Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Variable-Frequency Group Control of Chemical Process Pumps and Fan Arrays

공유

Executive Summary: 2025 Outlook for High-Efficiency, Low-Harmonic Group-Control Drives in Pakistan’s Chemical and Process Sectors

Across Pakistan’s chemical parks and process corridors, operators are under pressure to reduce energy per ton, stabilize coupled process parameters, and meet increasingly firm power-quality expectations. Pump and fan arrays running 24/7 are prime targets: many operate inefficiently at partial load, cycle on and off with hydraulic or aerodynamic shock, and inject harmonics that upset sensitive instruments and DCS networks. In 2025, the strongest response combines silicon carbide (SiC) power electronics with a digital group-control brain. By uniting active front-end (AFE) rectification, cascaded multilevel or interleaved inverters, low-inductance double-sided-cooled modules, and group scheduling based on efficiency curves, operators can trim 5%–12% from group energy use, raise site power factor toward unity, and increase stability under seasonal and recipe-driven load swings.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s silicon carbide manufacturing hub and is a member of the Chinese Academy of Sciences (Weifang) Innovation Park. With 10+ years of customization across R‑SiC, SSiC, RBSiC, and SiSiC and 19+ enterprise collaborations, Sicarbtech offers a full-cycle path: high-voltage devices, double-sided-cooled modules, busbar and topology co-design, fast protection gate driving, hybrid cooling, EMC discipline, online health monitoring, and MES-backed traceability. For Pakistan’s chemical clusters from Port Qasim to Faisalabad, this translates to faster pilots, replicable rollouts, and evidence packages that clear approvals while improving PKR-denominated operating economics.

Industry Challenges and Pain Points: Parallel Drives, Coupled Processes, and Power Quality Realities

Process pumps and fans do not fail in isolation; they fail as a group. Multiple mains-frequency units or simple VFDs in parallel can oscillate against each other, producing cycling that destabilizes pressure and flow. When a unit starts abruptly, pressure surges and water hammer propagate through pipework, stressing seals and bearings and triggering valve chatter. During seasonal changes—cooling towers in summer, solvent transfer under batch peaks—arrays drift far from their best-efficiency points. Operators often keep too many units idling “just in case,” sacrificing efficiency to ensure continuity.

Conventional silicon VFDs add their own limitations. With two-/three-level architectures and higher parasitics, they run with lower efficiency at partial load and poorer power factor. Harmonic currents spill into plant buses, elevating THDi and occasionally interfering with measurement loops and DCS I/O—even more so where instrument power is shared with drive feeders. Many panels rely on passive snubbing and long, unshielded busbars; during rapid load shifts or long-cable interactions, DC-bus overshoot and ringing rise, nudging protections toward nuisance trips.

The environment is rarely friendly. Chemical plants contend with humidity, corrosives, dust, and salt-laden air near the coast. Cooling loops scale or corrode; fins clog; cabinet seals degrade; and single-sided-cooled stages with commodity interface materials suffer pump-out and voiding under thermal cycling. As junction-to-case thermal resistance drifts upward, hotspot temperatures creep, derating margins shrink, and components age faster. Maintenance teams face short windows and long import lead times, while batch-to-batch variability complicates root-cause analysis.

Critically, procurement and financing have become data-driven. Tenders reference IEC 60747 (device characteristics) and IEC 60068 (damp heat, salt spray, dust, vibration, shock), while EMC expectations align with industrial adjustable-speed systems similar to IEC 61800‑3. Interconnection assessments increasingly seek PF near 0.99 and THDi within typical ≤5% bands (site-dependent). As Dr. H. Rehman, an industrial power electronics advisor, explains, “Energy savings look good on a slide, but approvals now hinge on PF/THD evidence, ripple envelopes, and event logs that prove stability. In 2025, the winning bid is measurable.” [Source: Regional Power Electronics Workshop, 2024]

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Group-Control VFD Architecture for Pumps and Fans

