Industriële siliciumcarbide-oplossingen voor de energie-intensieve industrieën van Pakistan in 2025

Haalbare toleranties en maatnauwkeurigheid:

Samenvatting: Pakistan's Next-Gen Industry aandrijven met siliciumcarbide

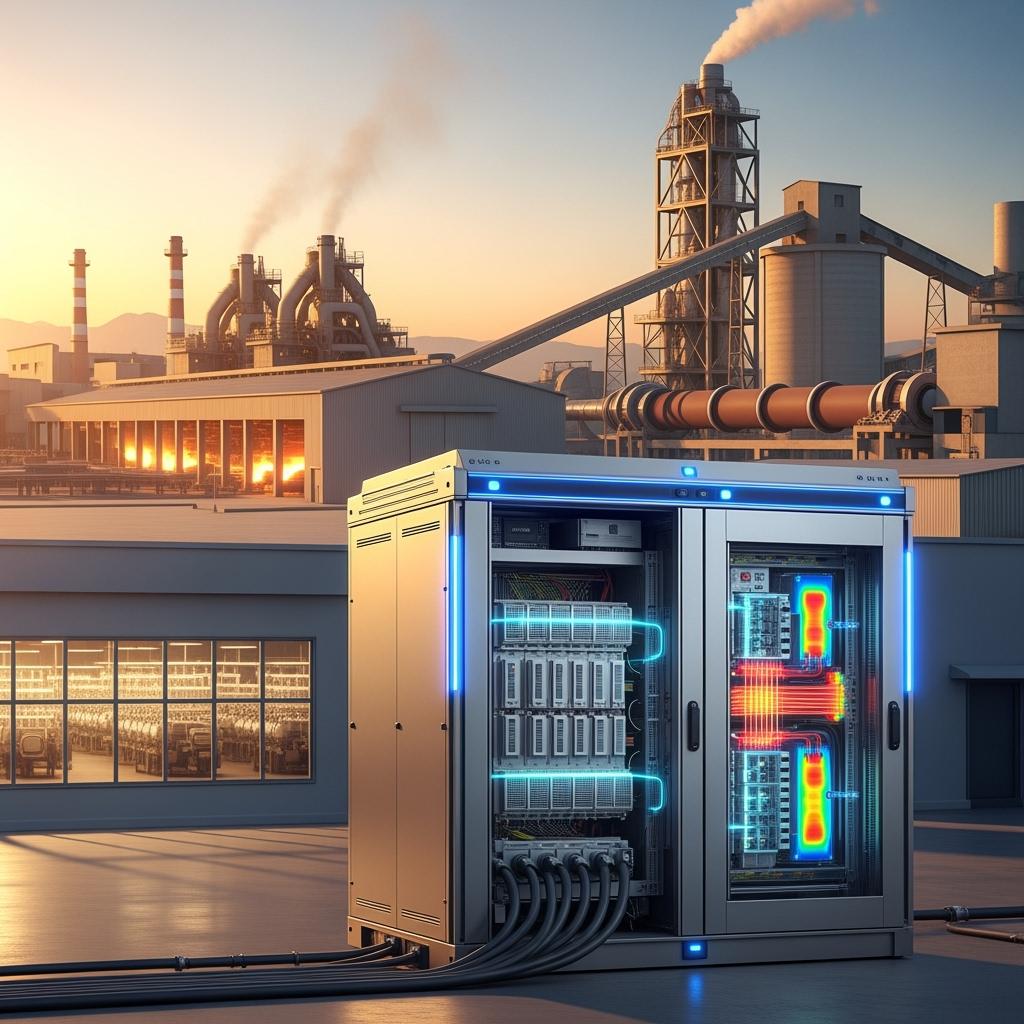

De textiel-, cement-, staal- en opkomende digitale sectoren van Pakistan gaan een fase van versnelde modernisering in, gedreven door energiezekerheid, digitale transformatie en naleving van het milieu. In 2025 zetten aanhoudende netinstabiliteit, stijgende energiekosten en strengere efficiëntieverwachtingen van NEPRA en provinciale milieu-instanties exploitanten onder druk om vermogenselektronica, aandrijvingen en thermische systemen te upgraden. Siliciumcarbide (SiC) is overgegaan van pilot naar productie en biedt een hogere efficiëntie, lagere koelbelastingen en superieure betrouwbaarheid in omstandigheden met hoge temperaturen, stoffige en fluctuerende netspanningen die in heel Pakistan voorkomen.

