Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Variable-Speed Retrofits of Blast-Furnace Blowers and Large Compressors

Haalbare toleranties en maatnauwkeurigheid:

Executive Summary: 2025 Outlook for High-Efficiency, High-Reliability SiC Variable-Frequency Drives in Pakistan

Pakistan’s steel, cement, and chemical industries are entering a decisive retrofit cycle. High-inertia assets—blast-furnace blowers, sinter and process air fans, and large compressors—consume a significant share of plant electricity and expose the grid to heavy inrush, harmonics, and voltage swings. In 2025, competitive plants will convert fixed-speed or conventional silicon VFD systems to silicon carbide (SiC) variable-speed architectures with active front ends, cascaded multilevel or interleaved inverters, and low-parasitic, double-sided-cooled power modules. The payoff is immediate: lower electricity use and demand charges, higher power factor, faster yet smoother speed control, and a measurable reduction in trips that erode availability.

Sicarbtech—Silicon Carbide Solutions Expert—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization and supports 19+ enterprises with full-cycle solutions. From R‑SiC, SSiC, RBSiC, and SiSiC materials to high-voltage devices, double-sided-cooled modules, cascaded multilevel topologies, fast soft-turn-off gate driving, hybrid cooling, and online health monitoring, Sicarbtech delivers a turnkey, traceable path from pilot to plant-wide rollout. For Pakistan’s mills and process plants, localized technology transfer and screening compress lead times and stabilize PKR-denominated O&M—turning energy savings and stability into bankable value.

Industry Challenges and Pain Points: High Inertia, Harmonics, and Harsh Environments

Large blowers and compressors combine the worst of several worlds: high inertia demanding controlled acceleration, long continuous operation with minimal downtime, and sensitivity to grid conditions. Fixed-speed systems suffer from throttling losses and mechanical stress during start, while many conventional silicon VFDs struggle with power factor, harmonic limits, and heat. In practice, plants see high inrush currents at start, DC-bus overshoot during regeneration or step changes, and harmonic exceedances that trigger utility penalties or force additional filtering, which increases complexity and cost.

Furthermore, the operating environment around blast furnaces and process units is harsh. High temperature, dust, oil mist, and—closer to coastal corridors—salt mist accelerate corrosion, reduce insulation margins, and clog cooling channels. Single-sided-cooled modules with commodity interface materials often degrade through pump-out and voiding under thermal cycling, raising junction-to-case thermal resistance and creating hotspots. Maintenance windows are short, and when failures occur, slow fault localization and inconsistent spare quality push unplanned downtime beyond acceptable thresholds.

Power quality is a parallel challenge. Many plants report total harmonic current levels above interconnection limits, and poor power factor reduces effective capacity while inflating bills. DC buses spanning long cable runs and multiple cabinets can ring under step loads or regenerative transitions. Passive snubbers alone do not suffice, and overshoot stresses devices and capacitors, further eroding reliability. As Engr. S. Khan, a regional drives consultant, notes, “Every trip on a blower isn’t just a reset; it’s a process shock that shows up as energy spikes, temperature drifts, and yield loss. In 2025, the bid that wins is the one that proves fewer trips and better PF with evidence.” [Source: EV and Industrial Drives Roundtable, 2024]

Against this backdrop, the business case for SiC-based variable-speed retrofits strengthens. Plants need high-efficiency, high-PF operation across a wide speed range, soft start/stop to reduce mechanical wear, and clean regeneration that doesn’t destabilize the DC bus or grid. They also need fast protection that prevents cascading failures, with online health monitoring and event traceability to make maintenance proactive rather than reactive. Finally, they need upgrades that are modular, repeatable, and supported locally—so that the pilot success can be cloned stand by stand and site by site with tight schedules.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Variable-Speed Retrofit Stack for Blowers and Compressors