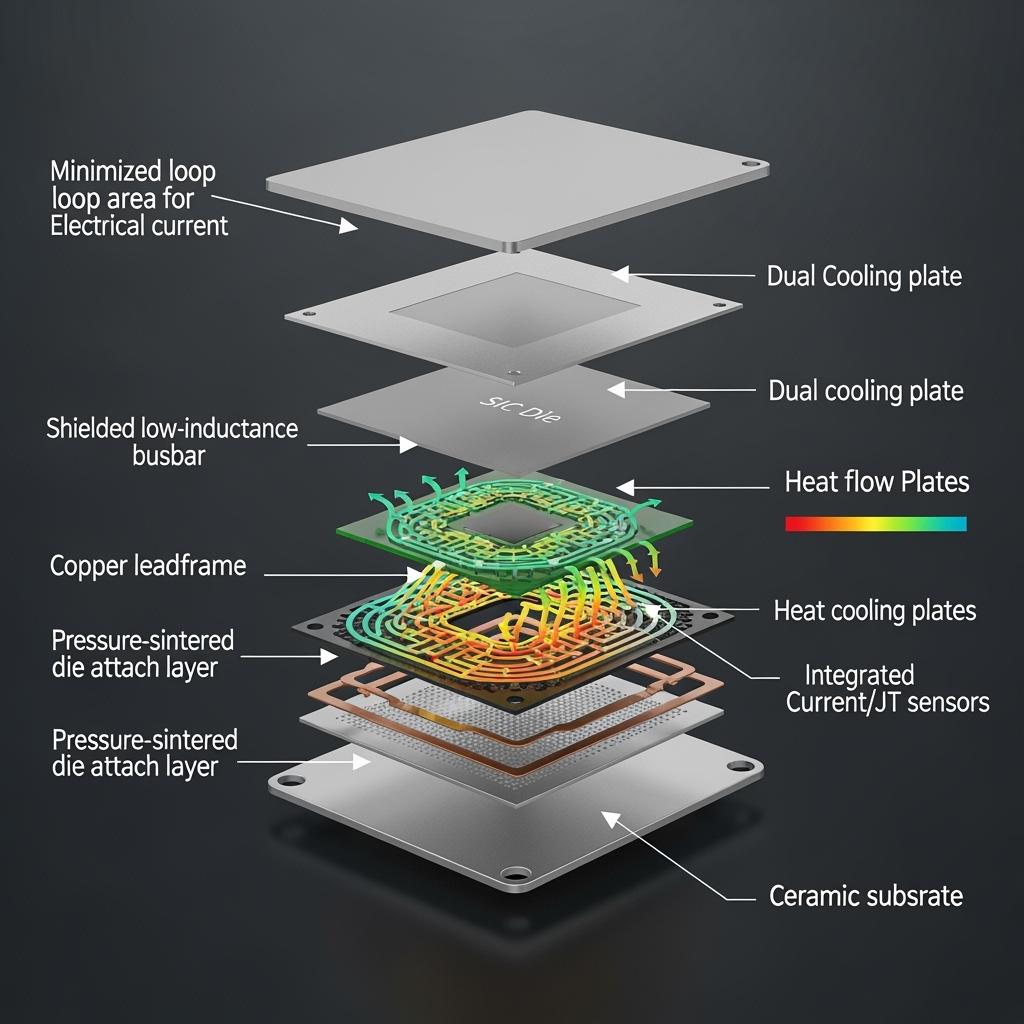

Sicarbtech approaches group-control retrofits as a full-chain coordination across devices, packaging, busbars, topology, gate driving, thermal management, EMC, monitoring/O&M, quality traceability, and algorithms. High-voltage, high-current SiC MOSFETs and diodes (1200/1700 V classes) populate double-sided-cooled modules with integrated junction-temperature and current sensing. Pressure-assisted sintering and vacuum brazing reduce voiding for stable thermal cycling life. Layered busbars and shielded zoning minimize loop area, reduce dv/dt stress, and improve EMC.

On the grid side, an AFE elevates PF and lowers THDi; on the motor side, cascaded multilevel or interleaved-parallel inverters distribute stress and shrink filters. Gate drivers implement soft turn-off, active clamping, and microsecond-level short-circuit protection, confining disturbances before they propagate. A low-impedance DC bus with active snubber/damping suppresses ripple and overshoot across long cabling and parallel cabinets.

Beyond power electronics, Sicarbtech delivers a digital group-control platform. A group-scheduling and energy-optimization library selects the optimal unit count and allocates load along best-efficiency curves while respecting process constraints. A coordinated process module links pressure, flow, temperature, and—in applicable cases—concentration, to reduce throttling losses and maintain stability. Online health monitoring estimates junction temperature, tracks interface thermal resistance, assesses gate health via charge/discharge signatures, and observes DC-bus oscillation. Bearing and vibration monitoring provide early warnings tied to VFD protection logic.

