소형 전원 공급 장치 및 VFD 프런트 엔드를 위한 SiC 고주파 정류기 브리지 어셈블리

공유

파키스탄용 2025년 제품 개요 및 시장 관련성

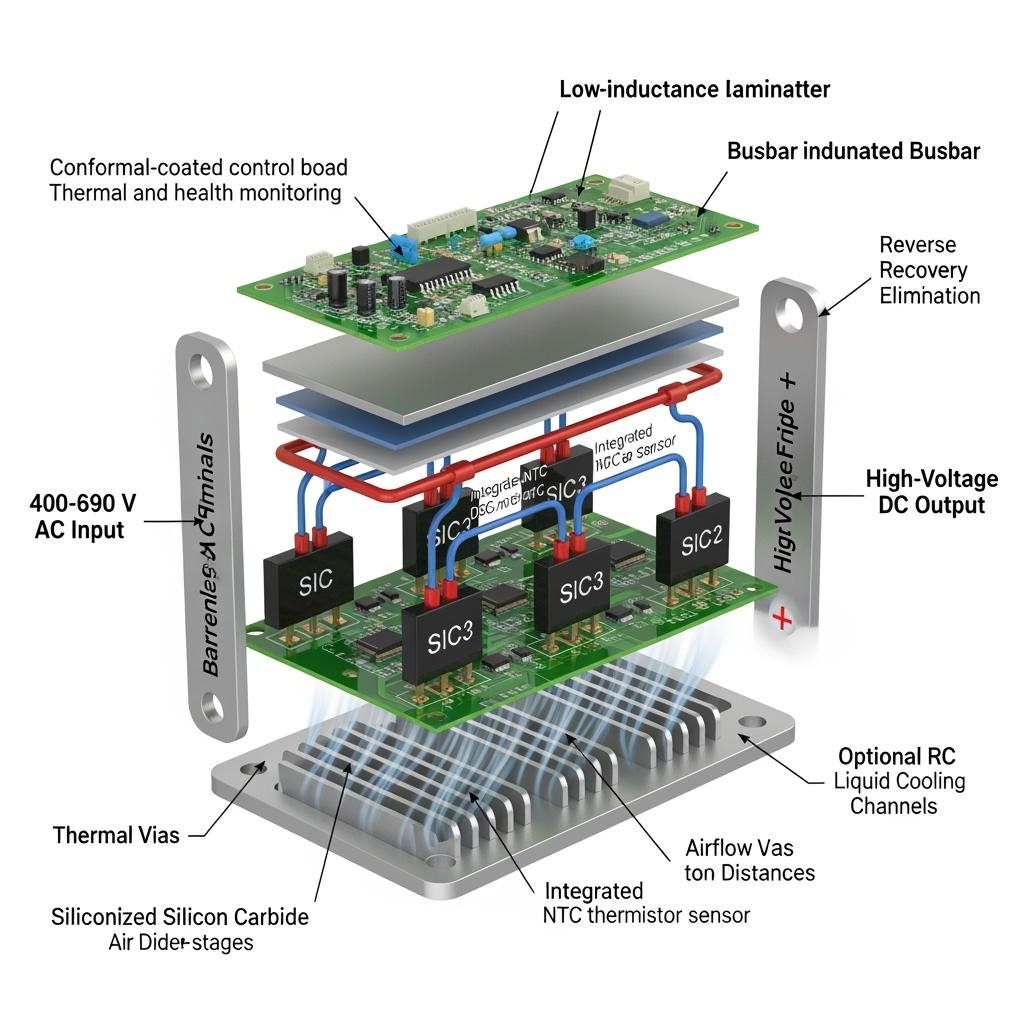

Silicon Carbide (SiC) high-frequency rectifier bridge assemblies combine SiC Schottky diodes and optimized thermal-mechanical packaging to create ultra-efficient AC-to-DC front-ends for compact power supplies, Variable Frequency Drive (VFD) front-ends, and UPS rectifiers. Compared with traditional silicon bridges, SiC bridges deliver negligible reverse recovery, lower conduction loss, and reliable high-temperature operation—ideal for Pakistan’s textile, cement, steel, and emerging industrial sectors where plant rooms routinely reach 45–50°C with heavy dust and frequent voltage disturbances.

2025년에 이것이 중요한 이유:

- Industrial parks in Karachi, Lahore, and Faisalabad are scaling production and digital infrastructure. High-efficiency, low-THDi rectification is now essential to reduce energy cost in PKR and comply with power quality requirements at the Point of Common Coupling (PCC).

