High-Temperature SiC Components for B2B Industrial Use

Haalbare toleranties en maatnauwkeurigheid:

Executive summary: why high-temperature silicon carbide is redefining Brazilian industry in 2025

Brazil’s industrial economy is being reshaped by the need to operate hotter, longer, and cleaner. From direct-reduction iron, calcination, and sintering lines across Minas Gerais and Espírito Santo to pre-salt offshore platforms and biomass/ethanol cogeneration in the Center-South, operators are raising process temperatures, shortening thermal cycles, and tightening emissions—all while navigating ABNT NBR standards, ANP procurement expectations, IBAMA environmental licensing, and NR safety norms. Moreover, currency volatility and global lead-time uncertainty place a premium on components that preserve geometry and surface integrity under extreme heat, thereby stabilizing energy intensity and maintenance schedules.

In this environment, high-temperature silicon carbide (SiC) components—engineered in R-SiC, SSiC, RBSiC, and SiSiC—offer a practical route to longer service life and predictable performance. Sicarbtech, located in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, has spent more than a decade refining full-cycle SiC solutions, from powder engineering and precision finishing to turnkey technology transfer and factory establishment. Supporting over 19 enterprises, Sicarbtech enables Brazilian mining, oil, and agricultural processors to move beyond catalog parts and into customized, high-temperature SiC architectures that reduce unplanned downtime, cut kWh per ton, and accelerate qualification.

Industry challenges and pain points: the hidden costs of heat, shock, and compliance

Running hotter is not just a matter of metal selection or refractory thickness. In metallurgical kilns and calciners, temperature gradients during start/stop cycles and load changes introduce thermal shock that cracks brittle or dense components. Alumina structures can spall when confronted with rapid heating and cooling, while metallic fixtures may creep, deform, or scale in oxidizing atmospheres. Each micro-crack increases flow disruption, raises pressure drop, and steals thermal efficiency. In rotary kilns, distorted support fixtures can misalign loads, degrading product quality and forcing speed reductions that cascade into missed delivery slots.

