Aangepaste hoofdregelaars met SiC-gematchte PCS-algoritmen voor FRT, reactief vermogen en netvorming/netvolgingmodi

Haalbare toleranties en maatnauwkeurigheid:

Productoverzicht en relevantie voor de markt in 2025

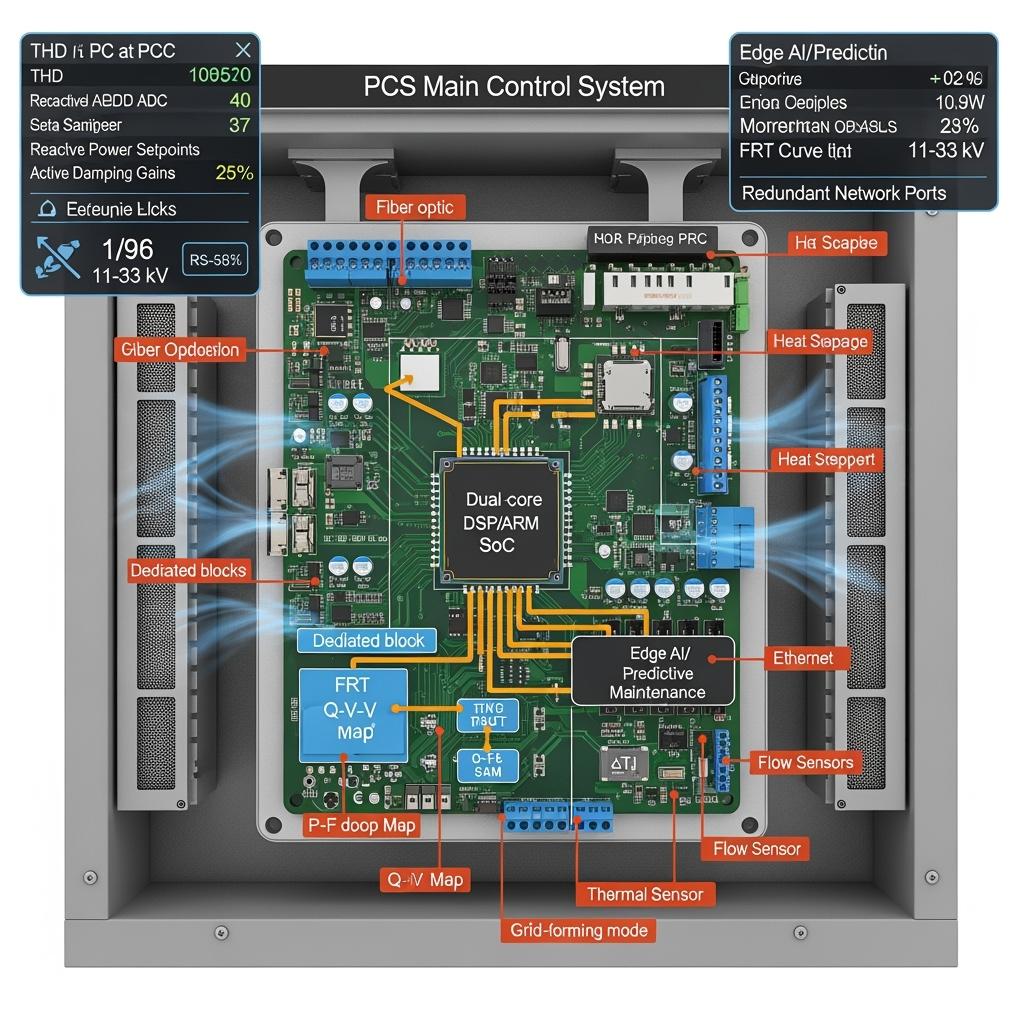

Aangepaste hoofdregelkaarten orkestreren de volledige prestatie-envelop van SiC-gebaseerde stroomconversiesystemen (PCS) en MV-omvormers. Ze combineren snelle signaalverwerking, robuuste communicatie en grid-support-algoritmen die zijn afgestemd op de snelle dynamiek en hoge schakelfrequenties (50–200 kHz) die mogelijk worden gemaakt door siliciumcarbide. In de textiel-, cement-, staalen opkomende industriële sectoren - waar 11-33 kV-voeders spanningsdalingen, frequentie-excursies en harmonische vervuiling ervaren - bepaalt de regelkwaliteit of systemen ≥98% efficiëntie bereiken, de netaansluiting bij de eerste poging doorstaan en uptime behouden bij 45–50°C omgevingstemperatuur.

