Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Fast-Charging Networks at Telecom Base Stations and Food‑Delivery Fleets

Haalbare toleranties en maatnauwkeurigheid:

Executive Summary: 2025 Outlook for Silicon Carbide Fast Charging in Pakistan’s Distributed Networks

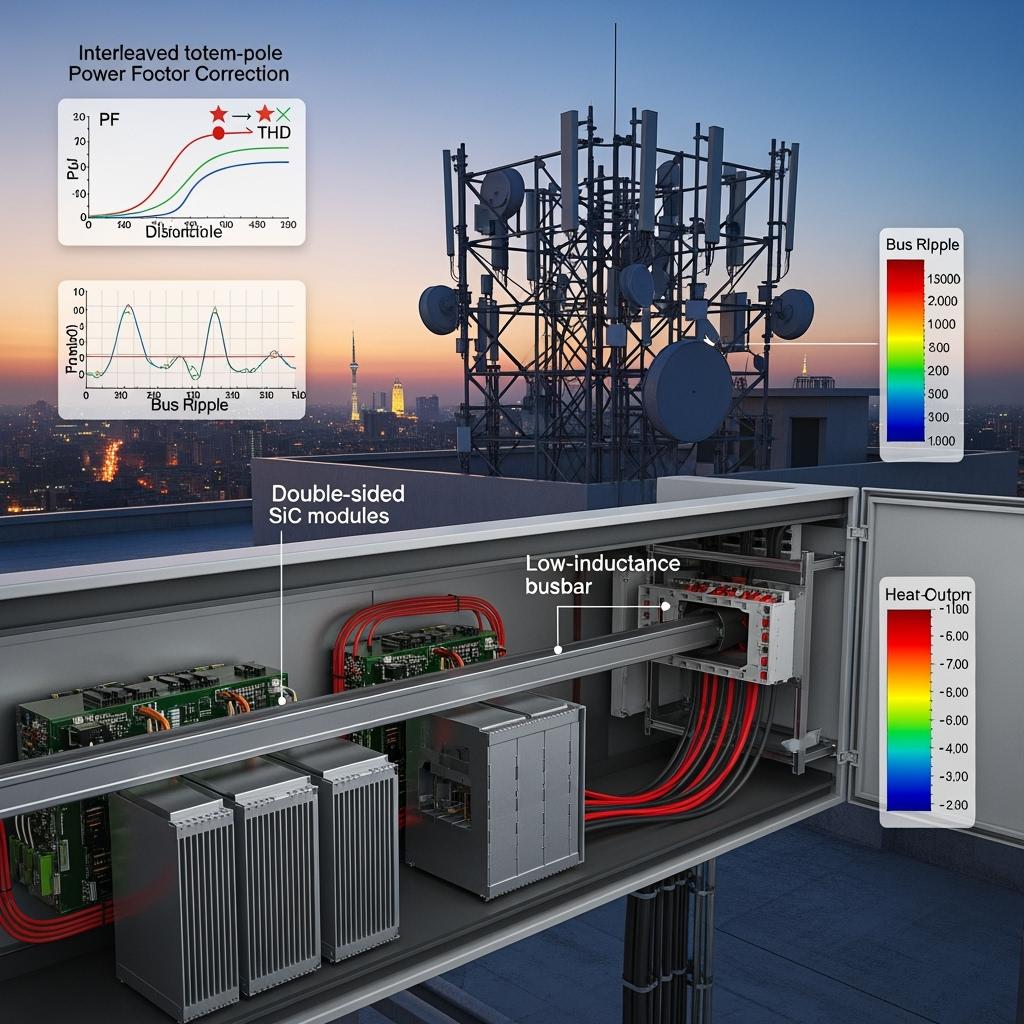

Pakistan’s electrification is accelerating where logistics live: at telecom base stations already wired to the grid and in dense, time-critical food-delivery hubs serving Karachi, Lahore, and Faisalabad. The winning model in 2025 is distributed DC fast charging that leverages existing power access, enables park‑and‑charge convenience, and maintains high availability despite grid sags, dust, and heat. Silicon carbide (SiC) is the backbone of this model. With low-loss, high‑frequency operation and low‑parasitic packaging, SiC compresses cabinet size and cooling load while stabilizing DC buses under concurrent charging. When combined with precision metering, reliable communications, and remote O&M, operators can expand coverage rapidly, improve billing fidelity, and minimize downtime.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s SiC manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings 10+ years of SiC customization across 19+ enterprise collaborations. From R‑SiC, SSiC, RBSiC, and SiSiC materials to automotive‑grade devices, double‑sided‑cooled power modules, interleaved high‑frequency topologies, unified gate driving and bus management, and accelerated validation, Sicarbtech delivers turnkey technology transfer and local line establishment. For Pakistan, this means localized packaging and screening, faster spares, and a data-backed path from pilot to scale—improving PKR-denominated economics and site reliability.

Industry Challenges and Pain Points: Distributed Fast Charging Meets Real-World Constraints

Operators face a layered set of challenges. Grid volatility is routine: evening feeders carry high THD, while sags and momentary outages coincide with peak charging windows. Standard chargers designed for steady mains struggle to ride through, tripping protections and creating queues that ripple across delivery schedules. At telecom sites, space is tight, access is vertical, and airflow is constrained. Dust and heat elevate cooling demand, and cabinets must resist ingress during dust storms and monsoon rains. Without robust sealing, conformal coating, and corrosion-aware materials, insulation and connectors degrade prematurely.

