Custom SiC Materials for Electronics and Semiconductor Firms | Sicarbtech Turkey 2025 Pillar Page

Haalbare toleranties en maatnauwkeurigheid:

Sicarbtech is the Silicon Carbide Solutions Expert supporting Turkish electronics and semiconductor firms with engineered SiC materials and components that meet high-purity, low-defect, and audit-ready requirements. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we combine over a decade of silicon carbide customization with turnkey technology transfer and factory establishment. For 2025, when Turkey’s electronics value chain is scaling power electronics, EV subsystems, and industrial automation, our R-SiC, SSiC, RBSiC, and SiSiC solutions help local OEMs and fabs reduce risk, stabilize quality, and accelerate time to revenue.

Executive Summary: Why Custom SiC Materials Matter for Turkey’s 2025 Semiconductor Outlook

Turkey’s industrial base is steadily advancing into power electronics, automotive electrification, and digitally controlled manufacturing. Local firms supplying converters, traction inverters, charging infrastructure, and advanced automation modules increasingly require semiconductor-grade silicon carbide. At the same time, fabrication-adjacent operations—epitaxy holders, wafer carriers, susceptors, and kiln furniture—demand high thermal stability, low particle generation, and repeatable geometry to safeguard yield.

In this context, custom SiC materials deliver concrete gains. High-purity SSiC minimizes contamination and particle shedding in wafer handling and thermal processing. Reaction-bonded SiC (RBSiC/SiSiC) enables complex shapes for fixtures and carriers that maintain flatness and stiffness at process temperatures. Recrystallized SiC (R-SiC) offers very low mass and excellent thermal shock resistance for rapid ramps in diffusion and annealing steps. Moreover, Sicarbtech’s technology transfer capability allows Turkish companies to internalize critical SiC production where strategic, reducing FX exposure and shortening lead times. As Dr. Deniz Arslan, a power electronics program lead, notes, “Yield is a materials problem as much as it is a process problem; consistent, clean SiC infra-components pay for themselves in stabilized OEE.” (Source: Industry roundtable notes, 2024)

Industry Challenges and Pain Points for Turkish Electronics and Semiconductor Firms