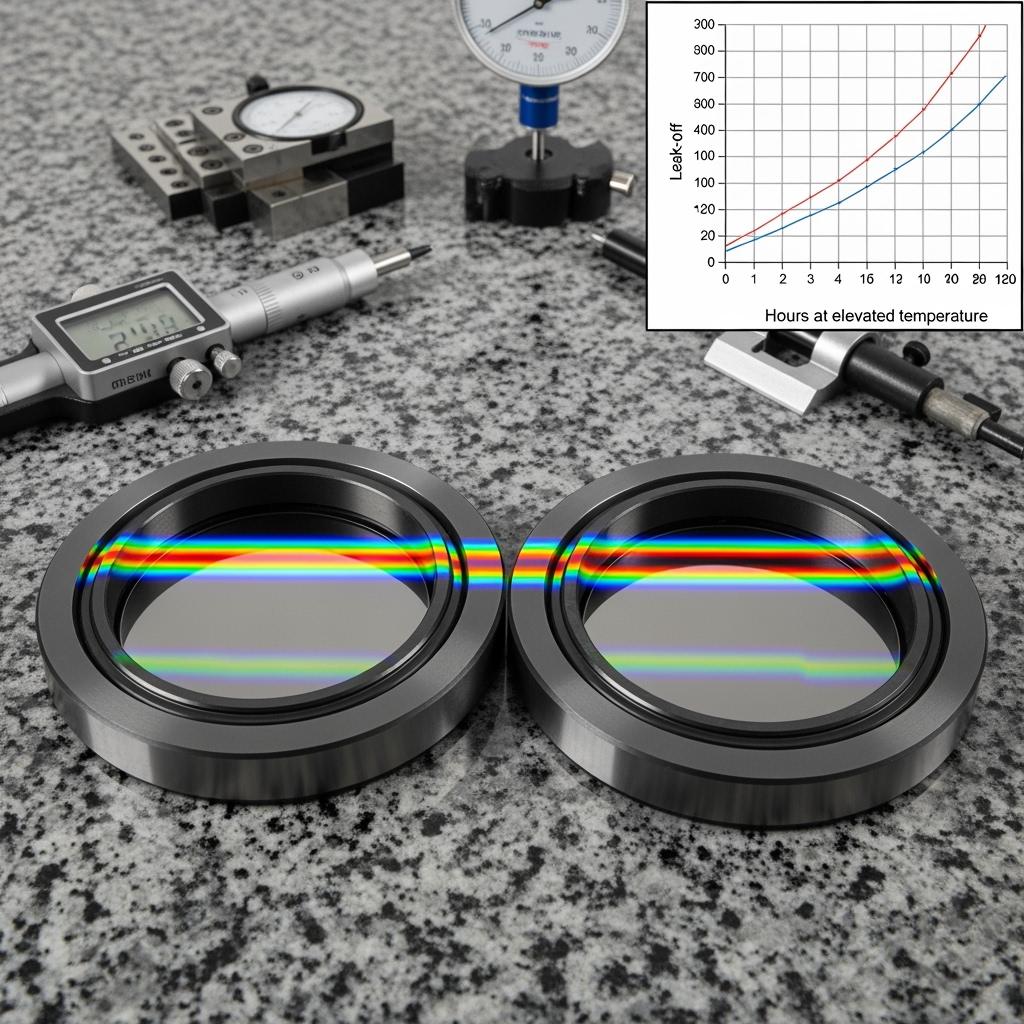

Offshore and upstream oil and gas processes, while not always at furnace temperatures, routinely couple high temperature with chlorides and pressure transients. Mechanical seal faces, bearings, choke trims, and valve seats face accelerated wear if materials cannot shed heat or resist chemical attack. ANP procurement frameworks referencing API 610/682 and NACE MR0175/ISO 15156 leave little room for improvisation. A single hot-running seal that loses flatness can lead to leak-off spikes, safety interventions, and costly vessel standbys.

Agribusiness and biomass introduce a different heat profile: cyclic thermal exposure during CIP, steam sterilization, and batch operations. Fertilizer handling sees corrosive species at elevated temperatures; biomass boilers and ash-handling lines experience erosive high-temperature flow where small geometry changes have outsized hydraulic effects. The seasonality of harvests compresses risk; an outage during peak crop windows may trigger port penalties in USD and contractual disputes that outlive the technical incident. With IBAMA’s environmental oversight and NR safety norms, operators cannot mask thermal wear with ad-hoc fixes.

Compounding the engineering risks is a documentation reality. Datasheets often report peak properties at ambient or steady-state temperatures, not fatigue behavior across thousands of thermal cycles. Without microstructural tuning—grain size, pore architecture, reaction bonding phases—and robust finishing, high-temperature parts lose geometry faster than predicted. This leads to inflated safety stocks, emergency airfreight, and FX exposure. “In high-temperature service, the cost curve is shaped by stability, not peak strength,” observes Dr. Renata Valença, an industrial materials expert who advises process plants in Southeast Brazil. “Suppliers win when they can prove how slowly surfaces roughen and how well flatness survives cycles.” (Source: Process Materials Brazil Review, 2024)

Furthermore, qualification delays are expensive. ABNT NBR-referenced tests and inspection records formatted for ANP workflows accelerate approvals, while audit-ready traceability reduces friction. Without these, technically sound upgrades can sit idle in procurement queues, turning potential energy savings into lost opportunity. Bridging performance and paperwork is thus central to the Brazilian high-temperature reality.

Advanced silicon carbide solutions portfolio tailored to high-temperature duty

Sicarbtech’s portfolio addresses heat not with a single grade, but with a family of SiC materials tuned to service reality.

Recrystallized SiC (R-SiC) leverages high-temperature stability with low density and open porosity. In kiln furniture, burner blocks, and thermal fixtures, low mass reduces thermal gradients and accelerates heat-up/cool-down, cutting cycle times while resisting thermal shock. Porosity and grain architecture can be tuned to minimize thermal stress concentrations, improving crack resistance during rapid transients.

Sintered SiC (SSiC) brings near-zero porosity and superior corrosion resistance at high temperatures, making it suitable for hot service mechanical seals, bearings, and throttling components subjected to thermal spikes. Its high thermal conductivity spreads heat quickly, protecting flatness and surface finish under aggressive duty cycles.

