Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide to SiC Powders and Aggregates for Low-Cement Castables and Ramming Mixes

Haalbare toleranties en maatnauwkeurigheid:

Pakistan’s cement, staal, and glass sectors are moving into 2025 with a common priority: more uptime at lower energy per ton, delivered with fewer surprises in procurement and maintenance. In the hottest sections—combustion chambers, regenerators, reheat and soaking zones, preheaters, tuyeres, and flues—the quality of monolithic refractories determines how reliably heat turns into product. Conventional aggregate systems often buckle under alkali-bearing dust, redox cycling, and rapid thermal gradients, leading to spalling, premature porosity growth, and unpredictable bake-outs. Industrial silicon carbide (SiC) powders and aggregates, engineered for purity, multi-peak grading, surface activation, and compatibility with low-cement systems, reset that performance baseline. Sicarbtech—located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of SiC customization, full-cycle manufacturing, and turnkey technology transfer to help Pakistani plants localize supply and take control of outcomes.

Executive Summary: 2025 Outlook and Why SiC Powders/Aggregates Matter for Pakistan’s Monolithics

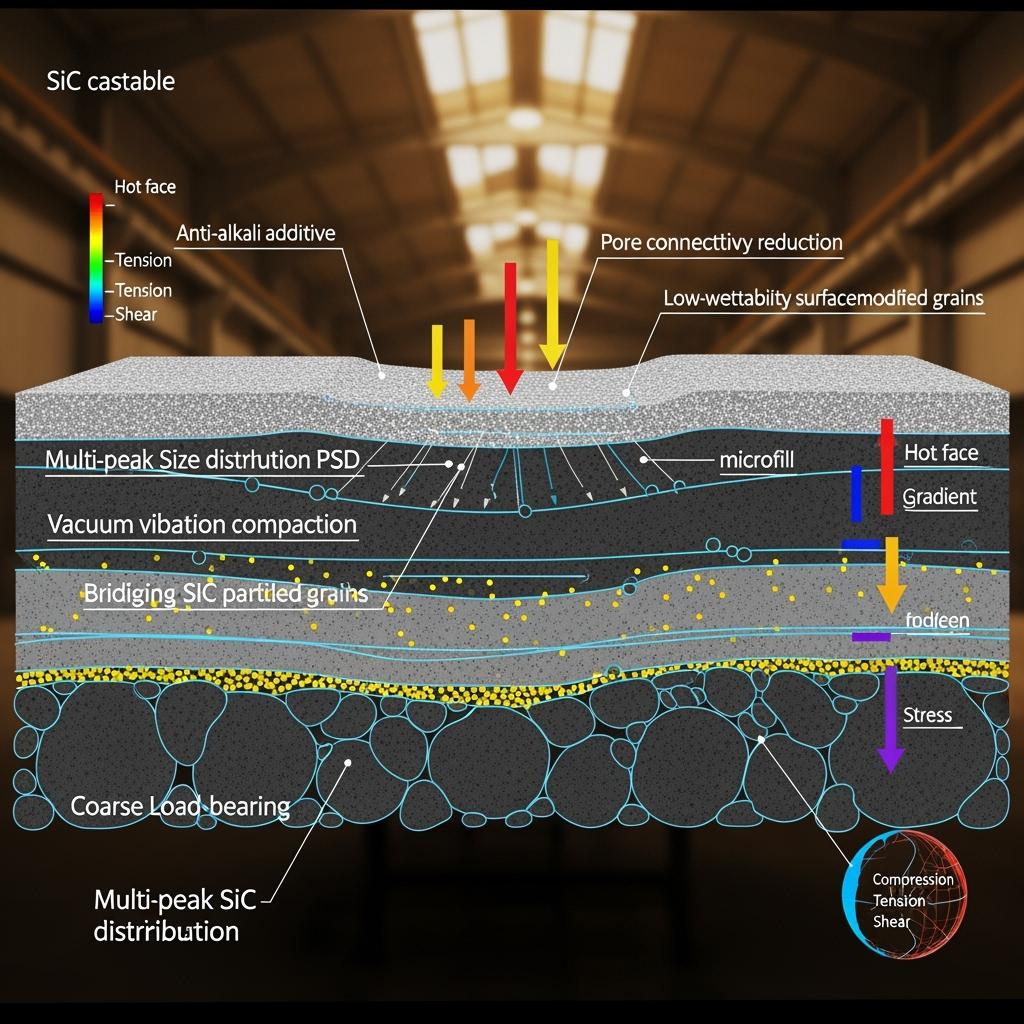

In kiln and furnace sections where temperatures soar and atmospheres swing, the refractories recipe is destiny. Low-cement castables and ramming mixes have become the preferred route for precise shapes, faster installs, and shorter bake-outs. Yet the devil is in the raw materials. Without high-purity SiC, tight particle-size grading, and surface activation tailored to low-cement systems, mixes bleed, segregate, or cure into porous matrices that let alkalis, sulfur, and chlorine win. SiC’s high thermal conductivity and low expansion accelerate heat equalization and shrink stress fields that drive cracks under start–stop cycling. When that physics is paired with multi-peak particle-size distributions, vacuum vibration, and functional additives, the result is dense, low-porosity structures with strong anti-permeation behavior and long thermal shock life.

Sicarbtech’s integrated workflow—“raw material purification + particle-size grading design + surface activation and coating + mixing and vacuum vibration + densification and post-firing performance control + onsite construction and bake-out curves + testing and life management”—is built for Pakistan’s realities. Through staged technology transfer, local teams can bring classification, demagnetization, mixing, surface modification, and programmed bake-outs in house, then expand to pressing/vibration forming and, when justified, reaction sintering for selected prefabs. That pathway compresses lead times, stabilizes quality through seasonal swings, and reduces exposure to FX volatility.

