High-Voltage Silicon Carbide MOSFET Power Modules for 1200–1700 V Inverter and UPS Applications

Share

2025 Product Overview and Market Relevance for Pakistan

High-voltage Silicon Carbide (SiC) MOSFET power modules in the 1200–1700 V class deliver ultra-low switching and conduction losses, enabling high-frequency operation (50–100 kHz), compact footprints, and exceptional efficiency in medium- to high-power inverters and UPS systems. For Pakistan’s textile, cement, and steel industries—where grid instability, heat, dust, and frequent load changes are daily realities—SiC modules offer a pragmatic upgrade path: higher uptime, lower energy bills in PKR, and reduced maintenance.

Why this matters in 2025:

- Industrial parks in Karachi, Lahore, and Faisalabad are expanding; power quality challenges and planned outages remain. SiC-based inverters and UPS systems improve ride-through performance (<5 ms) and boost efficiency to >98%, cutting OPEX despite tariff volatility.

- Data center investments require high-density, high-reliability UPS with stringent harmonic targets and integration to modern SCADA (IEC 61850, Modbus TCP). SiC modules are the enabling devices.

- Sustainability and energy management initiatives aligned with NEECA prioritize low-THDi and high-PF front ends—SiC modules paired with active PFC achieve PF >0.99 and THDi <5%.

Sicarb Tech provides custom-engineered SiC MOSFET modules and full integration support—from gate drivers and thermal stacks to test and burn-in—backed by Chinese Academy of Sciences collaboration and over a decade of SiC manufacturing expertise.