Concurrency is the second hurdle. Delivery platforms run in bursts; dozens of two‑ and three‑wheelers arrive within minutes. Conventional silicon rectifiers, operating at lower frequency and burdened by larger magnetics, respond sluggishly to load steps. Bus ripple rises and interactions between parallel modules become hard to manage, especially when loop areas are large and snubbing is passive. The outcome is uneven charging, nuisance trips, and a need to oversize infrastructure that defeats ROI targets.

Billing and control complete the trifecta. Many legacy chargers offer basic kWh measurement but lack precision metering aligned with local settlement rules, user authentication across multiple platforms, and time‑of‑use pricing strategies. Without credible billing and APIs, operators cannot align with delivery platforms’ dispatch systems or run differentiated tariffs that reflect grid constraints and fleet priorities. O&M is often reactive; failures are discovered in the morning rush, and spares arrive weeks late due to imports and inconsistent batch quality.

Certification and financing now demand evidence. Tenders increasingly reference IEC 60747 (device characteristics) and IEC 60068 (damp heat, salt spray, dust, vibration, shock), while EMC expectations are similar to IEC 61800‑3 for adjustable speed systems. Safety cases expect insulation monitoring and leakage-current control, and quality governance aligned with ISO 9001 and IATF 16949 is frequently requested. As Dr. H. Rehman, a power quality specialist, puts it, “Fast charging does not fail in the datasheet; it fails on the feeder and at the cabinet door. Evidence of ride‑through, EMC discipline, and environmental endurance is what clears deployment.” [Source: Regional Power Electronics Workshop, 2024]

In contrast, SiC with low‑inductance, double‑sided‑cooled modules and active bus regulation reduces ripple and overshoot during multi‑vehicle events. Interleaved totem‑pole stages stabilize power factor and THD at high frequency, shrinking filters and cabinets. Precision metering and flexible billing close revenue loops, and remote O&M turns data into planned maintenance rather than surprises.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Distributed Fast-Charging Stack