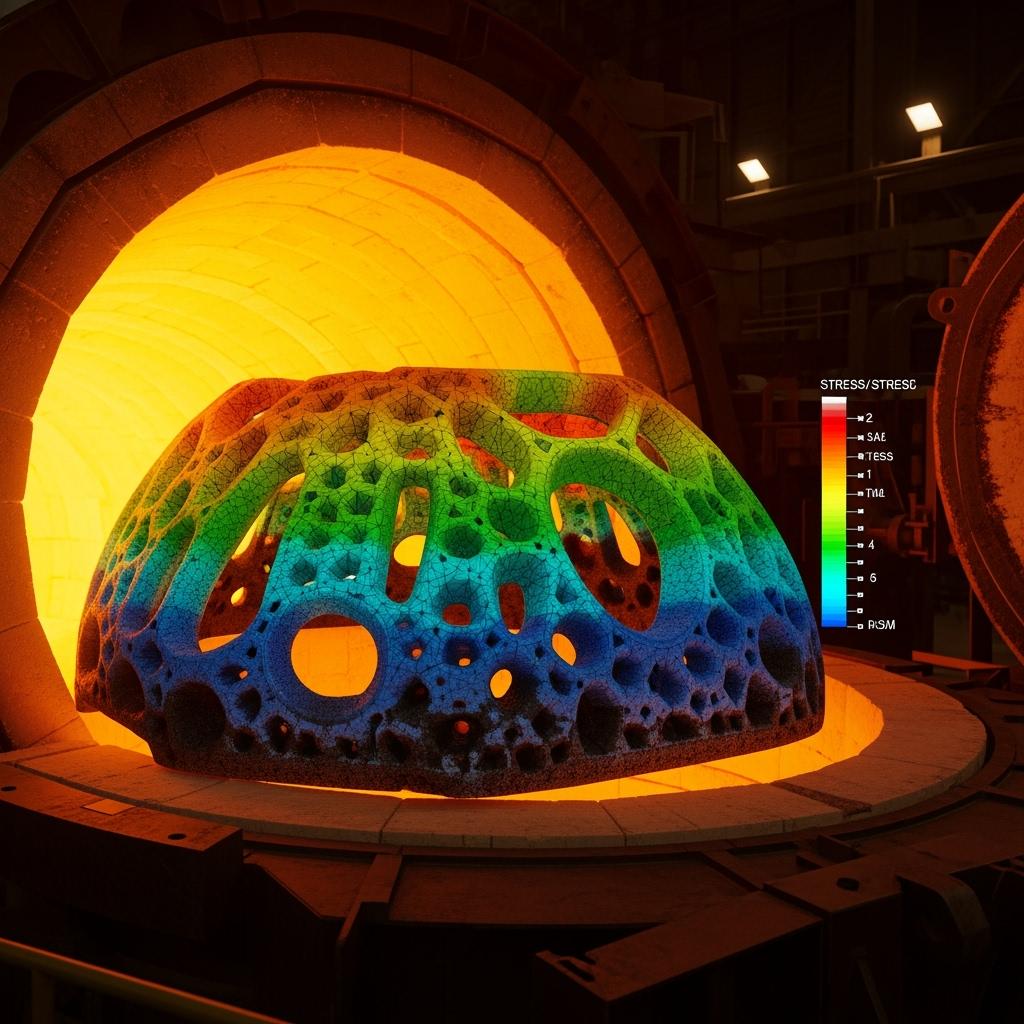

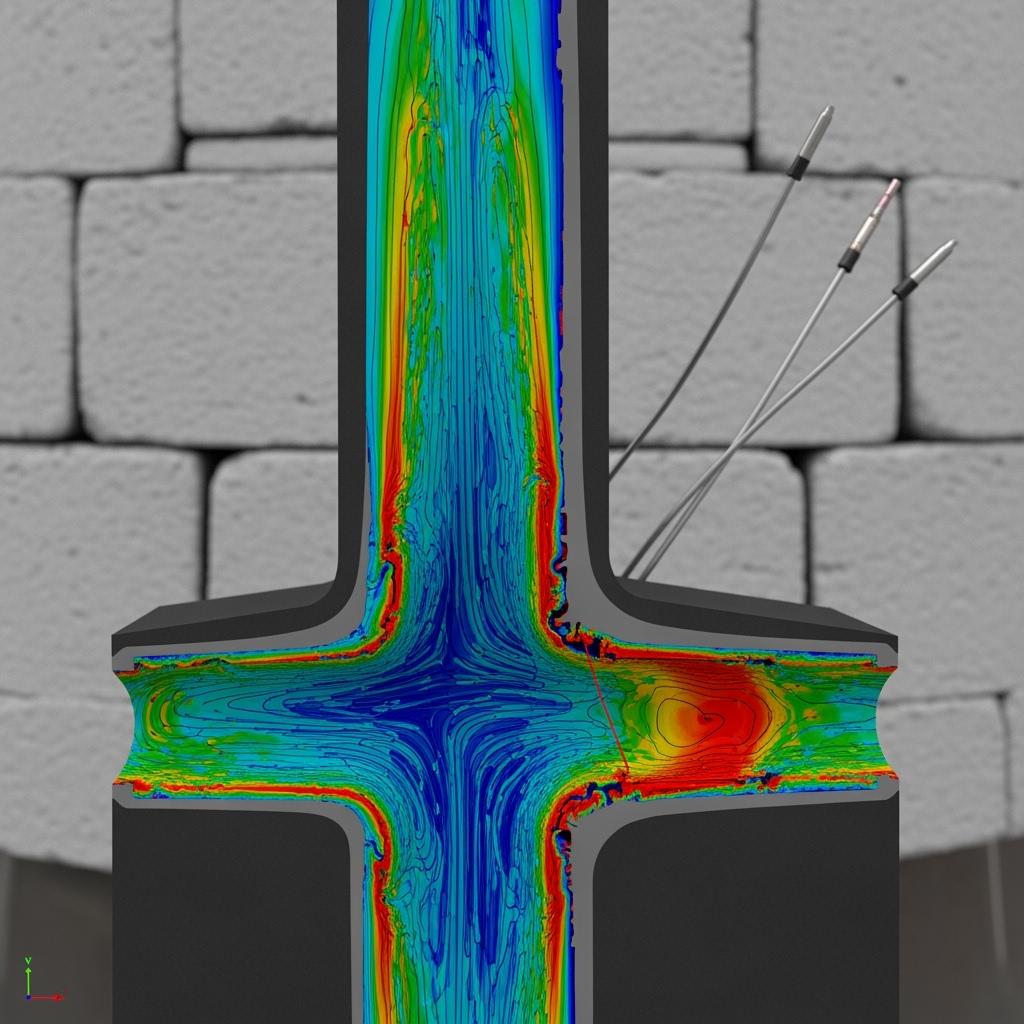

Reaction-bonded SiC (RBSiC/SiSiC) balances high strength with exceptional thermal shock tolerance and manufacturability of complex shapes. This makes it ideal for high-temperature cyclone liners, kiln rails, high-velocity nozzles, and hot-gas path components where near net-shape capability streamlines cost and reduces joints that can become failure points.

Sicarbtech co-engineers geometry and microstructure simultaneously. For kiln furniture, topology optimization reduces hot spots and stress risers; for hot-gas nozzles, internal profiles are CFD-tuned to smooth flow and lower impingement, which delays erosion and keeps pressure loss stable. For seals and bearings, SSiC faces are micro-lapped to optical flatness, then paired with validated counterfaces to lock in leak-off and friction parameters even as temperature swings. Each component is delivered with ABNT-linked test methods, dimensional/NDT reports, and full traceability, which shortens approvals and standardizes spares across multi-site operations.

Performance comparison: silicon carbide versus traditional materials under high-temperature conditions

Properties that govern life in heat: stability, shock resistance, and heat spreading

| Property / Condition | SSiC (gesinterd SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Mullite | Heat-Resistant Staal (e.g., 310/253MA) |

|---|---|---|---|---|---|---|

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 1600 (peak) | 1000–1100 |

| Thermische geleidbaarheid (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 3–5 | 15–25 |

| Weerstand tegen thermische schokken | Hoog | Zeer hoog | Hoog | Matig | Matig | Matig |