Sicarb Tech - een Silicon Carbide Solutions Expert gevestigd in Weifang City, China's SiC-productiehub en lid van het Chinese Academy of Sciences (Weifang) Innovation Park - brengt 10+ jaar ervaring in maatwerk en full-cycle mogelijkheden, van materiaalverwerking tot afgewerkte producten en kant-en-klare fabrieksoprichting. Wij zijn gespecialiseerd in R-SiC-, SSiC-, RBSiC- en SiSiC-producten, met een portfolio dat aansluit bij de prioritaire behoeften van Pakistan: zeer efficiënte UPS voor datacenters en financiële machineruimtes, hoogfrequente gelijkrichters en aandrijvingen voor cement en staal, en robuuste vermogensmodules voor textielmolens die worstelen met harmonische belasting en frequente spanningsdips.

Belangrijkste resultaten voor 2025 die we mogelijk maken:

- 5–8% hogere energie-efficiëntie van het systeem versus siliciumalternatieven

- ~30% reductie van de UPS-vo

- 20–30% langere levensduur van het systeem; 15–20% langere levensduur van de batterij

- 10–15% lagere jaarlijkse O&M-kosten door eenvoudigere koeling en voorspellende diagnostiek

Uitdagingen en pijnpunten in de industrie in Pakistan (Uitgebreide analyse)

Ondanks de voortdurende verbeteringen aan het elektriciteitsnet, worden Pakistaanse industriële operators geconfronteerd met een unieke convergentie van elektrische, milieu- en economische stressfactoren:

- Spanninginstabiliteit en harmonischen:

- Frequente dips, pieken en flikkeringen veroorzaken repetitieve stress op siliciumgebaseerde gelijkrichters en IGBT-gebaseerde aandrijvingen, wat leidt tot warmteopbouw, vroegtijdige veroudering van condensatoren en ongewenste uitschakelingen.

- Textielfabrieken en staalfabrieken met grote motorbelastingen genereren harmonischen die de arbeidsfactor verslechteren en transformatoren overbelasten; conventionele filters voegen complexiteit en verliezen toe.

- Hoge omgevingstemperaturen en stof:

- Omgevingstemperaturen van 35–45°C in veel industriële zones in combinatie met omgevingen met veel deeltjes (cementklinkerstof, textielpluis, staalschilfers) verminderen de prestaties van warmtewisselaars en versnellen het onderhoud van ventilatoren/filters.

- Geforceerde luchtkoeling in traditionele systemen heeft het moeilijk, wat leidt tot vermindering van de capaciteit en ongeplande uitvaltijd.

- Volatiliteit van energiekosten en OPEX-druk:

- Elektriciteitstarieven, aanpassingen van brandstofkosten en piekvraagkosten stellen operators bloot aan schokken in de factuur. Zelfs een efficiëntiewinst van 2–3% verbetert de EBITDA aanzienlijk voor continu-procesindustrieën.

- Afhankelijkheid van dieselback-up tijdens uitval verhoogt de kosten per kWh en bemoeilijkt de naleving van emissies.

- Uitvalrisico's in digitale infrastructuur:

- Datacenters en financiële machineruimtes vereisen vrijwel geen overdrachtstijd en ≥99,999% beschikbaarheid. Conventionele dubbele conversie UPS met siliciumschakelaars ondervinden efficiëntiedalingen bij gedeeltelijke belasting, waardoor de koelbehoefte en de exploitatiekosten toenemen.

- Naleving van regelgeving en normen:

- Lokale naleving wordt geleid door NEPRA-prestatienormen, NTDC Grid Code-interconnectiekwaliteitseisen en PEC-conforme elektrische veiligheidspraktijken. Grote faciliteiten volgen vaak internationale referenties zoals IEC 61000 (EMC), IEC 62477 (veiligheid van vermogenselektronica) en ISO 14644 (schoonheid voor elektronische ruimtes).

- Milieubeperkingen van provinciale EPAs worden aangescherpt rond energie-efficiëntie en emissies; groene certificeringen winnen aan populariteit bij de beoordeling van aanbestedingen.