Industry Challenges and Pain Points: The Reality on Pakistani Kiln Floors and Furnace Decks

Talk to a maintenance crew in Punjab during a seasonal turnaround and the same problems recur. Generic aggregates arrive with drifting particle-size distributions and variable impurities; water demand spikes and workable time collapses in hot weather; bleeding and segregation create weak planes that show up later as spalls or edge chipping. In dusty, alkali-laden gas, capillary networks become highways for penetrants, turning modest porosity into accelerated chemistry and strength loss. Under frequent start–stop or co-firing regimes, thermal shock drives microcrack networks that propagate under vibration and mechanical handling. Bake-outs take longer than planned, risking steam-pressure damage if vent paths are not disciplined, and construction windows slip into production schedules.

Pakistan’s broader context compounds these micro-level issues. Capacity additions and retrofits in clinker lines, steel reheating/charging units, and glass furnaces are pushing more tonnage through more aggressive operating envelopes. Alternative fuels—refuse-derived fuels, low-rank coal, heavy oils—raise the stakes on alkali resistance, sulfur/chlorine tolerance, and low wettability to slags and condensed salts. Meanwhile, imports of high-purity, properly graded SiC can suffer long and variable lead times, challenging plants to keep consistent material on hand without over-tying working capital. “We could live with the heat, but not with inconsistency,” a Lahore-based cement reliability manager told us in a 2024 review. “When flow changes from batch to batch, you spend your day solving yesterday’s pour, not today’s plan.”

Independent experts are blunt about root causes. “Porosity and pore connectivity dominate how fast your chemistry and your cracks advance,” notes a regional refractory consultant, citing standard thermal shock and corrosion literature. “If your grading, activation, and densification reduce connectivity, and your conductivity/expansion manage gradients, you shift failure modes from sudden spallation to slow, uniform wear.” With tenders increasingly referencing ISO 9001-aligned quality documentation, PSQCA conformity, and ISO 14001-aligned environmental targets, it is no longer enough to buy a “SiC castable.” Plants need documented PSD, impurity limits, flow/bleeding windows, adhesion and bake-out protocols, and post-firing property data that auditors and operators can both trust.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