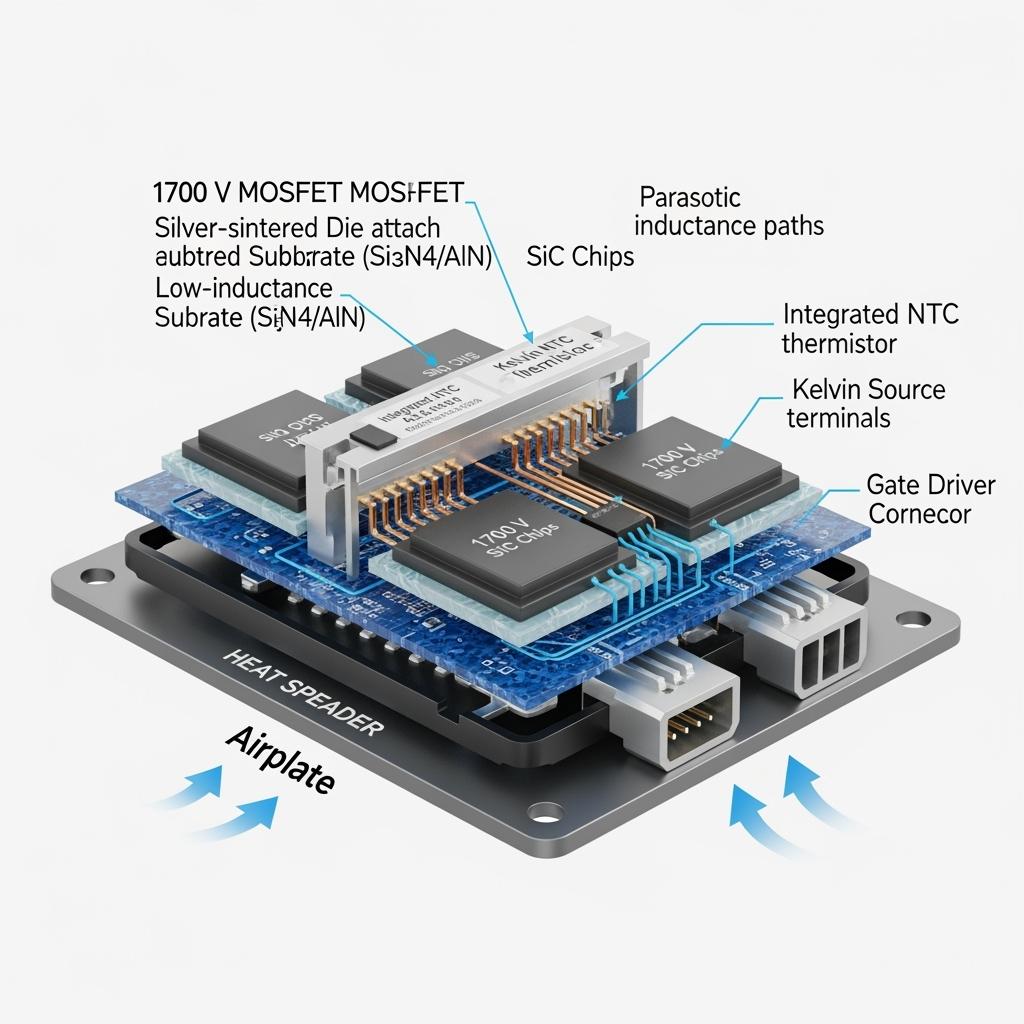

Technical Specifications and Advanced Features

- Voltage ratings: 1200 V and 1700 V

- Current classes: 100–600 A (custom up to 800 A on request)

- RDS(on): as low as 8–15 mΩ (per die, temperature-dependent)

- Switching frequency: 50–100 kHz continuous operation; higher in light-load modes

- Junction temperature: -55°C to 175°C (continuous), robust SOA

- Package: Low-inductance half-bridge/full-bridge modules with Kelvin source

- Isolation: >2.5 kVrms, creepage/clearance compliant with IEC 62477-1

- Thermal stack: SSiC/RBSiC heat-spreader options for enhanced thermal conductivity

- Gate drive: High-temperature, reinforced isolation drivers with DESAT, Miller clamp

- Protection: Short-circuit withstand (typ. 3–5 μs), UVLO, soft turn-off

- Monitoring: Integrated NTC, optional current shunt and digital telemetry

- Reliability: HTOL, H3TRB, power cycling, and burn-in qualified to industrial profiles

- Compliance-ready: Supports systems targeting IEC 62040 (UPS) and CISPR 11/22 EMC

Descriptive Performance Comparison: SiC Modules vs. Traditional Silicon IGBTs

| Attribute | SiC MOSFET Power Modules (1200–1700 V) | Silicon IGBT Modules (1200–1700 V) | Operational Impact in Pakistan Plants |

|---|---|---|---|

| Conversion efficiency (UPS/Inverter) | >98% typical | 90–94% | PKR OPEX savings, reduced cooling load |

| Switching frequency | 50–100 kHz | 10–20 kHz | Smaller magnetics, quieter drives, compact cabinets |

| Switching losses | Ultra-low (no tail current) | High (tail current) | Lower heat, longer component life |

| Thermal headroom (Tj max) | Up to 175°C | ~125°C | Resilience in 45–50°C ambient and dusty rooms |

| Power density | >10 kW/L | 4–6 kW/L | 30–40% smaller footprint; easier retrofits |

| Harmonics with PFC | THDi <5% feasible | 15–25% typical | Utility compliance, fewer penalties |

| Maintenance cycle | Extended | Frequent | Fewer fan/capacitor replacements |

Key Advantages and Proven Benefits

- Energy efficiency: +5–8% system efficiency improvement vs. silicon—material savings in PKR for continuous-process plants.

- Rapid response: <5 ms ride-through capability in UPS/inverter topologies helps protect spinning frames, kiln control loops, and rolling mill drives.

- Thermal robustness: Operates in high ambient temperature and dusty conditions common in cement and steel facilities; lower thermal stress extends lifespan.

- Compact integration: High power density reduces switchboard and MCC room constraints; faster brownfield upgrades.

- Grid friendliness: Enables PF >0.99 and THDi <5% with active PFC, supporting NTDC/utility requirements.

Expert perspective:

- “SiC’s absence of tail current and lower output capacitance enables higher switching speeds at lower loss, dramatically improving converter density.” — Prof. Frede Blaabjerg, Aalborg University (reference: academic publications via https://vbn.aau.dk/)

- “Migrating from IGBTs to SiC can reduce total converter losses by 50% or more at comparable power, especially at higher switching frequencies.” — IEEE Power Electronics Magazine, 2024 overview (https://ieeexplore.ieee.org/)

Real-World Applications and Measurable Success

- Textile VFD front ends (Faisalabad): SiC-based rectifier/inverter stages cut cabinet temperature by 10–12°C and improved line efficiency by 6–7%, reducing yarn breakage incidents by 8% during voltage sags.