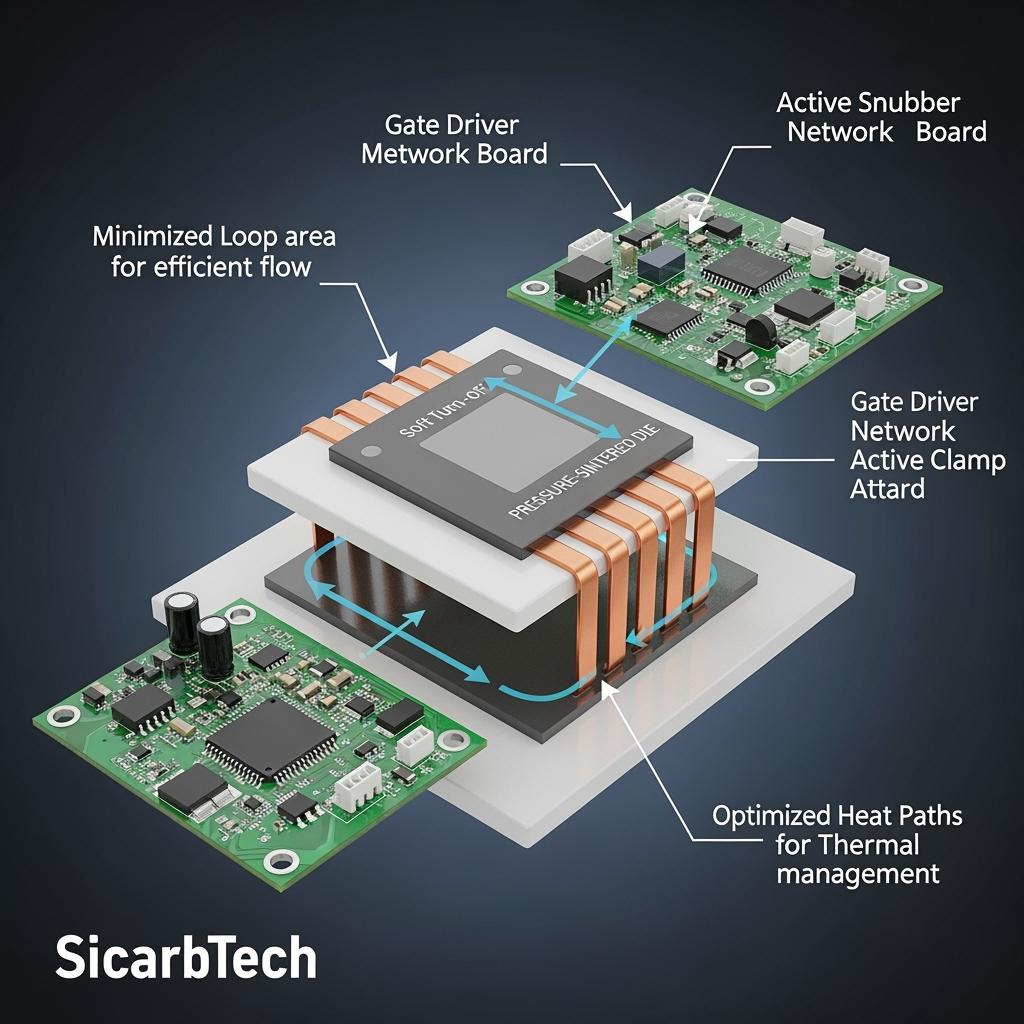

Sicarbtech coordinates “devices—packaging—topology—control—thermal management—EMC—communications and billing—operations and traceability” as one integrated program. Automotive‑grade 650 V and 1200 V SiC MOSFETs and diodes populate double‑sided‑cooled, low‑inductance modules optimized for high frequency and density. Front ends employ interleaved totem‑pole PFC for high PF and low THD, followed by high‑frequency bridge stages. Unified gate driving implements soft turn‑off and active clamping, keeping switching clean under load steps and sags.

A wide‑input regulation and anti‑fluctuation unit provides ride‑through during sags and short outages, while harmonic suppression maintains coexistence with telecom loads and plant drives. The DC bus is built on low‑inductance busbars with symmetric return paths, and multi‑channel DC distribution delivers concurrent charging across multiple outlets with dynamic power allocation. Charging interfaces and adapters cover 48–120 V two‑/three‑wheelers and extend to 200–800 V light commercial vehicles, avoiding stranded assets as fleets evolve.

