신뢰성 스크리닝 및 자격 획득을 위한 탄화규소 장치 번인 및 자동 테스트 장비

공유

De-risk SiC Supply in 2025: High-Throughput Burn-In and ATE for Pakistan’s Industrial Power Platforms

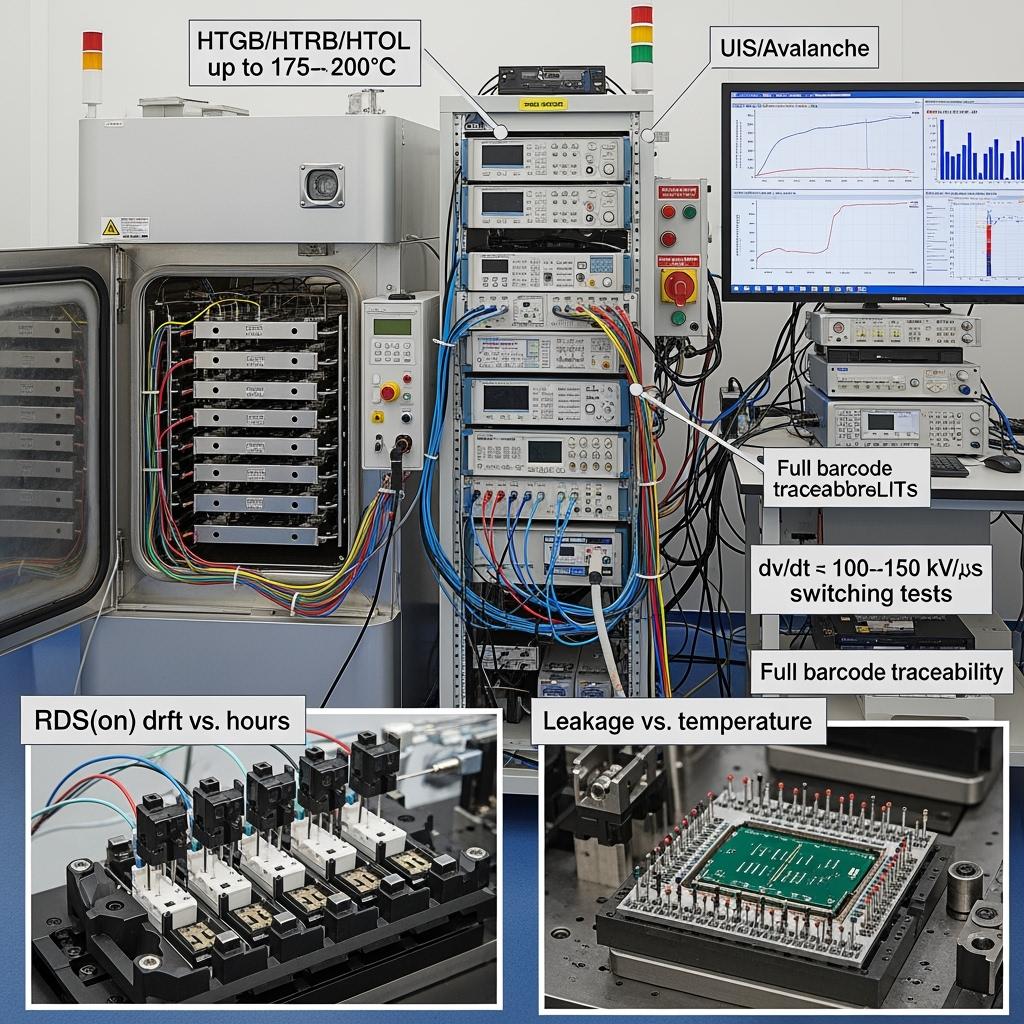

파키스탄의 섬유, 시멘트 및 강철 sectors adopt Silicon Carbide (SiC) across UPS, VFD front-ends, STATCOM/APF, EV charging, and high-reliability PSUs, rigorous reliability screening is essential. SiC devices operate at high dv/dt and elevated junction temperatures up to 175°C, making early-life defect removal and parameter monitoring critical to prevent field failures on weak grids. Silicon Carbide Device Burn-In and Automated Test Equipment (ATE) from Sicarb Tech provides production-grade screening and qualification: HTGB/HTRB/HTOL burn-in, dynamic switching stress, avalanche and UIS testing, and automated parametric characterization (RDS(on), Vth, Qg, Coss, body diode, leakage) with full traceability.