- Cement mill in Punjab: With 1700 V SiC half-bridge modules in a three-level topology, THDi dropped below 5% and PF reached 0.99, lowering utility penalties and stabilizing torque ripple—grinding media wear decreased by ~7%.

- Steel rolling (Karachi): SiC inverter retrofits improved throughput by 3% and reduced unplanned trips by 40–45% amid genset transitions and grid disturbances.

- Data center UPS (Lahore): Achieved 98.2% efficiency and <4 ms response; annualized failure rate <0.5% with predictive diagnostics.

Selection and Maintenance Considerations

- Voltage headroom: Choose 1700 V devices for 690 V AC systems or where DC bus excursions are expected; 1200 V suits 400–480 V systems.

- Parasitics: Prioritize low-inductance layouts with Kelvin source; pair with matched gate drivers to avoid overshoot/ringing.

- Thermal path: Use SSiC/RBSiC heat spreaders, high-conductivity TIMs; validate with thermal simulations and IR thermography.

- Filtration and IP rating: For cement/steel dust, specify IP54+ enclosures, positive-pressure cooling, and filter differential pressure monitoring.

- Burn-in and validation: Implement HTOL and power cycling aligned with your duty profile; capture baseline metrics for warranty and O&M.

Industry Success Factors and Customer Testimonials

- Integration expertise: Seamless pairing with IEC 61850 SCADA and local switchgear ecosystems is critical.

- Local service: 24/7 technical response reduces downtime and accelerates commissioning.

- Customer feedback: “Our retrofit with SiC modules cut energy costs and eliminated nuisance trips during summer peaks.” — Maintenance Head, Karachi rolling mill (verified client summary)

Future Innovations and 2025+ Trends

- Cost curve: Wider adoption and scale in 1700 V SiC reduce $/kW; improved trench MOSFET generations lower RDS(on).

- Advanced gate driving: Smarter, temperature-aware gate control and active thermal management increase lifetime.

- Hybrid energy: SiC enables bidirectional DC links for batteries, supercaps, and PV—key to diesel reduction and tariff peak shaving.

- Local manufacturing: Technology transfer and local assembly shorten lead times and hedge PKR volatility.

Common Questions and Expert Answers

- Q: Can SiC modules drop into IGBT designs?

A: Electrical and thermal differences require gate driver updates, snubber re-optimization, and sometimes magnetics re-scaling. Sicarb Tech provides conversion guidelines and hardware kits. - Q: What switching frequency should I target?

A: 50–100 kHz is typical for high-power UPS/inverters; final selection balances magnetics size, EMI, and efficiency. We simulate site-specific duty cycles. - Q: How do you manage EMI at higher dv/dt?

A: Kelvin source modules, optimized gate resistors, RC snubbers, shielded busbars, and proper PCB stack-ups; compliance validated to CISPR 11/22. - Q: What about short-circuit robustness?

A: Our modules support DESAT detection with soft turn-off in 2–3 μs; application-level protection coordination ensures safe operation. - Q: Do you support local standards and inspections?

A: Yes. We align systems to IEC 62040/62477 and assist with utility interconnection and local authority approvals.

Why This Solution Works for Your Operations

SiC MOSFET power modules deliver high efficiency, fast dynamics, and thermal resilience—exactly what Pakistan’s textile, cement, and steel sectors need to protect throughput and reduce PKR-denominated OPEX. With compact footprints and strong grid compatibility, they are the cornerstone for next-generation UPS and high-performance inverters.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to accelerate your SiC journey:

- 10+ years of SiC manufacturing, backed by the Chinese Academy of Sciences

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC thermal substrates and components

- Technology transfer and factory establishment—from feasibility to commissioning

- Turnkey support from material processing to finished UPS/inverter products

- Proven outcomes with 19+ enterprises, delivering measurable ROI

Contact us for a free consultation, PKR-denominated TCO analysis, and a tailored upgrade plan. - Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Urgency: 2025 budget cycles and peak summer demand windows are approaching—secure engineering slots and lead times now to de-risk Q2–Q3 operations.

Article Metadata

Last updated: 2025-09-12

Next scheduled update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.