De regelplatforms van Sicarb Tech zijn ontworpen rond:

- Op SiC afgestemde regellussen met hoogbandbreedte stroom-/spanningsregeling en dv/dt-bewuste modulatie

- Grid-support-functies: fault ride-through (FRT), Volt/VAR (Q–V) en P–f-droops, grid-forming (GFM) en grid-following (GFL) werking, virtuele traagheid en actieve demping voor compacte LCL-filters

- Klaar voor zware omgevingen: conforme coating, thermische derating-strategieën en voorspellende onderhoudshaken geïntegreerd met digitale twins

Voor implementaties in 2025 in de C&I- en grid-side-opslag van Pakistan (3–5 GWh verwacht over vijf jaar), verkorten aangepaste hoofdregelkaarten de inbedrijfstellingstijdlijnen, verminderen ze ongewenste trips op zwakke feeders en ondersteunen ze kasten met hoge dichtheid door nauw samen te werken met SiC-gate-drives, magnetische componenten en vloeistofkoeling.

Technische specificaties en geavanceerde functies

- Verwerking en I/O

- Hoogwaardige DSP/ARM SoC met FPU en real-time OS; deterministische looptijden ≤50–100 µs

- Geïsoleerde sigma-delta ADC's en precisieverwijzingen voor stroom-/spanningsmeting; anti-aliasing filters afgestemd op 50–200 kHz schakelen

- Hogesnelheids-PWM-generatoren met deadtime-regeling en fase-interleaving; gesynchroniseerde tijdbases over omvormerpoten

- Grid-support-regelreeks

- Grid-following (GFL): PLL met robuuste prestaties op zwakke grids (lage SCR); harmonische afwijzing en ride-through-logica

- Grid-forming (GFM): VSM/virtuele oscillatorregeling met synthetische traagheid, droopcurves en fault ride-through-overgangen

- Reactieve en frequentieondersteuning: Q–V- en P–f-droops met prioriteitsmodi; volt-watt- en frequentie-watt-karakteristieken voor gridcodes

- Actieve demping: LCL-resonantieonderdrukking via capacitor current feedback en adaptieve versterkingen

- Bescherming en coördinatie

- Gelaagde bescherming: snelle overstroom, DC-link-bescherming, DC-bus-balancering, eilanddetectie; integratie met gate-drive DESAT/TLO-gebeurtenissen

- FRT: configureerbare spannings-tijdprofielen (low/high voltage ride-through), reactieve stroominjectiestrategieën tijdens dalingen

- Systeemintegratie

- Interfaces met SiC-gate-drive-kaarten: fiber/geïsoleerde links voor immuniteit tegen ruis; compensatie van voortplantingsvertraging

- Thermische en hydraulische coördinatie: koelmiddelstroom-/temperatuuringangen, ventilatorregeling, ΔP-bewaking van stoffilters, derating-tabellen voor 45–50°C omgevingstemperatuur

- Cybersecurity en diagnostiek

- Ondertekende firmware-updates, op rollen gebaseerde toegangscontrole, veilig opstarten

- Gebeurtenisrecorder: oscillografie van dalinggebeurtenissen, redenen voor trips en momentopnamen van parameters voor snellere RCA

- Milieubestendigheid

- Conforme coating (selectief) en componenten van industriële kwaliteit; werking bij verlengde temperatuur; trillingstolerante montage

