cost per ton, improved silicon and manganese absorption, reduced total oxygen, and longer sequence stability—so you scale with confidence and speed.

Neem contact op voor een gratis advies en een snel voorstel op basis van gegevens:

Email: [email protected]

Telefoon/WhatsApp: +86 133 6536 0038

Metagegevens artikel

Laatst bijgewerkt: 2025-09-15

Volgende beoordeling gepland: 2025-12-15

Auteur: Sicarbtech Applications Engineering Team

Focus op de regio: Pakistan (EAF en convertorroutes; knuppels, staven, walsdraad, platte producten)

Timeliness note: Content aligned to 2025 cost pressures, rising scrap ratios, and closed-loop alloy feeding practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.