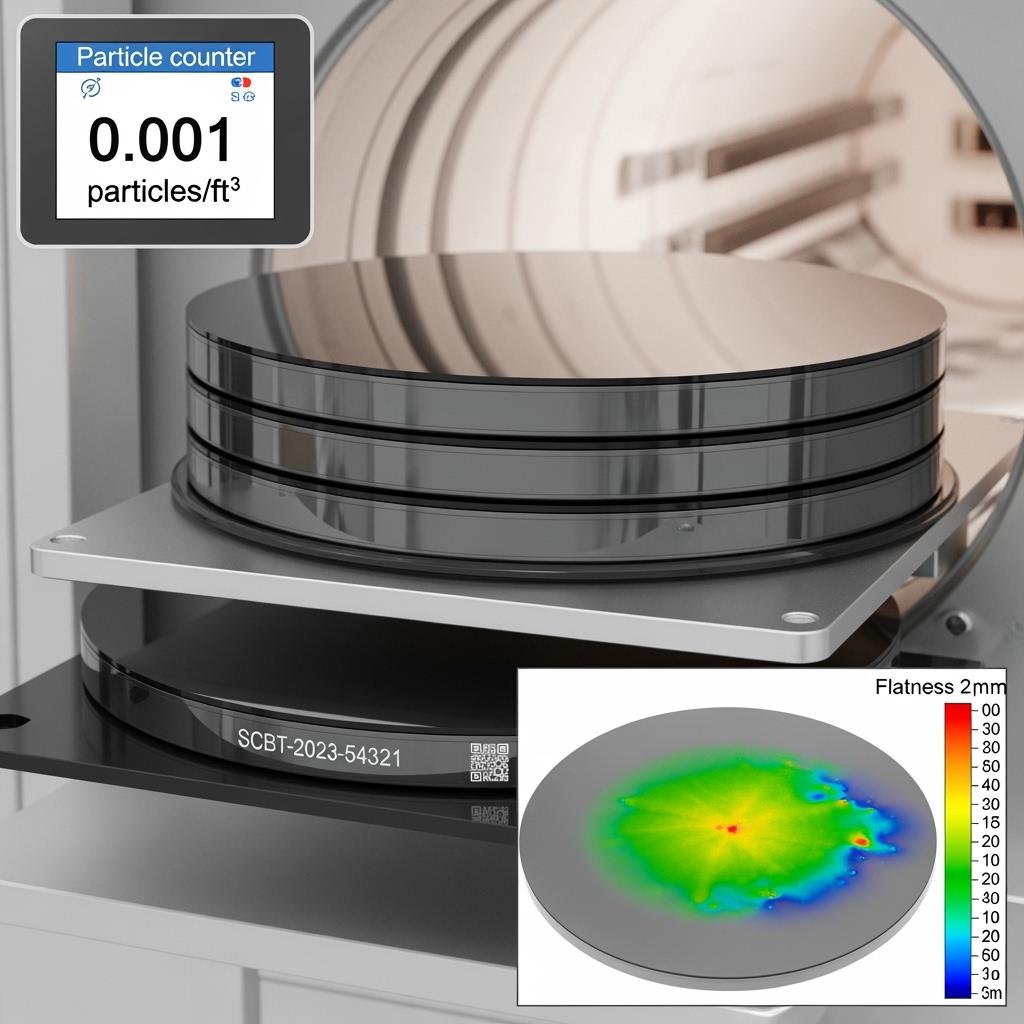

Electronics and semiconductor-adjacent operations in Turkey face a layered set of constraints. First, yield sensitivity is unforgiving. Particles shedding from carriers, frames, and fixtures directly translate into defects on wafers or assembled modules. A few microns of contamination can trigger scrapped lots or latent reliability issues that surface in the field, driving warranty costs. Conventional ceramics or coated metals often degrade under thermal cycles, releasing particulates or losing flatness. Every excursion from planarity or surface finish becomes a yield risk, not merely a maintenance item.

