Precision Engineered SiC Ceramics for Industrial Equipment | Sicarbtech Turkey 2025 Pillar Page

공유

Sicarbtech is the Silicon Carbide Solutions Expert partnering with Turkish textile, automotive, and steel manufacturers to engineer precision silicon carbide components that perform under harsh thermal, mechanical, and chemical conditions. Operating from Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we bring more than 10 years of customization experience across R-SiC, SSiC, RBSiC, and SiSiC. In 2025, when energy tariffs, export-grade quality, and audit-ready documentation define competitiveness, precision engineered SiC ceramics transform equipment reliability and lifecycle economics.

Executive Summary: Precision Silicon Carbide as a 2025 Advantage for Turkish Industry

Turkey’s manufacturing landscape is evolving toward tighter tolerances, shorter cycles, and stricter compliance. Textile producers in Denizli and Gaziantep target lower fabric defects and faster restarts. Automotive clusters around Bursa and Kocaeli pursue IATF 16949 rigor while ramping EV-adjacent programs. 철강 plants in Marmara and Iskenderun demand more stable furnace profiles and longer campaigns. Precision engineered silicon carbide—sintered SSiC for seals and rollers, SiSiC/RBSiC for complex high-temperature components, and R-SiC for low-mass fixtures—aligns directly with these objectives.