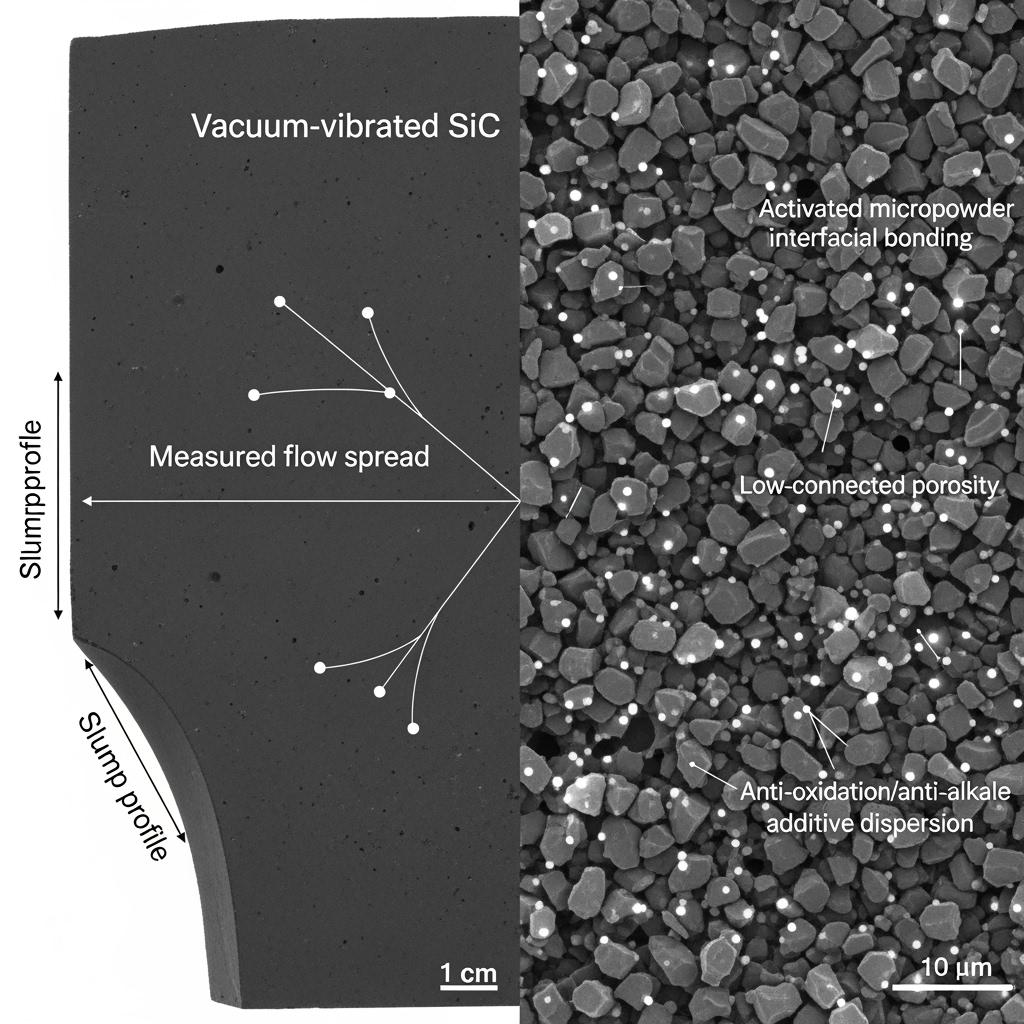

Sicarbtech’s SiC powders and aggregates portfolio is built to transform low-cement castables and ramming mixes from variable to predictable. At the core is a high-purity, multi-graded aggregate package that forms the skeleton. Carefully designed multi-peak PSD—from activated micropowder to wear-resistant coarse fractions—creates a microfill–bridge–load-bearing hierarchy that lifts green density and reduces connected porosity after cure and firing. Activated SiC micropowders, with tuned surface energy, enhance interfacial bonding in low-cement matrices and help widen the workable time window without sacrificing flow.

To tame chemistry, low-Na/low-K SiC fines and anti-alkali composite additives suppress low-melting phases and reactions with K₂O/Na₂O/SO₃/Cl⁻. An anti-oxidation additive system curbs high-temperature porosity growth, while low-wettability surface modifiers reduce slag wetting and adhesion for easier online maintenance. Where hotspots and ΔT spikes threaten, high-thermal-conductivity SiC heat-spreader powders even out temperature fields within the monolithic, lowering stress gradients.

Construction reliability is anchored by a low-cement dispersant and water-reducer package that balances flow with segregation resistance; an ultra-fine gap-filling grading package fine-tunes packing density and reshapes the flow window. For high-scour zones, wear-resistant coarse SiC aggregates bolster cutting resistance. Expansion-coordination micro-elastic phases introduce a controlled accommodation of thermal strain, reducing microcrack initiation. Rapid bake-out aids shorten the ramp and mitigate explosive spalling risk. To bring field agility, pre-mixed SiC ramming compounds support online gunning/patching with compatible chemistry to the parent lining.

