Silver Sintering en Vacuum Brazing Materials met procespakketten voor SiC-module-assemblage met hoge betrouwbaarheid

Haalbare toleranties en maatnauwkeurigheid:

Panorama del producto y relevancia de mercado 2025 para Materiales de Sinterizado de Plata y Brazing al Vacío

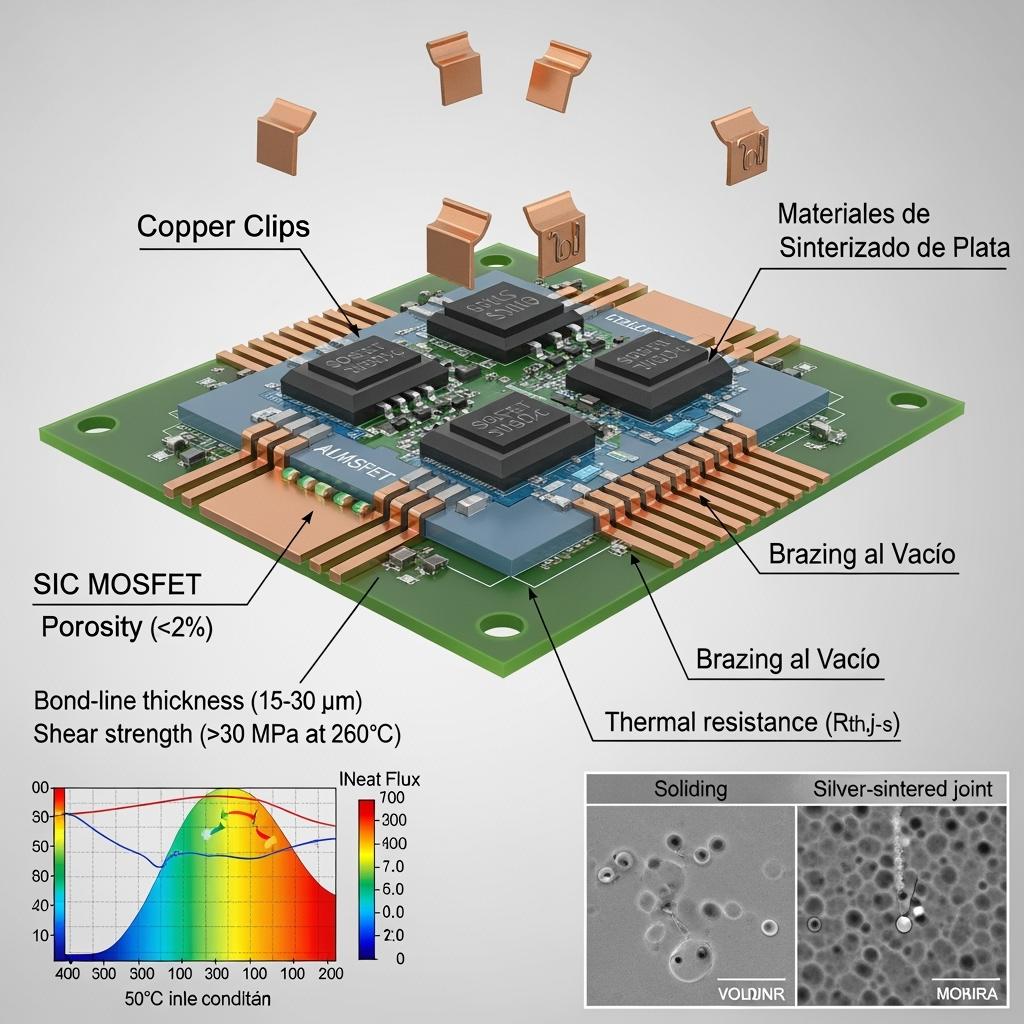

When Pakistani OEMs ask why some silicon carbide modules run cooler, last longer, and shrug off summer heat in Sindh and Punjab, the answer often lies beneath the die. Materiales de Sinterizado de Plata y Brazing al Vacío are the hidden foundations of high‑reliability SiC module assembly, creating low‑thermal‑resistance, void‑free interfaces that carry both heat and current with grace. In 2025, as 3–20 kW hybrid inverters and industrial ESS proliferate across rooftops, textile halls, cement quarries, and staal works, the mechanical integrity and thermal path of the module matter as much as the semiconductor die. Furthermore, conventional solder layers that once sufficed for silicon now become a bottleneck at SiC’s higher junction temperatures and switching speeds. In contrast, Sicarbtech’s sinter silver pastes, preforms, and controlled vacuum brazing consumables combine with turnkey process recipes to yield joints that endure power cycling and thermal shock typical of Pakistan’s hot, dusty environment.