- Kwetsbaarheid van de toeleveringsketen:

- Beperkte lokale productie voor geavanceerde vermogensmodules betekent lange levertijden en moeilijkheden bij het verkrijgen van bijpassende componenten (drivers, substraten, thermische interfaces), wat de onderhoudsstrategieën bemoeilijkt.

- Vaardigheden en integratiekloven:

- De overstap naar hoogfrequente topologieën vereist bijgewerkte beschermingsschema's, EMC-praktijken en gate-drive-expertise die veel teams nog steeds ontwikkelen.

Kostenimplicaties:

- Oververhitting en harmonische straffen leiden tot 8–12% hogere onderhoudskosten in de zware industrie.

- Overdimensionering van koeling om inefficiëntie te compenseren, voegt 10–25% toe aan de kapitaaluitgaven en 5–10% aan het jaarlijkse energieverbruik.

- Batterijvervangingen in UPS-cycli kunnen 1–2 jaar eerder plaatsvinden wanneer de thermische controle onvoldoende is, wat aanzienlijke levenscycluskosten toevoegt.

Deskundig perspectief:

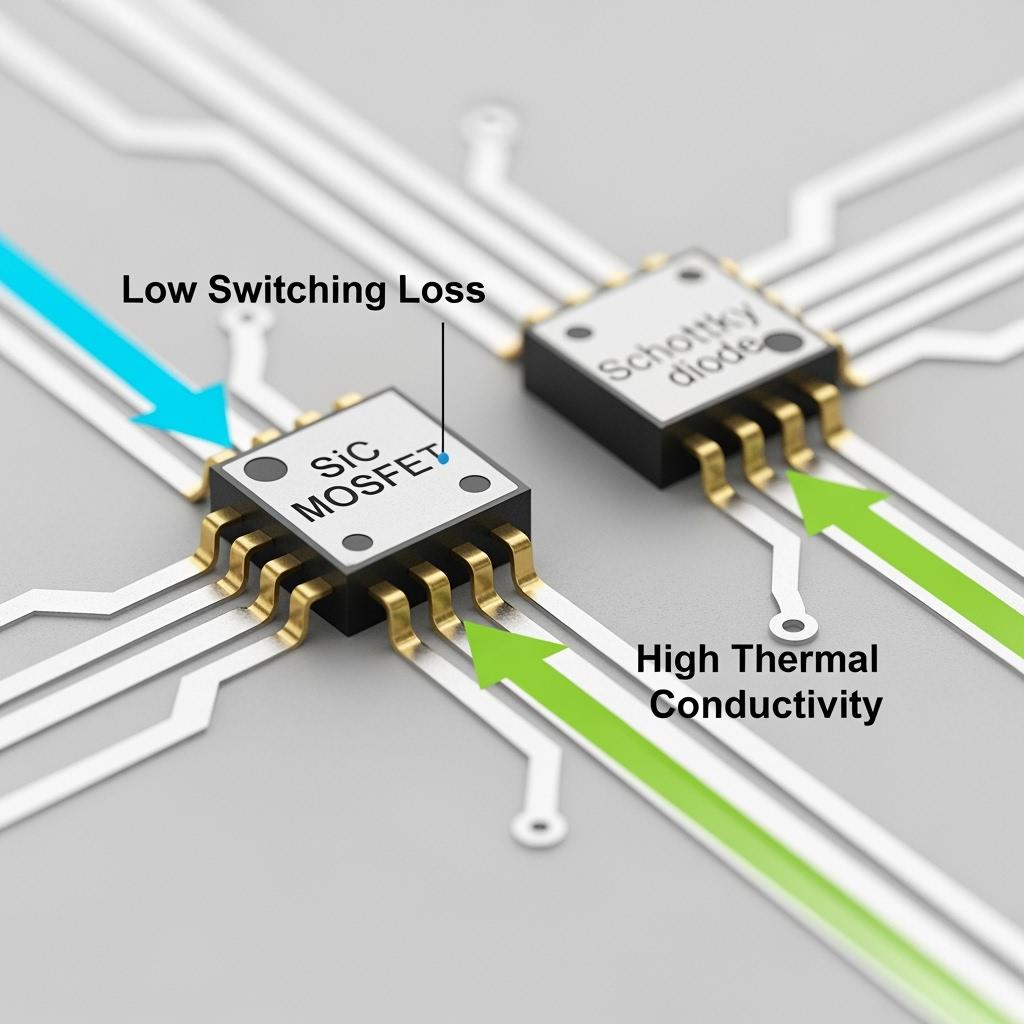

- “De capaciteit van SiC-apparaten om hoge junctietemperaturen te handhaven met lage schakelverliezen, vertaalt zich direct in kleinere, betrouwbaardere aandrijflijnen in hete, stoffige omgevingen die veel voorkomen in Zuid-Azië.” — Dr. Anant Agarwal, Power Electronics Researcher, IEEE Fellow (bron: IEEE Power Electronics Magazine, interviews met de industrie)

- “Voor datacenters levert elk efficiëntiepunt boven de 96% enorme besparingen op koeling op. De overstap naar wide-bandgap-halfgeleiders is een praktische weg geworden om de PUE in opkomende markten te verlagen.” — Analyse-referentie van het Uptime Institute en industriële brief

Geavanceerde portfolio van siliciumcarbide-oplossingen voor Pakistan

Sicarb Tech levert een uitgebreid SiC-ecosysteem, van apparaten tot integratieondersteuning, afgestemd op de realiteit van het Pakistaanse elektriciteitsnet en de eisen van de industrie.

- SiC-apparaten en -modules:

- Siliciumcarbide MOSFET-modules

- SiC Schottky-diodes en hoogfrequente gelijkrichterbrugmodules

- Hoogspanningsvermogensmodules en bidirectionele schakelmodules

- Zeer betrouwbare gate-drivers ontworpen voor zware netomstandigheden

- Bouwstenen voor vermogensconversie:

- PFC-besturingsmodules met >99% efficiëntie en <3% THD

- SiC-omvormervermogensfasen voor VFD's in textielspinning, cementventilatoren en staalwalsaandrijvingen

