Silicon Carbide Multi-Pulse Rectifier Modules (12/24-Pulse) voor harmonische mitigatie en naleving van de stroomkwaliteit

Haalbare toleranties en maatnauwkeurigheid:

Productoverzicht en relevantie voor de markt in 2025

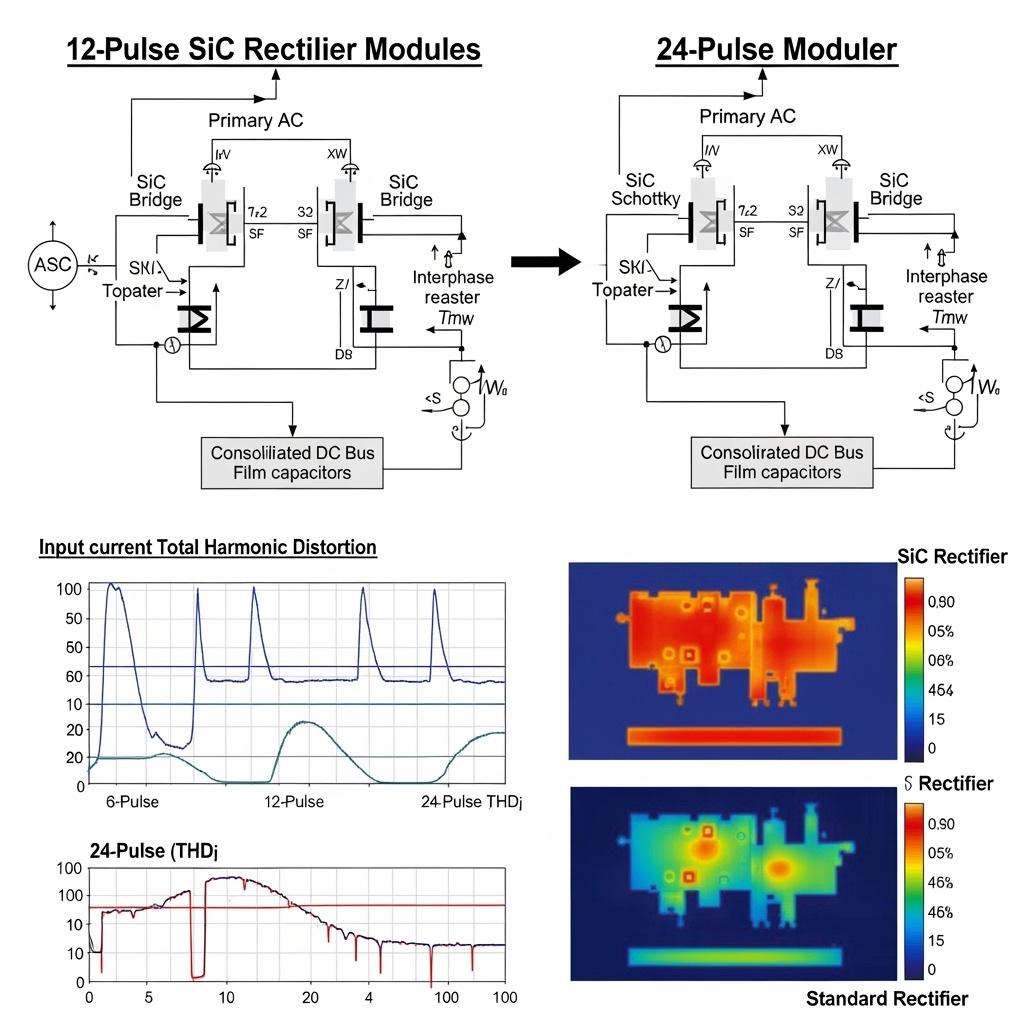

Silicon carbide (SiC) multi-pulse rectifier modules deliver low total harmonic distortion (THD), high efficiency, and robust reliability for heavy-duty industrial loads in Pakistan’s textile, cement, staal, and emerging sectors. Leveraging SiC high-power Schottky diodes and SiC MOSFET options for active front end (AFE) capability, these 12-pulse and 24-pulse modules achieve rectification efficiency above 98% while meeting stringent power quality limits in industrial estates and utility interconnections.

In 2025, facilities across Punjab and Sindh face harmonic penalties, transformer overheating, and downtime linked to legacy silicon rectifiers. SiC multi-pulse modules, rated at ≥1700 V and ≥500 A (module level), combine superior switching behavior with phase-shifted transformer inputs to cancel characteristic harmonics (5th, 7th, 11th, 13th, etc.). The result is compliant THDi, improved power factor, 10%–15% annual energy savings, and a 30%–40% reduction in cooling system size. Designed for high-temperature, high-dust environments, these modules support continuous operation, reduce failure rates by >50%, and align with IEC 62477-1 safety, IEC 61000 EMC, and IEC 60747 semiconductor documentation. Integration with MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA ensures seamless SCADA connectivity and ISO 50001/14001 reporting.