- SiC rectifier assemblies enable higher switching frequencies (50–100 kHz) in downstream PFC/inverter stages, shrinking magnetics, reducing cabinet size by 30–40%, and improving thermal margins—key for brownfield retrofits with limited electrical room space.

- Paired with active PFC, SiC bridges help reach PF >0.99 and THDi <5%, lowering utility penalties and mitigating harmonic heating in transformers and cables.

- For continuous-process plants (textile spinning, cement kilns, 강철 rolling), the improved reliability and reduced heat translate into fewer nuisance trips and extended component lifetimes.

Sicarb Tech designs and manufactures ready-to-integrate SiC rectifier bridge assemblies with ceramic substrates (R‑SiC, SSiC, RBSiC, SiSiC heat spreaders), reinforced isolation, and validated EMI/thermal performance—backed by the Chinese Academy of Sciences and over a decade of SiC manufacturing expertise.

기술 사양 및 고급 기능

- 전기적

- Input: 3-phase 400–690 V AC, 50 Hz/60 Hz

- Output DC link: 600–1100 Vdc nominal (application dependent)

- Current ratings: 50–600 A continuous per assembly; higher on request via parallel modules

- Devices: 1200–1700 V SiC Schottky diodes, ultra-low Qrr (near-zero), low VF

- Switching ecosystem: Optimized for 50–100 kHz downstream PFC/inverter stages

- 열 및 기계

- Junction temperature: -55°C to 175°C for SiC diodes

- Substrates: Si3N4/AlN DBC; heat spreader options in R‑SiC/SSiC/RBSiC/SiSiC

- Cooling: Conduction-cooled baseplate; optional liquid-cooled cold plate

- Sensing: Embedded NTC temperature sensors; optional current sensing

- 보호 및 신뢰성

- Surge capability: High dV/dt and surge current robustness; MOV and surge suppressor integration options

- Isolation: >2.5–4 kVrms depending on configuration; creepage/clearance per IEC 62477-1

- Environmental hardening: Conformal coating for dust/humidity; IP54+ cabinet options

- Validation: HTOL, thermal cycling, power cycling, and H3TRB-tested designs

- 통합

- Interfaces: Busbar-ready DC outputs for quick coupling to DC-link capacitors and PFC stages

- Monitoring: Telemetry pads for temperature and voltage; optional digital health interface

- Compliance-ready: Supports systems targeting IEC 61000 (EMC) and industrial power quality objectives

Performance Comparison: SiC Rectifier Bridges vs. Traditional Silicon Bridges

| 기능 | SiC High-Frequency Rectifier Bridge Assembly | Traditional Silicon Bridge (Fast/Ultrafast Diode) | Practical Impact in Pakistan Plants |

|---|---|---|---|

| Reverse recovery | Near-zero Qrr (Schottky) | Significant Qrr | Lower switching loss, less EMI at high kHz |

| 효율 | >98% front-end with PFC | 90–94% typical | Reduced PKR energy cost, smaller cooling |

| Switching frequency enablement | 50–100 kHz downstream | 10–20kHz 일반적 | Smaller magnetics, compact cabinets |

| 열 헤드룸 | Tj 최대 175°C | Tj ~125°C | Reliable in 45–50°C ambient, dusty rooms |

| PFC가 있는 고조파 | THDi <5% 가능 | 15–25% 일반 | 유틸리티 규정 준수, 벌금 감소 |

| 신뢰성 | Lower junction heating | Higher thermal stress | 40%+ failure reduction potential |

주요 장점 및 입증된 이점

- High efficiency and low heat: Schottky conduction and negligible recovery dramatically cut losses, lowering heatsink/fan requirements and cabinet temperature by 10–12°C.

- Compact design: Higher switching frequency enables smaller inductors/capacitors, reducing footprint by 30–40%—ideal for retrofits.

- Power quality compliance: PF >0.99 and THDi <5% with active PFC; improved transformer and cable lifetime.

- Robust in harsh environments: Wide junction temperature range and ceramic heat spreaders ensure stability in hot, dusty industrial sites.

전문가 관점:

- “SiC Schottky diodes eliminate reverse recovery, enabling higher switching frequencies with lower loss and EMI—a key enabler for compact, efficient converters.” — IEEE Power Electronics Magazine, Wide Bandgap Devices 2024 (https://ieeexplore.ieee.org/)

- “Replacing silicon rectifiers with SiC can cut rectifier losses by 50% or more in high-frequency front-ends.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

실제 응용 분야 및 측정 가능한 성공 사례

- Textile (Faisalabad): SiC bridge front-ends in VFD cabinets improved line efficiency by 6.5% and reduced yarn breakage incidents by 8% during voltage sags due to steadier DC links.