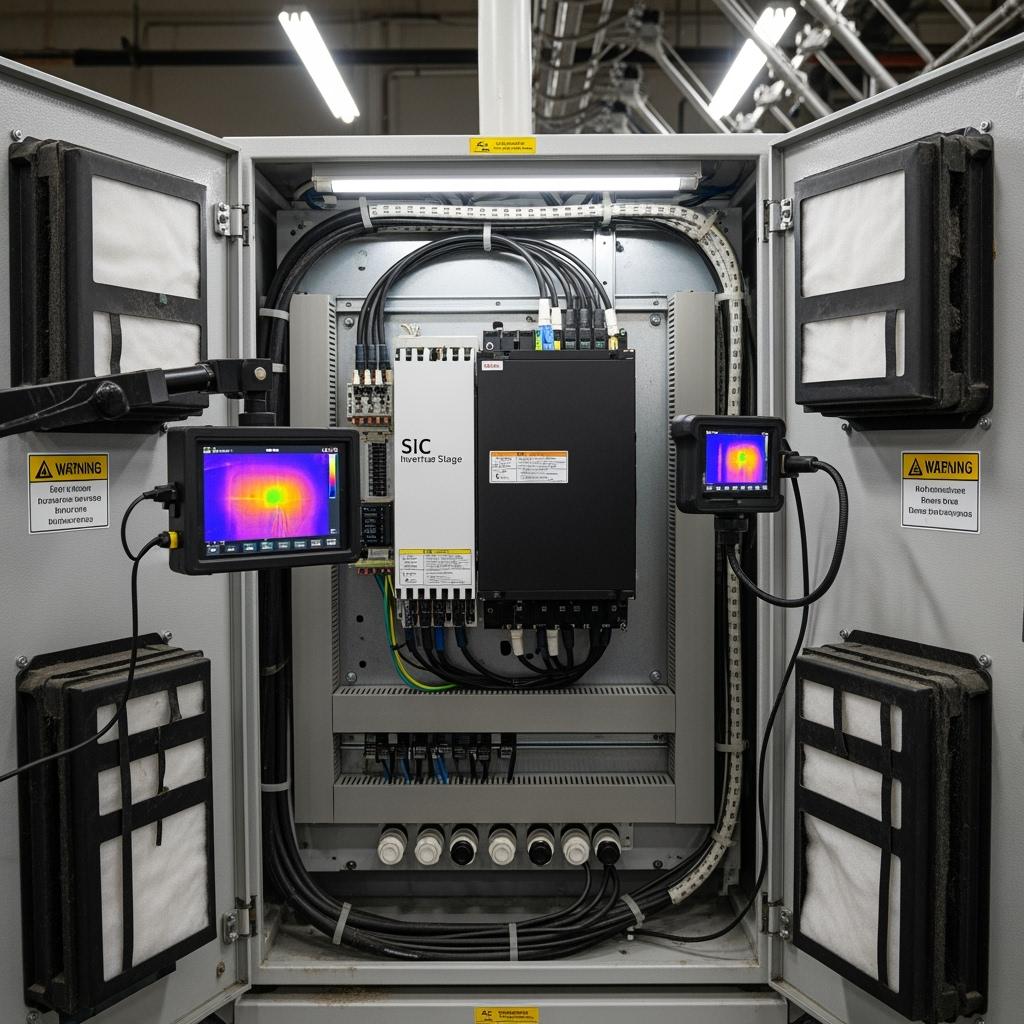

- Online dubbele conversie UPS-omvormermodules geoptimaliseerd voor hoge omgevingstemperaturen

- Thermische en verpakkingsinnovaties:

- Warmtespreider-substraten op chipniveau en geavanceerde keramische structurele componenten

- Apparaatverpakkingen en thermische beheersystemen op maat gemaakt voor >10 kW/L-ontwerpen

- Intelligentie en betrouwbaarheid:

- Bewakings- en diagnosemodules voor stroomsystemen met onderhoud op afstand op basis van conditie

- Specifieke apparaatinbrand- en testapparatuur om de betrouwbaarheid bij juncties van 175–200°C te garanderen

- Integratie en kant-en-klaar:

- Intelligente SiC-vermogensmodule-geïntegreerde systemen

- Hoogfrequente, high-density DC-stroomsystemen klaar voor datacenters en procesinstallaties

Waarom dit lokaal belangrijk is:

- Ontworpen voor fluctuerende 220/400 V-systemen met frequente dips en transiënten

- Stofbestendige thermische ontwerpen verminderen filteronderhoud

- Ondersteunt de overgang van Pakistan naar een efficiëntere infrastructuur met lage THD in overeenstemming met de kwaliteitsvereisten van de Grid Code

Technische prestatievergelijking: voordeel van wide-bandgap onder lokale omstandigheden

Prestatie-eigenschappen in de industriële omgevingen van Pakistan

| Attribuut | Siliciumcarbide-oplossing | Traditionele siliciumoplossing | Lokale relevantie |

|---|---|---|---|

| Rendement bij volledige belasting | 97–98% | 91–94% | Vermindert koeling en het gebruik van dieselback-up tijdens uitval |