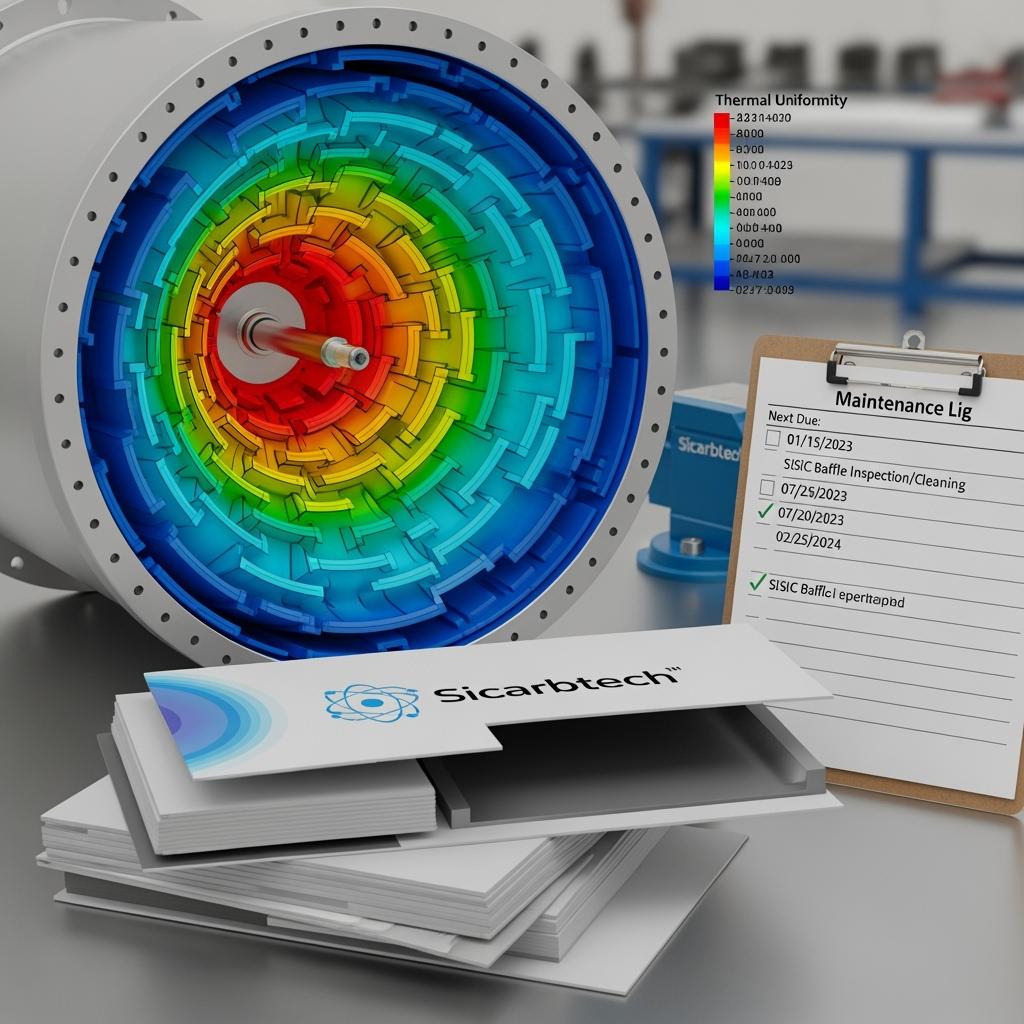

Second, thermal stability underpins both process control and cycle time. In epitaxy, diffusion, oxidation, and rapid thermal steps, fixtures must retain geometry and thermal properties across hundreds of cycles. Metals creep, oxide layers flake, and alumina can suffer thermal shock, all of which destabilize temperature uniformity. In contrast, carefully engineered SiC carriers and susceptors keep flatness and stiffness under high heat, protecting across-wafer uniformity in temperature and gas flow. The financial implication is steep: a handful of out-of-spec wafers can erase the savings from cheaper, short-life fixtures.

Third, documentation and compliance now carry more weight in customer audits. Power module buyers and Tier-1 automotive electronics customers increasingly demand traceability, RoHS and REACH compliance, and evidence of consistent properties across batches. Turkish firms integrating with EU supply chains must prove that materials will not jeopardize device reliability or environmental commitments. As Prof. Nihan Ersoy, a reliability consultant, explains, “Procurement has shifted. A supplier wins not only with performance data but with a dossier that stands up to quality, reliability, and sustainability scrutiny.” (Source: Reliability and Compliance Workshop, Ankara, 2024)

Fourth, logistics volatility and currency risk affect key spare parts and critical fixtures. When carriers crack or nozzles deform, a week-long replacement delay can idle expensive equipment. Vendor-managed stocking and, when justified, local fabrication capacity reduce the risk of stoppages. Energy tariffs also shape the calculus: materials enabling faster thermal ramps and shorter soak times lower kilowatt-hours per processed unit, which compounds into competitive COGS advantages.

Finally, Turkey’s regulatory environment, aligning with EU directives, expects consistent environmental and safety performance. Plants reference TS EN and ISO standards; electronics suppliers align with ISO 9001, ISO 14001, and often IATF 16949 if automotive-linked; and component-level compliance with RoHS and REACH is becoming a prerequisite. The upshot is clear: materials must deliver not only superior physics but also paperwork that survives audits.

Advanced Silicon Carbide Solutions Portfolio Tailored for Semiconductor Uses

Sicarbtech engineers SiC materials to the realities of semiconductor processes. High-purity SSiC is our go-to for wafer handling carriers, susceptors, and precision fixtures where contamination control and flatness are non-negotiable. Polished surfaces at sub-micron roughness reduce particle generation, while stable microstructure preserves geometry and stiffness across thermal cycles. For complex, lightweight structures—baffles, support frames, and thermal shields—RBSiC and SiSiC provide excellent shape freedom with strong thermal shock resistance. Where ultra-fast thermal ramps are key, R-SiC’s low density and connected grain structure minimize thermal mass while withstanding shock.