Sicarb Tech’s platform integrates high-temperature ovens, programmable SMUs/loads, isolated high-CMTI gate drive fixtures, and safety interlocks, all orchestrated by analytics that flag drift and outliers. Backed by the Chinese Academy of Sciences, we offer equipment supply, process recipes, and technology transfer to establish local test lines in Pakistan’s SEZs—shortening lead time and ensuring consistent quality for 2025 buildouts.

기술 사양 및 고급 기능

- Burn-in capabilities

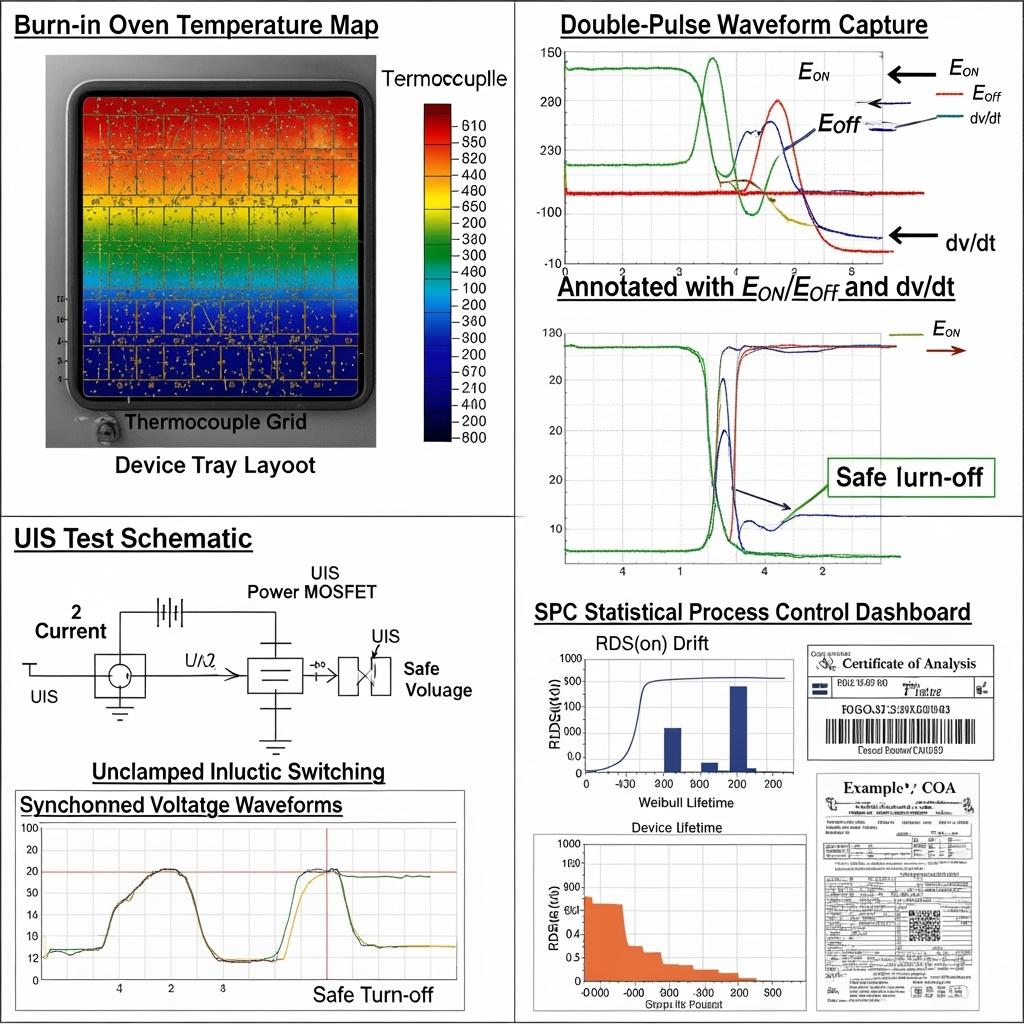

- HTGB (High-Temp Gate Bias), HTRB (High-Temp Reverse Bias), HTOL (High-Temp Operating Life) up to 175–200°C ambient