Finally, quality is anchored by MES-backed traceability. Device lots, process parameters, electrical/environmental screens, and site commissioning records are serialized and linked to field events, tightening feedback loops for continuous improvement and giving procurement and insurers a clear evidence trail.

Performance Comparison: SiC Group-Control Drives Versus Conventional Approaches

Efficiency, Power Quality, Transient Stability, and Group Energy Optimization

| 속성 | Sicarbtech SiC Group-Control (AFE + Multilevel/Interleaved) | Conventional Silicon VFDs on Parallel Units | Mixed Silicon with Passive Bus Control | 파키스탄에서의 운영 영향 |

|---|---|---|---|---|

| System efficiency (typical) | +2%–4% higher | 기준선 | +0%–1% | Lower PKR/m³ pumped or m³/s ventilated |

| Site power factor | ≥0.99 with AFE | 0.85–0.95 | 0.9–0.96 | Fewer penalties, higher transformer headroom |

| THDi at interconnection | ≤5% (site dependent) | 10%–20% | 8%–15% | Smoother compliance, smaller filters |

| Start/stop impact current | −50%–80% | 높음 | 보통 | Less water hammer and pressure surge |

| DC-bus ripple (p‑p) under load steps | −30% to −50% | 높음 | 보통 | Fewer trips, steadier PID loops |

| Group energy optimization | 5%–12% reduction | Unoptimized | 1%–3% | Lower total energy with same output |

By pairing AFE power quality with low-parasitic SiC modules and a control layer that allocates load by efficiency, Sicarbtech converts parallel-drive complexity into predictable savings and stability.

Real-World Applications and Success Stories in Pakistan

In a coastal chemical park, a cooling-water pump array retrofit introduced an AFE, interleaved SiC inverters, and group optimization. Site power factor improved to at least 0.99 with THDi around 5%, while group energy use fell by roughly 8%–12% as two of eight pumps shifted to efficient standby during cooler nights. Water-hammer incidents dropped by about 60% thanks to coordinated soft starts and ramped pressure control.

An exhaust-fan manifold serving process ventilation near Karachi adopted a cascaded multilevel SiC solution with active damping. Soft-start peaks reduced by approximately 70%, markedly lowering bus voltage fluctuation and noise. Unplanned downtime decreased by about 30% as nuisance trips vanished and mean time to repair fell with hot-swappable modules and front-service cabinets.

At a solvent-transfer station in Punjab, online health monitoring identified rising interface thermal resistance and atypical gate-charge signatures on one inverter weeks before failure. A planned swap during scheduled maintenance avoided a process halt, while MES traceability linked the event to a cooling-water quality variance, prompting filtration upgrades site-wide.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC enables higher control bandwidth at 2–12 kHz with lower switching and conduction losses, allowing tighter pressure/flow regulation without overheating. Double-sided cooling with high-conductivity interfaces reduces junction-to-case thermal resistance, trimming cabinet hotspots by 5–10 °C and extending component life. Layered, symmetric busbars reduce loop area, dv/dt stress, and overshoot, improving EMC margins. Active DC-bus damping restrains oscillations across long cables and parallel racks so PID loops remain stable. On the grid, an AFE boosts PF and curtails harmonic current, reducing interconnection friction and transformer heating.

Compliance is built in. Device characteristics align with IEC 60747; environmental validation follows IEC 60068 (damp heat, salt spray, dust, vibration, shock); and EMC engineering targets expectations similar to IEC 61800‑3 for industrial adjustable-speed systems. As Engr. S. Khan puts it, “When PF/THD envelopes, ripple logs, and thermal histories come with the bid, discussion shifts from ‘if’ to ‘when’.” [Source: EV and Industrial Drives Roundtable, 2024] Quality governance aligns with ISO 9001 and IATF 16949, and MES serialization provides auditable records for tenders, lenders, and insurers.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage for Group-Control Drives

Sicarbtech’s competitive edge is capability transfer backed by advanced R&D. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC to produce thermally robust substrates and assemblies that withstand corrosive, humid, and dusty environments.

The technology transfer package includes:

- Process know-how for pressure-assisted sintering, vacuum brazing atmospheres and flux control, metallization and passivation stacks, and low-inductance busbar/bond geometries.

- Gate-drive recipes covering soft turn-off, active clamping, and fast desaturation tuned for interleaved and multilevel operation under group-control dynamics.