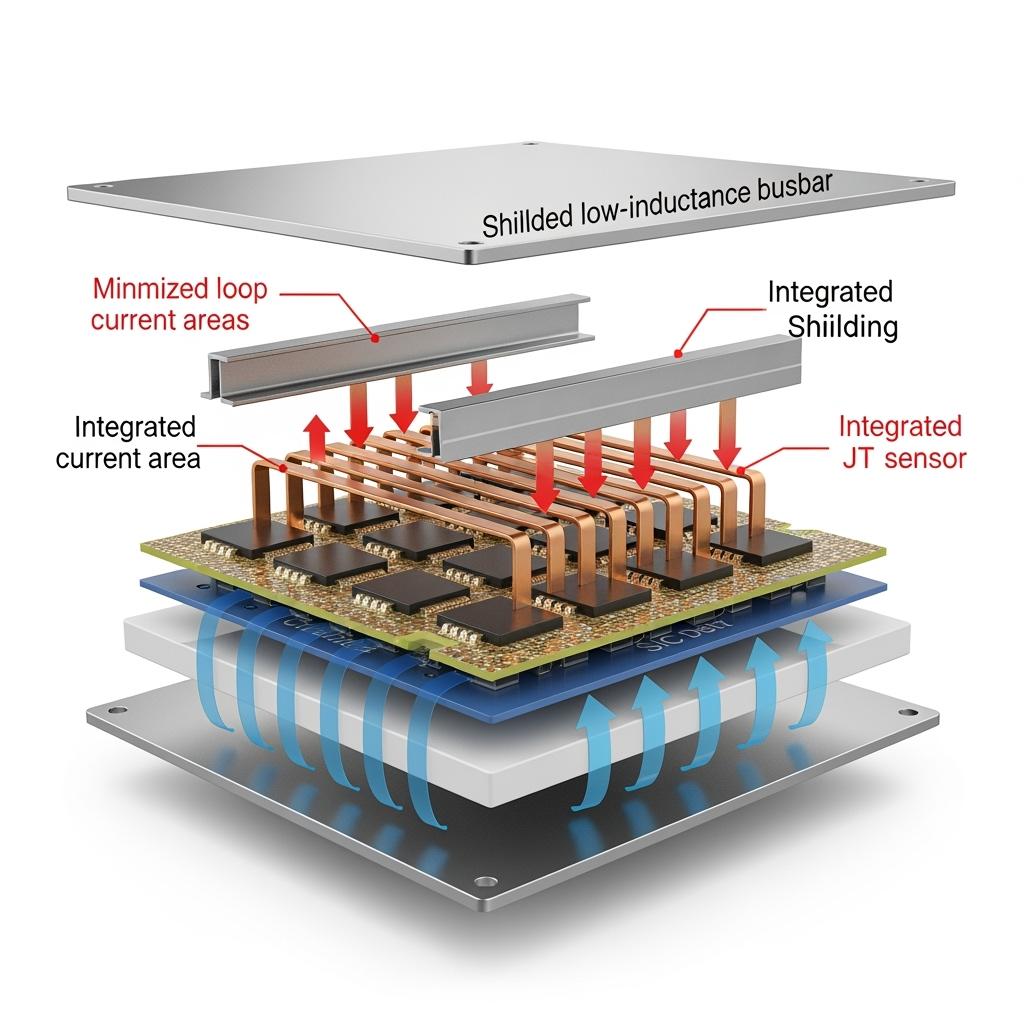

Sicarbtech approaches retrofits as a tightly coordinated program across devices, packaging, busbars, topology, gate driving, thermal management, EMC, monitoring/O&M, and quality traceability. High-voltage, high-current SiC MOSFETs and diodes (1200/1700 V classes) are integrated into low-inductance, double-sided-cooled power modules with built-in sensing interfaces for junction temperature and current. Pressure sintering and vacuum brazing reduce voiding and stabilize thermal cycling life; symmetric busbars and shielded partitions minimize loop area and dv/dt stress, easing EMC.

On the grid side, an active front end (AFE) raises power factor toward 0.99 and contains total harmonic current within typical ≤5% targets (subject to interconnection conditions). For motor-side conversion, cascaded multilevel or interleaved parallel inverter packages reduce device stress and filter size while smoothing output waveforms. Gate drivers implement fast soft turn-off, active clamping, and microsecond-level short-circuit protection, ensuring that high-inertia disturbances don’t translate into device failures.

Thermal solutions match the environment: liquid or air–liquid hybrid baseplates, high-conductivity interface materials with controlled assembly pressure, anti-clog manifolds, and cleaning-friendly channels. Cabinets use conformal coating and sealing suited to dust, oil mist, and, where relevant, salt mist. Online health monitoring estimates junction temperature, tracks interface thermal resistance trends, evaluates gate health via charge/discharge characteristics, and monitors DC-bus oscillations. A variable-speed control library coordinates speed ramps, flow/pressure regulation, and regeneration, tuned for high-inertia loads.