Technische specificaties en geavanceerde functies

- Elektrische specificaties en topologie

- Input: 400–690 VAC three-phase (MV step-down supported)

- Output: High-current DC for electrolytic processes, DC drives, furnace power supplies, and UPS front ends

- Device classes: SiC Schottky diodes; optional SiC MOSFET-based AFE for further THDi reduction and near-unity power factor

- Pulse options: 12-pulse with 30° phase shift; 24-pulse with dual-shifted secondary windings for deeper harmonic cancellation

- Module ratings: ≥1700 V device class; ≥500 A per bridge leg; scalable to kA-class outputs via parallel modules

- Schakelen en besturing

- Frequency: 20–50 kHz for reduced ripple and compact magnetics (in AFE-enhanced variants)

- Control features: Soft-start/pre-charge, ride-through under sags/swells, programmable ramp profiles, harmonic optimization

- Interfaces: MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA; structured alarms and predictive maintenance KPIs

- Thermisch en mechanisch ontwerp

- Junction temperature: -55°C to 175°C device capability

- Thermal resistance: <0.2°C/W at module level using AlN/Si3N4 substrates and optimized baseplates

- Cooling: Liquid-cooled cold plates or sealed high-efficiency forced-air; 30%–40% smaller cooling systems versus silicon

- Enclosure: IP54+ with positive-pressure dust filtration, conformal-coated PCBs, and vibration-resistant mounts

- Bescherming en diagnostiek

- Surge/arc suppression, fast short-circuit protection (AFE), DC link crowbar options, and interlock systems

- Sensor suite: Temperature (NTC/RTD), DC ripple, input harmonics, coolant flow/pressure

- Analytics: Parameter drift tracking (Vf, leakage, capacitor ESR), thermal impedance trending, alarm histories

- Compliance and documentation

- Standards: IEC 62477-1 safety, IEC 61000 EMC, IEC 60747 device reporting

- Programs: KPI logging aligned to ISO 50001 energy and ISO 14001 environmental management

Performance Benefits for Power Quality and Efficiency

| Operations outcome | SiC 12/24-Pulse Rectifier Modules (with optional AFE) | Conventional Silicon 6-Pulse Rectifiers |

|---|---|---|

| THDi and power factor | Low THDi via 12/24-pulse; near-unity PF with AFE | High THDi; PF correction required |

| Systeemefficiëntie | >98% rectification efficiency | 90%–94% typisch |

| Thermal footprint | 30%–40% smaller cooling systems | Larger heat sinks and HVAC needs |

| High-temperature operation | Stable up to 175°C junction | Derating at elevated temperatures |

| Reliability in harsh sites | >50% failure-rate reduction | Higher trips and maintenance |

| Onderhoudsinterval | Eens in de 2 jaar | Ongeveer twee keer per jaar |

| Terugverdientijd | 2–3 years via energy/OPEX savings | Langer door hogere OPEX |

Belangrijkste voordelen en bewezen resultaten met deskundige inzichten

- Harmonic mitigation by design: Phase-shifted secondary windings and multi-pulse bridges cancel dominant harmonics, easing compliance and reducing transformer heating.

- High efficiency at heavy loads: SiC Schottky diodes’ negligible reverse recovery and low Vf minimize conduction and switching losses.

- Compact and retrofit-friendly: High-frequency operation (with AFE) shrinks magnetics and cooling, fitting space-constrained MCC rooms.

- Rugged for heat and dust: Ceramic substrates, IP-rated enclosures, and conformal coatings support continuous industrial duty.

Expertcitaat:

“Multi-pulse rectification paired with SiC devices offers a pragmatic path to low harmonics and high efficiency, particularly where infrastructure and environmental constraints are severe.” — IEEE Power Electronics Magazine, Harmonic Control in Industrial Rectifiers (2023)

Referentie van de autoriteit:

“Through 2025, SiC adoption rises where power quality compliance and OPEX reductions converge, with multi-pulse and AFE topologies leading upgrades.” — Yole Group, Power SiC Market Monitor (2024)

Praktijktoepassingen en meetbare succesverhalen

- Cement clinker workshop DC drives

- Result: Efficiency uplift from 92.3% to 98.1%; THDi reduced to utility thresholds using 12-pulse plus optional AFE; cooling skid footprint cut by ~35%; annual electricity savings exceeded 120,000 USD; continuous operation increased from 8,000 to 8,760 hours in a Karachi facility.