- Configurable bias: up to 1.7 kV for 1700 V devices; gate stress profiles including ±VGE cycling and Miller stress conditions

- Step-stress and soak profiles with 48–168 h dwell, programmable ramps, and tight thermal uniformity (±2°C)

- Automated parametric test (ATE)

- Static: RDS(on) at multiple currents and temperatures (25–150°C), Vth/I DSS leakage, body diode VF/Qrr characterization

- Dynamic: double-pulse testing, Eon/Eoff vs. current/temperature, dv/dt ruggedness, Coss/Qg extraction

- Ruggedness: unclamped inductive switching (UIS), avalanche energy (EAS) with safe shutdown, short-circuit SOA and DESAT response

- Measurement accuracy and safety

- SMUs and DMMs with 6.5–7.5 digit resolution; Kelvin connections for low-ohmic accuracy

- High-voltage isolation, interlocked enclosures, arc detection, and emergency shutoff; IEC 61010-compliant design

- Data, analytics, and traceability

- Per-device barcode/RFID; full genealogy (lot/wafer/die location)

- Drift analytics and Weibull early-life failure modeling; SPC dashboards and automated COAs

- API integration to MES/ERP and cloud dashboards; data export (CSV/JSON)

- Fixtures and versatility

- Sockets for TO-220/TO-247, modules (half-bridge/NPC), and bare die-on-carrier

- High-CMTI isolated gate drivers (≥100–150 kV/µs) with adjustable RG and −VGE off bias

- Thermal control plates and micro-chamber fixtures for rapid temperature cycling

Why Production-Grade SiC Burn-In and ATE Outperform Ad-hoc Lab Testing for Industrial Reliability

| Reliability and throughput outcomes | SiC burn-in + automated ATE (production-grade) | Basic lab test benches | Practical impact for Pakistan deployments |

|---|---|---|---|

| Early-life failure screening | Systematic HTGB/HTRB/HTOL + drift analytics | Limited soak/spot checks | Fewer field failures and recalls |

| Dynamic ruggedness validation | Automated double-pulse, UIS, EAS, SC SOA | Manual or omitted | Confidence in weak-grid events |

| Throughput and repeatability | Parallel channels, fixtures, recipes | Low throughput, operator variance | Predictable lead time, lower cost |

| Traceability and compliance | Full genealogy, SPC, COA | Minimal records | Faster NTDC/utility audits |

| Safety and coverage | Interlocks, HV management, arc detect | Ad-hoc protections | Reduced lab risk, consistent results |

주요 장점 및 입증된 이점

- Lower DPPM and warranty risk: Early-life defects are eliminated, and drift is monitored, cutting field returns and downtime in harsh, hot environments.

- Validated dynamic robustness: UIS, avalanche, and dv/dt testing prove survivability under sags, surges, and fast transients common on weak feeders.

- Faster time-to-approval: Automated reports align with IEC/IEEE expectations, simplifying EPC and utility sign-off.

- Scalable and localizable: Equipment and recipes can be installed in Pakistan to reduce logistics delays and currency exposure.

전문가 인용문:

“Reliability of wide-bandgap devices hinges on robust screening and characterization across temperature and switching stress; automated test with strong data analytics is essential.” — Interpreted from IEEE PELS/IRPS reliability literature on WBG devices (https://www.ieee-pels.org/resources | https://ieeexplore.ieee.org/)

실제 응용 분야 및 측정 가능한 성공 사례

- Textile VFD front-end modules (Faisalabad, composite): Implementing HTOL + UIS screens reduced early drive failures by ~60% and improved MTBF by ~25%; commissioning trip rates fell notably during peak summer.

- Cement UPS modules (KP, composite): Parametric drift monitoring caught Vth shift outliers before shipment; site acceptance passed on first attempt with 98% online efficiency verified.

- EV charger power stages (Karachi, composite): Double-pulse and EAS verification allowed higher switching frequency with stable margins; RMA rate dropped below 200 DPPM over 12 months.