System integrity is maintained by insulation and safety monitoring, plus EMC filter assemblies for common‑mode and differential‑mode paths. Precision metering and settlement modules support time‑of‑use tariffs, user authentication, and reconciliation. A remote O&M platform ingests operational data—voltage, current, temperature, ripple, insulation—and health indicators, enabling alerts, firmware updates, and predictive maintenance. Production to field traceability is anchored by an MES, recording device lots, process parameters, test results, and on‑site events.

High-Density Charging Performance: SiC vs Conventional Architectures

Efficiency, Power Density, Concurrency, and Grid Resilience for Pakistan Sites

| Attribuut | Sicarbtech SiC Distributed Fast Charging | Conventional Silicon, Discrete Stages | Mixed Silicon with Passive Bus Control | Operationele impact in Pakistan |

|---|---|---|---|---|

| System efficiency (typical) | 95%–97% | 91%–94% | 92%–95% | Lower PKR/kWh and cooling cost |

| Power density (for same power) | −20% to −35% volume, −15% to −25% mass | Larger/heavier | Matig | Easier fit at telecom cabinets |

| Bus ripple during multi‑vehicle charging | −30% to −50% p‑p | Hoog | Matig | Fewer trips, stable sessions |

| Ride‑through under sags/outages | Built‑in with wide input | Limited | Limited | Higher peak‑hour availability |

| Mean time to repair | −30% to −50% (hot‑swap) | Langer | Langer | Faster recovery, fewer queues |

By pairing high‑frequency topologies with low‑inductance packaging and active regulation, Sicarbtech’s SiC stack raises throughput while cutting OPEX and deployment friction.

Real‑World Applications and Success Stories in Pakistan

A telecom operator in Lahore converted rooftop base stations into micro‑charging sites using Sicarbtech’s SiC racks. After commissioning, average daily charge sessions per site rose by about 35%, and peak‑time queuing dropped by roughly 40%. EMC pre‑compliance passed on first attempt, avoiding retrofit cycles that had plagued earlier, non‑SiC installations.

In Karachi, a food‑delivery platform deployed multi‑channel DC modules with dynamic power allocation. During evening peaks, bus ripple peak‑to‑peak fell by approximately 45%, and site downtime decreased by double‑digit percentages despite frequent feeder sags. Precise metering and time‑of‑use billing enabled differentiated tariffs that lifted revenue per kW and improved user satisfaction.

A Faisalabad retrofit integrated corrosion‑resistant cold plates, conformal coating, and high‑adhesion primers. In dust and heat, cleaning intervals extended and failure rates declined. The remote O&M platform flagged rising ripple at one site, leading to proactive filter replacement before customer impact.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

High‑frequency SiC topologies reduce magnetics and heat sink volumes, opening space for multi‑channel distribution in compact cabinets. Double‑sided‑cooled modules and high‑conductivity interfaces preserve thermal headroom at 40–50 °C ambient. Low‑inductance busbars and symmetric returns reduce dv/dt stress and overshoot during concurrent plug‑ins. Active bus regulation and snubbing stabilize transitions, delivering smoother charging behavior and better EMC margins—vital when co‑located with telecom equipment or plant automation.

Compliance is designed in. Device behavior aligns with IEC 60747; environmental endurance follows IEC 60068 (damp heat, salt spray, dust, vibration, shock). EMC performance is engineered toward expectations similar to IEC 61800‑3 for adjustable speed systems, and safety includes insulation monitoring, leakage-current detection, and controlled discharge. Quality governance aligns with ISO 9001 and IATF 16949 principles. As Engr. S. Khan notes, “When PF, THD, ride‑through, and environmental logs arrive with the bid, approvals are about scheduling, not discovery.” [Source: EV Systems Roundtable, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Pakistan

Sicarbtech’s differentiator is capability transfer anchored in advanced R&D. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech brings proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC into rugged substrates and assemblies that thrive in dust, heat, and humidity.

