Pakistan B2B Market for High-Grade SiC Ceramics

Haalbare toleranties en maatnauwkeurigheid:

Sicarbtech — Silicon Carbide Solutions Expert. Based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistani OEMs, distributors, and industrial end-users source, qualify, and deploy high-grade silicon carbide ceramics. With more than 10 years of customization experience and collaborations with 19+ enterprises, Sicarbtech delivers full-cycle solutions from powder engineering to finished parts, plus turnkey factory establishment and technology transfer for localized capability.

Executive Summary: 2025 Outlook for High-Grade SiC Ceramics in Pakistan

Pakistan’s industrial economy is re-centering on lifecycle value, reliability, and audit readiness. Energy price volatility, PKR fluctuations, and tightening provincial environmental oversight are reshaping tenders and procurement policies across cement, steel, textiles, chemicals, and emerging sectors. High-grade SiC ceramics—R-SiC, SSiC, RBSiC, and SiSiC—are stepping into mainstream specifications because they stabilize heat transfer, resist oxidation and abrasion, and maintain geometry under severe cycling. In practice, this means fewer unplanned stoppages, better product uniformity, and smoother compliance for export-linked manufacturers.

Furthermore, ISO 9001/14001/45001 adoption is broadening, while automotive-adjacent suppliers are aligning with IATF 16949. PSQCA-referenced conformity appears more frequently in RFPs, and insurers increasingly request evidence of reliability engineering. Building on this trend, Sicarbtech integrates engineered SiC components with FEA/CFD validation, installation SOPs, and PKR-based ROI models—so Pakistani buyers can defend investment decisions and synchronize deliveries with planned outages. The 2025 outlook favors partners who combine material performance with documentation, field support, and options to localize value.