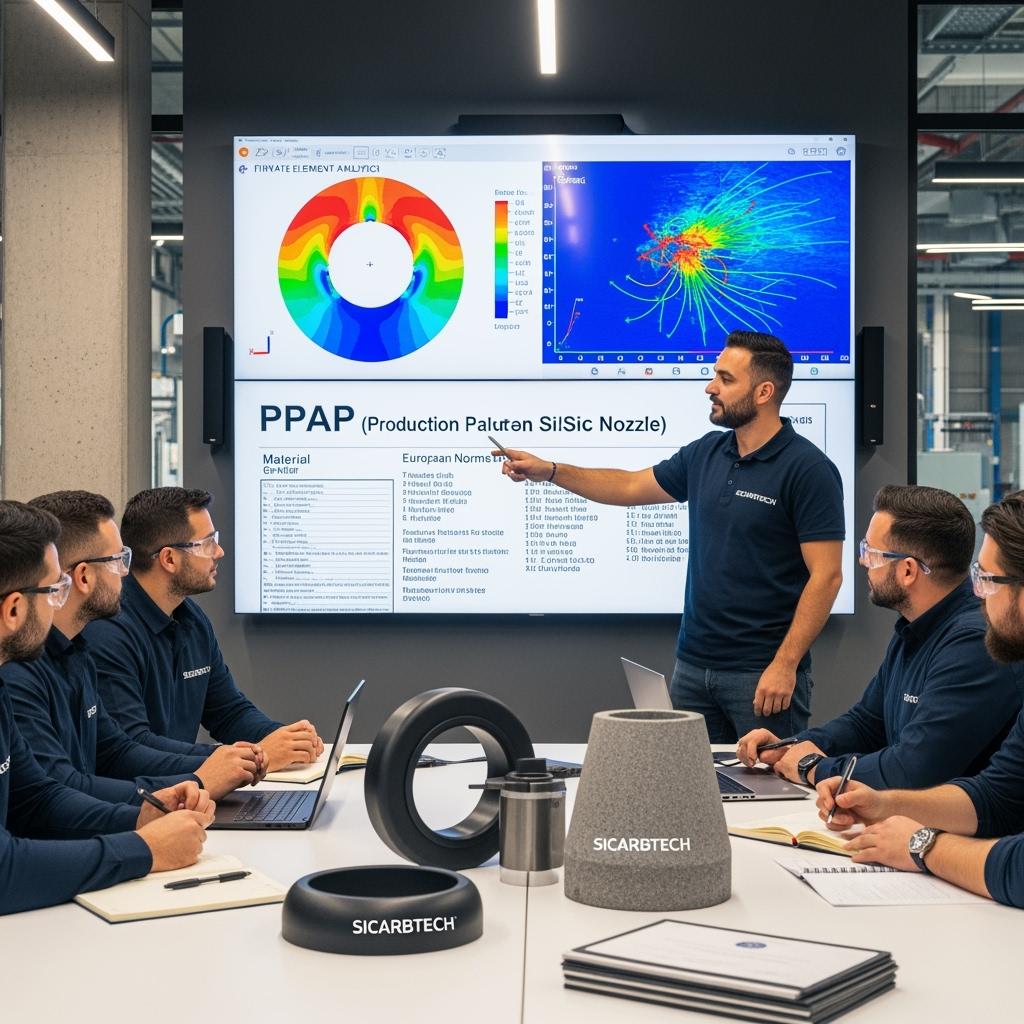

Beyond materials, Sicarbtech’s turnkey capabilities matter. We co-design geometries with FEA and CFD, validate manufacturability with DFM, and deliver EN-referenced data with serial-level traceability. Moreover, our technology transfer and factory establishment services give Turkish partners credible paths to localize critical SiC production, reducing FX exposure and lead-time risk. As Dr. Alper Soydan, an industrial materials consultant, notes, “Precision in ceramics is not just about microns—it’s about stability across cycles. Silicon carbide buys you a predictably wider process window.” (Source: Industrial Materials Workshop, 2024)

Industry Challenges and Pain Points in Turkish Operations

The unifying problem across textile, automotive, and steel facilities is variability. In textile finishing, rollers, guides, and spray nozzles endure chemical exposure and abrasive fibers. Standard alumina rollers and coated metals roughen or warp, nudging runout just enough to print visible patterns onto fabric. A single unplanned stop triggers a cascade: reheating energy, idle labor, and expediting costs to keep export commitments. Under ISO 9001 and ISO 14001 oversight, each deviation becomes a corrective action, increasing administrative load.

Automotive lines face the added constraint of documentation-heavy quality systems. Heat-resistant steels used in seals and fixtures creep with repeated cycles, shifting tolerances and gradually eroding process capability indices. Deviations demand containment and PPAP updates to satisfy IATF 16949, all while unplanned maintenance pushes takt-sensitive schedules. Currency fluctuations complicate spare-part budgeting in TRY, particularly when frequent imports are needed to keep equipment running.

