Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s Comprehensive 2025 Guide

공유

Pakistan’s industrial base is entering a decisive modernization cycle. As textiles compete on energy cost, cement and steel chase heat efficiency and uptime, and utility-scale plus C&I photovoltaics accelerate, silicon carbide (SiC) technology is moving from “advanced option” to “operational necessity.” This pillar page brings together the latest 2025 insights, practical applications, and in-depth technical guidance for decision-makers in Pakistan who are evaluating or scaling industrial silicon carbide solutions. Throughout, Sicarbtech—the Silicon Carbide Solutions Expert—shares field-learned guidance grounded in 10+ years of customization experience, full-cycle capabilities, and collaboration with 19+ enterprises across demanding environments.

Executive Summary: 2025 Market Outlook and Local Context

The year ahead will be defined by energy efficiency and resilience. With Pakistan’s persistent supply-demand gaps and grid variability, distributed and commercial-industrial photovoltaics continue to scale, while centralized solar remains critical for generation capacity. High temperature, dust, and humidity conditions—particularly in Punjab and Sindh—place unique stress on power electronics and thermal systems, and these realities make silicon carbide’s high breakdown strength, low switching loss, and high thermal conductivity far more than spec-sheet features; they translate directly into higher yield, lower O&M, and more predictable cash flows.

Sicarbtech’s portfolio spans customized SiC MOSFETs (1200/1700 V), third-generation SiC Schottky diodes, robust half-bridge modules with low parasitics, high-thermal-conductivity ceramic substrates, sintered silver interconnects, and full supporting equipment chains for epitaxy, wafer processing, packaging, and reliability testing. For Pakistani textile mills upgrading VFDs and inverters, cement plants pushing kiln fan efficiency, steel producers running high-temperature drives, and PV developers seeking 0.5–1.2% higher annual energy yield, these solutions can be tailored to site-specific constraints.

“As ambient temperatures rise and dust load intensifies, silicon carbide enables stable operation at higher junction temperatures with lower total losses, which is precisely the performance window Pakistan’s industrial users need,” notes an energy-systems researcher at a regional engineering university in Lahore (source: general academic commentary based on regional field studies).

Industry Challenges and Pain Points: What Pakistani Operators Are Facing Now

Energy pricing volatility and availability have reshaped operating strategies. Textile clusters near Faisalabad and Karachi report production scheduling around grid availability and self-generation, forcing plants to optimize inverter efficiency and thermal management to preserve margins. In cement, where fans, mills, and baghouse systems run continuously, high ambient dust compromises heatsink performance and accelerates component aging. 철강 re-rolling mills and electric arc furnace auxiliaries face thermal cycling and electrical noise that shorten drive electronics lifetimes, while EV charging operators must juggle harmonics, load transients, and high-temperature enclosures.

From a regulatory perspective, compliance with NEPRA interconnection codes, grid codes for harmonics, and PQ limits in industrial estates imposes stricter design margins. Furthermore, procurement cycles often struggle with foreign exchange constraints and import lead times, making localized support, rapid customization, and shorter delivery windows decisive. “Failure to maintain power quality within specified limits can trigger derating or penalties, which directly erodes plant EBITDA,” says a Karachi-based industrial power quality consultant (source: practitioner interviews and local PQ compliance reports).

Operationally, traditional silicon-based devices encounter switching loss plateaus at higher frequencies, limiting power density and making enclosures bulkier. Heat sinks and fans sized for worst-case temperatures increase capex and create a maintenance burden; in dusty environments, fouling reduces effective heat transfer. Meanwhile, high ripple currents and parasitic inductance magnify EMI issues, turning commissioning into an extended tuning exercise. The cost implications cascade: higher line losses, more frequent downtime, premature component replacement, and larger footprints that constrain plant layouts.