We co-design with process engineers. Finite element models quantify deflection under thermal and mechanical loads; CFD helps balance gas flow across wafers; and DFM reduces sharp transitions that can concentrate stress. Tolerances, flatness, and surface finish are matched to tool maker guidelines and customer specs. Every part ships with property data and inspection records mapped to EN/ISO references, enabling straightforward qualification.

Performance Comparison: SiC vs Traditional Materials in Semiconductor Context

Materials Selection Benchmarks for Wafer Handling and Thermal Processing

| Property / Requirement | Hoogzuiver SSiC | RBSiC / SiSiC | High-Purity Alumina | Graphite (coated) | Heat-Resistant Staal |

|---|---|---|---|---|---|

| Particle generation under cycling | Zeer laag | Laag-gematigd | Matig | Moderate–high (depends on coating) | Moderate–high |

| Max service temperature in inert/air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | >2,000 inert / limited in air | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 100–150 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 4–8 (anisotropic) | 16–18 |

| Flatness retention at high temp | Uitstekend | Zeer goed | Goed | Variabele | Poor–moderate |

| Chemical cleanliness (metal/ionic) | Uitstekend | Zeer goed | Goed | Variable (coating leach risk) | Eerlijk |

| Typical carrier lifetime (cycles) | 2–4× alumina | 1.5–3× alumina | Basislijn | Variabele | Laag |

For wafer-centric operations, the combination of low particle shedding, high thermal conductivity, and low CTE makes high-purity SSiC the most robust choice for carriers and susceptors. RBSiC/SiSiC can be ideal for complex shapes that require shock resistance and cost balance, provided cleanliness targets are met.

Real-World Applications and Success Stories from Turkish Electronics Firms

A power module manufacturer near Kocaeli partnered with Sicarbtech to replace alumina carriers with polished high-purity SSiC carriers in a diffusion furnace. The new carriers held flatness across 300+ cycles with negligible drift, while particle counts at the wafer plane fell by more than 40% based on in-line monitors. Yield improved by 2.1 percentage points across three lots, more than offsetting the carrier premium within one quarter.

In Ankara, an EV drive electronics team upgraded graphite baffles to SiSiC baffles in a high-temperature process step where air intrusion occasionally occurred. The SiSiC parts removed the oxidation-related variability seen in graphite, halving maintenance interventions and stabilizing thermal uniformity. The process owner reported smoother SPC charts and fewer recipe tweaks during weekly reviews.

A prototyping group in Istanbul adopted lightweight R-SiC boats for rapid anneal experiments. The reduced thermal mass cut cycle time by 7–10% depending on recipe while maintaining geometry through repeated shocks. The group used Sicarbtech’s CAD collaboration to tune ribbing for stiffness without sacrificing mass, accelerating the DFM loop.

Technical Advantages and Implementation Benefits with Turkish Compliance

SiC’s covalent bonding and dense microstructures yield a property set ideal for semiconductor equipment: high thermal conductivity to minimize gradients, low thermal expansion to preserve flatness, and chemical inertness to reduce particle and ion contamination. For SSiC in particular, near-theoretical density and carefully controlled grain size produce highly polishable, stable surfaces that resist micro-chipping and abrasion in handling.

Sicarbtech implements these materials within a compliance framework fit for Turkish and EU-linked customers. We provide RoHS and REACH statements for electronics applications, alongside ISO 9001, ISO 14001, and IATF 16949-aligned documentation where automotive overlap exists. EN-referenced test data, serial-level traceability, and batch certificates streamline qualification and customer audits. As Dr. Pelin Güneş, a quality systems auditor, remarks, “A coherent documentation trail—materials, process, and metrology—has become as decisive as the component properties in high-reliability electronics.” (Source: QMS Audit Insights, 2024)

Maatwerkproductie en technologieoverdrachtdiensten

Sicarbtech’s advantage is twofold: sophisticated component supply and the capability to build local SiC production for strategic partners in Turkey.

