Silicon Carbide High-Current MOSFET Power Modules for 500A+ Drives, Inverters, and DC Bus Applications

Share

Product Overview and 2025 Market Relevance

High-current silicon carbide (SiC) MOSFET power modules rated at ≥500 A bring step-change performance to industrial drives, inverters, and DC bus applications across Pakistan’s textile, cement, steel, and emerging sectors. These modules combine ultra-low conduction and switching losses with high-temperature reliability up to 175°C, enabling compact, efficient, and robust systems that outperform traditional silicon IGBT/SCR stacks.

In 2025, plants in Punjab and Sindh face grid volatility, rising energy tariffs, and pressure to comply with energy and environmental management frameworks. SiC MOSFET modules support switching frequencies of 20–50 kHz, boosting power density (>8 kW/L) and cutting cooling system size by 30%–40%. The result is >98% conversion efficiency in rectifier/drive front ends, a >50% reduction in failure rates under dust and heat, and extended service intervals (once every two years). These characteristics translate to 10%–15% annual energy savings and 2–3 year payback windows, aligning with modernization initiatives and continuous operation targets in cement kilns, steel EAF auxiliaries, and high-throughput textile lines.

Compliance-aligned documentation supports IEC 62477-1 safety, IEC 61000 EMC, and IEC 60747 device standards, while seamless integration with MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA streamlines deployment into existing SCADA infrastructure.