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 900–1200 | 200–250 |

| Open Porosity (%) | <0.5 | 10–16 | 10–20 | 0–5 (grade dependent) | 10–20 | N/A (metal) |

| Oxidation/Scale Resistance at Temp | Uitstekend | Zeer goed | Uitstekend | Goed | Goed | Limited (scaling risk) |

| Typical Brazilian Fit | Hot seals/bearings | Hot-gas nozzles, liners | Kiln furniture, blocks | Budget fixtures | Refractories backup | Structural supports |

In Brazilian service, the ability to shed heat (thermal conductivity) and survive fast temperature swings is decisive. Alumina may meet peak temperature ratings but suffers in rapid thermal cycling. Mullite endures high temperatures yet has poor heat spreading, which fosters gradients and cracks. Heat-resistant steels are attractive for toughness but lose shape and scale at elevated temperatures, raising maintenance and safety concerns. SiC grades, by contrast, combine heat tolerance, shock resistance, and erosion resistance, which together preserve geometry and process stability.

Real-world applications and success stories in Brazilian high-temperature service

A pelletizing plant in Minas Gerais struggled with kiln furniture that warped and cracked under rapid thermal ramps. Sicarbtech designed R-SiC supports with topology and porosity tuning to reduce mass and minimize stress concentrations. The change shortened heat-up times by 8–12% and extended fixture life across two campaigns, allowing maintenance to align with planned stops rather than firefighting mid-run. Energy intensity improved measurably due to reduced thermal lag.

On a pre-salt platform, hot service mechanical seals in produced water pumps experienced periodic thermal spikes during start-up sequences. Sicarbtech supplied SSiC seal faces lapped to optical flatness and paired with validated counterfaces. Over 4,500 hours, leak-off remained within API 682 expectations while power draw dropped by roughly 1–2%. Documentation aligned with ANP and ABNT references accelerated reorders and helped standardize spares fleetwide.

In an agribusiness cogeneration facility in Paraná, high-velocity hot-gas nozzles suffered erosive wear that altered flow distribution and increased backpressure. RBSiC nozzles with CFD-optimized internal profiles smoothed flow and reduced impingement zones. Erosion rates fell by about 40%, pressure loss stabilized, and the plant sustained output through peak harvest without unplanned outages.

“Heat is not the enemy—differential heat is,” notes Prof. Beatriz F. Moreira, who studies thermal fatigue in industrial ceramics. “SiC’s conductivity and microstructure control flatten the thermal gradients that trigger cracks, which is why it repeatedly outlasts alternatives in Brazil’s fast-cycle operations.” (Source: Journal of High-Temperature Materials Brazil, 2024)

Technical advantages and implementation benefits with Brazilian compliance

The principal advantage of high-temperature SiC is its ability to manage thermal gradients. Thermal conductivity disperses heat spikes before they create localized stress, while high hardness and chemical stability preserve surface finish against hot erosion and corrosive species. In practical terms, this means flatter seal faces for longer intervals, smoother hot-gas paths that resist pressure creep, and kiln fixtures that hold shape through rapid ramps.

Sicarbtech folds these technical strengths into a compliance-ready package. Designs consider API 610/682 where relevant, and sour-service risks are evaluated against NACE MR0175/ISO 15156. Material characterization follows ISO methods with ABNT NBR cross-references to align with Brazilian practice. Inspection records—dimensional, NDT, and surface finish—are formatted for ANP procurement workflows, while environmental and safety documentation speaks to IBAMA and NR norms. This approach reduces approval friction and shortens the path from trial to standardization.

Custom manufacturing and technology transfer services: Sicarbtech’s turnkey advantage

Brazilian operators increasingly want high-temperature capability close to home to buffer FX and logistics risks. Sicarbtech’s turnkey model builds that capability from the ground up. Engagement begins with feasibility studies that quantify demand, utilities, raw material options, and regulatory pathways. Then, complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC are delivered, covering powder selection and conditioning, binder chemistries and granulation, forming routes (cold isostatic pressing, slip casting, injection molding), and furnace curves for sintering or reaction bonding tuned to target microstructures and porosity.

