고효율 인버터 및 고속 스위칭 산업용 드라이브를 위한 실리콘 카바이드 MOSFET 전력 모듈

공유

제품 개요 및 2025년 시장 관련성

실리콘 카바이드(SiC) MOSFET 전력 모듈은 파키스탄의 섬유, 시멘트, 철강 및 신흥 디지털 부문에서 전력 변환을 재정의하고 있습니다. 와이드 밴드갭 디바이스 물리학을 첨단 패키징과 결합한 SiC 모듈은 높은 스위칭 주파수, 낮은 전도 및 스위칭 손실, 고온에서 견고한 작동을 제공합니다. 2025년 국내 산업이 잦은 전압 변동, 열악한 열/먼지 조건, 전기 요금 상승에 직면함에 따라 SiC 모듈은 가변 주파수 드라이브(VFD), 고밀도 UPS, 고압 컨버터 전반에서 더 높은 효율, 더 작은 설치 공간, 향상된 안정성을 제공합니다.

주요 속성:

- 실리콘 IGBT 모듈 대비 뛰어난 효율로 고전압 및 주파수 작동

- 높은 접합 온도(최대 175°C, 일부 장치 200°C)에서도 안정적

- 신속한 시스템 통합을 위한 컴팩트한 모듈형 폼 팩터

- 낮은 총 고조파 왜곡(SiC PFC 스테이지와 함께 사용 시) 및 개선된 역률

- 파키스탄 산업용 피더에서 흔히 발생하는 주전원 과도현상에 대한 복원력 향상

파키스탄의 시장 적합성:

- 섬유 클러스터(파이살라바드, 카라치)는 드라이브 손실 감소, 직기/방적실의 열 감소, 전압 강하 시 성가신 트립 감소 등의 이점을 누리고 있습니다.

- 시멘트 공장(펀자브, 카이버 파크툰크화)은 고주파, 고토크 응답으로 예열기/ID/FD 팬과 킬른 드라이브를 업그레이드합니다.

- 철강 제철소(카라치, 펀자브)는 압연기 보조 및 용융 공장 지원 시스템에서 더 나은 효율성을 달성합니다.

- 데이터 센터 및 금융 기계실은 부분 부하에서 더 높은 효율을 위해 SiC UPS/인버터 스테이지를 활용하여 더 낮은 PUE를 지원합니다.

기술 사양 및 고급 기능

대표 모듈 사양(프로젝트별로 구성 가능):

- 전압 등급: 650V, 1200V, 1700V

- 전류 정격: 모듈당 50-600A(병렬 연결로 확장 가능)

- 토폴로지: 하프 브리지, 풀 브리지, 식스팩, 초퍼

- RDS(on): 다이당 최저 8~15mΩ(온도 안정적 특성)

- 스위칭 주파수: 최대 100kHz(애플리케이션에 따라 다름)

- 접합 온도: Tj, 최대 175°C(최대 200°C까지 선택 가능)