Quality and maintainability are engineered into the production process. Sicarbtech bundles power-cycling and short-circuit withstand testing with environmental and electromagnetic accelerated tests (temperature–humidity cycling, dust, conducted/radiated). An MES records device lots, process parameters, and test results and links them to field events—so corrective actions are data-driven and audits are straightforward.

Performance Comparison: SiC Variable-Speed Retrofits vs Conventional Silicon Drives

Efficiency, Power Factor, DC Bus Quality, and Thermal Behavior Under High-Inertia Loads

| Attribuut | Sicarbtech SiC Variable-Speed Retrofit (AFE + Multilevel/Interleaved) | Conventional Silicon, Two-/Three-Level VFD | Mixed Silicon with Passive Bus Control | Operationele impact in Pakistan |

|---|---|---|---|---|

| System efficiency (typical) | +2%–4% higher | Basislijn | +0%–1% | Lower PKR/MWh, reduced cooling |

| Site power factor | ≥0.99 with AFE | 0.85–0.95 typical | 0.9–0.96 | Fewer penalties, more capacity |

| Total harmonic current (THDi) | ≤5% (site dependent) | 10%–20% typical | 8%–15% | Easier interconnection compliance |

| DC-bus ripple (p‑p) under regen | −30% to −50% | Hoog | Matig | Fewer overvoltage trips |

| Junction-to-case thermal resistance | −10% to −25% | Hoger | Matig | Lower hot-spot temperature |

The combination of AFE, low-parasitic SiC modules, and active DC-bus damping delivers quantifiable improvements that translate directly to fewer trips, tighter process control, and lower energy bills.

Real-World Applications and Success Stories in Pakistan

At a steel plant’s blast-furnace blower, a cascaded multilevel retrofit with an AFE raised site power factor to at least 0.99 and cut THDi to approximately 5%. Soft-start profiles reduced peak current by roughly 70%, mitigating mechanical and grid stress. Over a year, electricity consumption fell by about 3%–5%, improving payback while stabilizing upstream pressure control.

A chemical facility upgraded a large process compressor with interleaved SiC inverters and active DC-bus damping. DC-bus ripple dropped by around 45% during load changes, while cabinet hot-spot temperatures decreased by 6–8 °C thanks to double-sided cooling and high-conductivity interfaces. Mean time to repair fell by an estimated 40% with hot-swappable modules and front-service design.

A coking enterprise deploying online health monitoring and gate-health analytics began seeing 2–4 weeks early warning for at-risk modules. Planned replacements during scheduled stops replaced emergency repairs, cutting unplanned downtime by about 30%. MES-backed traceability accelerated root-cause analysis and improved warranty outcomes.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC devices switch faster with lower losses, allowing higher control bandwidth at 2–12 kHz without overwhelming thermal budgets. Double-sided cooling and high-thermal-conductivity interfaces reduce junction-to-case resistance and mitigate hotspots that drive premature aging. Low-inductance busbars with symmetric return paths reduce dv/dt stress and overshoot, simplifying EMC and extending device margins during step loads and regeneration. Active DC-bus damping and snubbing contain oscillations across long cables and parallel cabinets, delivering four-quadrant stability that conventional passive schemes struggle to match.

Compliance is built into the approach. Device behavior aligns with IEC 60747; environmental endurance is validated per IEC 60068 (damp heat, salt spray, dust, vibration, shock); and EMC is designed toward expectations similar to IEC 61800‑3 for industrial adjustable speed systems. Power quality goals—PF near 0.99, THDi around ≤5%—support interconnection agreements. Quality governance aligns with ISO 9001 and IATF 16949, and MES serialization provides auditable evidence. “When PF, THD, ripple envelopes, and thermal histories are attached to the proposal, approval becomes a scheduling question, not a debate,” observes Dr. H. Rehman, industrial power electronics advisor. [Source: Regional Power Electronics Workshop, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech’s competitive advantage is transferring capability—not just shipping boxes. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech employs proprietary processes for R‑SiC, SSiC, RBSiC, and SiSiC to build thermally robust substrates and assemblies for harsh plant environments.