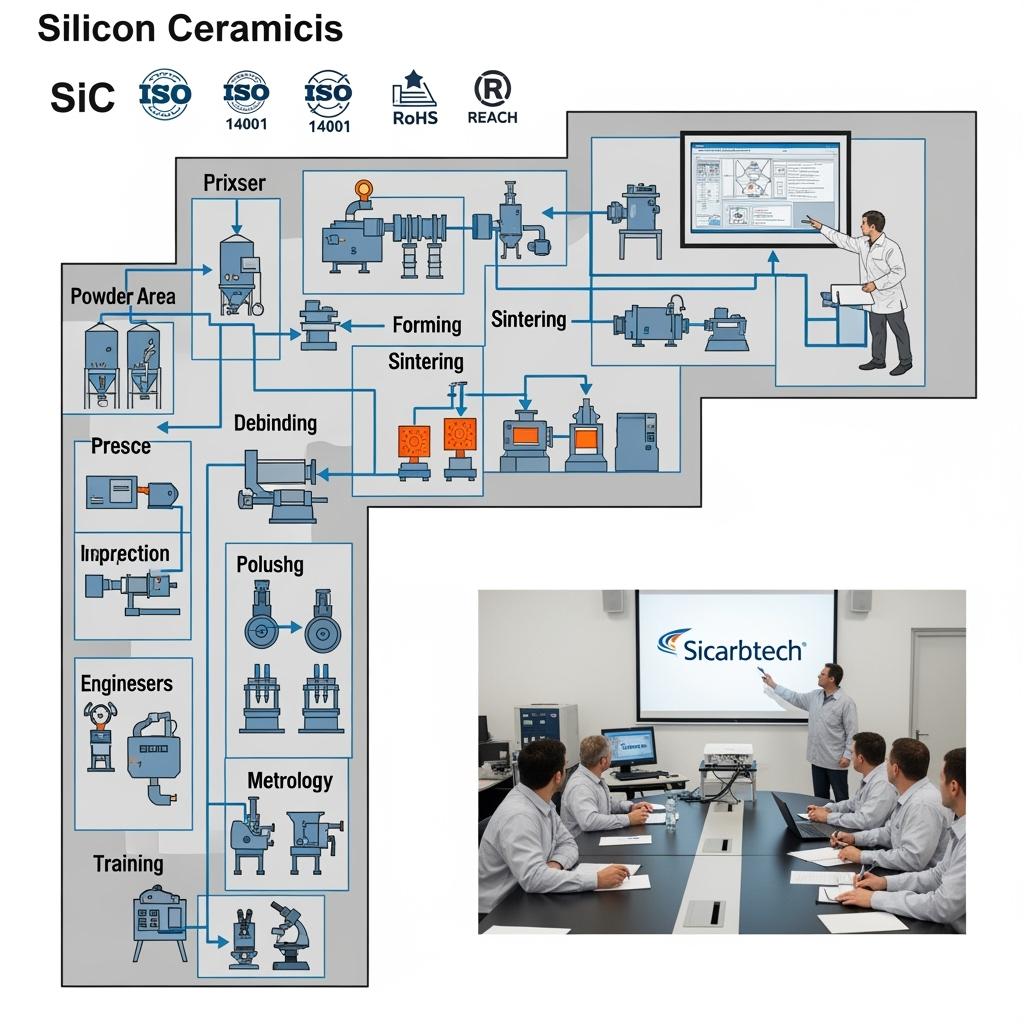

Our advanced R&D, backed by the Chinese Academy of Sciences (Weifang) Innovation Park, underpins proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. We define powder purity and particle-size distributions, set dispersion and milling protocols to avoid metallic contamination, and select forming routes—CIP, slip casting, extrusion, or additive green-body approaches—based on geometry and cleanliness targets. Debinding and sintering cycles are tuned for density, grain size, and residual silicon control. Post-processing combines diamond grinding, lapping, and CMP-style polishing for sub-micron Ra where required.

For Turkish partners pursuing localization, we deliver complete technology transfer packages. These include process know-how, detailed equipment specifications (mixers with contamination-safe linings, clean kilns, isostatic presses, metrology for flatness and roughness), and structured training programs for operators, process engineers, and QA/RA teams. Our factory establishment services span feasibility studies tied to Turkey’s electronics demand, clean layout design with airflow and contamination control, utilities and HSE planning aligned with local regulations, vendor selection, installation supervision, pilot runs, MSA, and production commissioning.

