Leading SiC Producers and Innovators in Japan

Share

Leading SiC Producers and Innovators in Japan

In the rapidly evolving landscape of advanced materials, silicon carbide (SiC) stands out as a material of unparalleled performance. Its exceptional properties, including extreme hardness, superior thermal conductivity, excellent chemical inertness, and high-temperature strength, make it indispensable for demanding applications across various industries. While global innovation drives SiC advancements, Japan has emerged as a significant hub for leading SiC producers and innovators, consistently pushing the boundaries of material science and manufacturing. This blog post explores the critical role of custom silicon carbide products, highlighting key applications and the unparalleled advantages they offer to engineers, procurement managers, and technical buyers.

1. The Rise of Custom Silicon Carbide in High-Performance Applications

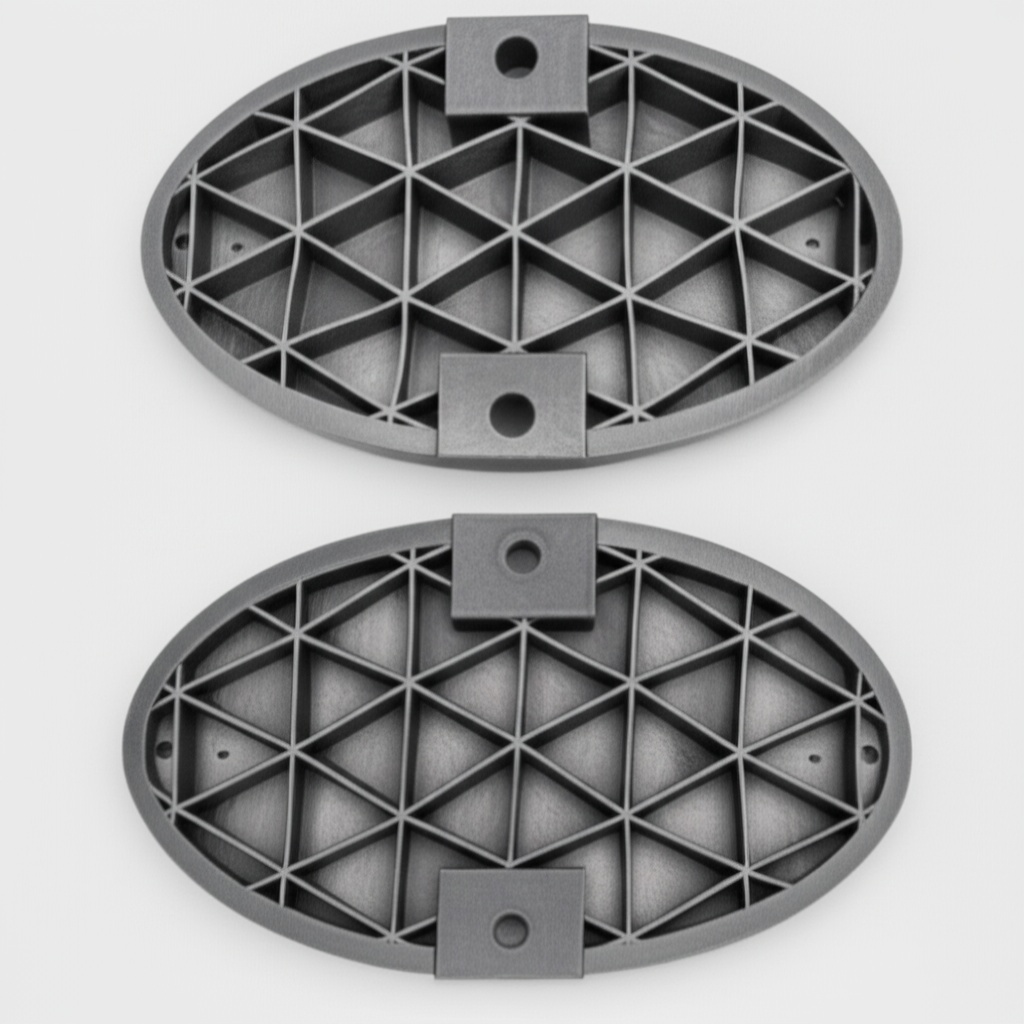

Custom silicon carbide products are engineered components tailored to meet precise specifications for specific industrial applications. Unlike standard off-the-shelf parts, custom SiC solutions provide optimized performance, efficiency, and longevity in the most challenging environments. These include technical ceramics designed for extreme temperatures, abrasive conditions, or corrosive chemicals. The demand for such specialized components is skyrocketing as industries strive for greater efficiency, miniaturization, and reliability.