Under the hood, the system is supported by precision classification and air-separation, high-efficiency demagnetization, intelligent metering and closed-loop mixing, surface modification and spray-coating lines, vacuum vibration and forming equipment, programmed drying/bake-out units, and nondestructive testing plus online PSD/impurity monitoring. “A great formulation poured poorly gives you poor results,” a Sicarbtech process engineer reminds clients. “We transfer not just powders but the metering, mixing, vacuum vibration, and bake-out discipline that make density and strength inevitable.”

Comparative Technical Performance of SiC-Based Monolithics vs Traditional Systems

| Performance profile for low-cement castables/ramming mixes | Sicarbtech SiC Powders/Aggregates System | Generic SiC or High-Alumina Baselines |

|---|---|---|

| Chemical purity (SiC, alkalis total) | SiC ≥ 90–98%; (Na₂O + K₂O) ≤ 0.30% | Wider ranges; alkalis often > 0.5% |

| Apparent porosity after cure/firing (%) | 8–16 (optimized ≤ 8 possible) | 12–22; connectivity higher |

| Bulk density after forming (g/cm³) | 2.60–3.00 | 2.30–2.70 |

| Cold crushing strength, cured/post-fired (MPa) | 100–220 / 130–260 | 80–180 / 100–210 |

| Flexural strength, cured/post-fired (MPa) | 10–30 / 14–35 | 8–20 / 10–25 |

| Thermal shock (1000°C quench, cycles) | ≥ 30–60 | 10–30 |

| Thermal conductivity at RT (W/m·K) | 18–48 | 8–25 |

| High-temperature linear change (3 h) | ≤ 0.5% | 0.6–1.0% typical |

| Flow spread (mm) | 220–280 (stable) | 180–240 (variable; bleed risk) |

| Workable time (min) | 30–90 (tunable) | 20–60 (narrow window) |

| Bleeding rate (%) | ≤ 0.5–1.5 | 1.5–4.0 |

Across Pakistani service conditions—dusty alkali-bearing atmospheres, redox cycling, frequent thermal shocks—the SiC system’s densification, purity, and conductivity deliver stable build quality and longer service life with fewer surprises at installation.

Real-World Applications and Success Stories in Pakistan

At a major cement producer’s preheater and upstream flue in northern Punjab, castables based on generic aggregates showed rising porosity and edge spalls within a season, pushing pressure-drop growth and cleanout frequency. The upgrade replaced the skeleton with Sicarbtech’s high-purity multi-peak graded SiC aggregates, layered in activated micropowder and a tuned low-cement dispersant package. Vacuum vibration and staged bake-outs were enforced, while anti-alkali additives and low-wettability modifiers were selected for alkali–chlorine indices measured onsite. Within the first campaign, apparent porosity fell from 12% to 8.2%; cold crushing strength rose by roughly 28%; thermal shock cycle life nearly doubled; pressure-drop growth rate dropped by about 30%; unplanned downtime reduced by around 22%; and unit energy consumption fell approximately 3.8%. “The pours got boring—that was the win,” the refractory contractor joked. “Same flow, same cure, same ramp—no drama.”

In a steel reheating furnace in Sindh, short workable time and bleeding caused honeycombing near tuyeres and frequent patching. The switch to activated SiC micropowder, low-Na/low-K fines, and a tighter gap-filling package widened workable time by about 35% at the same ambient conditions. Expansion-coordination microphases and rapid bake-out aids stabilized the ramp. Post-firing MOR and CCS gains translated into fewer microcrack-driven chips in high-velocity zones, and repair crews shifted from reactive to scheduled spot work.

Technische voordelen en implementatievoordelen met lokale naleving

Silicon carbide’s material physics align directly with Pakistani operators’ KPIs. High thermal conductivity spreads heat through the monolithic, shrinking gradients that seed cracks during start–stop and fuel swings. Low thermal expansion reduces strain when gradients do occur. High-purity SiC and multi-peak grading reduce connected porosity, starving alkalis and chlorides of permeation pathways. Surface activation and coating of micropowders improve binder interfaces, delivering strength without sacrificing workable time. Meanwhile, anti-alkali and anti-oxidation additive systems slow porosity growth during redox cycles, and low-wettability modifiers reduce slag wetting and adherence—an often-overlooked source of hot repairs.