- 내열성: 열 전도성이 높은 기판(AlN/Si3N4 DBC)을 통해 최적화됨

- 게이트 드라이브: ±15~20V 일반, 빠른 dv/dt 내성, 회로 단락 내성 향상

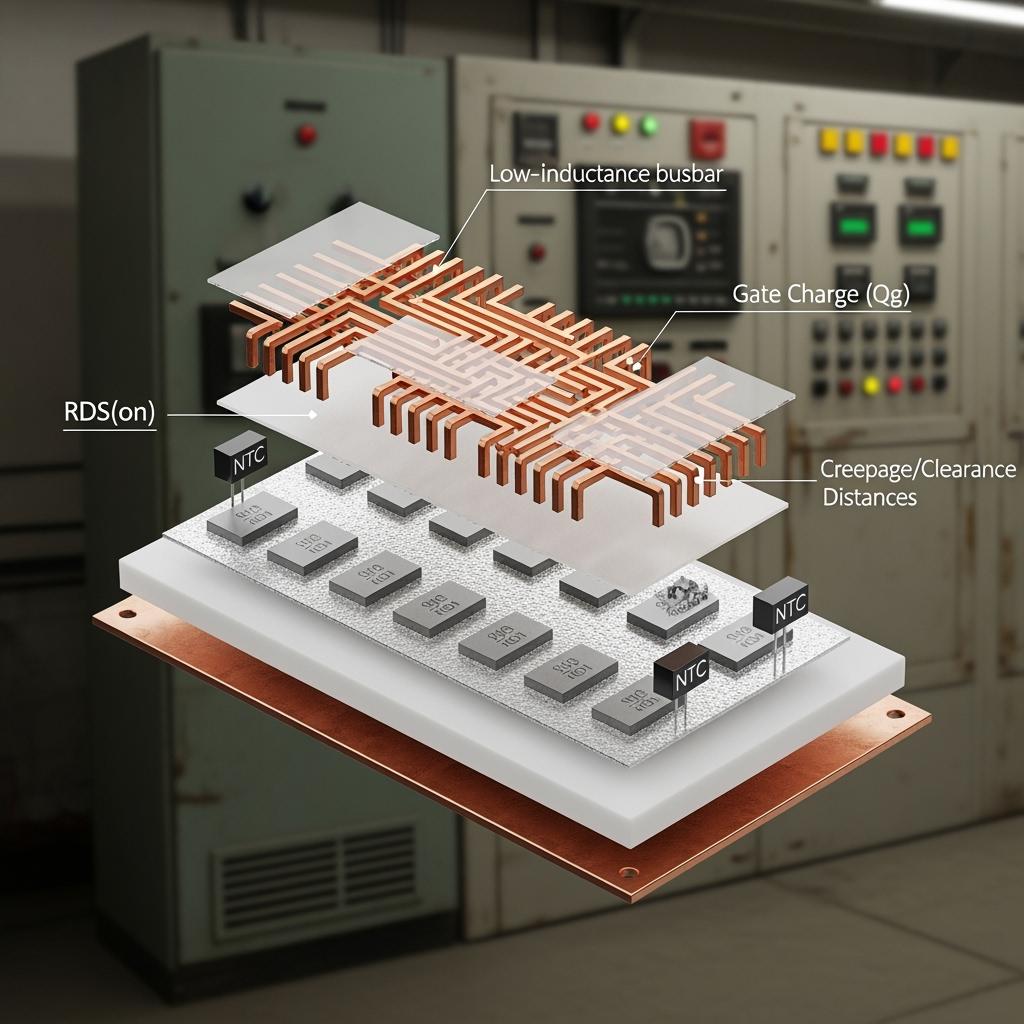

- 패키징: 저 인덕턴스 레이아웃, 켈빈 소스 연결, 통합 NTC

- 보호 준비 상태: 불포화/OC/SC 보호 및 능동 게이트 제어와 호환 가능

- 규정 준수 목표: IEC 61800(드라이브), IEC 62477-1(컨버터 안전), IEC 61000(EMC)

시카브 테크의 고급 기능:

- 높은 dv/dt에서 깨끗한 스위칭을 위한 최적화된 로우 루프 인덕턴스 버스바

- 밀러 클램프, DESAT, 소프트 턴오프 및 CMTI >100V/ns를 지원하는 공동 설계된 게이트 드라이버

- 먼지가 많은 시멘트/섬유 환경을 위한 컨포멀 코팅 및 밀폐형 인클로저(옵션)

- 열 균일성 향상을 위해 SSiC/RBSiC를 사용하는 칩 레벨 히트 스프레더

산업 환경의 효율성 및 안정성 향상

| 덥고 먼지가 많은 현장에서 인버터 스테이지의 성능 비교 | SiC MOSFET 모듈 솔루션 | 기존 실리콘 IGBT 모듈 |

|---|---|---|

| 최대 부하 효율(일반 VFD) | 97-98% | 92–95% |

| 경부하 효율(25~50%) | 96% | 88-92% |

| 스위칭 주파수 기능 | 최대 100kHz | 10–20 kHz |

| 방열 요구 사항 | 더 낮은(더 작은 방열판) | 더 높음(대형 방열판/팬) |

| 열 견고성(주변 온도 40~45°C) | 최소한의 감속 | 눈에 띄는 감액 |

| 캐비닛 설치 공간 | 최대 30~35% 할인 | 기준선 |

| 유지보수 간격 | 확장(팬/필터 교체 횟수 감소) | 더 자주 |

주요 장점 및 입증된 이점

- 에너지 효율 향상: 5~8%의 시스템 에너지 절감, 전기 요금 및 디젤 백업 런타임을 직접적으로 줄입니다.