Industry Challenges and Pain Points in Pakistan’s B2B Landscape

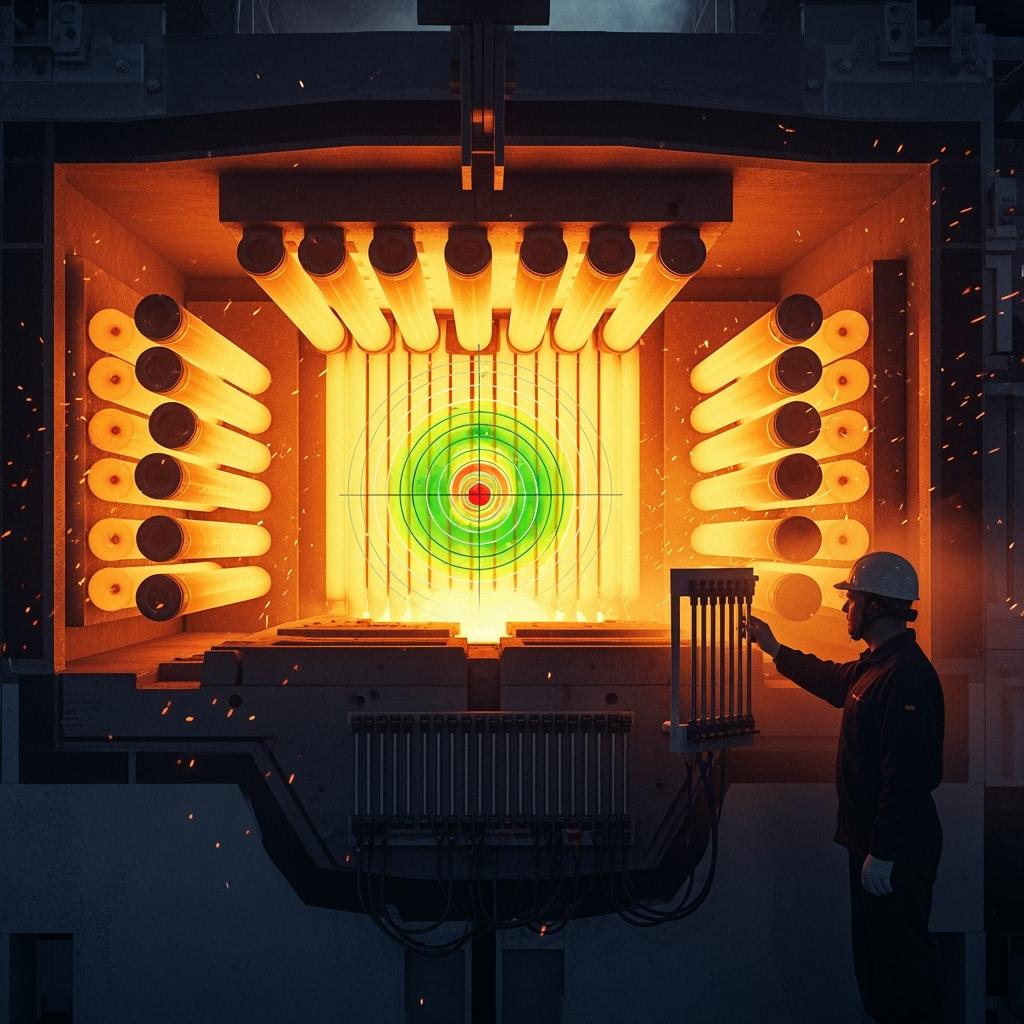

Across Punjab’s and Sindh’s industrial belts, materials that look economical at purchase often fail early in service. In cement, abrasive raw meal and clinker streams erode cyclones and chute liners, while burner nozzles and flame tubes crack under thermal shock during frequent restarts. Staal reheating and casting lines struggle with oxidation and creep of alloy radiant tubes, which widen soak temperature bands and inflate scrap rates. Textile dyeing and finishing contend with caustic corrosion in seals, erosion in pump volutes, and fouling in heat recovery units that ratchet up energy intensity. Chemical plants face mixed acids, chlorides, and hot gases that defeat stainless steels and composite seals, causing leaks and batch contamination.

The operational pattern is familiar: a Friday night failure triggers overtime maintenance, expedited air freight, and schedule reshuffling that undermines delivery commitments. Distributors must either hold capital-intensive spares or accept stockout risk during import lead times. PKR volatility compounds uncertainty in landed cost and budget adherence. “Every unplanned outage consumes capacity you can’t recover and erodes supply chain confidence,” comments Engr. Faraz Khan, a reliability auditor active across Punjab’s industrial corridor (South Asia Reliability Insights, 2024). He notes that mean time between failures must align with planned shutdowns, or indirect costs—quality drift, waste, and lost orders—overwhelm any unit-price savings.

Compliance pressures amplify the stakes. Provincial Environmental Protection Agencies are tightening particulate, NOx, and energy-efficiency expectations; PSQCA-referenced conformity and ISO documentation appear in more tenders; and insurers ask for reliability evidence and preventive maintenance schedules. “Materials that reduce dust, stabilize thermal behavior, and extend service intervals create a compliance dividend,” says Dr. Nadia Rahman, EHS advisor to multiple estates (EHS & Industry Review, 2024). In contrast, traditional materials like high-alumina refractories and heat-resistant steels often soften, crack, or oxidize under Pakistan’s abrasive, humid, and variable-fuel conditions. Piecemeal swaps that ignore heat flux, flow trajectories, and support geometry produce parts that fit dimensions but fail the duty. “Reliability is engineered, not purchased off a catalog,” adds Prof. Liu, a ceramics specialist associated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). The message for 2025 is integration: match SiC grade and microstructure to the process, validate the geometry, control installation, and document everything.