From semiconductor manufacturing to aerospace propulsion, the ability to customize SiC materials and geometries allows for breakthrough innovations. This adaptability makes custom SiC an essential material for critical components where conventional materials simply fail to perform adequately.

2. Key Applications of SiC Across Diverse Industries

Silicon carbide’s unique combination of properties makes it a material of choice across a vast spectrum of industries:

- Semiconductors: SiC is vital for high-power devices, power modules, and advanced packaging due to its superior electron mobility, breakdown voltage, and thermal conductivity. Custom SiC components are used in wafer processing equipment, susceptors, and various tooling.

- Automotive: In electric vehicles (EVs), SiC power electronics improve efficiency, extend range, and reduce charging times. Custom SiC parts are also found in braking systems and engine components for high-performance vehicles.

- Aerospace & Defense: Its lightweight, high-temperature resistance, and stiffness make SiC ideal for lightweight mirror substrates, aerospace bearings, missile nose cones, and thermal management systems in extreme environments.

- Power Electronics: SiC devices are revolutionizing power conversion, enabling smaller, lighter, and more efficient inverters, converters, and power supplies for renewable energy, industrial motors, and data centers.

- Renewable Energy: SiC components enhance the efficiency and reliability of solar inverters, wind turbine converters, and energy storage systems.

- Metallurgy & High-Temperature Processing: SiC crucibles, kiln furniture, and furnace components withstand extreme temperatures and corrosive atmospheres, crucial for metal melting, sintering, and heat treatment.

- Chemical Processing: Its exceptional chemical inertness makes SiC ideal for pump components, valves, and heat exchangers in aggressive chemical environments.

- LED Manufacturing: SiC substrates are used for growing GaN (Gallium Nitride) for high-brightness LEDs.

- Industrial Machinery: Wear-resistant SiC components, such as mechanical seals, nozzles, and pump parts, significantly extend the lifespan of industrial equipment operating in abrasive conditions.

- Medical Devices: Biocompatible SiC is explored for prosthetics and implantable devices due to its inertness and hardness.

3. Why Choose Custom Silicon Carbide Products?

The benefits of opting for custom silicon carbide products are numerous and directly impact performance and operational costs:

- Superior Thermal Resistance: SiC maintains its strength and integrity at temperatures exceeding 1,500°C, far beyond what most metals can withstand.

- Exceptional Wear Resistance: Its extreme hardness (second only to diamond) provides outstanding resistance to abrasion and erosion, extending component lifespan in harsh conditions.

- Outstanding Chemical Inertness: SiC is highly resistant to most acids, bases, and corrosive gases, making it ideal for chemical processing and high-purity applications.

- High Thermal Conductivity: Efficiently dissipates heat, critical for power electronics and high-temperature furnace components, preventing thermal runaway.

- Low Thermal Expansion: Minimizes thermal stress and distortion, ensuring dimensional stability across wide temperature fluctuations.

- High Strength and Stiffness: Offers excellent mechanical strength and rigidity, crucial for structural components under load.

- Tailored Performance: Customization allows for optimization of material properties and geometries for specific application requirements, maximizing efficiency and minimizing waste.

- Reduced Downtime & Maintenance: The durability of custom SiC parts leads to longer service intervals and lower replacement costs.

4. Recommended SiC Grades and Compositions

Silicon carbide is not a single material but a family of ceramics with various bonding methods and compositions, each offering distinct properties suited for different industrial applications. Understanding these grades is crucial for effective material selection.

| SiC Grade/Type | Key Characteristics | Typical Applications |

|---|---|---|

| Reaction-Bonded SiC (SiSiC) | High strength, excellent thermal shock resistance, good corrosion resistance, lower cost, high purity. Contains free silicon. | Kiln furniture, wear parts, heat exchangers, mechanical seals, semiconductor processing components. |

| Sintered SiC (SSiC) | Extremely high hardness, superior strength at high temperatures, excellent corrosion and wear resistance, no free silicon. | Mechanical seals, pump parts, nozzles, ballistic protection, high-temperature bearings, nuclear applications. |

| Nitride-Bonded SiC (NBSC) | Good strength, excellent thermal shock resistance, lower density, porous structure. | Kiln furniture, refractory linings, general wear parts. |

| Recrystallized SiC (ReSiC) | High purity, excellent thermal shock resistance, no free silicon, good strength. | High-temperature furnace linings, susceptors, radiant tubes. |

| CVD SiC (Chemical Vapor Deposition SiC) | Extremely high purity, theoretical density, superior strength, excellent surface finish. | Semiconductor tooling, optics, high-purity furnace components. |