- 열 부하 감소: 스위칭/전도 손실이 감소하면 제어실의 냉각 시스템과 HVAC 요구 사항이 줄어듭니다.

- 더 빠른 동적 응답: 높은 스위칭 주파수로 섬유 방적 및 철강 압연에서 정밀한 토크 제어가 가능합니다.

- 더 작은 설치 공간: 높은 전력 밀도(>10kW/L)로 좁은 MCC실과 데이터 홀의 공간을 확보할 수 있습니다.

- 높은 신뢰성: 그리드 처짐/팽창 시 승차감 개선, 열 스트레스 시 고장률 감소.

전문가 인용문:

"와이드 밴드갭 SiC MOSFET은 이제 높은 주변 온도에서 작동하는 고효율 산업용 드라이브에 선호되는 스위치입니다. 낮은 스위칭 손실과 견고한 고온 동작은 실제 운영 비용(OPEX) 절감으로 이어집니다." - IEEE 전력전자학회 산업 개요, 2024년(참조: IEEE PELS 인사이트)

실제 응용 분야 및 측정 가능한 성공 사례

- 라호르 데이터 센터 UPS 인버터 단계:

- SiC MOSFET 모듈로 업그레이드하면 DC-AC 변환 효율이 97.3%로 향상되고 UPS 공간 면적이 최대 35%까지 줄어듭니다.

- 첫해 전기 절감률 ~12.6%, 에너지 효율 인센티브 지원.

- 파이살라바드 섬유 방적 VFD:

- SiC 기반 인버터 파워 스테이지로 드라이브 캐비닛 온도를 18% 낮췄습니다.

- 5.5% 에너지 절감, 전압 강하 및 열 트립으로 인한 예기치 않은 가동 중단 20% 감소.

- 카이버 파크툰크화 시멘트 예열기 팬 드라이브:

- 높은 CMTI 드라이버가 탑재된 SiC 하프 브리지 모듈은 프론트 엔드 PFC로 3% THD를 달성했습니다.

- 팬 전력 소비량 최대 7% 감소, 먼지 필터의 유지보수 주기 연장.

이미지 프롬프트: 자세한 기술 설명]] 산업용 VFD 캐비닛 레트로핏의 사실적인 분할 장면: 왼쪽은 대형 방열판/팬 어셈블리가 있는 기존 IGBT 모듈, 오른쪽은 간소화된 방열판과 통합 게이트 드라이버가 있는 소형 SiC 모듈, 효율 대 부하 및 열 이미지의 오버레이 계측 그래프, 4K 해상도입니다.

선택 및 유지 관리 고려 사항

- 전기 설계:

- 파키스탄 피더에서 흔히 발생하는 처짐/팽창 및 과부하에 대비해 20~30%의 헤드룸이 있는 전압/전류 정격을 선택하세요.

- 깨끗하고 오버슈트가 낮은 스위칭을 위해 낮은 인덕턴스 레이아웃과 켈빈 소스를 우선시합니다.

- 게이트 드라이브 및 EMC:

- 모터 절연 스트레스를 관리하기 위해 밀러 클램프, DESAT 보호 및 조정 가능한 dV/dt를 갖춘 게이트 드라이버를 구현합니다.

- IEC 61800-3 EMC 관행에 따라 본딩/접지를 확인하고, 긴 모터 케이블에는 사인 필터를 고려하세요.

- 열 및 인클로저:

- 주변 온도 40~45°C에서 방열판과 공기 흐름을 검증하고 먼지가 많은 현장에서는 밀폐형/양압 인클로저를 고려하세요.

- 전도성이 높은 TIM을 사용하고 장기적인 안정성을 위해 접촉 압력을 확인합니다.

- 유지 관리:

- NTC 기반 열 추세를 모니터링하고 사전 예방적 팬/필터 서비스를 예약하세요.

- 버스바 패스너와 커넥터의 진동 시 토크 유지 여부를 주기적으로 검사합니다.

산업 성공 요인 및 고객 사용후기

- 성공 요인:

- 정확한 부하 프로파일링 및 고조파 평가

- 플랜트 계전기/차단기를 통한 강력한 보호 조정

- 여름철 성수기 현장 파일럿 검증

- 빈도가 높은 모범 사례에 대한 유지 관리 팀 교육

- 추천사(파이살라바드, 섬유 운영 관리자):

- "SiC 드라이브 개조를 통해 에너지 사용량을 줄이고 피더가 다운되는 동안 생산량을 안정화했습니다. 캐비닛 온도는 팬 유지보수 주기를 한 시즌 연장할 수 있을 정도로 떨어졌습니다."