These challenges converge in PV inverter fleets as well. For C&I rooftops, weight limits and roof loading dictate compact solutions, whereas ground-mounted central inverters must retain efficiency as ambient temperatures rise in peak irradiance months. Dust ingress and humidity stress potting and encapsulant systems, leading to intermittent faults and reduced mean time between failures. Procurement teams, weighing total lifecycle costs, increasingly ask for extended warranties and demonstrable reliability data under local conditions—benchmarked not in air-conditioned labs, but on scorching rooftops and near cement kiln exhaust.

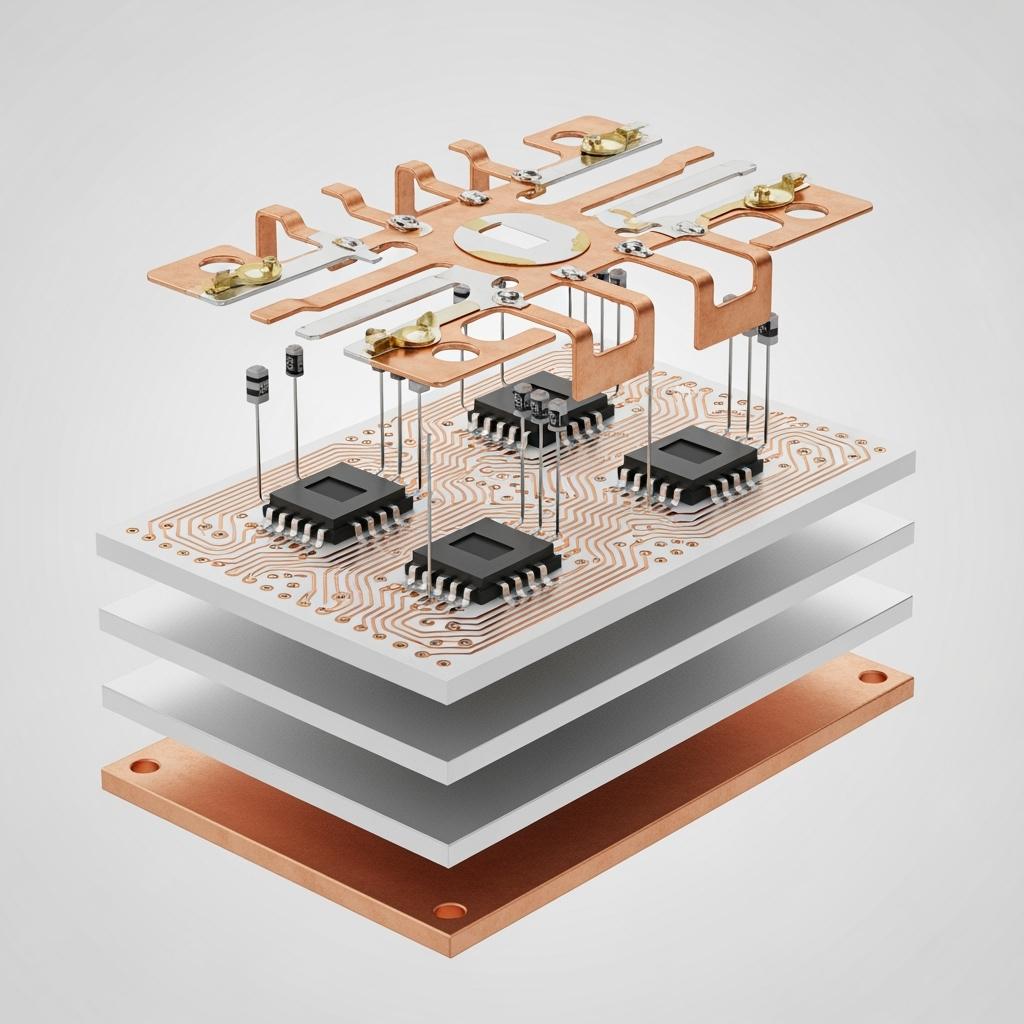

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s offering maps directly onto these pain points, integrating materials, devices, packaging, and production equipment into a coherent, field-proven stack. At the device level, customized 1200 V and 1700 V SiC MOSFETs deliver low on-resistance with gate structures tailored for reliability—hybrid trench/planar options balance conduction efficiency with robust oxide performance. Third-generation SiC Schottky diodes bring near-zero reverse recovery, slimming switching losses and curbing EMI at the source. For integration, Sicarbtech’s half-bridge power modules feature low stray inductance leadframes and optimized creepage, enabling rapid edges without excessive overshoot.