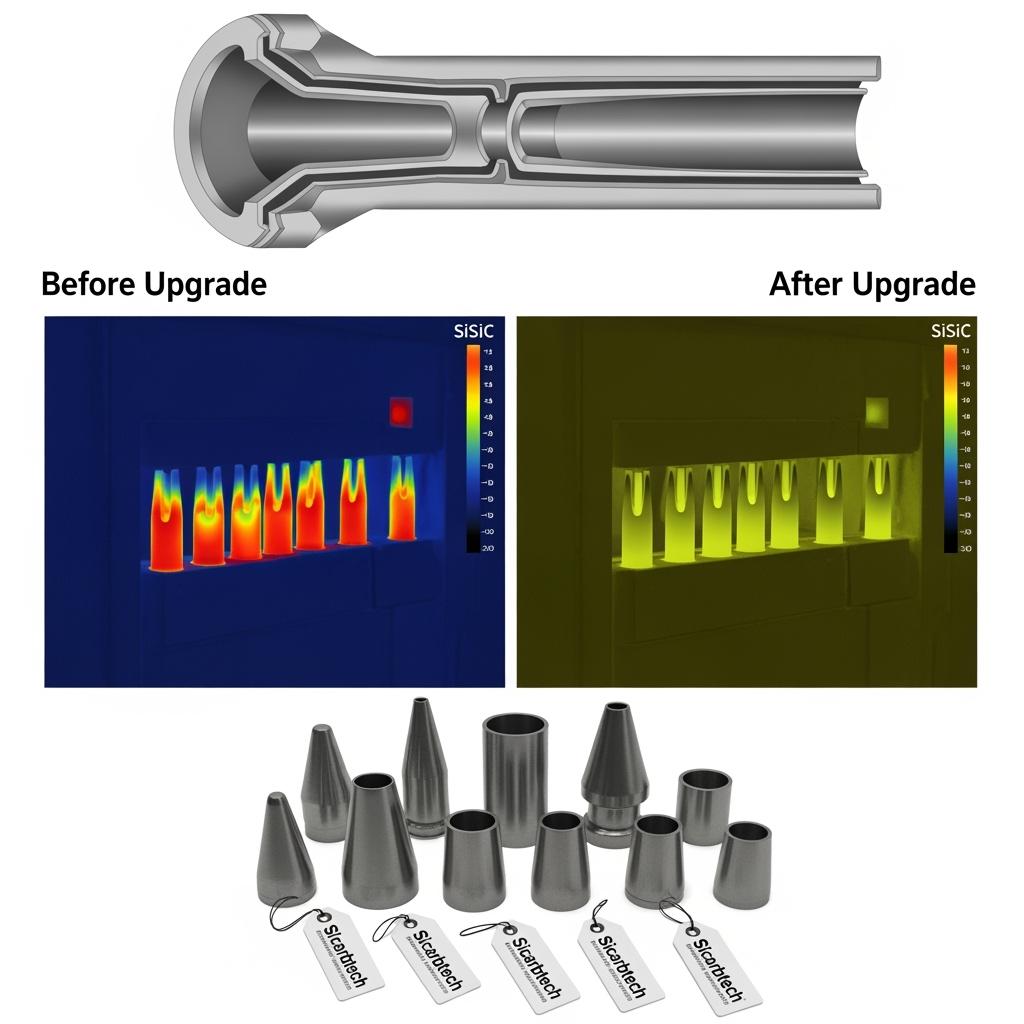

Steel furnaces live at the edge of materials performance. Burner nozzles, skid elements, and heat-exposed internals see flame impingement, oxidation, and slag attack. Conventional ceramics spall; metallics oxidize and deform. The result is unstable flame geometry, uneven heat fields, and higher energy per ton. When a nozzle fails prematurely, campaign plans shift, safety risks increase, and plant KPIs reported to the Ministry of Environment, Urbanization and Climate Change take a hit.

Turkey’s 2025 conditions intensify these stresses. Higher energy tariffs penalize long ramps and overfiring; logistics variability makes replacement lead times unpredictable; and EU-aligned expectations elevate the importance of EN-referenced data and CE considerations where components integrate with machinery. Buyers now look beyond price, favoring suppliers who bring application engineering, auditable documentation, vendor-managed inventories, and realistic paths to localize supply. As Prof. Gökhan Demirtaş, a metallurgical auditor, summarizes, “The penalty for inconsistency is growing—energy, rework, and compliance are a triple tax on poorly controlled materials.” (Source: Marmara Industry Audit Forum, 2024)