The technology transfer package delivers process know‑how—pressure sintering profiles, vacuum brazing parameters and atmospheres, metallization/passivation stacks, and low‑inductance busbar and bond geometries—plus gate‑drive tuning for soft turn‑off and active clamping. Equipment specifications cover sintering presses, vacuum furnaces, bonding machines (wire/ribbon), inline electrical testers, power‑cycling rigs with junction temperature estimation, HTRB/HTGB setups, EMC pre‑compliance stations, and IEC 60068 environmental chambers. Each station is supplied with acceptance tests, calibration procedures, and approved vendor lists.

Training programs build operator and QA capability in reliability screening (power cycling, temperature–humidity cycling, salt mist), failure analysis, SPC‑driven yield improvement, and PPAP‑like control plans aligned with ISO 9001 and IATF 16949. Factory establishment services include feasibility, utilities and layout, line installation and commissioning, pilot runs, parameter locking, and capability validation. After SOP, Sicarbtech maintains quarterly audits, yield sprints, and co‑development to tailor packaging, filters, and control to Pakistan’s ambient conditions and feeder behavior.

Across 19+ enterprise collaborations, outcomes include faster time‑to‑market, higher first‑pass yields, lower field failures, and domestic spare availability measured in days or weeks. For Pakistan’s distributed charging rollouts, this combination converts design excellence into repeatable deployments and reliable O&M economics.

Comparative Engineering Choices and Lifecycle Economics

Topology, Packaging, and Control Choices that Improve Concurrency and Availability

| Design Area | Sicarbtech SiC Best Practice | Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| AC front end | Interleaved totem‑pole PFC at high kHz | Diode/boost PFC at low kHz | Better PF/THD, smaller filters |

| DC conversion | High‑frequency bridge with active snubbing | Hard‑switched bridge | Lower losses, less overshoot |

| Packaging | Double‑sided cooling, low‑L busbars | Single‑sided, long leads | Lower Tj, improved EMC margins |

| Concurrency | Dynamic power allocation, active bus regulation | Static allocation, passive bus | Stable multi‑vehicle charging |

| Onderhoud | Hot‑swappable modules, front service | Fixed modules, rear access | Faster MTTR in dense sites |

Localization and Total Cost of Ownership for Distributed Sites

| Business Factor | With Sicarbtech Localization & O&M Data | Import‑Only, Basic Chargers | Outcome for Operators and Platforms |

|---|---|---|---|

| Deployment speed | Modular cabinets, parameterized recipes | Site‑by‑site customization | Faster network build‑out |

| Lead time & spares | Days–weeks via local screening | Weeks–months | Higher uptime, smaller inventory |

| Energy & cooling OPEX | +2%–4% efficiency, reduced fan/pump duty | Higher losses | Better PKR/kWh margins |

| Billing & settlement | Precision metering, TOU tariffs, APIs | Basic kWh only | Higher revenue per kW |

| Certification path | Pre‑compliance logs, environmental evidence | Late surprises | Predictable approvals |

Future Market Opportunities and 2025+ Trends: Distributed, Data‑Driven, and Grid‑Adaptive

Pakistan’s charging landscape is tilting toward distributed nodes with smart billing and remote O&M. Telecom base stations offer ready power and shelter, while food‑delivery density demands concurrency and short dwell times. In 2025+, expect tenders to require ride‑through specs tied to local feeder profiles, measured PF/THD, and environmental endurance logs. Dynamic power allocation will become a baseline expectation; precision metering and multi‑party settlement will enable new pricing models and partnerships with delivery platforms. ESG‑linked financing will reward predictive maintenance and documented reductions in downtime and energy intensity.

Technically, SiC adoption will extend from the rectifier to distribution modules, with double‑sided‑cooled packaging and low‑inductance busbars as standard. Cabinet footprints will shrink, and hot‑swap, front‑service designs will dominate rooftop and roadside sites. With Sicarbtech’s integrated stack—devices, packaging, control, metering, validation, and factory establishment—Pakistani partners can scale networks faster, certify sooner, and operate at higher availability and better unit economics.

