Low Thermal Resistance Ceramic Substrates (Si3N4/AlN) for SiC Module Packaging and Heat Spreader Integration

Share

Product Overview and 2025 Market Relevance

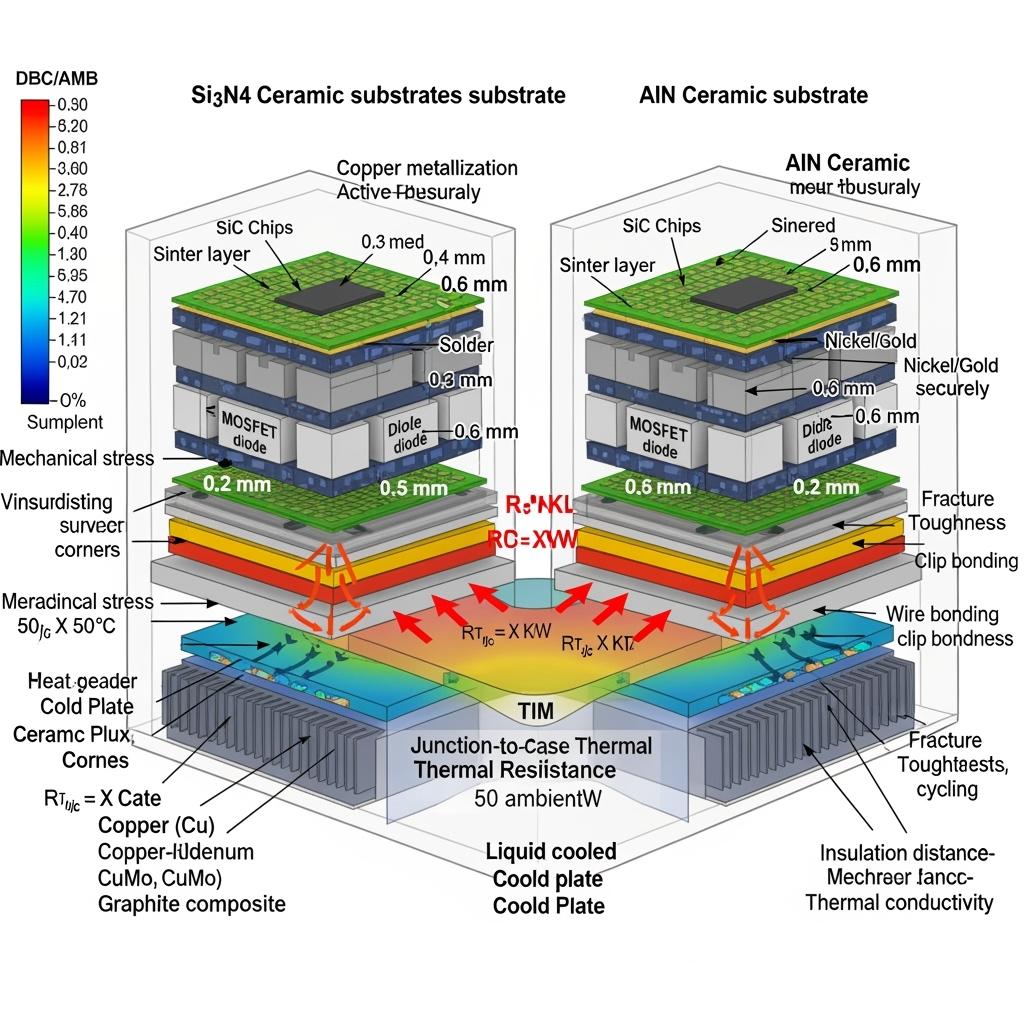

Low thermal resistance ceramic substrates—primarily silicon nitride (Si3N4) and aluminum nitride (AlN) in direct-bonded copper (DBC) or active metal brazed (AMB) configurations—are the thermal and mechanical backbone of silicon carbide (SiC) power modules. They provide high thermal conductivity, robust mechanical strength, and reliable electrical insulation, enabling compact, high-efficiency inverters and industrial drives that must operate in Pakistan’s hot (45–50°C) and dusty environments. When co-optimized with heat spreaders (Cu, CuMo, CuW, or graphite composites) and high-reliability die-attach (e.g., Ag sinter), these substrates lower junction-to-case thermal resistance, improve thermal cycling endurance, and extend module lifetime toward 200,000 hours—essential for 11–33 kV distribution-level photovoltaic interconnections and heavy-duty textile, cement, and steel applications.