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

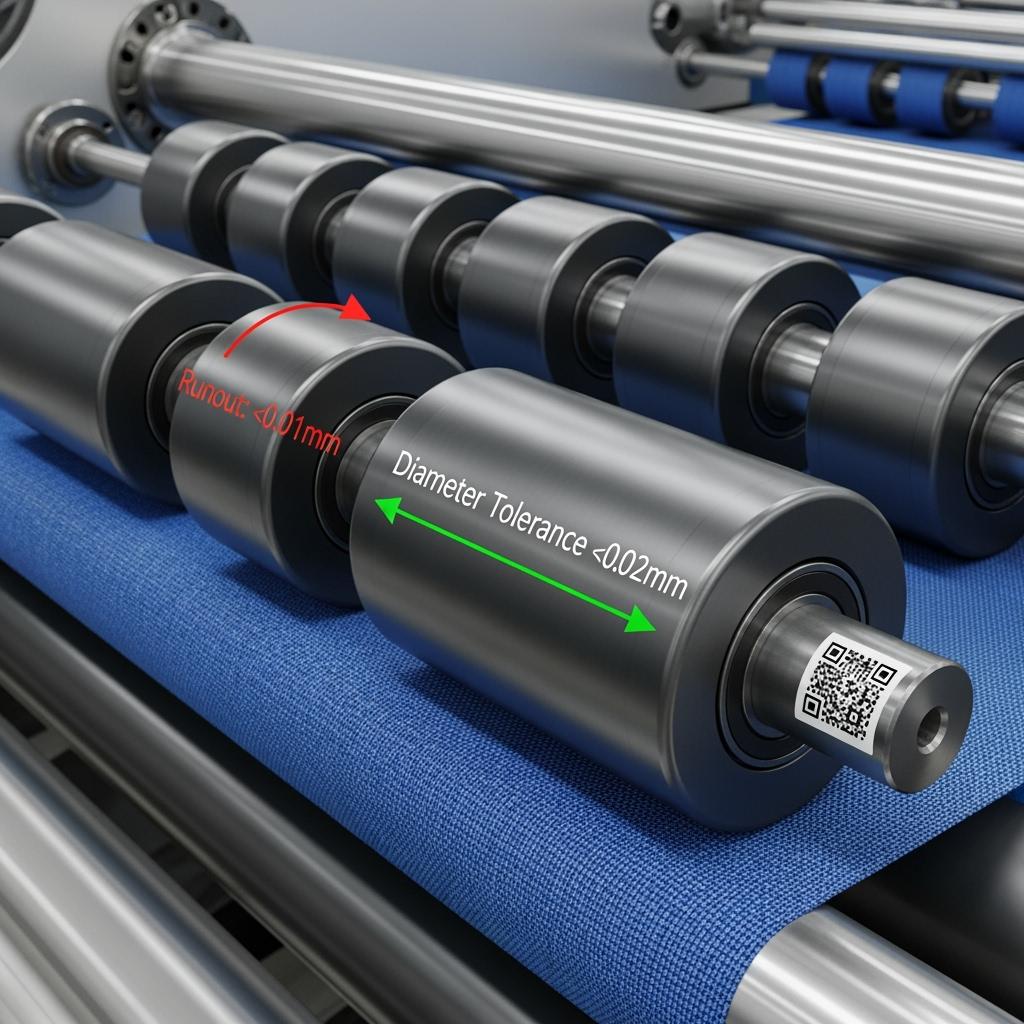

Sicarbtech’s precision SiC portfolio is built to remove variance at the source. In textile finishing, SSiC guide and spreader rollers are precision-ground and lapped to maintain low runout across long spans. Bore geometries and bearing seats are held to tight tolerances, controlling vibration and tension. SiSiC and RBSiC spray and jet nozzles retain flow geometry through rapid cycling, while resisting chemical attack.

Automotive lines benefit from SSiC mechanical seals and pump components that maintain flatness, parallelism, and surface finish under heat and chemical exposure, protecting pump efficiency and sealing performance. R-SiC lattice fixtures and kiln furniture lower thermal mass in paint-curing and heat-treatment steps, enabling quicker ramps and tighter temperature uniformity. In steel furnaces, SiSiC burner nozzles and RBSiC skid elements withstand flame shock and slag corrosion, stabilizing heat profiles and extending campaign life.

We embed application engineering into every project. FEA quantifies stress and deflection; CFD optimizes gas and liquid paths; and DFM mitigates stress raisers while aligning geometry with sintering and finishing realities. Each delivery includes EN-referenced property data, dimensional and surface inspection, and serial-level traceability to streamline Turkish audits and customer acceptance.

Performance Comparison: Precision SiC vs Traditional Materials

Thermal and Mechanical Benchmarks for Textile, Automotive, and Steel Equipment

| Property / Metric | SSiC (sintered) | SiSiC / RBSiC (reaction-bonded) | High-Alumina Ceramic | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 100–160 | 60–130 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 150–300 | 200–300 |

| Chemical/oxidation resistance | 우수 | 매우 좋음 | Good | 공정 |

| 열 충격 저항 | 우수 | 매우 좋음 | 보통 | 보통 |

| Typical service life in severe duty | 2–4× alumina | 1.5–3× alumina | 기준선 | 낮음 |

High conductivity and low CTE allow SiC parts to operate closer to the design envelope with less drift. For Turkish plants, that typically means shorter ramps, steadier SPC charts, and fewer unplanned interventions.

Real-World Applications and Success Stories in Turkey

A Bursa Tier-1 automotive supplier replaced heavy stainless fixtures with R-SiC lattice designs and SSiC wear sleeves at contact points in a paint-curing oven. The lower thermal mass reduced ramp time by 6–8% and tightened temperature uniformity. Coating thickness variation narrowed, decreasing rework by 21% over two quarters. PPAP documentation mapped to IATF 16949 was accepted with minimal iterations due to serialized metrology.

A Denizli textile finisher replaced alumina rollers with SSiC precision-ground rollers. Runout declined to ≤ 0.02–0.05 mm across long spans, defect complaints tied to roller artifacts fell by 28%, and roller changeouts halved within six months. ISO 9001 auditors flagged fewer corrective actions thanks to traceable inspection data.