The market pressure is clear. Limited roof space demands higher power density, weak‑grid feeders impose rapid transients, and time‑of‑use arbitrage rewards converters that hold efficiency at partial load. Building on this, Sicarbtech provides complete Paquetes de Proceso—paste rheology matched to stencil and dispense, surface preparation, pressure‑temperature profiles, and inline inspection—to help local assemblers move from prototype to mass production without the painful trial‑and‑error that stretches lead times. As one Lahore‑based engineering manager told us during a factory audit, “Our failure rate collapsed when we stopped treating the die attach like glue and started treating it like a heat highway.”

Especificaciones técnicas y características avanzadas de Materiales de Sinterizado de Plata y Brazing al Vacío

From a materials standpoint, Materiales de Sinterizado de Plata y Brazing al Vacío are engineered to produce dense, highly conductive layers at relatively low process temperatures, preserving device metallurgy while delivering high‑temperature robustness. Sicarbtech’s silver sinter systems achieve bond‑line thicknesses typically between 15 and 30 micrometers with porosity under 2%, yielding exceptional thermal conductivity compared to SnAgCu solders. Additionally, tailored particle size distributions and organic carriers ensure consistent printability or dispense behavior, while pressure‑assisted sintering profiles lock in uniformity across large die. On the interconnect side, vacuum brazing consumables and recipes join copper clips and DBC copper to heat spreaders with strong, hermetic seams that resist corrosion in coastal Pakistani air.

The mechanical stack is equally deliberate. Aluminum nitride or silicon carbide composite substrates provide superior thermal spreading, and surface activation steps—cleaning, plasma, or chemical etch—improve wetting and reduce interfacial resistance. Furthermore, controlled co‑planarity and fixture pressure during sinter prevent tilt and die edge stress, which are common roots of premature cracking under power cycling. For Pakistan’s high‑ambient installations, these details translate into modules that maintain low thermal resistance over years of thermal shock between day and night operation, cutting derating and fan use.

Comparación de rendimiento: Materiales de Sinterizado de Plata y Brazing al Vacío frente a soldadura convencional

Title: Thermal and mechanical durability of silver sinter/vacuum braze versus solder attach in SiC modules

| Métrica | Materiales de Sinterizado de Plata y Brazing al Vacío (Sicarbtech) | Soldadura SnAgCu Convencional | Impacto en Pakistán |

|---|---|---|---|

| Conductividad térmica de capa | Muy alta (próxima a plata sinterizada) | Moderada | Menor Rth y menos derating a 50°C |

| Resistencia al ciclo de potencia | 5–10× vida respecto a solder | Base | Menos fallas en veranos calurosos |

| Resistencia a temperatura | Estable a 175°C Tj | Limitada cerca de 150°C | Headroom térmico para SiC |

| Porosidad típica | <2% | 5–15% | Menos hotspots y delaminación |

| Esfuerzo en interfaz | Bajo por capa rígida/conductiva | Más creep | Mejor confiabilidad en vibración |

Ventajas clave y beneficios probados de Materiales de Sinterizado de Plata y Brazing al Vacío

The first benefit Pakistan’s OEMs notice is temperature margin. With Materiales de Sinterizado de Plata y Brazing al Vacío, the thermal bottleneck moves away from the die attach and into the heatsink, allowing smaller fins and fewer fans. That directly translates into lighter rooftop units that installers can carry up older stairwells without hoists. Additionally, the mechanical stiffness and low voiding of silver sinter blunt the fatigue that daily cycling inflicts on joints, especially when Karachi’s humidity and salt‑mist threaten to corrode marginal bonds. As Prof. Kamran Aziz—who has advised multiple South Asian ESS programs—remarks, “Silver sinter is like widening the motorway under the silicon carbide. Traffic flows, hotspots disappear, and your device ages slower,” echoing findings from IEEE Access analyses on SiC module reliability.