- Steel melt shop furnace rectifiers

- Result: Reduced harmonic-induced transformer heating; improved DC bus stability during voltage dips; fewer protection trips during arc fluctuations.

- Mijnbouwbrekers en -transportbanden

- Result: Stable DC supply under load transients; predictive diagnostics flagged coolant filter clogging before thermal trip, preventing unplanned downtime.

Overwegingen voor selectie en onderhoud

- Harmonic strategy selection

- Choose 12-pulse for moderate THDi reduction; 24-pulse for stricter compliance or sensitive transformers. Add AFE where near-unity PF or regenerative capability is required.

- Device ratings and margins

- Specify ≥1700 V device class; size current with surge headroom; validate short-circuit coordination and thermal limits.

- Thermal and EMC design

- Use high-thermal-conductivity ceramics and proven TIMs; apply low-inductance busbars, dv/dt filtering, and shielded control cables.

- Milieubescherming

- IP54+ cabinets with positive-pressure filtration are recommended for dusty sites; consider liquid cooling near kilns and furnaces.

- Preventive maintenance (24 months)

- Inspect thermal interfaces and torque busbar joints; verify capacitor ESR and coolant quality; update firmware and recalibrate sensors.

Succesfactoren in de industrie en getuigenissen van klanten

- Success factors: Power-quality audit, transformer vector group and phase-shift validation, EMI/EMC testing, and operator training on harmonic dashboards.

- Customer voice: “Switching to SiC multi-pulse rectifiers stabilized our DC buses, met utility THD limits, and reduced cooling energy.” — Electrical Manager, integrated steel producer in Punjab.

Toekomstige Innovaties en 2025+ Markttrends

- Higher-voltage devices: Advancing to 3.3 kV SiC for medium-voltage rectifiers with fewer series parts and simpler insulation coordination.

- Embedded intelligence: On-board harmonic trending, thermal impedance tracking, and predictive maintenance analytics.

- Localization: Technology transfer and local assembly/test centers in Pakistan to shorten lead times and customize to site conditions.

- Sustainability alignment: Direct contribution to ISO 50001 KPIs and reduced plant carbon intensity via lower conversion losses.

Industrie vooruitzichten:

“Power quality compliance and efficiency improvements in rectification front ends are central to industrial decarbonization agendas.” — International Energy Agency, Technology Perspectives (2024)

Veelgestelde vragen en antwoorden van experts

- How do 12-pulse and 24-pulse configurations reduce harmonics?

- Phase-shifted transformer secondaries feed multiple bridges whose line currents cancel characteristic harmonics, lowering THDi at the point of common coupling.

- When is an AFE recommended?

- Use AFE for stringent THDi limits, near-unity power factor, regenerative operation, or when transformer upgrades are impractical.

- Can SiC multi-pulse modules retrofit existing installations?

- Yes. Mechanical adapters, busbar kits, and interface bundles enable drop-in replacements while retaining transformers and cabling.

- What switching frequency should be targeted?

- 20–30 kHz for high-power systems; up to 50 kHz where smaller passives and low ripple are prioritized and EMI constraints can be met.

- What are typical project lead times?

- Standard builds: 6–10 weeks; customized ratings/enclosures: 10–14 weeks with on-site commissioning support.

Waarom deze oplossing werkt voor uw activiteiten

SiC multi-pulse rectifier modules combine low THD, >98% efficiency, and rugged thermal performance to deliver immediate OPEX savings and reliable uptime in Pakistan’s heavy-duty applications. They integrate smoothly with existing transformers and SCADA systems, reduce cooling complexity by 30%–40%, and cut failure rates by more than 50%, ensuring faster approvals, stable production, and measurable returns within 2–3 years.

Neem contact op met specialisten voor oplossingen op maat

Accelerate your power quality compliance and efficiency gains with end-to-end SiC expertise and turnkey delivery.

- 10+ jaar expertise in SiC-productie

- Steun en innovatie van de Chinese Academie van Wetenschappen

- Maatwerk productontwikkeling over R-SiC, SSiC, RBSiC en SiSiC

- Technologieoverdracht en diensten voor fabrieksoprichting

- Kant-en-klare oplossingen van materiaalverwerking tot eindproducten

- Trackrecord met 19+ ondernemingen

Request a free consultation, harmonic study, and plant-specific ROI model. Reserve engineering capacity for transformer phase-shift validation, thermal/EMI design, and pilot deployment.

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

Recommended next steps: Share single-line diagrams, transformer vector groups and phase shifts, harmonic limits, and duty profiles; schedule a power-quality audit; plan a pilot 12/24-pulse retrofit with KPI targets.

Artikelmetadata

- Laatst bijgewerkt: 2025-09-12

- Volgende geplande update: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) Harmonic Control in Industrial Rectifiers; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.