| Efficiëntie bij lichte belasting | >96% | 88–92% | Kritisch voor de werking van datacenters bij gedeeltelijke belasting (lagere PUE) |

| Bedrijfstemperatuur van de junctie | 175–200°C | ≤125°C | Handhaaft de output op locaties met hoge omgevingstemperaturen en veel stof |

| Schakelfrequentie | Tot 100 kHz | 10–20 kHz | Kleinere magnetica; compacte UPS/VFD-kasten |

| Vermogensdichtheid | >10 kW/L | 3–6 kW/L | 30–35% reductie van de voetafdruk voor ruimtes met beperkingen |

| THD (met SiC PFC) | <3% | 5–10% | Ondersteunt de kwaliteit van de Grid Code en de levensduur van de transformator |

| Koelvereisten | Laag | Hoog | Minder ventilatoren/filters; minder onderhoud in cement/textiel |

| Uitvalpercentage (veld) | Laag | Gemiddeld | Betere ride-through tijdens spanningsdips/pieken |

Materiaal- en componentkeuze voor zware locaties

| Eigendom | R-SiC | SSiC | RBSiC / SiSiC | Primair gebruik in Pakistan |

|---|---|---|---|---|

| Thermische schokbestendigheid | Hoog | Gemiddeld | Hoog | Ovencomponenten, cycloonscheiders, hete gaspaden |

| Dichtheid/porositeit | Gemiddeld | Hoge dichtheid, lage porositeit | Gemiddeld-hoog | Structurele onderdelen versus warmtespreiders |

| Slijtvastheid | Hoog | Zeer hoog | Hoog | Schurende cement- en staalomgevingen |

| Max. bedrijfstemperatuur | 1.400–1.600°C | ~1.600°C | ~1.400–1.500°C | Keramische componenten met lange levensduur voor procesinstallaties |

| Elektrische rollen | Substraten/isolatoren | Zeer betrouwbare keramiek | Structureel + thermisch | Warmtespreiders en apparaatverpakkingen |