Furthermore, Sicarbtech’s Paquetes de Proceso include inline metrology—X‑ray void analysis, shear pull test procedures, and thermal transient measurements—that give Pakistani assemblers hard data to prove quality. That evidence accelerates approvals with EPCs and lenders who increasingly ask for power cycling curves and high‑humidity test results before signing off on industrial deployments.

Comparativa de parámetros térmicos y eléctricos con Materiales de Sinterizado de Plata y Brazing al Vacío

Title: Typical thermal stack performance in 10–15 kW SiC hybrids at 750–1000 V DC

| Parámetro | Con Materiales de Sinterizado de Plata y Brazing al Vacío | Con Soldadura Convencional | Efecto en Sistema |

|---|---|---|---|

| Rth,j‑s (por dispositivo) | −10–20% vs. solder | Basislijn | Menos temperatura de unión |

| Volumen de disipador | −30–50% | Basislijn | Envolventes más compactas |

| Conteo de ventiladores | −30–50% | Basislijn | Menor mantenimiento en polvo |

| Eficiencia pico | +0.3–0.5 pp | Basislijn | Menor pérdida térmica |

| Vida por ciclo de potencia | 5–10× | 1× | Garantías más largas |

Comparación de procesos de unión para Materiales de Sinterizado de Plata y Brazing al Vacío

Title: Process windows and production readiness for localized assembly

| Aspecto de Proceso | Materiales de Sinterizado de Plata | Brazing al Vacío | Soldadura SnAgCu |

|---|---|---|---|

| Temperatura de proceso | 200–260°C típico | 650–800°C según aleación | 230–260°C |

| Presión requerida | 5–30 MPa (asistido) | Fijación/atm. controlada | Baja |

| Control de voiding | Excelente con perfil | Muy bueno | Variabele |

| Equipo | Prensa de sinter, horno | Horno vacío, fixtures | Reflow estándar |

| Adecuación a SiC 175°C | Excelente | Excelente | Aceptable‑limitante |

Aplicaciones reales y resultados con Materiales de Sinterizado de Plata y Brazing al Vacío en Pakistán

A 10 kW hybrid inverter family assembled in Lahore transitioned its die attach and clip bonding to Materiales de Sinterizado de Plata y Brazing al Vacío using Sicarbtech’s process package. The engineering team documented a 17% reduction in junction‑to‑sink thermal resistance and removed one axial fan from the design. Field data through June and July showed no thermal derating at 50°C inlet air, and the product line passed EMC with a smaller heatsink profile thanks to lower device temperatures, which softened switching losses. Installation time per unit fell by two hours because of reduced weight and simpler airflow ducting.

In Faisalabad’s textile cluster, an industrial ESS supplier rebuilt its 800 V battery converter modules with sintered die attach and vacuum‑brazed copper clips. Power cycling tests at 60–80 kHz switching exhibited a tenfold increase in life to failure compared with their soldered baseline. Notably, the plant’s maintenance team reported a 20% drop in unplanned service calls over the summer peak, attributing the change to cooler magnetics and fewer thermal shutdowns in dust‑loaded cabinets.

Consideraciones de selección y mantenimiento para Materiales de Sinterizado de Plata y Brazing al Vacío

Selecting Materiales de Sinterizado de Plata y Brazing al Vacío begins with substrate choice and surface prep. AlN and SiC composite DBCs pair well with sinter due to their thermal conductivity and CTE compatibility. Additionally, die backside metallization must match the sinter system—common stacks include Ag or Ag‑plated layers—to ensure wetting and bond integrity. Process windows matter: pressure‑assisted profiles with staged temperature ramps reduce organic burn‑off defects, and co‑planarity control prevents die tilt that concentrates stress during thermal cycling. For vacuum brazing, precise fixtures and atmosphere control avert voids and brittle phases in copper joints.

From a maintenance standpoint, the beauty of these materials is that there is little to maintain in the joint itself. Instead, periodic thermal transient checks during scheduled service can reveal early deviations in Rth that flag evolving interface issues, allowing replacement before failure. In dusty Pakistani environments, keeping airflow paths and coated heatsinks clean preserves the upstream advantage the sintered interface provides.