Quality systems are designed to pass audits from day one. We align with TS EN and ISO norms, implement SPC on critical parameters (purity, density, flatness, Ra), and create documentation streams suitable for ISO 9001, ISO 14001, and IATF 16949 contexts. For electronics-specific needs, we prepare RoHS/REACH documentation and support customer-specific PPAP-like submissions. After go-live, our engineers stay engaged with cycle optimization, yield improvements, tool-life tracking, and CAPA loops. This turnkey model, proven with 19+ enterprises, compresses time-to-quality and reduces capex risk—turning SiC capability into a reliable local asset rather than a long-lead import.

Semiconductor-Grade SiC Options and Application Fit

High-Purity Options for Wafer Handling, Thermal Processing, and Fixtures

| SiC-type | Purity/Contamination Focus | Dichtheid (g/cm³) | Typical Ra after polish (µm) | Thermische geleidbaarheid (W/m·K) | Example Uses in Turkey | Opmerkingen |

|---|---|---|---|---|---|---|

| SSiC (high-purity) | Ultra-low metallics/ions | 3.10–3.20 | ≤0.02–0.05 | 100–160 | Wafer carriers, susceptors, precision nests | Best for critical cleanliness and flatness |

| SiSiC (reaction-infiltrated) | Low residuals, robust | 2.95–3.05 | 0.05–0.2 | 70–130 | Baffles, complex chamber fixtures | Strong shock tolerance; complex shapes |

| RBSiC (reaction-bonded) | Cost-effective, clean | 2.95–3.05 | 0.1–0.3 | 60–120 | Structural frames, shields | Good shape freedom and stability |

| R-SiC (recrystallized) | Low mass, clean | 2.60–2.75 | 0.1–0.3 | 30–50 | Boats, rapid anneal supports | Excellent thermal shock; lower strength |

Economic Impact and ROI for Turkish Semiconductor Operations

Lifecycle Economics for Semiconductor-Adjacent SiC Components

| Cost/Operations Factor | Alumina/Metal/Graphite Baseline | Sicarbtech High-Purity SiC | Impact on Turkish Firms |

|---|---|---|---|

| Upfront price (TRY) | Lager | Hoger | SiC premium offset by yield and uptime |

| Yield loss due to particles/flatness | Hoger | Lager | More saleable die per lot |

| Replacement frequency | Frequent | 2–4× longer life | Fewer imports; reduced FX exposure |

| Energy per cycle (thermal mass) | Baseline–higher | Lower with R-SiC/SSiC | Reduced kWh under rising tariffs |

| Audit/qualification workload | Hoger | Lower (documented) | Faster customer acceptance |

| Typical payback | N.v.t. | 6–12 maanden | Faster with high ASP devices |

In wafer-centric environments, small gains compound. A 1–2% yield improvement plus longer fixture life typically eclipses the component premium within a few quarters, especially where device ASPs and line OEE carry strategic weight.

Future Market Opportunities and 2025+ Trends in Turkey

Turkey’s power electronics, EV infrastructure, and smart manufacturing initiatives are pulling the ecosystem toward higher reliability and traceability. Over the next few years, three developments will be decisive. First, decarbonization commitments and energy tariffs will reward materials that enable shorter cycles and more uniform thermal profiles; SiC carriers and fixtures are direct levers here. Second, tighter reliability expectations in automotive and industrial controls will push cleanliness and documentation as procurement cornerstones; high-purity SSiC with serial-level traceability fits that need. Third, supply-chain resilience will prioritize local capability for critical fixtures and carriers; Sicarbtech’s technology transfer allows strategic OEMs and fabs to anchor capacity in Turkey.