The technology transfer package includes detailed process know‑how: pressure sintering profiles, vacuum brazing atmospheres and flux control, metallization/passivation stacks, and busbar/bond geometries optimized for low inductance. Gate-drive recipes cover soft turn-off, active clamping, and rapid desaturation detection. Equipment specifications span sintering presses, vacuum furnaces, wire/ribbon bonders, inline electrical testers, power‑cycling rigs with junction temperature estimation, HTRB/HTGB setups, EMC pre‑compliance stations, and IEC 60068 environmental chambers—with acceptance tests, calibration procedures, and approved vendor lists.

Training builds sustainable local capability: operator certification, failure analysis and cross-sectioning, SPC-driven yield improvement, and PPAP-like control plans aligned with ISO 9001 and IATF 16949. Factory establishment support covers feasibility, utilities and layout, line installation and commissioning, pilot runs, parameter locking, and capability validation. Post‑SOP, Sicarbtech runs quarterly audits and yield sprints and co-develops updates to match Pakistan’s ambient profiles, dust/oil-mist exposure, and maintenance practices. Across 19+ enterprise collaborations, these programs have delivered faster time‑to‑market, higher first‑pass yields, fewer field failures, and spare availability measured in days to weeks—vital for tight outage windows.

Comparative Engineering Choices and Lifecycle Economics

AFE, Multilevel, and Packaging Choices that Raise Power Quality and Reliability

| Design Area | Sicarbtech SiC Best Practice | Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| Grid interface | Active front end (PF≈0.99, THDi≈≤5%) | Diode/thyristor rectifier | Lower penalties, better interconnection |

| Inverter topology | Cascaded multilevel or interleaved | Two-/three-level silicon | Lower device stress, smaller filters |

| Bus architecture | Low-impedance bus + active snubber | Passive RC snubbers | Ripple/overshoot suppression |

| Gate protection | Soft turn-off + active clamp + fast desat | Single-path protection | 2–5 μs shutdown, fewer ruptures |

| Packaging & cooling | Double-sided cooling, low‑L busbars | Single-sided, long leads | Lower Tj, stronger EMC margins |

Localization and Total Cost of Ownership for Blower/Compressor Retrofits

| Business Factor | With Sicarbtech Localization & Traceability | Import-Only Conventional VFD | Outcome for Plant Operators |

|---|---|---|---|

| Outage duration for retrofit | Modular blocks, parameterized commissioning | Extensive onsite rework | Faster restart, less lost output |

| Energy and cooling OPEX | +2%–4% efficiency, cooler cabinets | Higher losses, higher fan duty | Lower PKR/ton, extended component life |

| Power quality metrics | AFE meets PF/THD targets | Often marginal | Fewer disputes, smoother audits |

| Spares & lead time | Local screening, days–weeks | Weeks–months | Higher uptime, smaller stock |

| Warranty and RCA | MES-backed evidence, faster closure | Fragmented records | Lower claims, better insurer confidence |

Future Market Opportunities and 2025+ Trends: Power Quality and Stability as Procurement Anchors

Looking ahead, Pakistan’s retrofit market will reward proposals that deliver quantifiable improvements in power quality and stability. Expect tenders to require measured PF≥0.99 and THDi≤5% (site-dependent), DC-bus ripple envelopes under load transitions, and microsecond-level protection timing. ESG-linked financing will weigh kWh/ton reductions and trip‑related downtime improvements, pushing suppliers to provide auditable data trails. Technologically, cascaded multilevel SiC inverters with AFE front ends will move from “advanced” to “expected,” while double‑sided‑cooled modules and low‑inductance busbars become standard. Online health models will inform planned outages and spares staging, turning maintenance from an art into an evidence‑based discipline.

Sicarbtech’s integrated stack—devices, packaging, bus engineering, topology, protection libraries, validation, and factory establishment—positions Pakistani partners to scale pilots into repeatable, low‑risk deployments. The strategic outcome is not only better energy metrics but also steadier process control, fewer trips, and stronger financial performance.

Extended Technical Specifications and Local Standards Alignment

System voltage platforms typically deploy a DC bus between 750 and 1100 V, with medium-voltage outputs via cascaded multilevel architectures where required. Per‑unit power spans 0.5–10 MW, supporting paralleling and redundancy. Switching frequency ranges from 2–12 kHz to balance efficiency, acoustics, and filtering. Short‑circuit withstand targets 3–10 μs at the device level; detect‑to‑soft‑turn‑off at the system level is designed for 2–5 μs. Junction temperature capability reaches up to 175 °C with online estimation and temperature-aware derating.