미래 혁신 및 시장 동향

- 2025-2027년 전망:

- 시멘트 및 강철에서 중전압 멀티 레벨 드라이브를 지원하는 고전류 1700V SiC 모듈.

- 실시간 SOA 모니터링 및 디지털 트윈을 위한 센서가 내장된 통합 전원 모듈.

- 규모와 현지 조립 파트너십을 통한 비용 절감, 남아시아의 공급망 복원력 향상.

- 먼지가 많은 파키스탄 환경에 맞춘 고급 코팅과 밀폐형 디자인.

기관의 관점:

"모듈 통합과 신뢰성 테스트가 성숙해짐에 따라 SiC의 산업 채택 곡선이 가파르게 상승하고 있어 MV 드라이브와 미션 크리티컬 전력에 더 광범위하게 배포할 수 있게 되었습니다." - IEA 기술 전망, 2024년(시장 논평)

일반적인 질문 및 전문가 답변

- SiC 모듈은 더 높은 dv/dt로 모터 절연에 어떤 영향을 미칩니까?

- 조정 가능한 게이트 저항 및 출력 필터(dV/dt 필터 또는 사인 필터)는 레거시 모터의 안전한 전압 상승률을 유지합니다.

- 이 모듈은 220/400V, 50Hz 시스템 및 PEC에 부합하는 보호 기능과 인터페이스할 수 있나요?

- 예. 설계는 PEC 관행 및 NTDC 그리드 코드 품질 기대치에 따라 현지 전압 및 보호 체계에 맞게 조정됩니다.

- 파키스탄 공장은 어떤 ROI를 기대할 수 있을까요?

- 일반적인 ROI는 18~30개월이며, 4~8%의 에너지 절감, 냉각 비용 감소, 다운타임 비용 감소로 인해 발생합니다.

- 모듈은 먼지가 있는 45°C 주변 환경에서도 안정적으로 작동하나요?

- 적절한 인클로저 밀봉/압축 및 검증된 열 설계를 통해 SiC 모듈은 최소한의 부하 감소로 성능을 유지합니다.

이 솔루션

SiC MOSFET 전력 모듈은 파키스탄의 산업 현실에 필요한 효율성, 열 복원력, 소형화를 정밀하게 조합하여 제공합니다. 이 모듈은 에너지 및 냉각 비용을 절감하고, 전력망 이벤트 시 운영을 안정화하며, 현지 표준에 부합하여 섬유, 시멘트, 철강 및 디지털 인프라에서 측정 가능한 수명 주기 가치를 제공합니다.

맞춤형 솔루션을 위해 전문가와 연결

시카브 테크와 협력하여 SiC 로드맵을 가속화하세요:

- 중국 과학 아카데미의 지원을 받는 10년 이상의 SiC 제조 전문 지식

- R-SiC, SSiC, RBSiC, SiSiC를 아우르는 맞춤형 개발과 고급 모듈 패키징

- 기술 이전 및 턴키 공장 설립 서비스 - 타당성 검토에서 시운전까지

- 엔드투엔드 솔루션: 재료 가공부터 완제품 전력 모듈 및 통합 지원까지

- 19개 이상의 기업에서 입증된 성과, 신속한 프로토타이핑 및 현지 지원

무료 상담과 파키스탄 사이트를 위한 맞춤형 ROI 모델을 받아보세요.

- 이메일: [email protected]

- 전화/왓츠앱: +86 133 6536 0038

지금 행동하여 2025년 4분기 파일럿 배포를 위한 엔지니어링 슬롯을 확보하고 성수기에 대비한 리드 타임을 확보하세요.

문서 메타데이터

- 최종 업데이트: 2025-09-11

- 다음 예정된 검토: 2025-12-15

- 저자: 시카브 테크 애플리케이션 엔지니어링 팀

- Contact: [email protected] | +86 133 6536 0038

- 표준 초점: IEC 61800, IEC 62477-1, IEC 61000, PEC 지침 및 NTDC 그리드 코드 품질 기준 준수

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.