Real-world toepassingen en succesverhalen

- Hoogrendements-UPS voor het datacenter van Lahore:

- Een grote telecomoperator implementeerde een SiC-gebaseerde online dubbele conversie UPS van Sicarb Tech.

- Behaalde 97,3% systeemefficiëntie, ~35% reductie van de UPS-ruimte en ~12,6% elektriciteitsbesparing in het eerste jaar.

- Verkreeg nationale stimulansen voor energiebesparingscertificering, ter ondersteuning van ESG-doelstellingen.

- Textielspinning-aandrijvingen in Faisalabad:

- Retrofitte bestaande VFD's met SiC-omvormerfasen en PFC-frontends.

- Resultaat: 5,5% energiebesparing, 18% reductie van de temperatuur van de aandrijfkast, 20% minder ongeplande stops als gevolg van spanningsdips.

- Cementvoorverwarmer-ventilatorsystemen in Khyber Pakhtunkhwa:

- Implementeerde hoogfrequente SiC-gelijkrichterbruggen en gate-drivers met verbeterde overspanningsbestendigheid.

- Resultaat: 7% lager specifiek energieverbruik op grote ventilatoren, langere onderhoudsintervallen voor filters en lagers.

- Hulpstroom van staalwalserij in Karachi:

- Geïntegreerde SiC-hoogspanningsvermogensmodules met intelligente diagnostiek.

- Resultaat: THD teruggebracht tot <3%, arbeidsfactor verbeterd tot 0,99, waardoor optimalisatie van de transformatorbelasting mogelijk werd.

Technische voordelen en implementatievoordelen met nalevingsafstemming

- Hoge efficiëntie bij variabele belastingen:

- Handhaaft >96% efficiëntie tot 25–30% belasting, ideaal voor datacenters die een lage PUE nastreven en voor fabrieken die in verspringende ploegen werken.

- Robuuste interactie met het elektriciteitsnet:

- SiC PFC houdt de ingangsstroom bijna sinusvormig, THD <3%, PF ~0,99, wat helpt bij de naleving van de kwaliteitsverwachtingen van het NTDC/Disco-net en het minimaliseren van de verwarming van de transformator.

- Thermische veerkracht:

- Junctietemperaturen tot 175°C standaard (tot 200°C op bepaalde apparaten) zorgen voor ride-through tijdens piek zomeromstandigheden zonder agressieve vermindering van de capaciteit.

- Compacte, modulaire topologieën:

- 10+ kW/L vermogensdichtheid maakt plug-in modules mogelijk; snellere MTTR en toekomstige uitbreiding zonder ruimtevergroting.

- Intelligente diagnostiek:

- Geïntegreerde bewaking signaleert vroege degradatie van condensatoren en ventilatoren, waardoor ongeplande uitvaltijd wordt verminderd.

Naleving en standaarden:

- Afstemming met IEC 61000 (EMC), IEC 62477-1 (vermogenelektronica-omvormersystemen), IEC 62040 (UPS) en IEC 61800 (instelbare elektrische aandrijfsystemen)

- Ondersteuning voor lokale veiligheidscodes zoals verwezen door de Pakistan Engineering Council (PEC) en naleving van de kwaliteitscriteria van de NTDC Grid Code

- Milieuoverwegingen die compatibel zijn met de vereisten van de provinciale EPA's en de duurzaamheidskaders van bedrijven

Maatwerkproductie en technologieoverdrachtdiensten door Sicarb Tech

Sicarb Tech biedt een kant-en-klare weg van concept tot volumeproductie, waardoor Pakistaanse partners waarde kunnen lokaliseren en de afhankelijkheid van import kunnen verminderen.

- Geavanceerde R&D, ondersteund door het Chinese Academy of Sciences (Weifang) Innovation Park:

- Gezamenlijke ontwikkeling van apparaatstructuren, gate-drive-strategieën en thermische verpakkingen voor locaties met veel stof en hoge temperaturen.