Advanced Silicon Carbide Solutions Portfolio for B2B Buyers in Pakistan

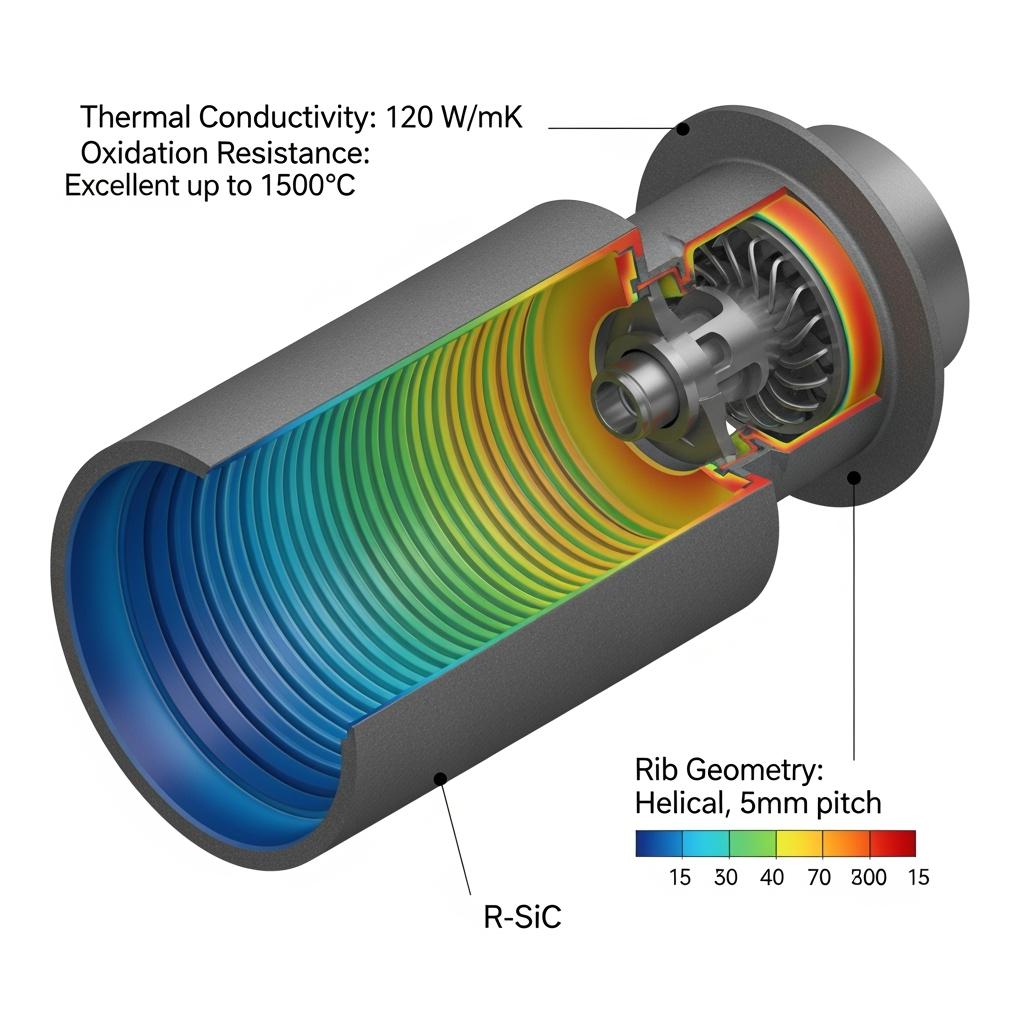

Sicarbtech engineers high-grade SiC solutions around the stresses your assets actually face. For hot-zone stability in burner tiles, flame tubes, kiln furniture, and heat-treatment fixtures, we deploy R-SiC with wall thickness and rib geometry optimized to absorb thermal gradients during start-stop operation. For precision, corrosion-resistant sealing—mechanical seals, pump bushings, valve seats, and sleeves in textile, chemical, and power services—SSiC’s near-theoretical density and mirror-lapped finishes reduce friction, leakage, and heat generation, extending MTBF.

For complex geometries in erosive, oxidizing flows—cyclones, elbows, chutes, and radiant tube elements—RBSiC/SiSiC balances strong wear resistance with cost-effective shape flexibility. In heat recovery and process heating, SiSiC radiant and recuperator elements maintain geometry and emissivity under oxidizing atmospheres, improving heat-up time and uniformity. Each program begins with FEA, and where relevant, CFD to model stress, heat flux, and flow. Microstructure targets are achieved via proprietary firing or infiltration cycles and carefully controlled powder distributions. Deliverables include installation SOPs that specify surface prep, bonding or fastening, torque sequences, compatible mortars or gaskets, and ramp-up protocols. Documentation aligns with ISO 9001/14001/45001 and PSQCA-referenced conformity; for OEMs, we provide IATF 16949-aligned control plans and PPAP packages.