- Equipment specifications for sintering presses, vacuum furnaces, wire/ribbon bonders, inline electrical testers, power-cycling rigs with junction-temperature estimation, HTRB/HTGB setups, EMC pre-compliance stations, and IEC 60068 environmental chambers—each delivered with acceptance tests, calibration procedures, and approved vendor lists.

Training programs build sustainable local skills: operator certification, failure analysis and cross-sectioning, SPC-driven yield improvement, and PPAP-like control plans aligned with ISO 9001 and IATF 16949. Factory establishment support spans feasibility, utilities and layout, line installation and commissioning, pilot runs, parameter locking, and capability validation. Post-SOP, Sicarbtech conducts quarterly audits and yield sprints and co-develops updates to packaging, busbars, and algorithms tailored to Pakistan’s ambient profiles and process rhythms.

Across 19+ enterprise programs, this turnkey approach has accelerated time-to-market, improved first-pass yields, reduced field failures, and cut spare lead times to days or weeks—critical where array uptime underpins safety and production KPIs.

Comparative Engineering Choices and Lifecycle Economics

AFE, Topology, and Bus Design Choices that Stabilize Parallel Units and Processes

| Design Area | Sicarbtech SiC Best Practice | Conventional Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| Grid interface | Active front end (PF≈0.99, THDi≈≤5%) | Diode/thyristor rectifier | Fewer penalties, easier interconnection |

| Inverter topology | Cascaded multilevel or interleaved parallel | Two-/three-level silicon | Lower device stress, smaller filters |

| Bus architecture | Low-impedance bus + active damping | Passive RC snubbers | Ripple/overshoot suppression |

| Gate protection | Soft turn-off + active clamp + fast desat | Single-path protection | 2–5 μs shutdown, fewer ruptures |

| Packaging & cooling | Double-sided cooling, low‑L busbars | Single-sided, long leads | Lower Tj, stronger EMC margins |

Localization and Total Cost of Ownership for Pump/Fan Group Retrofits

| Business Factor | With Sicarbtech Localization & Traceability | Import-Only, Generic VFD Approach | Outcome for Operators |

|---|---|---|---|

| Deployment time | Modular cabinets, parameterized commissioning | Heavy onsite customization | Faster start, less production disruption |

| Energy and cooling OPEX | +2%–4% efficiency, cooler cabinets | Higher losses, more fan duty | Lower PKR per unit throughput |

| Power-quality compliance | AFE meets PF/THD targets | Often marginal | Fewer disputes, smoother audits |

| Spares & lead time | Local screening, days–weeks | Weeks–months | Higher uptime, lean inventory |

| Warranty & RCA | MES-backed evidence, faster closure | Fragmented records | Lower claims, better insurer confidence |

Future Market Opportunities and 2025+ Trends: Data-Driven Group Control and Grid-Friendly Operations

In 2025 and beyond, Pakistan’s process industries will tilt further toward data-driven group control. Tenders are likely to specify measured PF≥0.99 and THDi≤5% (site dependent), ripple envelopes under step loads, and microsecond protection timing. Expect algorithmic requirements, too: optimal unit-count selection, efficiency-curve allocation, and maintenance rotation will move from “nice-to-have” to “expected,” with APIs for DCS integration and energy dashboards. ESG-linked financing will emphasize verified kWh savings, downtime reductions, and improved process stability metrics.

Technically, SiC modules with double-sided cooling, layered low-inductance busbars, and AFE fronts will become default for critical arrays. Interleaved parallels and cascaded multilevel topologies will spread across pump stations and ventilation manifolds, while online health models for junction temperature, interface thermal resistance, and gate health inform planned maintenance and spare staging. With Sicarbtech’s integrated stack and local technology transfer, operators can move from pilot to plant-wide replication without re-learning lessons site by site.

Extended Technical Specifications and Local Standards Alignment

Typical DC bus platforms operate between 750 and 1100 V, with medium-voltage outputs achieved via cascaded multilevel architectures when needed. Per-unit power ranges from 0.2 to 3 MW, scaling via parallel units and redundancy. Switching frequencies of 2–12 kHz balance loss, acoustics, and filtering. Overload capabilities commonly include 150% for 60 s and instantaneous protection near 200%. Short-circuit withstand targets 3–10 μs at the device level, with system detect-to-soft-turn-off designed for 2–5 μs. Junction temperature capability reaches up to 175 °C with online estimation and derating.