- Toegang tot expertise in materiaalkunde voor R-SiC-, SSiC-, RBSiC- en SiSiC-componenten.

- Eigen productieprocessen:

- Gecontroleerde sinterprofielen voor SSiC-dichtheid en korrelstructuur

- Reactieve bindingsmethoden voor RBSiC/SiSiC met hoge thermische schoktolerantie

- Precisiebewerking voor warmtespreiders

- Complete technologieoverdrachtpakketten:

- Procesdocumentatie (SOP's), apparatuurspecificaties en leverancierslijsten

- Opleidingsprogramma's voor operators, procestechnici en onderhoudsteams

- Inbedrijfstelling ter plaatse, proefdraaien en ondersteuning bij het opvoeren van de opbrengst

- Diensten voor fabrieksoprichting:

- Haalbaarheidsstudies, planning van nutsvoorzieningen ter plaatse en lay-outs voor schone/gecontroleerde omgevingen

- Installatie, kalibratie en acceptatietests van apparatuur

- Opschalingsstrategieën van prototyping tot massaproductie

- Kwaliteitssystemen en certificeringsondersteuning:

- Implementatiebegeleiding voor ISO 9001 en ISO 14001

- Productconformiteitsdocumentatie voor IEC/UL-doelstellingen

- Betrouwbaarheidstestprotocollen (HTRB, H3TRB, power cycling, thermische schok)

- Voortdurende technische ondersteuning:

- Diagnostiek op afstand, procesoptimalisatie en verbeteringen voor ontwerp voor fabricage

- Continu verbeteringslussen geïnformeerd door veldgegevens van 19+ bedrijfsimplementaties

Bedrijfsresultaten:

- Snellere time-to-market met lokale assemblage of productiepartnerschappen

- Verminderde FX-exposure en importlevertijden; betere controle over reserveonderdelen

- Concurrentievoordeel bij aanbestedingen met nadruk op lokale waardetoevoeging en levenscycluskosten

Contact our engineering team: [email protected] | +86 133 6536 0038

Toekomstige marktkansen en trends voor 2025+

- Uitbreiding van datacenters:

- De Pakistaanse UPS-markt zal naar verwachting jaarlijks met ~15% groeien en in 2025 USD 100 miljoen overschrijden, gedreven door cloud-adoptie, fintech en digitalisering van de overheid.

- Edge- en telecomvoeding:

- 5G-uitrol en edge computing vereisen DC-voedingssystemen met hoge dichtheid, lage THD en hoge PF - een natuurlijke match voor SiC.

- Industriële elektrificatie en ESG:

- SiC maakt motoren en aandrijvingen met een hogere efficiëntie mogelijk, ter ondersteuning van de ESG-rapportage van bedrijven en provinciale energie-efficiëntieprogramma's.

- Gelokaliseerde productie:

- Joint ventures om SiC-modules te assembleren en keramische componenten te integreren, zouden de levertijden kunnen verkorten en de responsiviteit van de service kunnen verbeteren.

- AI-operaties en voorspellend onderhoud:

- Ingebouwde diagnostiek en cloud analytics zullen het onderhoud verschuiven van reactief naar voorspellend, waardoor OPEX wordt verlaagd en de uptime wordt verbeterd.

Deskundig inzicht:

- "Wide-bandgap halfgeleiders komen in 2025-2027 in de mainstream van industriële voeding, waarbij de kostenpariteit verbetert naarmate de aanvoer opschaalt." - International Energy Agency technology outlook brief

- "In regio's met hoge omgevingstemperaturen en variabele netkwaliteit kan de adoptie van SiC de levenscycluskosten met dubbele cijfers verbeteren." - IEC TC22 technische gemeenschapscommentaar

Veelgestelde vragen

- V: Kan een op SiC gebaseerde UPS voldoen aan een overdrachtstijd van nul en strenge harmonische grenzen voor financiële datakamers?

- A: Ja. Onze online dubbele conversie-architecturen garanderen een overdrachtstijd van nul. Met SiC PFC is de ingang THD <3% en PF ~0,99, in overeenstemming met de IEC 62040-richtlijnen en de lokale netkwaliteitsverwachtingen.