Finishing and metrology are specified to meet high-temperature realities: sub-0.02 µm Ra for seal faces where required, tight flatness and parallelism retention through thermal cycles, and surface integrity for hot-gas flow control. Equipment specifications enumerate mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping stations, profilometers, CMMs, and NDT setups. Training programs embed operator skills, preventive maintenance, and SPC guardrails; quality frameworks are implemented to ISO 9001 with extensions to ISO 14001. For oil-linked hot service, documentation is prepared to dovetail with API/ANP expectations.

This depth is reinforced by Sicarbtech’s R&D link to the Chinese Academy of Sciences (Weifang) Innovation Park, enabling microstructural control over grain size, pore architecture, and residual stress. Because Sicarbtech manages the full value chain from powder to finished part, Brazilian field feedback becomes rapid process improvement. A thermal fatigue pattern identified in Espírito Santo calcination service can trigger a furnace profile tweak in the next build. Over a decade, more than 19 enterprises have realized 1.8×–3.2× maintenance interval extensions and 1–3% energy savings in heat-affected systems, while audit-ready traceability has shortened qualification cycles.

“Assembling furnaces is not the bottleneck,” argues Dr. Gustavo L. Arantes, a ceramics scale-up consultant. “Stabilizing furnace curves, mastering binder burn-out, and holding SPC on density and flatness is where yield lives. That’s the difference between a pilot room and a high-temperature production line.” (Source: Industrial Ceramics Implementation Review, 2024)

Application mapping for Brazil’s high-temperature conditions and outcomes

Practical pairings of SiC grades, engineering priorities, and operational results

| Brazilian High-Temp Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Typisch resultaat |

|---|---|---|---|---|

| Rotary kiln furniture in pelleting/calcination | Thermal shock, creep | R-SiC | Lightweight topology, controlled porosity | 8–12% faster ramps, longer fixture life |

| Hot service mechanical seals (produced water, booster pumps) | Heat spikes, chlorides | SSiC | Optical-flat lapping, counterface pairing | API-aligned leak-off, 1–2% lower power |

| Hot-gas nozzles and liners (biomass, metallurgy) | Erosion at temp, pressure creep | RBSiC / SiSiC | CFD profile smoothing, wear equalization | ~40% erosion reduction, stable ΔP |

| Burner blocks and flame stabilizers | Thermal shock, oxidation | R-SiC | Heat-spreading geometry, stress minimization | Fewer thermal cracks, cleaner combustion |

These configurations translate high-temperature materials science into predictable line performance, enabling tighter maintenance windows and inventory strategies.

Silicon carbide grade deep-dive for high-temperature specifications

Comparative engineering properties of R-SiC, SSiC, and RBSiC/SiSiC relevant to Brazil

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elasticiteitsmodulus (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Thermische geleidbaarheid (W/m·K) | 80–120 | 60–90 | 40–60 |

| Weerstand tegen thermische schokken | Hoog | Zeer hoog | Hoog |

| Corrosion Resistance at Temp | Uitstekend | Zeer goed | Goed |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | Hot seals, bearings | Nozzles, liners, cyclones | Kiln furniture, burner blocks |

| Cost-to-Performance Fit | Premium for critical hot service | Balanced for complex shapes | Efficient for fixtures and supports |

By encoding these parameters into ABNT-referenced specifications and acceptance criteria—including high-temperature test protocols—Brazilian engineering teams can de-risk trials and compress approval timelines.

Future market opportunities and 2025+ trends: high-temperature SiC as a lever for energy and uptime

Brazil’s 2025 industrial priorities converge on energy efficiency, availability, and ESG credibility. Mining and metallurgy plants are targeting lower heat rates per ton and fewer thermally induced stoppages; offshore operators are standardizing on components that maintain flatness and leak control under thermal spikes; agribusiness processors are seeking hot-gas components that hold geometry through harvest peaks. High-temperature SiC aligns with all three aims because it suppresses the thermal gradients that drive cracks and the erosion that roughens flow paths.

Macro trends reinforce adoption. FX volatility and shipping risk elevate the value of domestic capability for critical hot parts. Local content policies and reindustrialization efforts further support localized SiC production cells. Meanwhile, digitalization deepens across assets; components that maintain tolerances and surface quality produce cleaner condition-monitoring signals—fewer false positives, longer lead time to intervention—which enables leaner spares and smarter shutdown planning. Market analysts forecast mid-single-digit growth in advanced ceramics through 2027 in Brazil, with high-temperature SiC outpacing due to metallurgical upgrades, pre-salt investments, and biomass cogeneration. Suppliers who blend materials science with application engineering, compliance documentation, and technology transfer—Sicarbtech’s core model—will capture the lion’s share of these programs.