From a compliance lens, predictable bake-outs and fewer interventions support ISO 14001 goals by lowering energy waste and scrap. Sicarbtech’s quality packs align with ISO 9001 and support PSQCA submissions in Pakistan, providing batch PSD certificates, impurity and demagnetization logs, flow/bleeding/viscosity windows, and post-firing CCS/MOR/porosity results. Construction SOPs—substrate cleanliness and roughness, water-to-binder control, vacuum vibration parameters, staged bake-out and soak curves—integrate with CMMS, turning every pour into an auditable, repeatable step.

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for SiC castables/ramming mixes | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| SiC mass fraction (%) | ≥ 90–98 (by service zone) | Certificate of analysis per batch |

| Alkalis total (Na₂O + K₂O) (%) | ≤ 0.30 | XRF/ICP and supplier SPC |

| Ferromagnetic impurities (%) | ≤ 0.05 (post-demag) | Magnetics log; demag records |

| Bulk density after forming (g/cm³) | 2.60–3.00 | Sample pucks per pour; SPC |

| Apparent porosity after firing (%) | 8–16 (≤ 8 in optimized zones) | Open porosity by ASTM/ISO |

| CCS, cured/post-fired (MPa) | 100–220 / 130–260 | ASTM C133/ISO 10059 equivalents |

| MOR, cured/post-fired (MPa) | 10–30 / 14–35 | 3-point bend; soak logs |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Correlate with start–stop logs |

| Thermal conductivity (W/m·K) | 18–48 | IR thermography validation |

| Linear change at temperature | ≤ 0.5% (3 h hold) | Dimensional checks pre/post |

| Flow spread (mm) | 220–280 | Ring/slump tests by ambient temp |

| Workable time (min) | 30–90 | Stopwatch and rheology logs |

| Bleeding rate (%) | ≤ 0.5–1.5 | Filter pad method; shift audits |

Operational Outcomes Comparison That Move Energy, Uptime, and Safety

| Outcomes central to Pakistani kiln/furnace operations | SiC Multi-Peak + Activated Micropowder + Low-Cement System | Generic Aggregate/Cement Baselines |

|---|---|---|

| Levensduur | 1.5–2.5× longer | Shorter; early spalling |

| Thermal shock stability | +50–150% cycles | Lower; crack propagation |

| Apparent porosity/connectivity | −2–5 points; −30–60% connectivity | Higher; faster penetration |

| Energy per ton | −2–6% | Higher with ΔP and repairs |

| Bake-out/return-to-service | Shorter, controlled venting | Longer; risk of steam damage |

| Flow/bleeding consistency | Stable windows; low bleed | Variable; segregation events |

| Ongeplande uitvaltijd | −20–40% | Elevated; reactive repair |

| Safety at heat | Fewer hot interventions | More hot patching cycles |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s edge is not only in powders and aggregates but in installing capability on Pakistani soil. Supported by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary manufacturing processes for R-SiC, SSiC, RBSiC, and SiSiC where needed, and, crucially for monolithics, a complete raw-material and process suite tailored to low-cement systems.

We begin with feasibility and factory layout keyed to local utilities, labor, and throughput. Equipment specifications include precision classification and air-separation for PSD control; high-efficiency demagnetization and tramp-iron removal; intelligent metering and closed-loop mixers to stabilize rheology; surface modification and spray-coating units for micropowder activation; vacuum vibration and forming rigs to lock in density; and low-temperature drying and programmed bake-out units. Nondestructive testing and online PSD/impurity monitors, plus XRF/ICP for chemistry and magnetics logs, anchor traceable QA.

Quality systems are embedded from the start. We implement ISO 9001-aligned QC with SPC on PSD, impurity levels (including alkalis and magnetics), flow spread and workable time, bleeding rate, density, CCS/MOR, porosity, and thermal shock performance. ISO 14001 environmental practices and safety SOPs aligned with ISO 45001 principles round out the framework. Training programs cover:

- PSD design logic and grading algorithms tied to target pore-size distributions.

- Surface activation/coating chemistry and contact-angle implications for flow and bonding.

- Mixing and vacuum vibration set-points vs ambient temperature and moisture.

- Staged bake-out curves and vent-path design to prevent steam-pressure failure.

- Field QA: flow, bleeding, adhesion cores, density pucks, and IR thermography for validation.