- V: Hoe presteren SiC-aandrijvingen met spanningsdips die vaak voorkomen in industriële feeders?

- A: Snelle besturing en superieure thermische marges verbeteren de ride-through. We kunnen supercondensator- of DC-link-optimalisatie integreren voor gerichte spanningsvalimmuniteit.

- V: Zijn uw oplossingen compatibel met 220/400 V, 50 Hz-systemen en lokale beveiligingsschema's?

- A: Ja. We ontwerpen voor de standaard distributiespanningen van Pakistan en coördineren met beveiligingsapparatuur volgens PEC-praktijken en sitespecifieke beveiligingen.

- V: Wat is de typische ROI bij het upgraden naar SiC voor textiel VFD's?

- A: Afhankelijk van de bedrijfsuren en het tarief, ligt de ROI vaak tussen de 18 en 30 maanden, gedreven door 4-7% energiebesparing en verminderde koeling/O&M.

- V: Ondersteunt u certificering en documentatie voor aanbestedingen?

- A: We leveren datasheets, testrapporten en conformiteitsdocumentatie voor IEC-categorieën, plus begeleiding voor ISO 9001/14001-uitlijning.

- V: Hoe gaat u om met stoffige omgevingen in cementfabrieken?

- A: Afgesloten of positieve drukbehuizingen, geoptimaliseerde koellichaamvingeometrie en deratingsprofielen die zijn afgestemd op de omgevingsomstandigheden, minimaliseren de filterbelasting en vervuiling.

- V: Kunnen we assemblage in Pakistan lokaliseren?

- A: We bieden technologieoverdracht, apparatuurlijsten, training en inbedrijfstelling om lokale assemblagelijnen voor modules en subsystemen op te zetten.

- V: Welke ondersteuning is er beschikbaar na de inbedrijfstelling?

- A: Bewaking op afstand, periodieke prestatie-audits en procesoptimalisatiediensten zijn inbegrepen in ons langetermijnondersteuningsmodel.

De juiste keuze maken voor uw activiteiten

Voor de textiel-, cement-, staal- en digitale infrastructuuroperators van Pakistan is de overstap naar siliciumcarbide niet langer een speculatieve upgrade - het is een strategische noodzaak. Met bewezen winsten in efficiëntie, thermische veerkracht en betrouwbaarheid verminderen SiC-systemen de levenscycluskosten, beschermen ze de uptime in onstabiele netomstandigheden en ondersteunen ze de naleving van evoluerende normen en ESG-doelstellingen.

Sicarb Tech-differentiatoren:

- 10+ jaar SiC-maatwerk en 19+ bedrijfsimplementaties

- CAS-ondersteunde R&D en eigen productie voor R-SiC, SSiC, RBSiC, SiSiC

- Full-cycle ondersteuning: engineering, productie, technologieoverdracht en lokale inschakeling

- Meetbare resultaten: 5-8% efficiëntiewinst, ~30% footprintreductie, 10-15% O&M-besparingen

- Een partnerschapsmodel gericht op continue verbetering en snelle respons

Deskundig advies en oplossingen op maat krijgen

Bespreek uw operationele doelen, nalevingsvereisten en ROI-verwachtingen met onze engineers. We beoordelen uw siteomstandigheden en stellen een stapsgewijs migratieplan voor met prototypes, proefdraaien en prestatiegaranties die zijn afgestemd op de Pakistaanse normen en marktrealiteit.

- Email: [email protected]

- Telefoon/WhatsApp: +86 133 6536 0038

- Bedrijf: Sicarb Tech, Weifang City, China - Silicon Carbide Solutions Expert

Artikelmetadata

- Laatst bijgewerkt: 2025-09-11

- Volgende geplande beoordeling: 2025-12-15

- Auteur: Sicarb Tech Application Engineering Team

- Contact: [email protected] | +86 133 6536 0038

Indicatoren voor de actualiteit van de inhoud:

- 2025 marktvooruitzichten geïntegreerd met de huidige overwegingen voor het Pakistaanse net en tarieven

- Referenties voor de nieuwste apparaatcapaciteit (175-200°C juncties, >10 kW/L vermogensdichtheid)

- Inclusief lokale naleving en operationele praktijken die zijn afgestemd op PEC-, NTDC Grid Code- en IEC-kaders

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.