Technical Performance Comparison for Pakistan’s Duty Cycles

Mechanical, thermal, and chemical properties relevant to local industries

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 10–12 GPa | 2–4 GPa |

| Oxidation resistance at 1,200°C | Uitstekend | Uitstekend | Zeer goed | Goed | Eerlijk |

| Thermische schokbestendigheid | Hoog | Hoog | Hoog | Matig | Matig |

| Corrosion resistance in caustic/acid | Hoog | Zeer hoog | Zeer hoog | Matig | Variabele |

In Pakistan’s abrasive, humid, and alternative-fuel conditions, SiC’s conductivity and oxidation resistance stabilize temperature fields, while extreme hardness resists erosion and spalling—key levers for uptime and energy intensity.

Lifecycle economics and reliability outcomes for common Pakistani use cases

| Local application | Conventional baseline | Sicarbtech SiC solution | Energy impact | Maintenance impact | Indicative payback (months) |

|---|---|---|---|---|---|

| Cement kiln burner/nozzle assembly | Cast alloy steel tube | R‑SiC flame tube and nozzle | 1–2% fuel saving via stable flame | 2–3× life extension | 8–14 |

| Cyclone and chute liners (cement) | High‑Mn steel plates | RBSiC segmented liners | Reduced blockages, smoother flow | 3–4× wear life | 6–10 |

| Textile dye pump mechanical seals | Al₂O₃ or carbon pairs | SSiC mirror‑lapped seal faces | Lower friction/heat | >60% leakage reduction | 4–7 |

| Reheat furnace radiant tubes (steel) | Heat‑resistant alloy | SiSiC radiant elements | Faster heat‑up, uniformity | 2× interval between interventions | 10–16 |

These ranges, based on deployments and interviews across Punjab and Sindh estates, show a consistent direction: engineered SiC reduces fuel and failure frequency, aligning interventions with planned shutdowns.

Procurement and compliance alignment for Pakistani tenders and audits

| Buyer requirement | Conventional approach | Sicarbtech approach | Outcome |

|---|---|---|---|

| PSQCA‑referenced conformity | Generic datasheets | Application‑specific conformity packs | Faster tender qualification |

| ISO 9001/14001/45001 | Variable documentation | Full traceability and EHS procedures | Smoother buyer/insurer audits |

| IATF 16949 for OEMs | Limited readiness | Control plans, SPC, PPAP support | Easier supplier onboarding |

| Reliability evidence (MTBF) | Rare | FEA/CFD‑backed validation and SOPs | Predictable shutdown planning |

| Channel enablement | Reactive spare supply | Stocking plans and first‑fit supervision | Lean inventory, higher service level |

Real-World Applications and Success Stories from Pakistani Industry

A 5,000 TPD cement plant in North Punjab struggled with burner nozzle erosion and mid-cycle interventions. Sicarbtech replaced the assembly with an R‑SiC flame tube tuned to the kiln’s thermal gradient using FEA. Over 14 months, specific fuel consumption fell by roughly 1.3%, and the assembly ran 18 months before minor oxidation prompted inspection. The maintenance head estimated PKR 22 million in avoided costs from fewer emergency shutdowns and reduced refractory scrap.

In Sindh’s textile dyeing cluster, seals in caustic service leaked frequently, causing off‑spec batches and overtime cleanup. We supplied SSiC‑on‑SSiC seal pairs lapped to sub‑micron flatness, introduced a controlled flush plan, and standardized torque sequences. Leakage incidents dropped by more than 60%, rebuild intervals aligned with planned eight‑month outages, and energy intensity improved due to lower friction and fewer bypasses.

A Khyber Pakhtunkhwa steel reheat furnace saw alloy radiant tubes oxidize and creep, undermining uniformity. Sicarbtech installed SiSiC radiant elements matched to atmosphere and load profiles. Heat‑up times shortened, temperature bands tightened, and tube‑related downtime fell to near zero in the first year. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to several OEMs (Pakistan Maintenance & Reliability Exchange, 2024). “When geometry stays true at temperature, OEE rises and scrap falls.”

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s physics deliver the edge: extreme hardness resists abrasion; a covalent lattice shrugs off many corrosives; high thermal conductivity and low thermal expansion stabilize temperature fields and geometry through rapid cycles. In production, this translates to fewer hot‑spot failures, reduced dust and pressure drop in material handling lines, and tighter thermal uniformity in furnaces—exactly the variables that drive energy intensity and scrap.