A Marmara-region steel annealing line adopted SiSiC burner nozzles and RBSiC skid elements after a joint CFD and DFM exercise. Flame profiles stabilized, nozzle replacement intervals shifted from monthly to quarterly, and energy per ton dropped by about 15–20% after tuning. Thermal shock incidents declined substantially across two campaigns.

Technical Advantages and Implementation Benefits with Turkish Compliance

Silicon carbide’s covalent bonding yields a triad of advantages for industrial equipment. First, low thermal expansion preserves geometry under rapid cycling, protecting alignment and flatness in seals, rollers, and fixtures. Second, high thermal conductivity smooths gradients, enabling faster ramps and reducing hot spots that drive energy usage and material fatigue. Third, chemical and oxidation resistance guards against corrosive chemistries and combustion products, extending maintenance intervals.

Sicarbtech integrates these strengths within Turkey’s compliance ecosystem. We supply EN-referenced material data, support ISO 9001 and ISO 14001 documentation flows, and provide CE-related inputs where SiC components integrate into machinery. For automotive-linked operations, we prepare PPAP-style dossiers aligned with IATF 16949. As Emre Kalkan, a quality systems auditor, remarks, “Performance quantified with stable metrology and traceable certificates is what accelerates audits. It’s the difference between a debate and a sign-off.” (Source: Quality and Compliance Briefing, 2024)

맞춤형 제조 및 기술 이전 서비스

Sicarbtech’s competitive edge is a complete stack: from advanced R&D to turnkey localization in Turkey.