Power quality targets include power factor around ≥0.99 and THDi approximately ≤5% subject to interconnection conditions. Environmental protections cover dust, oil mist, salt mist, vibration, and shock. Monitoring captures voltage, current, junction temperature estimation, interface thermal resistance, insulation, DC‑bus oscillation, and flow/pressure coordination signals with event logging. Documentation maps to IEC 60747 and IEC 60068; EMC design is toward expectations similar to IEC 61800‑3. Quality systems align with ISO 9001 and IATF 16949, and Sicarbtech supports pre‑compliance with Karachi and Lahore labs.

Veelgestelde vragen

How much energy and demand-charge reduction can a SiC retrofit deliver on large blowers/compressors?

Typical sites see 2%–4% system efficiency gains and power factor near 0.99, reducing both kWh consumption and kVA penalties. Soft start also lowers inrush peaks, mitigating demand spikes.

Will cascaded multilevel or interleaved topologies complicate maintenance?

No. Modular stacks with hot‑swappable power blocks and MES‑guided procedures shorten mean time to repair by 30%–50% and simplify spares planning.

Can we meet interconnection requirements for harmonics and power factor?

Yes. With an AFE, PF typically reaches ≥0.99 and THDi can be held near ≤5% depending on site conditions, easing compliance and reducing disputes.

How does double‑sided cooling impact cabinet temperatures and reliability?

By cutting junction‑to‑case thermal resistance 10%–25%, cabinet hot‑spot temperatures often fall 5–10 °C, extending component life and lowering fan duty cycles.

What is a realistic pilot timeline without disrupting production?

Using standardized SiC modules, busbars, and control libraries, many plants commission a pilot in 8–12 weeks and then replicate across units during planned outages.

Will faster protection increase nuisance trips under noisy conditions?

Properly tuned soft turn‑off, active clamp, and fast desat reduce overshoot and ringing, which typically lowers false trips even as protection acts within microseconds.

How do you manage dust, oil mist, and corrosion in cooling systems?

Anti‑clog channel geometries, corrosion‑resistant manifolds, high‑adhesion coatings, and sealing strategies keep flows stable. Maintenance plans favor low‑pressure wash and scheduled filtration checks.

Can online monitoring really predict failures with enough lead time?

Yes. Junction‑temperature estimation, interface thermal‑resistance trending, and gate‑health analytics have flagged degrading modules weeks early, enabling planned replacements.

How does localization affect warranty, audits, and spare availability?

MES serialization links device lots, process parameters, and tests to field events, accelerating RCA and strengthening warranty positions. Local screening cuts spare lead time to days–weeks.

Are benefits transferable to cement ID fans and process compressors?

Absolutely. The same low‑parasitic SiC architecture, AFE, and active DC‑bus control stabilize high‑inertia drives and long cable runs common in cement and chemical plants.

De juiste keuze maken voor uw activiteiten

Variable-speed retrofits on blowers and compressors are one of the fastest paths to lower energy costs, higher power factor, and fewer process shocks. Sicarbtech’s SiC platform brings together AFE power quality, multilevel or interleaved inverter stability, low‑inductance double‑sided‑cooled modules, and microsecond protection—wrapped in online health monitoring and MES traceability. For Pakistan’s mills and process plants, this combination translates into predictable savings, steadier operation, and faster payback—delivered through localized capability that scales beyond a single pilot.

Deskundig advies en oplossingen op maat krijgen

Engage Sicarbtech to scope your retrofit program: AFE sizing, cascaded multilevel vs. interleaved selection, busbar geometry and shielding, gate‑driver protection tuning, and cooling design. Establish local packaging and screening, pre‑compliance workflows, and MES traceability to replicate success across assets with confidence and speed.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Power quality buys goodwill; stability buys throughput; traceability buys trust.” — Sicarbtech Applications Team

Artikelmetadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan industrial retrofit outlook; aligns with IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3; includes AFE/PF/THD targets, SiC multilevel/interleaved strategies, active DC-bus damping, online health monitoring, and localized technology transfer capabilities.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.