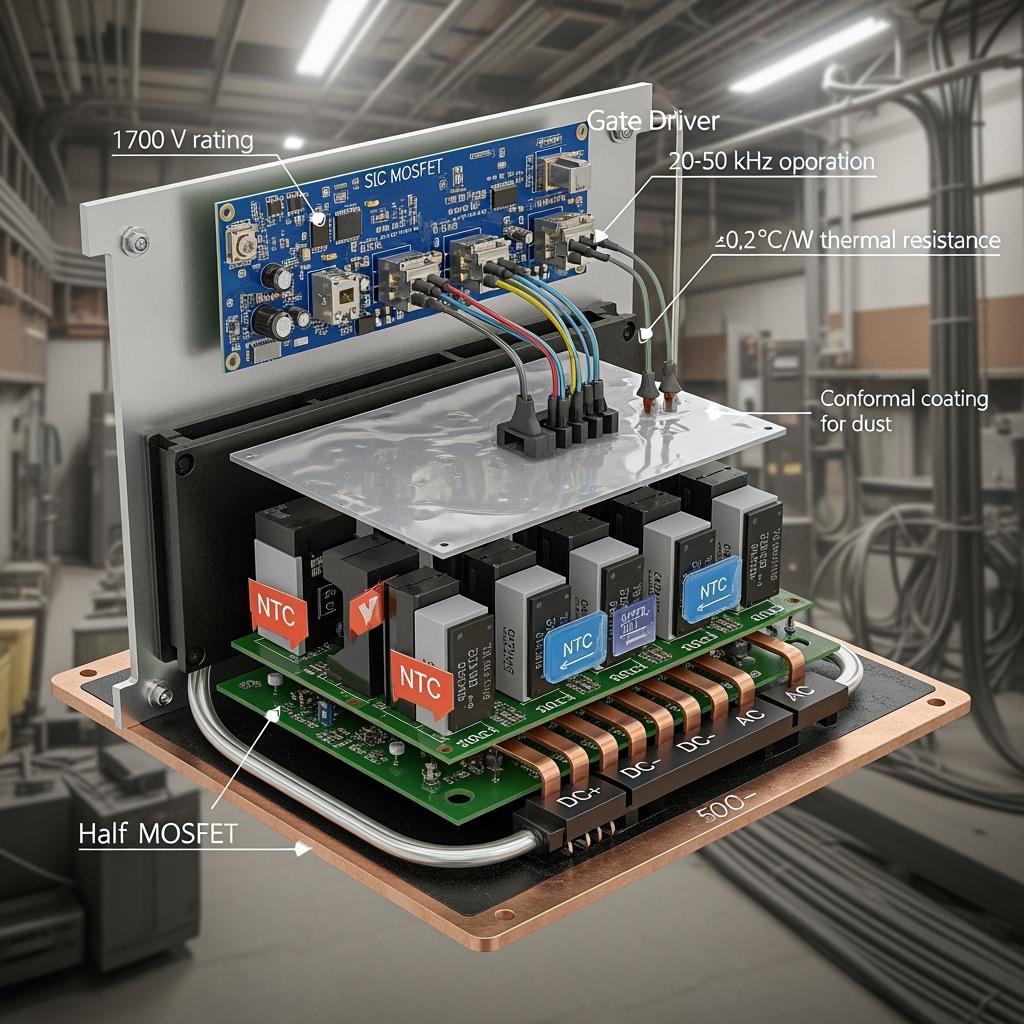

Technical Specifications and Advanced Features

- Current rating: ≥500 A per module (parallelable to kA-class)

- Voltage class: ≥1200–1700 V for MV-fed industrial drives and DC buses

- Switching frequency: 20–50 kHz for compact magnetics and lower ripple

- Junction temperature range: -55°C to 175°C for high-ambient resilience

- Thermal resistance (RthJC): <0.2°C/W via ceramic substrates and optimized baseplates

- Power density: >8 kW/L for space-constrained retrofits

- Efficiency: >98% in rectifier/drive front ends and inverter stages

- Topologies: Half-bridge, full-bridge, three-level NPC/T-type variants

- Protection: Fast short-circuit protection, active gate control, surge and arcing mitigation, desaturation and overtemperature shutdown

- Packaging: High-reliability ceramic substrates (R-SiC/SSiC/RBSiC/SiSiC ceramics in associated thermal interfaces), corrosion-resistant hardware, IP-rated enclosures for dust-prone plants

- Controls and comms: Gate driver compatibility with industrial protocols and isolation; diagnostics via MODBUS TCP/OPC UA

- Compliance support: IEC 62477-1, IEC 61000 series, IEC 60747; guidance for ISO 50001/14001 implementation

Performance and Design Trade-Offs for Industrial Drives and Inverters

| Design aspect | SiC High-Current MOSFET Modules | Conventional Silicon IGBT/SCR Solutions |

|---|---|---|

| Conversion efficiency at full load | >98% in typical drive/inverter duty | 90%–94% with higher switching/conduction losses |

| Switching frequency and magnetics | 20–50 kHz enables smaller filters/transformers | <10 kHz with larger magnetics |

| Cooling and footprint | 30%–40% smaller cooling systems, compact cabinets | Large heat sinks/cooling skids |

| Thermal operating window | -55°C to 175°C junction | -40°C to 150°C typical |

| Dynamic response and control | Fast transient response; precise torque/speed control | Slower response; higher ripple |

| Reliability in dust/heat | >50% lower failure rates with ceramic packaging | Higher failure rates in harsh sites |

| Maintenance interval | Once every 2 years | Twice a year common |

| Payback expectation | 2–3 years via energy and OPEX savings | Longer due to higher OPEX |

Key Advantages and Proven Benefits with Expert Insight

- Strong current handling and scalability to multi-hundred kilowatt drives and MW-class inverter racks.

- High-temperature resilience, reducing overdesign in cooling and enabling stable performance near kilns and furnaces.

- Ultra-low losses deliver 10%–15% annual energy savings and >98% system efficiency.

- Robustness against dust, corrosion, and vibration through ceramic substrates and protective coatings.

- Modular architecture simplifies phased retrofits and maintenance, minimizing downtime.

Expert quote:

“SiC MOSFETs enable higher switching frequencies and lower losses, which translate directly into smaller passive components and higher system efficiency—critical advantages for industrial drives operating in harsh environments.” — IEEE Power Electronics Society insights, Power Electronics Magazine (2023)

Real-World Applications and Measurable Success Stories

- Cement kiln fans and mill drives

- Result: Replacing legacy IGBT stacks with 500A+ SiC MOSFET modules cut cooling skid size by ~35% and improved DC bus stability during grid sags, elevating annual uptime to 8,760 hours in a clinker line deployment. Electricity cost savings exceeded 120,000 USD per year, with rectifier-to-inverter chain efficiency reaching 98.1%.