In 2025, SiC switching frequencies of 50–150 kHz reduce magnetics size but increase heat flux density. Substrates with high thermal conductivity (AlN) and superior fracture toughness (Si3N4) mitigate thermo-mechanical stress from rapid load and temperature swings. Integrated design—substrate, copper metallization thickness, surface finish, and heat spreader stack-up—directly translates to higher system efficiency (≥98.5%), up to 2× power density, and approximately 40% reduction in cooling system volume compared to traditional silicon designs.

Technical Specifications and Advanced Features

- Ceramic options and properties:

- Si3N4 DBC/AMB: High fracture toughness and excellent thermal shock resistance; typical thermal conductivity ~70–90 W/m·K

- AlN DBC/AMB: Very high thermal conductivity ~150–180 W/m·K; suitable for maximum heat flux and compact layouts

- Copper and finishes:

- Copper thickness: 0.3–0.6 mm typical (customizable per current and thermal spread requirements)

- Surface finishes: Ni/Au, Ag, or OSP compatible with Ag sinter or solder attach; roughness controlled for bond reliability

- Thermal performance:

- Junction-to-case (per die) reduction via optimized ceramic selection and heat spreader coupling

- Support for ΔTj control with high-frequency operation (50–150 kHz), enabling stable junction temperatures up to +175°C

- Mechanical and reliability:

- Power cycling endurance through matched CTE stack-ups (SiC–Ag sinter–ceramic–Cu–spreader)

- High partial discharge inception voltages with controlled dielectric thickness for MV insulation margins

- Integration with heat spreaders:

- Cu for cost-effective spreading; CuMo/CuW for CTE matching and bow control; graphite composites for weight reduction and in-plane conductivity

- TIM selection guidance (grease, phase-change, or gel pads) to minimize case-to-cold-plate resistance

- Manufacturing and quality:

- Tight flatness and bow specifications; laser structuring for copper patterns; solder mask or passivation options

- Full traceability with lot certificates: thermal conductivity, dielectric strength, metallization adhesion, and thickness metrology

Descriptive Comparison: Si3N4 vs AlN Substrates for SiC Modules in Harsh Ambient Conditions

| Criterion | Si3N4 DBC/AMB (mechanical robustness) | AlN DBC/AMB (maximum thermal conductivity) |

|---|---|---|

| Thermal conductivity | ~70–90 W/m·K | ~150–180 W/m·K |

| Fracture toughness / thermal shock | Excellent; best for aggressive cycling | Good; requires careful mechanical design |

| Typical use | Heavy cycling, high-mechanical-stress drives | Highest power density, compact modules |

| Cost | Moderate | Higher |

| Recommended heat spreader | Cu/CuMo for balanced stress | CuMo/CuW or graphite composite to control bow |

Key Advantages and Proven Benefits with Expert Quote

- Lower thermal resistance: AlN provides top-tier heat removal for dense layouts, while Si3N4 offers robust cycling endurance—both supporting ≥98.5% inverter efficiency and reduced cooling burden.

- Reliability at high ambient: Materials and stack-ups maintain integrity under 45–50°C environmental conditions and frequent load transients common in Pakistan’s industrial sites.

- Compact modules: High thermal conductivity plus optimized heat spreaders support up to 2× power density and smaller enclosures.

- Consistent performance: Controlled metallization, dielectric thickness, and flatness reduce assembly variation and improve yield.

Expert perspective:

“Selecting the right ceramic substrate and copper stack is pivotal for SiC module reliability. AlN delivers unmatched thermal conductivity, while Si3N4 excels in mechanical robustness under power cycling. Both can achieve long lifetimes when paired with appropriate die-attach and heat spreading.” — IEEE power module packaging insights (ieee.org)

Real-World Applications and Measurable Success Stories

- MV PV inverters (southern Pakistan): Transitioning from alumina to AlN DBC with CuMo spreaders reduced junction temperatures by 8–12 K at full load, supporting ≥98.5% efficiency and approximately 40% cooling system volume reduction.

- Textile plant drives: Si3N4 substrates paired with Ag sinter improved power cycling life by an estimated 20–30% versus alumina-based stacks, reducing thermal trip events during peak summer months.