Power-quality objectives set PF near 0.99 and THDi around ≤5%, subject to interconnection conditions. Environmental design addresses dust, oil mist, salt mist, vibration, and shock; cabinet protection and coatings are specified by site severity. Measurement and control include voltage, current, pressure, flow, temperature, and vibration, plus junction-temperature estimation, interface thermal-resistance trending, and DC-bus oscillation with event logging. Documentation maps to IEC 60747 and IEC 60068; EMC engineering targets expectations similar to IEC 61800‑3. Quality governance aligns with ISO 9001 and IATF 16949, with pre-compliance supported through labs in Karachi and Lahore.

자주 묻는 질문

How much total energy can group-control optimization save compared with independent VFDs?

In typical arrays, optimized unit count and efficiency-based allocation reduce group energy by about 5%–12% beyond the intrinsic VFD gains, with additional savings from improved PF and reduced throttling.

Can we reliably meet local PF and harmonic limits on a shared plant bus?

Yes. With an AFE, sites commonly achieve PF ≥ 0.99 and THDi around ≤ 5% (site dependent), which eases interconnection reviews and reduces transformer heating and neighboring instrument interference.

Will adding high-frequency SiC inverters increase EMC risks for our DCS?

No. Low-inductance packaging, layered busbars, shielded zoning, and active snubbing reduce dv/dt and overshoot, improving EMC margins. Proper cable routing and filtering complete a clean co-existence with DCS.

How does double-sided cooling translate into real-world reliability?

By cutting junction-to-case thermal resistance 10%–25%, cabinet hotspots fall 5–10 °C, extending component life, reducing fan duty, and preserving derating margins during heat waves or fouling.

Can the system prevent water hammer and pressure surges during sequencing?

Yes. Coordinated ramps, minimum-flow logic, and soft starts reduce peak current by 50%–80% and suppress hydraulic shock. Group scheduling avoids sudden, inefficient on/off patterns.

What timeline should we expect from pilot to full rollout?

Standardized modules, busbars, and algorithm libraries typically enable a pilot in 8–12 weeks. MES-backed commissioning data then streamlines replication across arrays during planned windows.

How does online monitoring provide early failure warnings?

Junction-temperature estimation, interface thermal-resistance trending, and gate-health analytics detect degradation weeks ahead, allowing planned replacements and avoiding unplanned stops.

Will localization really improve spare availability and warranty handling?

Local screening brings lead times down to days–weeks. MES serialization links device lots and process parameters to field events, accelerating root-cause analysis and strengthening warranty positions.

Can these solutions cope with corrosive, humid coastal environments?

Cabinet protection, high-adhesion coatings, selective potting, and corrosion-aware manifolds, combined with anti-scaling cooling design, maintain performance in high-humidity, salt-mist conditions.

Are benefits transferable to utilities beyond core process pumps and fans?

Absolutely. The same SiC+A FE architecture and group algorithms lift efficiency and stability for cooling towers, scrubbing fans, chilled-water loops, and wastewater stations.

운영에 적합한 선택하기

Group-control retrofits are more than drives—they are systems that blend power quality, dynamic control, and health visibility. Sicarbtech’s SiC platform couples AFE grid friendliness with multilevel and interleaved stability, low-inductance double-sided-cooled modules, microsecond protection, and an optimization layer that keeps arrays on their efficiency curves. For Pakistan’s chemical and process plants, the result is lower energy per unit throughput, fewer trips, calmer instruments, and stronger PKR economics—repeatable across sites and seasons.

전문가 상담 및 맞춤형 솔루션 받기

Co-design your group-control program with Sicarbtech: AFE sizing and filter strategy, cascaded multilevel versus interleaved selection, busbar geometry and shielding, protection timing, cooling design, and optimization algorithms tied to your process curves. Establish local packaging and screening, pre-compliance routines, and MES traceability to replicate success with confidence and speed.

Sicarbtech — Silicon Carbide Solutions Expert

이메일: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Power quality buys calm plants; optimization buys cheap kWh; traceability buys trust.” — Sicarbtech Applications Team

문서 메타데이터

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan process-industry outlook; aligns with IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3; integrates AFE/PF/THD targets, SiC multilevel/interleaved strategies, active DC-bus damping, group-control optimization, online health monitoring, and localized technology transfer capabilities.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.