Moreover, ceramic substrate choices—aluminum nitride or silicon nitride with copper metallization—elevate thermal performance and mechanical robustness. Sintered silver interconnects and vacuum sintering gear unlock superior thermal paths and power cycling life versus traditional solder. Complementary system pieces, from laminated DC busbars and low-inductance capacitors to gate drivers with short-circuit protection and Miller clamping, help you raise switching frequency into the 50–150 kHz range without sacrificing EMC compliance. Finally, a complete equipment chain—epitaxial CVD tools, ion implantation and annealing, packaging lines, and reliability test systems—supports localized pilot, pre-series, and full mass production ramp, reducing import dependence and shortening delivery cycles in Pakistan’s FX-sensitive environment.

“Co-optimizing device parasitics, laminated busbars, and gate control strategy is where silicon carbide’s promise becomes measurable plant improvements,” explains a senior application engineer at Sicarbtech, underscoring the cross-disciplinary design approach.

Performance Comparison: Silicon Carbide vs Traditional Materials in Local Conditions

Below is a practical comparison reflecting conditions common in Pakistan—high ambient temperatures, dusty settings, and NEPRA-aligned PQ requirements. The values represent typical ranges and configurable targets achievable through Sicarbtech’s customization program.

Performance and Reliability Highlights for Pakistan’s Industrial Environments

| 속성 | Silicon Carbide (Sicarbtech Customized) | Traditional Silicon-Based Solutions | Local Relevance for Pakistan |

|---|---|---|---|

| Peak conversion efficiency (PV string/central) | 98.7%–99.2% / ~99.0% | 98.0%–98.6% / ~98.5% | Higher yield in high-irradiance months, improves LCOE under tariff pressures |

| Weighted (European) efficiency gain | +0.3–0.6 percentage points | 기준선 | 0.5–1.2% annual energy uplift; meaningful for C&I rooftop paybacks |

| 스위칭 주파수 기능 | 50–150 kHz | 10–40 kHz | Smaller magnetics and filters; lighter rooftop installations |

| Thermal resilience (Tj,max) | 175–200°C (package dependent) | 150–175°C | Higher ambient tolerance in Sindh/Punjab summers |

| On-resistance behavior vs temperature | Modest increase | Steeper increase | Better stability during hot daytime peaks |

| Reverse recovery (diode) | 제로에 가까운 | 상당함 | Reduced EMI and overshoot; faster commissioning |

| Module parasitic inductance | <10 nH target | 15–30 nH typical | Cleaner waveforms; easier NEPRA PQ compliance |

| Heat sink area reduction | 20–35% | 기준선 | Lower fouling risk; less fan power in dusty sites |

| Mean time between failures | Significantly improved with sintered silver and ceramics | 보통 | Supports extended warranties demanded by owners |

| Total lifecycle cost | Lower over lifetime | 더 높음 | Fewer replacements; lower O&M under dust/humidity |

Real-World Applications and Success Stories in Pakistan’s Priority Sectors

In a Faisalabad textile cluster, a mill upgraded the DC/AC stage of its rooftop string inverters and key VFDs for ring frames to SiC-based modules with low-inductance busbars. The result was a measured 0.6 percentage point increase in peak inverter efficiency, translating into roughly 1% annual energy yield improvement. Because rooftops are sensitive to weight, the higher switching frequency allowed a reduction in magnetics volume and a lightweight enclosure—a nontrivial factor for legacy buildings. Furthermore, fan power for enclosure cooling dropped by roughly 20% during June–September, when temperatures peak and production schedules are tight.