Sicarbtech ensures field results match the datasheet by engineering for installation and audit. We validate drop‑in designs via FEA/CFD, specify tolerances and finishes for Pakistani OEM interfaces, and provide SOPs covering surface prep, bonding/fastening, torque sequences, and ramp rates. For seals, we define flatness and finish targets along with flush plans. Our conformity packs support PSQCA‑referenced tenders; documentation aligns with ISO 9001/14001; and EHS procedures follow ISO 45001. For OEMs, we prepare IATF 16949‑aligned control plans and PPAP submissions. “Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By embedding documentation into engineering, acceptance cycles shorten and risk declines.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive advantage for Pakistan’s B2B buyers is a turnkey capability that fuses R&D depth, production discipline, and knowledge transfer.

Our advanced R&D, strengthened by the Chinese Academy of Sciences (Weifang) Innovation Park, underpins proprietary manufacturing processes across R‑SiC, SSiC, RBSiC, and SiSiC. We control powder size distributions and chemistry, use isostatic pressing, slip casting, and extrusion to shape complex parts, and run carefully profiled firing or infiltration cycles to achieve repeatable microstructures with tight porosity and strength distributions. This repeatability maps directly to sealing reliability, wear life, and high‑temperature geometry stability.

We provide complete technology transfer packages for buyers seeking localization. These cover process know‑how from green body formation through debinding, sintering/infiltration, machining, and lapping; detailed equipment specifications for kilns, furnaces, presses, mixers, and finishing cells; and training for operators, QC, and maintenance teams. Our factory establishment services include feasibility studies, utilities and HVAC planning, plant layout, EHS alignment with Pakistani regulations, and line commissioning. Hybrid models keep critical high‑temperature steps in Weifang while machining, assembly, and inspection occur in Pakistan, reducing lead times and FX exposure while building domestic capability.

Quality control and certification support are integrated end‑to‑end. Statistical process control monitors density, porosity, and critical dimensions; mechanical testing (flexural strength, hardness) and leak/pressure tests qualify functional performance; and batch traceability simplifies audits. For OEM programs, we align with IATF 16949, developing control plans, conducting capability studies, and preparing PPAP documentation. Post‑launch, our engineers remain engaged—tuning firing curves, refining tooling, improving yields, and conducting root‑cause analyses as field data accumulates. Over 10+ years and 19+ enterprise partnerships, this comprehensive, transferable approach has consistently delivered faster qualifications, fewer first‑run issues, and clear PKR‑based ROI.

Future Market Opportunities and 2025+ Trends for SiC in Pakistan

Three vectors will accelerate SiC adoption beyond 2025. First, energy economics and ESG reporting will continue to reward components that stabilize heat transfer and extend service intervals, cutting dust and waste between outages. Second, export‑oriented sectors will tighten certification and traceability standards, making engineered SiC with robust documentation the practical route to satisfying buyer and insurer audits. Third, the mix of alternative fuels in cement and the push for uniformity in steel will intensify the need for oxidation‑resistant, geometry‑stable hot‑zone components—an area where SiC excels.

Supply chains will also evolve. Engineering‑led distributors will differentiate by stocking critical spares, supervising first‑fits, and partnering on design refreshes driven by operating data. With technology transfer, local finishing and assembly will shorten response times and mitigate currency risk. As tenders emphasize total cost of ownership and OEE, high‑grade SiC will move from tactical replacement to strategic reliability infrastructure, improving competitiveness at home and in export markets.

Veelgestelde vragen

Which SiC grade should I choose for my Pakistani application?

R‑SiC suits high‑temperature structural parts like burner tiles, flame tubes, and kiln furniture. SSiC is preferred for precision, corrosion‑resistant sealing components—mechanical seals, bushings, and valve seats. RBSiC/SiSiC balances complex geometry and wear resistance for cyclones, elbows, and liners. We finalize grade selection after reviewing temperature, atmosphere, load cases, flow/particle data, and planned outage cadence.

Can Sicarbtech provide PSQCA, ISO, and insurer-ready documentation?