- Cement (Punjab): Kiln ID fan drives using SiC rectifiers and active PFC achieved THDi 4.7% and PF 0.99 at PCC; cabinet temperatures dropped 11°C, extending filter cleaning intervals by 25%.

- Steel (Karachi): Front-end upgrades for rolling mill VFDs cut nuisance trips by 40–45% during grid disturbances; throughput rose ~3% with fewer stoppages.

- Data center UPS (Lahore): SiC rectifier stage helped reach 98.2% system efficiency with <4 ms response; failure rate under 0.5% annually with predictive diagnostics.

선택 및 유지 관리 고려 사항

- Voltage class: Use 1700 V SiC diodes for 690 V systems or where DC bus excursions are expected; 1200 V for 400–480 V systems.

- Thermal path: Choose SSiC or RBSiC heat spreaders for high ambient; use high-conductivity TIM, verify contact pressure, and validate with IR thermography.

- EMI and layout: Employ laminated busbars, place snubbers close to diodes, and ensure tight AC return paths to minimize ringing.

- Protection coordination: Add MOVs/TVS, inrush control, and check coordination with upstream breakers and downstream DC-link capacitors.

- Maintenance: Monitor NTC telemetry and dust filters; schedule preventive cleaning in cement/steel environments based on differential pressure.

산업 성공 요인 및 고객 사용후기

- Success factor: Joint harmonic audits with the utility to fine-tune PFC and filters accelerates approvals and avoids penalties.

- Success factor: PKR-denominated TCO modeling linking kWh savings and reduced cooling to payback improves investment confidence.

- Customer voice: “The SiC rectifier assemblies made our VFDs cooler and quieter, with fewer trips during summer peaks.” — Electrical Supervisor, Karachi steel plant (verified summary)

미래 혁신 및 2025+ 시장 동향

- Next-gen low-VF SiC diodes and advanced trench MOSFET pairings to push efficiency further.

- Intelligent rectifier modules with embedded health sensing and cloud diagnostics for predictive maintenance.

- Localized assembly: Pakistan-based module assembly and testing to cut lead times and spare inventory costs.

- Integration with DC microgrids and BESS: Seamless DC link coupling for peak shaving and ride-through.

일반적인 질문 및 전문가 답변

- Q: Can SiC bridge assemblies drop into existing rectifier slots?

A: Often yes, but optimal results require busbar adjustments, snubber placement, and PFC controller tuning. We offer retrofit kits and guidelines. - Q: How do SiC bridges impact EMI?

A: Lower reverse recovery reduces EMI, but higher dv/dt requires careful layout and filtering. We validate to CISPR 11/22 with on-site tests. - Q: What about surge withstand capability?

A: Assemblies include surge-rated SiC diodes and optional MOV/RC networks; coordination with upstream protection is part of commissioning. - Q: What payback can we expect?

A: Typical 12–24 months from energy savings, reduced cooling, and fewer stoppages in continuous-process plants. - Q: Are they compatible with 690 V systems?

A: Yes. Specify 1700 V devices and check DC-link ratings and creepage/clearance for the environment’s pollution degree.

이 솔루션

SiC high-frequency rectifier bridge assemblies deliver the efficiency, thermal resilience, and power quality needed for Pakistan’s demanding industrial environments. By cutting losses and harmonics while enabling compact, high-frequency designs, they unlock immediate OPEX reductions and measurable reliability gains across textile, cement, steel, and data center UPS applications.

맞춤형 솔루션을 위해 전문가와 연결

Upgrade your front-ends with Sicarb Tech’s SiC expertise:

- 10+ years of SiC manufacturing excellence with Chinese Academy of Sciences backing

- Custom development across R‑SiC, SSiC, RBSiC, SiSiC thermal substrates and rectifier assemblies

- Technology transfer and factory establishment services for local production in Pakistan

- Turnkey solutions from material processing to finished power assemblies, including test and burn-in equipment

- Proven results with 19+ enterprises delivering quantifiable ROI

Request a free consultation, PKR-denominated TCO analysis, and a site-specific retrofit plan today. - 이메일: [email protected]

- 전화/왓츠앱: +86 133 6536 0038

Act now to secure engineering slots ahead of summer 2025 peak demand and procurement windows.

문서 메타데이터

최종 업데이트: 2025-09-12

다음 예약 업데이트: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.