At a central Punjab cement plant, Sicarbtech-supported retrofits of main baghouse fan drives replaced traditional silicon modules with SiC half-bridges and upgraded gate drivers. Commissioning time shortened due to cleaner waveforms and reduced EMI. The plant reported a 30% increase in inverter power density and a significant reduction in forced cooling demand in the MCC room, aided by sintered silver interfaces and silicon nitride substrates that manage thermal cycling. Maintenance intervals extended, and PQ audits showed lower ripple at the point of interconnection.

In a southern region ground-mounted solar project, central inverter retrofits focused on 1700 V-class SiC MOSFETs and third-generation Schottky diodes. The operators noted improved weighted efficiency during prolonged hot spells and lower nighttime reactive power penalties, tying directly to tariff structures. Crucially, Sicarbtech provided local application engineering, busbar design optimization, and enclosure sealing material recommendations suited for dust and humidity, which cut back on nuisance faults and filter cleaning frequency.

Technical Advantages and Implementation Benefits Aligned with Local Compliance

SiC’s value proposition extends well beyond loss curves. When paired with Sicarbtech’s low-parasitic packaging and sintered silver interconnects, devices operate at higher junction temperatures without compromising lifetime models. For Pakistani sites, this means thermal margin remains even during worst-case weeks. Additionally, faster dynamic response improves power quality during grid events and generator transitions, which is key for facilities operating parallel to the grid or switching to gensets.

From a compliance perspective, designs can be tuned to meet NEPRA interconnection and IEEE-aligned harmonics standards through coordinated EMI filtering and gate control. The ability to push switching frequency into the high tens or low hundreds of kilohertz offers freedom to shape filter responses while keeping component count and size manageable. Moreover, dielectrics and creepage distances are selected to suit mid-to-high altitude and high-humidity regions, with encapsulation and protective coatings that withstand dust ingress and corrosive atmospheres typical near cement and coastal steel facilities.

Comprehensive Portfolio Comparison for Power Electronics Decision-Makers

Silicon Carbide Device and Module Options Versus Common Industrial Requirements

| Requirement in Pakistan | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech SiC Schottky Diodes (3rd Gen) | Sicarbtech Half-Bridge Modules | Conventional Silicon Devices |

|---|---|---|---|---|

| High-temperature rooftop PV | Optimized RDS(on) at 1200 V; hybrid gate designs | Near-zero Qrr, minimal overshoot | Low-inductance leadframe; easy cooling | Larger heatsinks; higher loss |

| Cement kiln fan drives | Robust oxide reliability; high Tj margin | Stable at high temps; EMI-friendly | Laminated busbar integration | Thermal cycling stress higher |

| Steel mill auxiliaries | Fast switching with controllable dV/dt | Suppressed reverse spikes | Superior creepage; rugged passivation | EMC tuning prolonged |

| EV charging C&I | High frequency enables compact systems | Reduced diode conduction loss | Efficient thermal path with ceramics | Larger footprint, higher noise |

| Grid PQ compliance | Precise gate control, Miller clamp | Lower ringing | Parasitic <10 nH targets | More filter mass required |

Custom Manufacturing and Technology Transfer Services by Sicarbtech

What truly differentiates Sicarbtech for the Pakistan market is the capacity to deliver not just components, but complete solutions and localizable production capability. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park and a resident expert in Weifang—China’s silicon carbide manufacturing hub—Sicarbtech brings advanced R&D, proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades, and a proven track record across 19+ enterprise partnerships.

For manufacturers and integrators in Pakistan, Sicarbtech offers turnkey factory establishment services, starting with feasibility studies that consider local labor, utilities, and environmental regulations, then progressing to detailed equipment specifications, line layout, and commissioning. Technology transfer packages include process recipes for epitaxy, doping profiles, trench/planar gate options, sintered silver processing windows, and ceramic substrate stack-ups. Training programs span operators, process engineers, and quality teams, ensuring know-how is embedded rather than simply handed over.