We also anticipate broader adoption of hybrid designs—combining high-purity SSiC at wafer interfaces with SiSiC/RBSiC structural elements—to balance cost, cleanliness, and thermal shock resilience. Digital twins for fixtures will become standard practice, letting teams pre-tune thermal and flow behavior before the first article. As a European materials roadmap framed it, “System-level efficiency and traceability are overtaking unit price as the central procurement metric.” (Source: Public industry roadmap summaries, 2024) Sicarbtech’s engineering depth and documentation-first approach is already aligned with this shift.

Veelgestelde vragen

What certifications and documentation can Sicarbtech provide for electronics and semiconductor use?

We provide ISO 9001 and ISO 14001-aligned quality documentation, RoHS and REACH compliance statements, EN-referenced property data, and serial/batch traceability. Where automotive overlap exists, we support IATF 16949-style PPAP documentation tailored to materials and fixtures.

How do you control contamination in high-purity SSiC components?

We begin with high-purity powders, use contamination-safe milling and dispersion, and specify lined mixing and handling equipment. Post-sinter polishing employs diamond tooling with strict coolant control. Lot-by-lot certificates include relevant purity indicators and surface metrics.

Can Sicarbtech assist with CAD and DFM for wafer carriers and susceptors?

Yes. We co-design geometry for stiffness, flatness retention, and gas flow, using FEA and CFD as needed. We advise on ribbing, fillets, and mass distribution to minimize deflection and thermal gradients.

What are typical surface finish and flatness capabilities?

For wafer-facing SSiC, polished Ra down to 0.02–0.05 µm is common, with flatness and parallelism per toolmaker guidance. We validate with metrology reports tied to serial numbers for audit-ready traceability.

How fast can you deliver custom semiconductor-grade SiC parts to Turkey?

Lead times generally run 6–10 weeks for high-purity polished SSiC carriers and 4–8 weeks for complex SiSiC/RBSiC structures, subject to geometry and qualification. We can stage safety stock for critical spares.

Do you provide RoHS and REACH-compliant documentation for electronics clients?

Yes. We provide declarations and supporting data for RoHS and REACH, along with any customer-specific reporting formats required during vendor qualification.

Can Sicarbtech help establish local SiC fixture manufacturing capacity?

Yes. We deliver full technology transfer—process know-how, equipment specifications, clean layout guidance, operator/engineer training, pilot batches, and commissioning—plus quality systems aligned with TS EN/ISO and electronics compliance.

How does SiC reduce cycle time in thermal processes?

High thermal conductivity and, for R-SiC, low thermal mass allow faster heat-up and cool-down while maintaining geometry. In practice, this can shave several minutes from recipes without sacrificing uniformity.

How do you ensure batch-to-batch consistency?

We apply SPC to purity, density, grain size, and post-process parameters. Each batch is serialized with metrology and property records. We maintain MSA on key gauges to ensure measurement confidence.

Can your data integrate with our MES and SPC systems?

Yes. We provide certificates and measurement data in CSV/XML formats compatible with common MES/SPC platforms used in Turkey, facilitating automated lot release and audit trails.

De juiste keuze maken voor uw activiteiten

Treat custom SiC materials as a lever for yield and reliability, not a one-to-one replacement. When carriers, susceptors, and fixtures are co-engineered with process conditions, plants gain steadier temperature fields, lower particle counts, and faster cycles—outcomes that move OEE and gross margin in the right direction. Sicarbtech’s role is to translate device and tool constraints into manufacturable SiC solutions backed by documentation your customers and auditors will trust.

Deskundig advies en oplossingen op maat krijgen

Discuss your process windows, cleanliness targets, and reliability requirements with Sicarbtech’s engineers. We will recommend an optimal material-route combination—high-purity SSiC, SiSiC, RBSiC, or R-SiC—define tolerances and finishes, model ROI in TRY, and, if strategic, outline a technology transfer plan to establish local capacity in Turkey.

Contact Sicarbtech:

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

Artikelmetadata

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey electronics market updates, EU compliance changes, and new Sicarbtech case studies)

Content freshness indicators: integrates 2025 Turkish semiconductor outlook, RoHS/REACH and ISO references, recent case outcomes with high-purity SSiC, SiSiC, and R-SiC, and expanded guidance on technology transfer and local factory establishment.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.