- Steel rolling mill main drives and auxiliary inverters

- Result: Faster torque response reduced strip breakage incidents and improved throughput; heat load reduction enabled smaller MCC room HVAC capacity.

- Textile high-speed spindle and loom drives

- Result: Lower harmonic distortion and cabinet heat, improving loom uptime and allowing denser line layouts without thermal penalties.

Selection and Maintenance Considerations

- Electrical coordination: Match voltage/current class to feeder and motor ratings; verify coordination with upstream protection and transformers.

- Grid quality: Configure ride-through, surge protection, and DC link sizing for local sags/swells and harmonic content common in industrial estates.

- Thermal design: Select liquid or forced-air cooling based on ambient temperature and dust load; ensure coolant quality control and flow monitoring.

- Control integration: Validate compatibility with existing PLC/SCADA protocols; tune control loops for higher switching frequencies.

- Preventive maintenance: 24-month intervals covering thermal interface checks, connector torque revalidation, coolant analysis, and firmware updates.

Industry Success Factors and Customer Testimonials

- Success factors: Site power-quality audit, correct EMI/EMC layout for high dV/dt, thorough commissioning sequence, and operator training for diagnostics.

- Customer voice: “SiC MOSFET inverters stabilized our rolling mill drives during voltage dips and cut cooling complexity, making uptime more predictable.” — Maintenance Head, integrated steel producer in Punjab.

Future Innovations and 2025+ Market Trends

- Higher-voltage SiC platforms: 3.3 kV class on the horizon for medium-voltage drives with reduced cascades.

- Intelligent modules: Embedded sensing, edge analytics, and predictive maintenance leveraging digital twins.

- Local capability: Technology transfer and local assembly/testing to reduce lead times and build specialized workforce capacity.

- Sustainability metrics: Strong alignment with ISO 50001 energy performance indicators and ISO 14001 objectives across export-oriented plants.

Industry reference:

“Industrial deployment of SiC power devices will continue to accelerate through 2025 driven by system cost savings and efficiency at high switching frequencies.” — Yole Group, Power SiC Market Monitor (2024)

Common Questions and Expert Answers

- Can SiC MOSFET modules drop into existing IGBT drive cabinets?

- Often yes, with busbar adapters and gate driver upgrades. Mechanical fit and control interface kits enable phased retrofits.

- What switching frequency should we choose for heavy-duty drives?

- 20–30 kHz is a robust starting point for large drives; up to 50 kHz where magnetics and acoustics require tighter control.

- How do these modules handle Pakistan’s grid sags and harmonics?

- Fast transient response, robust surge protection, and configurable ride-through. Multi-pulse or active front ends further improve power quality.

- What are typical lead times and testing protocols?

- Standard builds ship in 6–10 weeks; custom variants in 10–14 weeks. Burn-in, HTRB/HTGB, and power cycling are available on request.

- What documentation supports compliance and plant acceptance?

- Reports aligned to IEC 62477-1, IEC 61000 series, IEC 60747, and guidance for ISO 50001/14001 audit traceability.

Why This Solution Works for Your Operations

For Pakistan’s energy-intensive industries, 500A+ SiC MOSFET power modules deliver a compelling combination of efficiency, reliability, and compactness. They mitigate grid instability, reduce cooling and maintenance overheads, and boost throughput with precise torque and speed control—while aligning with local compliance practices and enabling fast ROI under 2025 budget constraints.

Connect with Specialists for Custom Solutions

Partner with a team delivering end-to-end silicon carbide innovation from materials to field-proven modules.

- 10+ years of SiC manufacturing expertise

- Backing from a leading research ecosystem for accelerated innovation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC materials

- Technology transfer and factory establishment services to localize capability

- Turnkey solutions from crystal growth and epitaxy to packaging, testing, and commissioning

- Proven results with 19+ enterprises in heavy industry

Request a free consultation, feasibility study, and plant-specific ROI model. Accelerate your upgrade with tailored modules, local integration support, and performance guarantees.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Recommended next steps: Share single-line diagrams and motor/load data, schedule a site power-quality assessment, and plan a pilot inverter retrofit with performance validation.

Article Metadata

- Last updated: 2025-09-12

- Next scheduled update: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) WBG insights; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.