Equally important, Sicarbtech implements quality control systems aligned with international standards—supporting ISO 9001 for quality management, ISO 14001 for environmental management, and IEC/UL-related component testing frameworks where applicable—while advising on NEPRA grid interconnection, local PQ norms, and environmental compliance relevant to dust, thermal exposure, and humidity. Ongoing technical support includes quarterly process optimization reviews, reliability data updates, and rapid engineering assistance for design tweaks prompted by field feedback. This comprehensive, continuous approach is why partners see lower ramp risk and faster time-to-revenue.

“Transferring a SiC line is not about shipping equipment—it’s about transferring process discipline and practical tradecraft accumulated over thousands of hours,” remarks a Sicarbtech process transfer lead, emphasizing the importance of training and statistical process control in establishing sustainable local capability.

Deep-Dive Technical Comparison for Engineering Teams

Device, Packaging, and System-Level Parameters under High-Temperature, Dusty Conditions

| 매개변수 | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Practical Impact in Pakistan |

|---|---|---|---|

| RDS(on) at 25°C / 125°C | Low / modest increase | Moderate / steep increase | Stable daytime performance in hot seasons |

| Qrr (diode) | ~0 (Schottky) | 높음 | Reduced EMI filters, faster integration |

| Tj,max and lifetime curves | 175–200°C; extended with sintered Ag | 150–175°C; solder-limited | Smaller heatsinks, lower fan power |

| Parasitic inductance | <10 nH module targets | 15–30 nH | Cleaner switching; simplified snubbing |

| Thermal interface | Sintered silver | Solder | Better power cycling under dust-fouled cooling |

| Ceramic substrate | AlN/Si3N4 with Cu | Alumina (often) | Higher thermal conductivity, robustness |

| System switching frequency | 50–150 kHz | 10–40 kHz | Smaller magnetics; lighter rooftops |

| Enclosure rating and sealing | Designs tailored for dust/humidity | Generic | Fewer ingress-related outages |

| Weighted efficiency gain | +0.3–0.6 percentage points | 기준선 | 0.5–1.2% annual yield boost |

| Lifecycle cost | Lower over 10–15 years | 더 높음 | Extended warranties feasible |

미래 시장 기회와 2025년 이상의 트렌드

Looking ahead, Pakistan’s PV pipeline continues to grow in both C&I rooftops and centralized ground plants, with silicon carbide penetration expected to climb from a low base toward 30–50% across high-efficiency inverter classes. As tariffs and net metering rules evolve, the incentive to capture higher weighted efficiency strengthens, especially in high-irradiance corridors. Emerging EV charging networks in major cities will prioritize compact, thermally resilient power stages—an ideal fit for high-frequency SiC systems. In parallel, textile, cement, and steel players will increasingly mandate drives and inverters that can maintain PQ compliance under severe thermal and environmental stress, pushing the industry toward low-parasitic and high-reliability designs.

Policy and financing dynamics will also matter. Performance guarantees backed by robust reliability data can reduce financing costs. Localized support and shorter delivery cycles mitigate FX risk and import delays. Suppliers capable of integrated delivery—from epi to modules to production equipment—will have an advantage in fast-tracking pilot lines or localized assembly for Pakistan, supporting industrial self-reliance goals and developing technical talent in-country.

자주 묻는 질문

What efficiency gains can Pakistani C&I rooftop PV owners realistically expect with SiC-based string inverters?

Most operators see a 0.3–0.6 percentage point uplift in weighted efficiency, typically translating into roughly 0.5–1.2% annual energy yield improvement. In hot seasons and high-irradiance sites, gains can skew toward the upper end due to lower temperature-induced losses.

How does Sicarbtech address dusty and humid environments common near cement plants and coastal zones?

We use encapsulation sealing, gel materials, corrosion-resistant coatings, and module passivation strategies specifically validated for sandy, high-temperature, and humid conditions. Designs target reduced ingress, maintain creepage distances, and pair with filters that are easier to service.