Commissioning includes supervised trial batches, on-site curve tuning, and first-of-kind pours by zone (e.g., preheater, tuyere belts, reheating hearths), followed by quarterly audits and formulation tuning linked to KPIs—cycle time, porosity, ΔP growth, repair frequency, and energy per ton. Through 19+ enterprise collaborations, this “materials + equipment + process + training” stack has reduced lead times from months to weeks, stabilized batch quality through monsoon humidity, and cut inventory buffers even amid FX volatility. As a Sicarbtech technical director frames it, “Owning a spec sheet is not capability. Owning PSD, activation, vacuum vibration, and the bake-out curve is how Pakistani teams turn SiC into schedule certainty.”

Comparative Design Elements: SiC-Optimized Monolithics vs Conventional Mixes

| Design and execution elements | Sicarbtech SiC-Optimized Monolithics | Conventional Mix Approach |

|---|---|---|

| PSD architecture | Multi-peak, algorithmic grading (microfill–bridge–load-bearing) | Single/two-peak; ad hoc substitutions |

| Micropowder interface | Activated/coated for low-cement systems | Unmodified; variable wetting |

| Chemistry control | Low-alkali; demag and decontamination logged | Impurity drift; weak traceability |

| Densification method | Vacuum vibration; set-point recipes | Manual vibration; variable outcomes |

| Additive suite | Anti-alkali, anti-oxidation, low-wettability, expansion-coordination | Generic deflocculants; limited chemistry suite |

| Bake-out regime | Programmed, staged; vent-path design | One-size-fits-all; steam spall risk |

| Field QA toolkit | Flow/bleed logs, density pucks, adhesion cores, IR maps | Visual checks; limited testing |

| Localization pathway | Full tech transfer and operator training | Vendor-dependent; sporadic support |

Innovation That Matters: From PSD Algorithms to Expansion Coordination

Sicarbtech’s innovation engine targets where monolithics fail. Our custom multi-peak grading algorithms reverse-design PSD to drive a target pore-size distribution and packing density that starves connectivity. Surface activation and coating on micropowders tune surface energy for wetting and bonding in low-cement matrices, widening workable time without adding water. Precision impurity control—demagnetization plus chemical decontamination—stabilizes high-temperature phase behavior and suppresses low-melting phases. Functional additive systems coordinate anti-alkali and anti-oxidation roles with micro-elastic phases that accommodate thermal strain and blunt microcrack initiation. Finally, process digitalization—online PSD, moisture, and magnetics monitoring with audit trails—turns variability into a measured, managed parameter.

Future Market Opportunities and 2025+ Trends in Pakistan

Three vectors define Pakistan’s near-term trajectory. First, energy and emissions pressure will keep pushing lines toward monolithics with lower porosity, better thermal shock, and shorter bake-outs—SiC-based, low-cement systems excel on all three. Second, alternative fuels and complex atmospheres will favor chemistries that resist alkali, sulfur, and chlorine attack; the combination of low-alkali SiC purity, anti-alkali additives, and low-wettability modifiers will become standard. Third, localization will accelerate to de-risk supply, stabilize quality, and align spares with production cycles; plants will start with classification/demag/mixing and surface activation, then add vacuum vibration and programmed drying, with selected reaction sintering for hybrid monolithic–prefab strategies as volumes justify capex.

In scale terms, a single 5,000–8,000 t/d clinker line or medium-to-large steel/glass unit typically consumes 100–300 tons per year of SiC powders/aggregates for low-cement castables and ramming mixes, depending on section and thickness. Nationally, Pakistan’s retrofit and expansion pipeline implies several thousand tons of annual demand. Including premixes, admixtures, field services, and enabling equipment/training, the addressable market sits in the tens to hundreds of millions of Pakistani Rupees, moderated by adoption speed and financing. Providers who combine stable raw materials, disciplined PSD and activation, onsite vacuum vibration/bake-out know-how, and audited QA will define the category. Sicarbtech’s integrated approach is purpose-built for this moment.

As a South Asia-focused refractory technologist noted in a 2025 panel, “When porosity falls and bake-outs stop breaking your heart, your energy, uptime, and safety graphs all move the right way—and that starts with the powder, not the patch.”

Veelgestelde vragen

What Sicarbtech SiC products are most impactful for low-cement castables and ramming mixes?

Prioritize the high-purity multi-graded aggregate package as the skeleton, then add activated SiC micropowder, low-Na/low-K fines, and the low-cement dispersant/water-reducer system. Layer in anti-alkali and anti-oxidation additives, low-wettability modifiers, and, for hot spots, high-thermal-conductivity heat-spreader powders. For construction reliability, use vacuum vibration and programmed bake-outs.