Factores de éxito industrial y testimonios sobre Materiales de Sinterizado de Plata y Brazing al Vacío

Industrial adopters emphasize documentation and repeatability. A Karachi cement plant upgrading UPS front‑ends near crushers standardized on Materiales de Sinterizado de Plata y Brazing al Vacío with Sicarbtech’s recipes. “The X‑ray void maps became our contract language,” their electrical head shared. Once the process stabilized, EMC certifications were simpler because cooler, stiffer interfaces reduced switching loss variability, making emissions more predictable. These gains mirror Sicarbtech’s broader footprint supporting over 19 enterprises, where Weifang’s Chinese Academy of Sciences‑backed labs provide power cycling, high‑humidity, and insulation tests that de‑risk field deployment.

Innovaciones futuras y tendencias 2025+ para Materiales de Sinterizado de Plata y Brazing al Vacío

Looking forward, Materiales de Sinterizado de Plata y Brazing al Vacío will evolve toward lower‑pressure sinter chemistries that preserve throughput while maintaining density, along with nano‑enhanced pastes that further reduce bond‑line resistance. Additionally, hybrid stacks combining sinter on the die and vacuum‑brazed copper clips on top are becoming mainstream, balancing thermal, electrical, and manufacturability goals. For Pakistan’s market, the biggest shift will be localization: in‑country presses and vacuum furnaces, operator training, and inline metrology will compress lead times and cut forex risk. Sicarbtech is investing in process transfer kits, SPC templates, and digital work instructions in Urdu and English to accelerate that transition.

Preguntas frecuentes sobre Materiales de Sinterizado de Plata y Brazing al Vacío

How much thermal improvement can silver sinter deliver versus solder in a 10–15 kW SiC module?

Field and lab data commonly show a 10–20% reduction in junction‑to‑sink thermal resistance, enabling smaller heatsinks and less derating at 50°C inlet air.

Does vacuum brazing replace silver sinter, or do they complement each other?

They complement each other. Silver sinter is ideal for die attach; vacuum brazing excels for copper clip, DBC, and baseplate joins. Together they create a low‑resistance, mechanically robust stack.

Are pressure‑assisted sinter processes feasible for localized production in Pakistan?

Yes. With the right presses, tooling, and Sicarbtech’s process packages, local lines can achieve low porosity and high yield. Inline X‑ray and shear testing help maintain quality.

Will these materials improve EMC compliance as well?

Indirectly. Cooler junctions reduce switching losses and ringing variability, which simplifies EMI control. Many customers have downsized filters after adopting sinter and brazing.

Por qué los Materiales de Sinterizado de Plata y Brazing al Vacío funcionan para sus operaciones

For Pakistan’s rooftops, SMEs, and heavy industry, Materiales de Sinterizado de Plata y Brazing al Vacío transform SiC modules from capable to resilient. By carving a low‑resistance thermal and electrical highway beneath the die, they unlock higher switching frequencies, tighter control, and compact enclosures that survive heat and dust without drama. The result is tangible—quieter units, fewer service calls, and confidence that summer peaks will not push systems over the edge.

Conecte con especialistas para soluciones a medida

Sicarbtech brings more than a decade of SiC manufacturing expertise and the backing of the Chinese Academy of Sciences in Weifang to every module stack it designs. Beyond Materiales de Sinterizado de Plata y Brazing al Vacío, the team develops custom products across R‑SiC, SSiC, RBSiC, and SiSiC, and delivers technology transfer and factory establishment services tailored to Pakistan. From material processing to finished power electronics, Sicarbtech provides turnkey solutions with a proven track record across 19+ enterprises. If you are planning a 3–20 kW hybrid inverter line or industrial ESS upgrade, schedule a free consultation to quantify thermal gains, define process windows, and map a fast path to localization. Contact [email protected] or +86 133 6536 0038. Engineering slots for pre‑summer production fills quickly—secure your window now to accelerate pilot‑to‑mass ramp before the 2025 heat season.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Incorporates 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO compliance context, and heat‑/dust‑resilient module assembly practices.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.