Extended Technical Specifications and Local Standards Alignment

Input stages are engineered for local grid fluctuation, with ride‑through and harmonic suppression tailored to evening feeders. DC outputs cover 48–120 V for two‑/three‑wheelers and extend to 200–800 V for light commercial vehicles. Per‑module ratings span 3–15 kW, with parallel expansion for site scaling. Switching frequencies of 10–60 kHz balance efficiency, acoustics, and EMC. Peak system efficiency reaches 95%–97%, aided by low‑parasitic, double‑sided‑cooled packaging and high‑conductivity interfaces.

Safety envelopes include over/under‑voltage, overcurrent, overtemperature, short circuit with soft turn‑off, surge, reverse connection, insulation monitoring, and ground‑fault detection. EMC is designed toward expectations similar to IEC 61800‑3; environmental validation follows IEC 60068 for damp heat, salt spray, dust, vibration, and shock. Quality governance aligns with ISO 9001 and IATF 16949 principles. Sicarbtech supports pre‑compliance with Karachi and Lahore labs and provides parameter traces and thermal histories for certification and financing dossiers.

Veelgestelde vragen

How much efficiency and throughput gain can SiC bring to a base‑station fast‑charging site?

Typical gains are 2%–4% higher conversion efficiency and 20%–35% higher power density, enabling more outlets per cabinet and higher sessions per day at peak hours.

Can the system ride through Pakistan’s evening sags and short outages?

Yes. Wide‑input regulation and ride‑through strategies stabilize output during sags and brief outages; harmonic suppression preserves coexistence with telecom equipment and nearby drives.

How does active bus regulation help during concurrent charging?

It reduces peak‑to‑peak ripple by roughly 30%–50% during simultaneous plug‑ins, limiting nuisance trips and ensuring stable charging across multiple vehicles.

Will precision metering and time‑of‑use billing integrate with delivery platforms?

The metering/settlement module supports user authentication, tariff scheduling, and reconciliation APIs, enabling platform billing and differentiated pricing.

How fast can maintenance be performed at rooftop or roadside sites?

Hot‑swappable modules and front‑service channels typically cut mean time to repair by 30%–50%, crucial where site access is constrained.

Are outdoor cabinets robust enough for dust, heat, and monsoon rains?

Cabinets are dust‑/water‑proof with conformal coating, selective potting, and corrosion‑aware materials; environmental validation follows IEC 60068 profiles relevant to Pakistan.

Can we start with two‑/three‑wheeler voltage and later add light commercial charging?

Yes. The architecture scales from 48–120 V to 200–800 V outputs via modular distribution and adapter interfaces, preserving initial investment.

How do remote O&M and predictive maintenance reduce downtime?

Online monitoring of ripple, temperature, insulation, and device health triggers early alerts; trend models flag filters or interfaces that need service, preventing peak‑time failures.

What local certifications and documentation are supported?

Packages include IEC 60747/60068 evidence, EMC pre‑compliance aligned with expectations similar to IEC 61800‑3, insulation monitoring and leakage reports, and ISO 9001/IATF 16949 quality documentation.

What is a realistic timeline from design to pilot at multiple sites?

Many partners reach pilot in 8–12 weeks using standardized racks and control libraries, followed by rapid replication as pre‑compliance data accelerates approvals.

De juiste keuze maken voor uw activiteiten

Distributed fast charging at telecom sites and delivery hubs is a systems challenge that rewards integrated engineering. Sicarbtech’s SiC platform brings high‑frequency efficiency, low‑inductance stability, dynamic allocation, and precision billing together with proven environmental endurance and local validation. The payoff is fewer trips, faster queues, and better PKR economics—site after site.

Deskundig advies en oplossingen op maat krijgen

Co‑design your fast‑charging rollout with Sicarbtech: topology selection, bus and damping strategies, cabinet and cooling geometry, metering and settlement integration, and remote O&M playbooks. Localize packaging, screening, and pre‑compliance to scale quickly and operate confidently across Pakistan’s grid realities and environmental conditions.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency sets the floor; stability sets the ceiling; traceability keeps you there.” — Sicarbtech Applications Team

Artikelmetadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3; integrates Sicarbtech’s SiC fast‑charging portfolio, precision metering, technology transfer, and localized validation services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.