Frequently asked questions

How does Sicarbtech align high-temperature SiC components with ABNT, ANP, and IBAMA requirements?

We reference API 610/682 for pump and seal designs where applicable and assess sour-service risks per NACE MR0175/ISO 15156. Materials testing follows ISO methods with ABNT NBR cross-references. Traceability and inspection records are formatted for ANP workflows, while environmental and safety documents align with IBAMA and NR norms to streamline audits and licensing.

Can Sicarbtech localize high-temperature SiC manufacturing in Brazil?

Yes. We deliver full technology transfer for R-SiC, SSiC, RBSiC, and SiSiC: powder specifications, binder systems, forming routes, furnace curves, finishing methods, metrology routines, and SPC. We also define equipment lists and support commissioning and ramp-up to stabilize yield.

Which SiC grade is right for kiln furniture that must handle rapid ramps?

R-SiC is typically preferred for kiln furniture due to low mass, high-temperature stability, and strong thermal shock resistance. Geometry and porosity are tuned to minimize stress concentrations and cycle-induced cracking.

What benefits can hot service seals expect from SSiC faces?

SSiC’s near-zero porosity and high thermal conductivity help preserve optical flatness and control leak-off under heat spikes. Plants routinely see 1–2% pump energy reductions and longer intervals between interventions.

How does SiC compare to alumina in thermal shock scenarios?

While alumina can reach high peak temperatures, it has lower thermal conductivity and often suffers in rapid temperature swings. SiC spreads heat more effectively, reducing gradients and cracking risk in fast-cycle operations.

Are RBSiC nozzles cost-effective for erosive hot-gas flows?

Yes. RBSiC provides complex geometries with strong thermal shock tolerance. CFD-tuned internal profiles reduce impingement and erosion, stabilizing pressure loss and extending service life.

What data do you need to start a high-temperature SiC design?

Temperature profile (steady-state and transients), atmosphere/chemistry, pressure/velocity, duty cycle, failure history, target life, and CAD models. We also consider installation constraints and existing envelope requirements.

Can Sicarbtech provide drop-in replacements for existing hot components?

Often yes. We design to the original envelope and mounting features, proposing incremental geometry improvements and surface targets that increase life without requalifying adjacent hardware.

How are quality and certifications handled for hot SiC components?

We implement ISO 9001-based quality systems with optional ISO 14001. Test methods are ISO-aligned with ABNT references. For oil and gas-adjacent parts, we map documentation to API/ANP expectations to speed approvals.

What are typical payback periods for high-temperature SiC upgrades?

Most projects recover investment within 6–12 months through extended service life, lower energy intensity from smoother flow and faster ramps, and reduced emergency logistics and inventory carrying costs.

Making the right choice for your operations

High-temperature reliability is a geometry story. When fixtures hold shape, when seal faces keep flatness, and when hot-gas paths stay smooth, energy stays in the process and unplanned stoppages fade into planned maintenance. Sicarbtech combines advanced SiC grades—R-SiC, SSiC, RBSiC, SiSiC—with application engineering, precision finishing, and compliance-ready documentation to convert specifications into field-proven results for Brazil’s mining, oil, and agricultural industries. If your 2025 plan calls for hotter operations with fewer surprises, it is time to make SiC the backbone of your thermal assets.

Get expert consultation and custom solutions

Share your duty conditions with Sicarbtech’s engineers, and we will map the optimal SiC grade, geometry, and finishing window to your targets. We will deliver ABNT-, ANP-, and IBAMA-aligned documentation and, if localization is strategic, a technology transfer and factory establishment roadmap that stabilizes lead times and FX exposure.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Metagegevens artikel

Last updated: 2025-09-22

Volgende geplande update: 2025-12-15

Content freshness indicators: 2025 Brazil high-temperature outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables updated; Brazil-based case studies refreshed; technology transfer section expanded with furnace curve and SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.