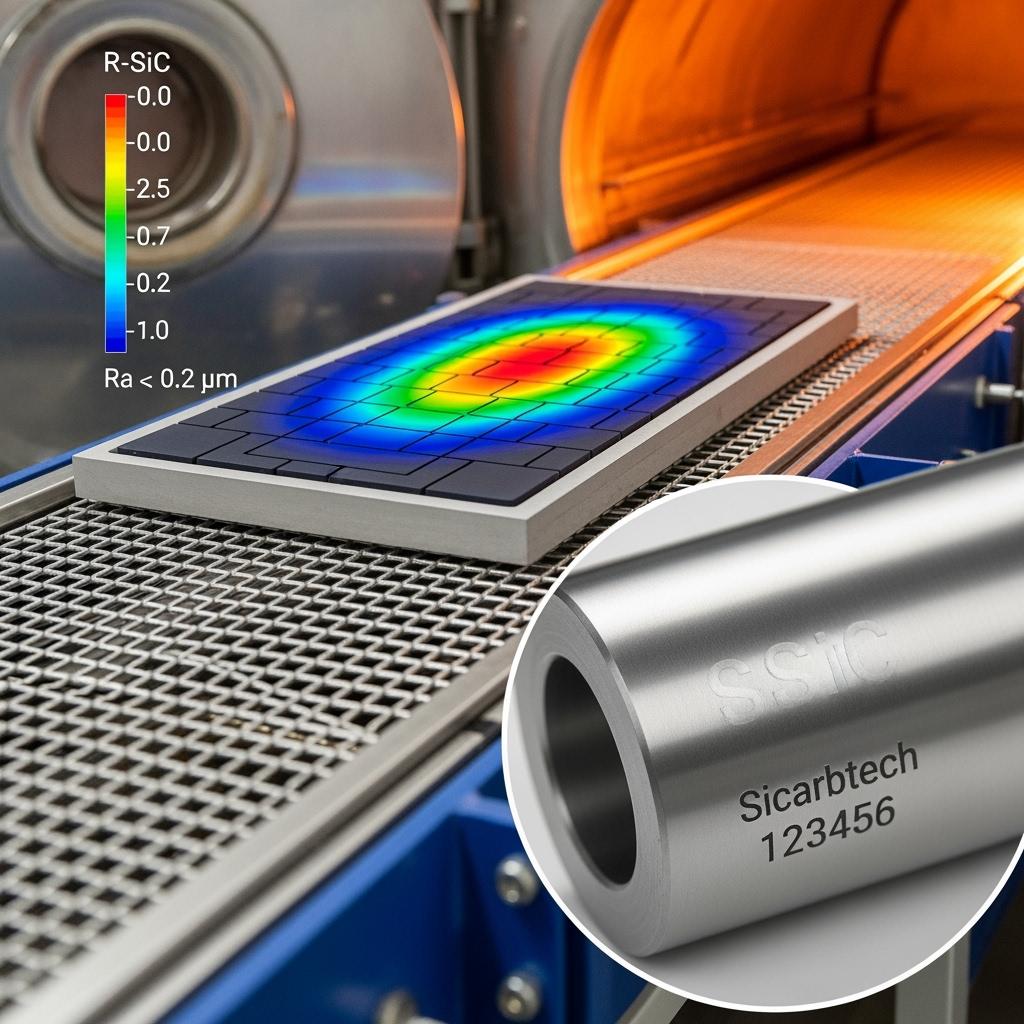

Our R&D—backed by the Chinese Academy of Sciences (Weifang) Innovation Park—anchors proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. We define powder chemistries and particle-size distributions, enforce contamination-safe dispersion and milling, and select forming routes to match geometry and tolerance needs, including cold isostatic pressing, slip casting, extrusion, and additive green-body strategies. Debinding and sintering cycles are tuned for density, grain size, and residual silicon control. Precision finishing uses diamond grinding, lapping, and, where required, CMP-style polishing to deliver sub-micron Ra on seal faces and critical flats.

For Turkish partners, we provide complete technology transfer packages: process know-how documents; equipment specifications for lined mixers, isostatic presses, clean kilns, handling fixtures; and metrology suites for flatness, roundness, thickness, and surface roughness. Structured training programs cover operators, process engineers, maintenance, and QA. Our factory establishment services begin with feasibility studies grounded in Turkish textile, automotive, and steel demand; proceed through layout and utilities design, HSE planning per local regulation, vendor selection, installation supervision, pilot runs, MSA, and full commissioning.

Quality control systems are embedded from day one. We align inspections with TS EN and ISO frameworks, implement SPC on critical variables (purity, density, porosity, flatness, roughness), and structure documentation that maps directly into customer audits. For automotive interfaces, we support PPAP and IATF 16949 expectations. Post-launch, our engineers remain engaged in cycle optimization, kiln profile refinement, yield improvement, downtime root-cause analysis, and preventive maintenance planning. This turnkey approach—validated in collaborations with 19+ enterprises—compresses time-to-quality, de-risks capex, and builds resilient local supply for critical SiC components.

Engineering Data and Grade Fit for Turkish Equipment Builders

Precision SiC Grades and Application Fit

| SiC 등급 | 밀도(g/cm³) | Open Porosity (%) | 굽힘 강도(MPa) | 열 전도성(W/m-K) | Typical Turkish Applications | Engineering Notes |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Mechanical seals, precision rollers, pump/valve internals | Highest strength and corrosion resistance; polishable to sub-µm Ra |

| SiSiC (Si-infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, HX plates, furnace elements | Strong shock resistance; good creep behavior |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Complex nozzles, kiln furniture, structural supports | Cost-effective shape freedom; robust cycling |

| R-SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lattice fixtures, radiant tubes, lightweight shelves | Lowest thermal mass; outstanding shock tolerance |

Cost and Energy Impact for Turkish Buyers

Lifecycle Economics and Energy KPIs Under 2025 Conditions

| 요소 | Conventional (Alumina/Steel) | Sicarbtech Precision SiC | Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | 낮음 | 더 높음 | Premium offset by long life and energy savings |

| Replacement frequency | 빈번함 | 2–4× lower | Reduced FX exposure; fewer emergency imports |

| Downtime per failure | 상당함 | Far less frequent | Protects export schedules and SLAs |

| Energy per unit output | Baseline–higher | Lower via uniform heat and low mass | Savings amplified by tariffs |

| Audit workload | 더 무거움 | Lighter (traceable documentation) | Faster ISO/IATF/CE acceptance |

| Typical payback | 중국 SiC 허브의 비용 경쟁력 있는 솔루션, 효율성을 위한 최적화된 프로세스. | 6–18 months | Shortest in heat-intensive steps |

미래 시장 기회와 2025년 이상의 트렌드

Three currents shape the business case for precision SiC in Turkey. First, decarbonization and energy cost pressure reward materials that reduce kWh per unit, shorten ramp times, and stabilize thermal profiles. SiC’s conductivity and low CTE are direct levers. Second, reliability expectations in export supply chains elevate traceable, EN-referenced materials supported by serial-level metrology; Sicarbtech’s documentation-first approach shortens audits and accelerates approvals. Third, supply-chain resilience favors localization; technology transfer and local stocking reduce risk linked to FX and logistics variability.