- Cement and steel mills: Si3N4 modules demonstrated fewer substrate cracks and stable partial discharge performance after extended thermal cycling, improving uptime under dusty, high-vibration environments.

Selection and Maintenance Considerations

- Application-driven choice:

- Choose AlN for highest heat flux and compact MV inverter modules; prioritize Si3N4 for drives facing aggressive cycling and mechanical stress.

- Stack-up and CTE matching:

- Pair ceramics with CuMo/CuW spreaders when minimizing bow and CTE mismatch is critical; use Ag sinter for die-attach to enhance thermal and fatigue performance.

- Copper patterning and thickness:

- Size copper for current density and spreading; consider thicker Cu for current peaks but validate against warpage and stress.

- Insulation and creepage:

- Define dielectric thickness and creepage distances for MV insulation requirements; verify partial discharge margins.

- TIM and cold plate interface:

- Select low-bleed, stable TIMs; validate case-to-cold-plate thermal resistance under 45–50°C ambient and dust-protected airflow.

- Quality control:

- Require adhesion, thermal conductivity, dielectric withstand, and flatness certificates; inspect for voids, delamination, and surface defects before assembly.

Industry Success Factors and Customer Testimonials

- Co-design process: Packaging, power stage, and cooling teams must jointly optimize ceramic choice, copper thickness, and spreader to meet ΔTj, EMI, and mechanical targets.

- Early thermal-structural simulation: FEA for thermo-mechanical stress and CFD for cooling de-risk production and accelerate qualification.

Customer feedback:

“Switching to Si3N4 DBC with Ag sinter stabilized our modules under frequent load cycles. Thermal performance improved without sacrificing mechanical robustness.” — Head of engineering, industrial drive OEM serving textile and steel plants

Future Innovations and Market Trends

- Advanced composite spreaders with anisotropic conductivity for improved lateral heat spreading and reduced weight

- Thicker copper with stress-relief patterning for current surges in MV applications

- Embedded temperature sensing within substrates for real-time junction estimation and predictive maintenance

- Local assembly and testing capabilities to support Pakistan’s >5 GW MV PV expansion and approximately USD 500 million inverter market

Common Questions and Expert Answers

- When should I choose Si3N4 over AlN?

Select Si3N4 for superior cycling robustness and mechanical reliability; choose AlN for maximum thermal conductivity and the most compact module footprints. - How much can substrates influence efficiency?

Reducing thermal resistance lowers junction temperatures, which reduces conduction and switching losses, helping achieve ≥98.5% inverter efficiency targets. - Which heat spreader is best for MV SiC modules?

CuMo or CuW provide good CTE control and stiffness; graphite composites reduce weight and offer high in-plane conductivity—validate with FEA and flatness specs. - Are these substrates compatible with Ag sinter and high-temperature operation?

Yes. DBC/AMB Si3N4 and AlN with appropriate finishes are widely used with Ag sinter and support junction operation up to +175°C. - How do dust and high ambient temperatures impact substrate choice?

They primarily affect cooling. With robust substrates and spreaders, maintain thermal margins through proper TIM selection and dust-resistant cold plates or heat exchangers.

Why This Solution Works for Your Operations

Optimized ceramic substrates and heat spreader integration transform SiC device capability into system-level benefits: lower junction temperatures, higher efficiency, and compact, rugged modules suited to Pakistan’s hot, dusty industrial settings. Whether prioritizing maximum thermal conductivity (AlN) or cycling durability (Si3N4), the right substrate stack-up enables up to 2× power density, ≥98.5% efficiency, and long service life across MV PV, textile, cement, and steel applications.

Connect with Specialists for Custom Solutions

Advance your module packaging with materials engineered for performance and reliability:

- 10+ years of SiC manufacturing expertise and packaging know-how

- Backing from a leading research ecosystem driving innovation in ceramics, metallization, and heat spreading

- Custom development across R-SiC, SSiC, RBSiC, and SiSiC components for thermal and structural integration

- Technology transfer and factory establishment services for local substrate-to-module assembly

- Turnkey solutions spanning materials, devices, packaging, cooling, and qualification

- Track record with 19+ enterprises delivering efficiency gains and longer lifetimes

Request a free consultation and a tailored substrate/spreader stack recommendation:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure 2025–2026 development and production slots now to align with MV inverter and industrial drive rollouts and reduce time-to-market.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.