Prestatievergelijking: Op SiC afgestemde hoofdregelkaarten versus generieke PCS-controllers

| Criterium | Op SiC afgestemde aangepaste regelkaarten (GFM/GFL, FRT, actieve demping) | Generieke PCS-controllers (beperkte WBG-optimalisatie) |

|---|---|---|

| Bandbreedte van de stroomlus | Hoog, afgestemd op 50–200 kHz SiC-schakeling | Lager, gedimensioneerd voor ≤20 kHz silicium |

| Netondersteuningsfuncties | Volledige GFM + GFL, Q–V/P–f, programmeerbare FRT | Basis GFL; beperkte droops; vaste FRT |

| Prestaties op zwak grid | Robuuste PLL/VSM; actieve demping voor LCL | Gevoelig voor resonantie en trips |

| Inbedrijfstellingstijd | Korter met parameterpakketten en automatisch afstemmen | Langere afstemcycli ter plaatse |

| Uptime op zware locaties | Thermische/hydraulische derating geïntegreerd | Beperkt milieubewustzijn |

Belangrijkste voordelen en bewezen resultaten met citaat van experts

- Snellere acceptatie door nutsbedrijven: Pre-gevalideerde FRT-curves, reactieve vermogensondersteuning en lage THD via actieve demping sluiten aan bij MV-aansluitpraktijken op 11–33 kV-feeders.

- Hogere efficiëntie en dichtheid: Strakke SiC-coördinatie maakt hogere schakelfrequenties en kleinere LCL-filters mogelijk, wat ≥98% PCS-efficiëntie en >30% footprintreductie ondersteunt.

- Betrouwbaarheid in hitte en stof: Door de regeling gestuurde derating, ΔP-bewaking van filters en fouttolerante overgangen handhaven de uptime tijdens de extreme zomerse omstandigheden van Pakistan.

Deskundig perspectief:

“Advanced control—particularly grid-forming, fast droop response, and active damping—is essential to leverage wide bandgap hardware on weak grids without sacrificing stability or efficiency.” — IEEE Power Electronics Magazine, grid-support control of WBG converters (https://ieeexplore.ieee.org)

Praktijktoepassingen en meetbare succesverhalen

- 2 MW/4 MWh PCS in Punjab: Met GFM/VSM ingeschakeld en afgestemde actieve demping bereikte het systeem ≤2,8% THD bij PCC, doorstond het ride-through-tests bij de eerste poging en verminderde de inbedrijfstellingstijd met ~30%. De round-trip-efficiëntie verbeterde met ~0,7% bij ~100 kHz schakelen.

- Microgrid van een textielfabriek in Sindh: Aangepaste Q–V-droops stabiliseerden de spanning tijdens de opstartpieken van de weefgetouwen; ongewenste trips daalden met >40% tijdens de moessonmaanden, aangezien de thermische derating-logica de omgevingstemperatuur van 50°C en de belasting van het stoffilter aankon.

- MV-omvormerpilot in het zuiden van Pakistan: Naadloze GFL-naar-GFM-overgangen handhaafden de frequentieondersteuning tijdens dalingen van de feeder; het systeem voldeed aan de vereisten voor reactieve stroominjectie en respecteerde tegelijkertijd de thermische grenzen.

Overwegingen voor selectie en onderhoud

- Algoritme selectie per missieprofiel

- Kies GFM voor eilandbedrijf, microgrids en zwakke feeders; gebruik GFL voor sterke grids met strakke PLL-behoeften. Handhaaf terugvalmodi.

- Integratie van actieve demping

- Co-design LCL-componentwaarden en dempingslussen; valideer over feeder SCR-variaties en gridimpedantiesweeps.

- Bescherming en FRT-afstemming

- Configureer FRT-curves volgens lokale nutsbedrijfsspecificaties; geef prioriteit aan reactieve stroominjectie tijdens LVRT; valideer overgangen met HIL vóór veldproeven.

- Milieubescherming

- Breng conforme coating aan op gevoelige gebieden; zorg ervoor dat thermische sensoren en koelmiddel-/ventilatorregeling zijn gekalibreerd voor een omgevingstemperatuur van 45–50°C.

- Levenscyclus en updates

- Gebruik ondertekende firmware-updates, onderhoud parameterpakketten per site en log oscillografie voor continue verbetering en training.

Succesfactoren in de industrie en getuigenissen van klanten

- Cross-disciplinair co-design (apparaten, gate-drives, magnetische componenten, regelsoftware en thermisch beheer) is cruciaal voor het bereiken van stabiliteit bij hoge schakelfrequenties.

- Parameterbibliotheken voor Pakistaanse nutsbedrijven en feeder-archetypen versnellen de replicatie over sites.