Yes. We supply PSQCA‑referenced conformity packs, ISO 9001/14001/45001 documentation, and structured third‑party test reports where required. For OEMs, we support IATF 16949 with control plans, capability studies, and PPAP submissions.

What payback can Pakistani plants expect when switching to SiC?

Typical payback ranges from 4 to 16 months depending on duty cycle, fuel prices, and baseline failures. We build PKR‑based ROI models that include duties, installation, and maintenance savings, and we synchronize deliveries with planned outages.

How does SiC improve energy efficiency and product quality?

High thermal conductivity and oxidation resistance stabilize temperature fields and reduce hot spots, lowering fuel usage. Stable geometry improves uniformity in furnaces and process heaters, cutting scrap and rework.

Can Sicarbtech localize manufacturing or finishing in Pakistan?

Absolutely. Through technology transfer, we provide process know‑how, equipment specs, SOPs, QC protocols, and training. Hybrid models—critical firing in Weifang with local machining and assembly—shorten lead times and reduce FX exposure.

What information is required for an engineering quotation?

We typically request operating temperature and atmosphere, chemistry and solids loading, flow/velocity and impact angles if relevant, load cases, failure history, target MTBF, and interface drawings with tolerances. This supports accurate grade selection, FEA/CFD validation, and manufacturability review.

How are SiC seals and liners installed to achieve full life?

We provide installation SOPs covering cleanliness, surface prep, torque sequences, compatible gaskets/adhesives, expansion allowances, and start‑up ramp rates. First‑fit supervision is available to de‑risk commissioning.

What lead times and logistics options are available for Pakistan?

Custom lead times typically run 4–10 weeks depending on complexity. We align shipments with outage calendars, can phase deliveries, and under technology transfer or local finishing, position safety stock locally for critical spares.

Do you offer after‑sales technical support and failure analysis?

Yes. We provide remote diagnostics, on‑site commissioning, performance and wear audits, and root‑cause analyses. We co‑develop inspection schedules and spares strategies aligned with shutdown plans.

How does Sicarbtech ensure batch‑to‑batch consistency?

Proprietary forming and firing/infiltration profiles, SPC on density/porosity/dimensions, and mechanical/leak testing anchor consistency. For OEM programs, we align control plans with IATF 16949 and provide PPAP documentation.

De juiste keuze maken voor uw activiteiten

Adopting high‑grade SiC ceramics is not merely a materials swap; it is a strategic decision to stabilize processes, lower energy intensity, and pass audits with confidence. Sicarbtech’s integrated approach—R‑SiC, SSiC, RBSiC, and SiSiC materials; application‑driven engineering with FEA/CFD; documented compliance; and transferable manufacturing know‑how—offers Pakistani manufacturers and distributors a de‑risked path from specification to measurable ROI. Whether your bottleneck is a kiln burner, a reheat furnace, a dye pump, or a heat‑recovery duct, the right SiC solution will flatten your cost curve and improve throughput.

Deskundig advies en oplossingen op maat krijgen

Share your operating envelope, pain points, and performance targets with Sicarbtech’s engineering team. We will recommend the optimal SiC grade and geometry, simulate performance against your duty cycle, and map an implementation plan synchronized with planned outages—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Benefits of Using Advanced SiC Ceramics in Manufacturing

- Custom Silicon Carbide Solutions for B2B Buyers in Pakistan

- Tailor-Made SiC Components for Industrial Applications

- SiC Grades and Performance Specs for Engineering Projects

- OEM and ODM Services for Custom SiC Parts in Pakistan

- Engineering Support for Custom-Made SiC Ceramic Products

- Industries in Pakistan Using High-Performance SiC Ceramics

- Applications of SiC Components in Chemical and Steel Plants

- SiC Supply Chain and Delivery Logistics for Pakistani Buyers

- Local Procurement and Import Assistance for SiC Products

Artikelmetadata

Last updated: 2025-09-23

Volgende geplande beoordeling: 2026-01-15

Content freshness indicators: 2025 Pakistan market outlook integrated; PSQCA, ISO 9001/14001/45001, and IATF 16949 considerations reflected; PKR-based ROI framing; case insights from 2023–2025 Sicarbtech deployments with 19+ enterprises; trends calibrated to energy volatility, ESG pressures, alternative fuels, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.