5. Design Considerations for Custom SiC Products

Designing with silicon carbide requires careful consideration due to its unique properties. Engineers must account for the material’s inherent brittleness and high hardness during the design phase to ensure manufacturability and optimal performance. Key considerations include:

- Geometry Limits: Avoid sharp internal corners and abrupt changes in cross-section, as these can create stress concentration points. Radius corners are generally preferred.

- Wall Thickness: Aim for uniform wall thickness where possible to minimize differential cooling and thermal stress during processing.

- Stress Points: Identify potential stress points during operation and design to distribute loads evenly. Finite Element Analysis (FEA) is often employed.

- Machinability: SiC is extremely hard, making post-sintering machining challenging and expensive. Design should aim for near-net-shape processing wherever possible.

- Joining Methods: Consider how SiC components will be joined to other parts (e.g., brazing, adhesive bonding, mechanical fastening) and design appropriate features.

6. Tolerance, Surface Finish & Dimensional Accuracy

Achieving precise tolerances and surface finishes with SiC is a testament to advanced manufacturing capabilities. While SiC’s hardness makes it difficult to machine, skilled manufacturers can achieve remarkable precision:

- Achievable Tolerances: Depending on the SiC grade and manufacturing process (e.g., pressing, casting, green machining, or post-sintering grinding), tolerances can range from ±0.5% to ±0.005mm for critical dimensions.

- Surface Finish Options: As-fired surfaces typically have a matte finish. For demanding applications requiring superior sealing, reduced friction, or optical clarity, processes like grinding, lapping, and polishing can achieve surface roughness (Ra) values well below 0.1 µm.

- Dimensional Accuracy: High precision is crucial for components in semiconductor equipment, optical systems, and precision machinery, where even minor deviations can impact performance.

7. Post-Processing Needs for Enhanced Performance

After initial sintering, custom SiC components often undergo various post-processing steps to enhance their performance, durability, or meet specific functional requirements:

- Grinding & Lapping: Essential for achieving tight tolerances and fine surface finishes. Diamond grinding wheels are typically used.

- Polishing: For mirror-like surfaces required in optics or semiconductor tooling.

- Sealing: For porous SiC grades, impregnation or coating may be used to improve impermeability.

- Coating: Application of thin films (e.g., CVD SiC, SiC/SiC composites) can enhance surface properties, corrosion resistance, or add specific functionalities.

- Brazing: For joining SiC parts to themselves or to dissimilar materials, often using active brazing alloys.

8. Common Challenges and How to Overcome Them

While SiC offers extraordinary benefits, working with it presents certain challenges:

- Brittleness: Like most ceramics, SiC is brittle and susceptible to fracture under tensile stress or impact. Design strategies such as generous radii, compressive loading, and proper mounting techniques can mitigate this.

- Machining Complexity: Its extreme hardness makes machining difficult and costly. Near-net-shape forming and advanced diamond grinding techniques are crucial.

- Thermal Shock: Although SiC generally has good thermal shock resistance, rapid temperature changes can still induce stress. Careful design and controlled heating/cooling rates are necessary.

- Cost: SiC components can be more expensive than conventional materials. However, their extended lifespan and superior performance often lead to a lower total cost of ownership.

9. How to Choose the Right SiC Supplier

Selecting a reliable supplier for custom silicon carbide products is paramount. A good supplier acts as a technical partner, offering expertise beyond just manufacturing. When evaluating potential vendors, consider:

- Technical Capabilities: Do they possess in-depth knowledge of various SiC grades, manufacturing processes (sintering, reaction bonding, CVD), and post-processing techniques?

- Material Options: Can they offer the specific SiC grade and composition best suited for your application?

- Quality Certifications: Look for ISO certifications and other relevant industry standards (e.g., AS9100 for aerospace, IATF 16949 for automotive).

- Design Support: Can they provide engineering assistance for optimizing designs for manufacturability and performance?

- Production Capacity & Lead Time: Can they meet your volume requirements and deliver within your project timelines?

- Experience: A proven track record in supplying SiC components to demanding industries is a strong indicator of reliability.

- R&D and Innovation: Are they actively involved in research and development to offer cutting-edge solutions?