- PV-wind inverters (Sindh, composite): HTRB screening at 1.2× rated voltage prevented leakage-related field returns during monsoon humidity spikes.

선택 및 유지 관리 고려 사항

- Define screening objectives

- Choose HTGB/HTRB/HTOL durations and stresses based on application (UPS, SVG/APF, EV DC fast charge) and target DPPM

- Include dynamic tests (double-pulse, UIS) for drives/inverters exposed to grid disturbances

- Fixture and channel planning

- Size channel count for target UPH (units per hour); ensure sockets for intended package mix and module formats

- Provide Kelvin paths and thermal control for accurate low-ohmic measurements

- 안전 및 규정 준수

- Ensure interlocks, HV isolation, and E-stops; certify to IEC 61010 and local regulations

- Train operators and enforce ESD controls; audit procedures quarterly

- 데이터 거버넌스

- Implement SPC with control limits and automated quarantines for out-of-family behavior

- Maintain secure backups and version-controlled recipes; integrate with ERP for COA issuance

- 예방 유지 관리

- Quarterly SMU calibration and scope verification; annual hipot/PD tester calibration if applicable

- Replace sockets/relays on cycle counts; verify oven uniformity semi-annually

산업 성공 요인 및 고객 사용후기

- Start with a pilot lot to tune stress levels, avoiding over-screen that erodes margins

- Correlate test outcomes with field performance to refine acceptance limits

- Establish local spare parts and training to minimize ATE downtime

고객의 소리(합성):

“Our SiC drives stopped failing during hot season after we adopted HTOL + UIS screening. The automated COAs also accelerated customer approvals.” — Quality Director, Industrial Power OEM, Pakistan

미래 혁신 및 시장 동향(2025+)

- Inline burn-in with real-time parametric monitoring and ML-based drift prediction

- Expanded short-circuit SOA characterization for next-gen trench SiC MOSFETs

- Combined wafer-level stress mapping and die-level ATE correlation for tighter bins

- Local test centers in Pakistan via technology transfer, reducing lead time by 30–40%

일반적인 질문 및 전문가 답변

- What burn-in duration is recommended?

Typical programs use 48–168 h depending on risk tolerance and application; we tailor profiles by device family and field data. - Do we need UIS and avalanche tests for all devices?

For inverter legs exposed to grid transients, UIS/EAS add confidence; for rectifiers-only roles, reduced dynamic testing may suffice. - How is dv/dt ruggedness verified?

Through double-pulse tests with high-CMTI drivers and layout-accurate fixtures to emulate real switching loops. - Will screening affect device lifetime?

When correctly profiled (current/temperature margins), screening removes early failures without accelerating wear-out; we validate via HTOL/Arrhenius models. - Can you integrate with our MES/ERP?

Yes—our ATE software supports REST/OPC-UA interfaces and generates digital COAs and SPC reports.

이 솔루션

SiC excels only when reliability is proven. Sicarb Tech’s burn-in and ATE solutions screen out early defects, validate dynamic robustness, and provide audit-ready documentation—ensuring Pakistan’s industrial power systems run cooler, longer, and with fewer interruptions, even on weak grids and in harsh climates.

맞춤형 솔루션을 위해 전문가와 연결

Set up a robust SiC reliability pipeline with Sicarb Tech:

- 10년 이상의 SiC 제조 전문 지식

- 중국 과학 아카데미의 지원 및 혁신

- Custom product development (R‑SiC, SSiC, RBSiC, SiSiC) and SiC device/module packaging

- Technology transfer and factory establishment services for local burn-in/ATE lines

- Turnkey solutions from materials and devices to complete test cells, fixtures, and analytics

- Proven track record with 19+ enterprises—lower DPPM, faster approvals, higher uptime

Book a free screening plan review, ATE capacity sizing, and ROI model today.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

문서 메타데이터

- 최종 업데이트: 2025-09-11

- 다음 예약 업데이트: 2025-12-15

- Prepared by: Sicarb Tech Reliability Engineering & Test Systems Team

- References: IEEE PELS and IRPS reliability papers on WBG device screening; IEC 61010 safety; JEDEC/JEITA guidance for HTGB/HTRB/HTOL; NTDC/NEPRA audit practices and PQ requirements

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.