Additionally, hybrid architectures are maturing—SSiC at precision interfaces with SiSiC or RBSiC bodies for cost-performance balance—and digital twins are becoming routine for burners, fixtures, and rollers, enabling teams to tune flow and heat before first article. As a European advanced ceramics brief observed, “System efficiency and evidence-backed reliability are now decisive procurement KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s engineering rigor and turnkey localization align precisely with this shift.

자주 묻는 질문

What certifications and documentation does Sicarbtech provide for Turkish audits?

We provide EN-referenced material data, ISO 9001 and ISO 14001 documentation support, and CE-related inputs for machinery integrations. For automotive-linked customers, we deliver PPAP-style dossiers aligned with IATF 16949.

How quickly can you deliver precision SiC components to Turkey?

Lead times are typically 4–8 weeks for established geometries and 8–12 weeks for complex assemblies or polished surfaces. We can implement vendor-managed inventory and local safety stock for critical spares.

Which SiC grade is best for high-speed textile rollers?

SSiC is usually preferred for its strength, corrosion resistance, and ability to hold low runout across long spans. We validate with FEA/DFM and provide serialized metrology for audit readiness.

How does SiC reduce energy use and cycle time in ovens and furnaces?

High thermal conductivity and dimensional stability eliminate hot spots and enable faster ramps. R-SiC’s low mass further shortens cycles. Plants often record 10–20% energy reductions after tuning profiles.

What finishes and tolerances can you achieve on precision parts?

For SSiC seals and rollers, Ra ≤ 0.2 µm and tolerances down to ±0.01–0.02 mm on critical features are achievable, subject to geometry. Flatness and parallelism are verified with serialized inspection reports.

Can Sicarbtech localize SiC manufacturing in Turkey?

Yes. We deliver full technology transfer—process know-how, equipment specs, training, pilot runs, and commissioning—plus quality systems aligned with TS EN/ISO and IATF expectations where relevant.

How do you ensure batch-to-batch consistency and traceability?

We apply SPC to powder properties, forming parameters, and sintering cycles, linking certificates and inspection data to batch or part serials. This accelerates audits and root-cause analysis.

Will your data integrate with our ERP/MES and quality systems?

Yes. We provide certificates and serial/batch data in standard digital formats compatible with ERP/MES platforms used in Turkey, supporting automated receiving, maintenance, and audit trails.

What local standards and regulations should we plan for?

Expect TS EN and ISO frameworks, IATF 16949 for automotive supply chains, and CE considerations for equipment. Environmental reporting follows national rules aligned with EU guidance.

How do you compare with other SiC suppliers in Turkey?

Our differentiator is the combination of application engineering, rigorous documentation, and the ability to localize capability through technology transfer—advantages validated in work with 19+ enterprises.

운영에 적합한 선택하기

The value of precision silicon carbide lies in system-level stability. When grade selection, geometry, and thermal regimes are co-engineered, lines run closer to design intent with fewer stops and lower energy per unit. Sicarbtech translates your constraints—ramp rates, chemistries, geometry limits, and compliance targets—into engineered SiC components with measurable ROI and, where strategic, into localized capability that de-risks supply.

전문가 상담 및 맞춤형 솔루션 받기

Engage Sicarbtech’s engineers to review your duty cycles, failure modes, and quality objectives. We will recommend the optimal SiC grade and geometry, model ROI in TRY with sensitivity to energy tariffs and downtime, define validation steps, and, if beneficial, design a technology transfer roadmap to establish local capability in Turkey.

Contact Sicarbtech:

- 이메일: [email protected]

- 전화/왓츠앱: +86 133 6536 0038

문서 메타데이터

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff updates, EU compliance changes, and new Sicarbtech case studies)

Content freshness indicators: integrates 2025 Turkish market outlook; localized EN/ISO/CE references; updated grade benchmarks for R-SiC, SSiC, SiSiC, and RBSiC; new Turkish case results; expanded guidance on technology transfer and factory establishment.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.