Feedback van klanten:

"De op SiC afgestemde controller gaf ons consistente gridtests over nutsbedrijven. Actieve demping en GFM transformeerden een zwakke feeder in een stabiel platform voor onze PCS." — Hoofd Engineering, Pakistan ESS-integrator

Toekomstige innovaties en markttrends

- Adaptieve grid-support: Door AI afgestemde droops en dynamische traagheid die reageren op feedercondities zonder handmatige herafstemming

- Real-time Tj-schatting feed-through van gate-drives voor thermisch bewuste regeling en derating

- Cyberveilige fleet-updates met externe getuigentests voor naleving van nutsbedrijven

- Lokalisatie: assemblage van regelkaarten en HIL-labs in Pakistan om de doorlooptijden te verkorten en de ondersteuning ter plaatse te verbeteren

Veelgestelde vragen en antwoorden van experts

- Hebben we grid-forming-mogelijkheden nodig voor C&I-opslag?

GFM is steeds waardevoller voor zwakke grids, microgrids en ride-through-stabiliteit. Veel integrators implementeren dual-mode (GFL + GFM) met automatische overgangen. - Hoe vermindert actieve demping de LCL-grootte?

Door resonantie elektronisch te onderdrukken, maakt actieve demping hogere schakelfrequenties en kleinere passieve componenten mogelijk, terwijl een lage THD wordt gehandhaafd. - Kunnen deze controllers integreren met bestaande gate-drives?

Ja. Fiber/geïsoleerde links en gestandaardiseerde telemetrie maken coördinatie met SiC-gate-drives (DESAT/TLO) mogelijk, waardoor snelle bescherming en gesynchroniseerde regeling worden gewaarborgd. - Hoe worden FRT-profielen geconfigureerd?

Via parameterreeksen die zijn afgestemd op nutsbedrijfscodes; profielen definiëren spannings-tijdvensters, prioriteiten voor reactieve stroominjectie en herstelgedrag. - Wat is de impact op de inbedrijfstelling?

Pre-gevalideerde parameterpakketten en HIL-geteste profielen verkorten de inbedrijfstellingstijd doorgaans met 20–30% ten opzichte van generieke controllers.

Waarom deze oplossing werkt voor uw activiteiten

De operationele context van Pakistan - hete omgeving, stof en variabele feeders - vereist regelsystemen die de snelheid van SiC volledig benutten en tegelijkertijd de gridstabiliteit waarborgen. Aangepaste hoofdregelkaarten met op SiC afgestemde algoritmen leveren:

- ≥98% efficiëntie met compacte LCL-filters

- Soepele FRT, reactieve ondersteuning en GFM/GFL-werking op zwakke grids

- Thermische/hydraulische coördinatie voor minder trips en een langere levensduur

Deze combinatie versnelt goedkeuringen, verhoogt de uptime en verlaagt de LCOE in de textiel-, cement-, staal- en opkomende sectoren.

Neem contact op met specialisten voor oplossingen op maat

Werk samen met Sicarb Tech om uw SiC-regelstack te ontwerpen:

- 10+ jaar ervaring in SiC-productie en applicatie-engineering

- Steun van de Chinese Academie van Wetenschappen voor algoritme- en hardware-innovatie

- Aangepaste productontwikkeling over R-SiC, SSiC, RBSiC, SiSiC en geavanceerde regelkaarten

- Technologieoverdracht en diensten voor fabrieksoprichting - HIL-testbedden, productielijnen en certificeringsondersteuning in Pakistan

- Kant-en-klare levering van materialen en apparaten tot gate-drives, hoofdregelkaarten, LCL-filters, thermische systemen en compliance-documentatie

- Bewezen resultaten met 19+ ondernemingen die een hogere efficiëntie, snellere inbedrijfstelling en robuuste betrouwbaarheid bereiken

Vraag een

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

Verkrijg co-design- en implementatiesleuven voor 2025–2026 om de risico's van netaansluiting te verminderen, de inbedrijfstellingstijden te verkorten en op te schalen in de industriële centra van Pakistan.

Artikelmetadata

Laatst bijgewerkt: 2025-09-10

Volgende geplande update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.