How much improvement can we expect in strength, porosity, and thermal shock life?

Typical gains include 10–30% higher CCS (15–35% post-firing), 15–40% higher MOR, 2–5 percentage point reductions in apparent porosity (with 30–60% lower connectivity), and 50–150% improvements in thermal shock cycles. In field results, service life extends by 1.5–2.5× with 20–40% fewer unplanned interventions.

Can Sicarbtech help localize PSD, activation, and mixing so we reduce FX exposure?

Yes. We transfer PSD recipes, classification/air-separation specifications, demagnetization protocols, surface activation/coating process sheets, closed-loop mixing parameters, vacuum vibration set-points, and programmed drying/bake-out curves—plus ISO 9001/14001-aligned QA systems and safety SOPs aligned with ISO 45001. Commissioning includes supervised first pours and quarterly audits.

How do SiC systems perform under alkali-bearing dust and redox cycling?

High-purity SiC with multi-peak grading reduces connectivity; anti-alkali additives and low-wettability modifiers slow chemical attack and slag wetting; anti-oxidation systems blunt porosity growth under oxygen exposure. Together, these preserve strength and dimensional stability across redox cycles.

What installation practices matter most to avoid bleeding, segregation, and steam spalls?

Control water-to-binder ratio; use intelligent mixing and immediate vacuum vibration to remove entrapped air and reduce closed pores; design vent paths; enforce staged bake-out and soak curves tied to moisture content; and verify with flow/bleed tests, density pucks, and IR thermography.

Which KPIs should we track to verify benefits and tune the recipe?

Monitor flow spread and workable time at pour, bleeding rate, density and porosity after cure/firing, CCS/MOR, thermal shock cycles, IR wall temperature uniformity, ΔP trends in flues, repair frequency, and energy per ton. Link these to PSD/impurity logs and ambient conditions.

Are SiC pre-mixed ramming compounds compatible with our existing monolithics?

Yes, when matched to the parent chemistry. We supply compatibility charts and can tailor ramming mix additives to ensure adhesion and CTE compatibility for in-shift patches and online gunning.

How do we manage expansion mismatch with adjacent refractory layers?

We tune expansion-coordination micro-elastic phases and select transition layers to harmonize modulus and CTE with backing refractories. Joint design and flexible shims at interfaces further mitigate stress concentrations.

What documentation supports Pakistani tenders and audits?

We provide batch PSD certificates, impurity/demagnetization logs, flow/bleeding windows, density/porosity and CCS/MOR data, thermal shock results, bake-out profiles, and installation SOPs. Packs align with ISO 9001 and ISO 14001, and we support PSQCA conformity documentation.

What is a realistic roadmap to full local capability?

Phase 1: classification/demagnetization, surface activation, mixing, vacuum vibration, and programmed drying with digital QC. Phase 2: pressing/vibration forming and expanded QA (NDT, IR). Phase 3: selective reaction sintering for hybrid prefab–monolithic strategies. We align capex, staffing, training, and QA gates with your schedule.

De juiste keuze maken voor uw activiteiten

If your monolithics are writing your maintenance calendar—and your fuel bill—then the aggregate is running your plant. Silicon carbide puts you back in charge. With high purity, engineered PSD, activated micropowders, and a disciplined low-cement process, SiC systems deliver denser structures, lower connectivity, better thermal shock life, and shorter, safer bake-outs. Sicarbtech’s integrated approach—materials, PSD algorithms, activation chemistry, vacuum vibration, programmed curves, and localizable QA—turns a mix design into predictable performance that Pakistani teams can plan, audit, and improve.

Deskundig advies en oplossingen op maat krijgen

Share your window—temperature profiles, atmosphere chemistry, dust loading, scour severity, start–stop cadence, flow/bleed data, and failure maps—and Sicarbtech will engineer a tailored SiC package with modeled porosity and strength targets, PSD and activation designs, additive suites, vacuum vibration parameters, and staged bake-out protocols. If localization is your goal, we will map a phased technology transfer with equipment specs, operator training, and certification support.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Telefoon/WhatsApp: +86 133 6536 0038

Artikelmetadata

Last updated: 2025-09-19

Volgende geplande update: 2026-01-15

Content freshness indicators: 2025 Pakistan refractory market outlook validated; technical ranges aligned with current field deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.