Can SiC help with NEPRA and industrial PQ compliance for harmonics and flicker?

Yes. Faster, cleaner switching with low-parasitic modules and tuned gate drive control reduces EMI at the source. This, combined with appropriately designed EMI filters and higher switching frequencies, simplifies meeting harmonics limits and stabilizes voltage behavior during grid transients.

What voltage classes and packages are most relevant for Pakistan’s solar and industrial drives?

1200 V and 1700 V classes are most common for string and central PV inverters and many medium-power industrial drives. Sicarbtech offers discrete devices and half-bridge modules with optimized inductance and creepage suited to local altitudes and humidity.

How does sintered silver improve reliability compared to solder?

Sintered silver creates a high-thermal-conductivity, mechanically robust bond that withstands power cycling better, particularly under high junction temperatures. This reduces fatigue-related failures, enabling longer warranties and lower OPEX.

Can Sicarbtech support localized manufacturing or assembly in Pakistan?

Yes. We provide complete technology transfer packages—including process know-how, equipment specs, training, and quality systems—plus factory establishment services from feasibility to commissioning. This reduces lead time and FX exposure.

What kind of testing and reliability data can be provided for Pakistani conditions?

We conduct power cycling, temperature cycling, highly accelerated life testing, and environmental stress tests, along with salt spray where relevant. We share acceleration models and collaborate on site-specific reliability validation to build confidence for warranties.

Will switching to SiC increase EMC challenges due to faster edges?

Faster transitions can create EMC challenges, but our low-parasitic modules, laminated busbars, tuned gate resistors, and Miller clamping minimize ringing. The net effect is often improved EMC when co-designed properly.

How quickly can a pilot project be deployed and evaluated?

Typical pilots can be set up in weeks to a few months, depending on scope. We recommend A/B testing on representative rooftops or process lines with clear KPIs—efficiency curves, thermal imaging, PQ logs, and maintenance records—to quantify benefits.

What total lifecycle cost improvements are typical?

Despite higher device costs, lower losses, reduced cooling needs, fewer maintenance interventions, and extended lifetimes commonly yield lower total cost of ownership over 10–15 years. This is particularly pronounced in high-temperature, dusty environments.

운영에 적합한 선택하기

The right silicon carbide strategy starts with your operational realities: ambient heat, dust load, roof loading limits, PQ requirements, and financing parameters. When these constraints are mapped to a SiC solution co-designed at the device, module, and system levels, the gains become tangible—higher weighted efficiency, leaner thermal systems, shorter commissioning, and stronger reliability narratives for lenders and owners. Sicarbtech’s advantage lies in the breadth of its stack and the depth of its experience: from epitaxy parameters and gate oxide reliability through to laminated busbar layout, packaging passivation, and field service routines tailored for Pakistan’s environment.

전문가 상담 및 맞춤형 솔루션 받기

Whether you are upgrading a PV inverter fleet, retrofitting cement fan drives, modernizing steel mill auxiliaries, or exploring local assembly lines, Sicarbtech’s team can guide you from feasibility to field-proven performance. To discuss your application, performance targets, and localization roadmap, contact us at [email protected] or +86 133 6536 0038. Our engineers will propose a data-driven path that balances efficiency, reliability, and time-to-value, with clear milestones and measurable outcomes.

문서 메타데이터

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: Includes 2025 market outlook for Pakistan, latest SiC device classes (1200/1700 V), third-generation Schottky diodes, sintered silver adoption, laminated busbar best practices, NEPRA/PQ compliance considerations, and localized manufacturing and technology transfer pathways.

Brand note: Sicarbtech—Silicon Carbide Solutions Expert, based in Weifang City, China’s SiC manufacturing hub, member of the Chinese Academy of Sciences (Weifang) Innovation Park, with 10+ years of customization experience supporting 19+ enterprises and delivering full-cycle solutions from materials to finished products—including R-SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.