Speaking of reliable suppliers, it’s worth noting the significant advancements and concentrated expertise in silicon carbide manufacturing within China. Specifically, Weifang City of China has emerged as a global hub for silicon carbide customizable parts manufacturing. This region is home to over 40 silicon carbide production enterprises, collectively accounting for more than 80% of China’s total silicon carbide output.

We, Sicarb Tech, have been instrumental in this growth, introducing and implementing advanced silicon carbide production technology since 2015. We’ve supported local enterprises in achieving large-scale production and technological advancements, witnessing the emergence and ongoing development of this robust industry. As part of Chinese Academy of Sciences(Weifang) Innovation Park, an entrepreneurial park closely collaborating with the National Technology Transfer Center of the Chinese Academy of Sciences, we leverage robust scientific and technological capabilities. This allows us to offer more reliable quality and supply assurance within China.

Our domestic top-tier professional team specializes in customized production of silicon carbide products. With our support, over 475 local enterprises have benefited from our technologies, encompassing material, process, design, measurement, and evaluation expertise. This integrated approach from materials to products enables us to meet diverse customization needs. We can offer higher-quality, cost-competitive customized silicon carbide components in China. Furthermore, if you are looking to establish a professional silicon carbide products manufacturing plant in your country, Sicarb Tech can provide comprehensive technology transfer and full-range services (turnkey project), including factory design, specialized equipment procurement, installation, commissioning, and trial production. This ensures an effective investment, reliable technology transformation, and a guaranteed input-output ratio.

10. Cost Drivers and Lead Time Considerations for Custom SiC

The cost and lead time for custom silicon carbide components are influenced by several factors:

- Material Grade and Purity: Higher purity and specialized SiC grades (e.g., CVD SiC) are generally more expensive due to complex manufacturing processes.

- Part Complexity: Intricate geometries, thin walls, and tight tolerances increase manufacturing difficulty and, consequently, cost.

- Volume: Economies of scale apply; higher volumes typically lead to lower unit costs.

- Post-Processing Requirements: Extensive grinding, lapping, or polishing adds to the overall cost and lead time.

- Tooling Costs: For new designs, non-recurring engineering (NRE) costs for molds or tooling can be a significant initial investment.

- Lead Time: This depends on the complexity, current production queue, and availability of raw materials. Expect several weeks to months for custom SiC components. Early engagement with suppliers is crucial for planning.

11. Frequently Asked Questions (FAQ)

Here are some common questions regarding custom silicon carbide products:

- What is the maximum operating temperature for silicon carbide?

Silicon carbide can operate continuously at temperatures up to 1650°C (3000°F) in oxidizing atmospheres, and even higher in inert or vacuum environments, depending on the specific SiC grade. - Can silicon carbide be machined easily?

No, silicon carbide is extremely hard and cannot be machined using conventional methods after sintering. It requires specialized diamond grinding techniques. Therefore, designing for near-net-shape manufacturing is highly recommended. - Is silicon carbide electrically conductive?

While some forms of SiC (especially n-type doped) are semiconductor materials used in power electronics, bulk ceramic SiC typically exhibits insulating or semiconducting properties, depending on its purity and doping. - What are the main advantages of SiC over other advanced ceramics like Alumina or Zirconia?

SiC generally offers superior thermal conductivity, higher hardness, better high-temperature strength, and excellent chemical resistance compared to Alumina (Al2O3) or Zirconia (ZrO2), making it suitable for more extreme applications. - How do I get a quote for a custom SiC part?

To get an accurate quote, you typically need to provide detailed engineering drawings (CAD files preferred), material specifications, quantity required, and any specific performance criteria. You can easily initiate this process by visiting our contact page.

12. Conclusion: The Indispensable Role of Custom SiC

Custom silicon carbide products are not merely components; they are strategic investments that empower industries to achieve unprecedented levels of performance, efficiency, and reliability in their most demanding applications. From the blistering heat of industrial furnaces to the intricate circuits of advanced power electronics, SiC offers a unique blend of properties that few other materials can match.

As the demand for high-performance engineered ceramics continues to grow, the expertise of leading SiC producers and innovators, particularly in hubs like Japan and Weifang, China, will be crucial. By partnering with experienced suppliers who understand the intricacies of custom SiC manufacturing, businesses can unlock new possibilities, overcome critical engineering challenges, and gain a significant competitive edge in their respective markets. Investing in custom SiC is investing in the future of high-performance industrial solutions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.