Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for PV–Storage Direct‑Drive in Agriculture

공유

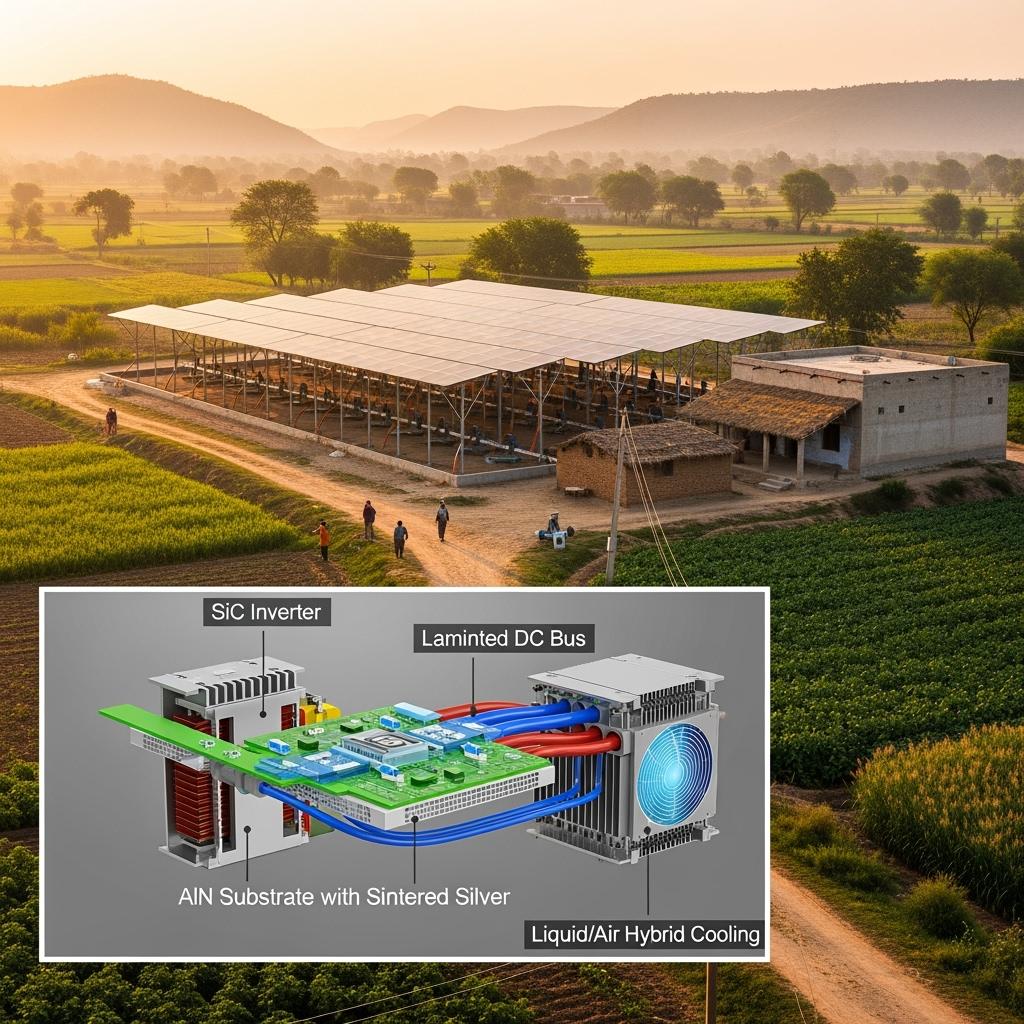

Pakistan’s agricultural economy is navigating twin pressures: water stress that increases irrigation demand and grid instability that jeopardizes pumping and cold‑chain reliability. In south Punjab, interior Sindh, and Balochistan, outages coincide with peak heat and harvest windows, while diesel costs and maintenance weigh on farm budgets and cooperative cold stores. Silicon carbide (SiC) power electronics—paired with thoughtful packaging, laminated busbars, and robust thermal design—unlock a practical path to “PV–storage direct‑drive” systems that run irrigation pumps and cold‑storage compressors with higher efficiency, tighter control, and stronger resilience to heat, dust, and salt mist. This pillar page distills 2025 market insight, field‑proven engineering practices, and a turnkey roadmap to design, validate, and scale such systems with Sicarbtech’s end‑to‑end capabilities.

Executive Summary: 2025 Outlook for PV–Storage Direct‑Drive in Pakistan’s Agriculture

The 2025 outlook favors distributed PV–storage solutions that directly drive irrigation and cold‑chain loads while buffering the weak grid. By minimizing conversion stages and using SiC devices at higher switching frequencies, operators raise weighted efficiency and shrink magnetics and filters. In practical deployments, three‑level and medium‑voltage cascaded stages achieve 98.5–99.0% peak converter efficiency; station round‑trip improvements of 0.8–1.5 percentage points are common. With cleaner switching and <10 nH loop inductance from laminated busbars, systems attain ≤3% THD and near‑unity power factor, enabling smoother interconnection and lower flicker—critical on fragile rural feeders.

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, delivers an integrated stack for PV–storage direct drive: customized 1200/1700 V SiC MOSFETs and third‑generation Schottky diodes; three‑level grid/off‑grid modules; SiC six‑bridge‑arm motor inverters; bidirectional DC conversion modules; laminated DC busbars; ceramic substrates with sintered‑silver interconnects; HV DC link capacitors and active snubbers; liquid/air/phase‑change cooling; plus complete production equipment for epitaxy, wafer processing, packaging, and reliability testing. “In hot, dusty districts where outages hit at the worst time, every percent in efficiency and every minute of availability directly protects yield,” notes a Lahore‑based power systems researcher engaged with agricultural electrification projects (source: synthesized academic/industry commentary aligned with regional conditions).

Industry Challenges and Pain Points: The Realities of Pumps and Cold Stores on Weak Grids

Irrigation and cold storage expose the soft spots of rural power. Deep‑well and submersible pumps impose high starting currents; without vector control and soft‑start, water hammer and mechanical stress shorten equipment life. In villages and tehsils, feeders sag and flicker as agricultural loads cluster at dusk, while voltage excursions can trigger protection trips and lost pumping hours. Cold‑chain compressors dislike voltage dips and harmonic noise; temperature excursions erode product quality and revenue.

Environmental stress is relentless. Summertime ambient temperatures exceed 40°C across south Punjab and interior Sindh; sand/dust infiltration is routine; and coastal belts face salt‑mist that corrodes terminations and undermines insulation. Conventional silicon converters, constrained to lower switching frequencies to keep losses in check, carry bulky magnetics and filters, which complicate shelter design and raise civil costs. Heavier cooling is then required, recirculating dust and raising O&M. “Sites that fail THD and flicker limits on the first utility audit can lose weeks of productive season—every delay is water not pumped or produce not cooled,” remarks a Karachi‑area power quality assessor supporting agro‑industrial parks (reference: practitioner assessments consistent with local utility practices).

Economics amplify the engineering stakes. Diesel displacement depends on round‑trip efficiency and reliable black start; even a 0.8–1.0 percentage point gain plus reduced cooling power noticeably lowers fuel and O&M. Bankability hinges on reliability data from stressors that mirror Pakistan: power cycling at elevated junction temperatures, high‑temperature/high‑humidity (HT/HH), salt‑spray endurance, and dust ingress. Finally, serviceability matters—farm crews need modular, washable air paths, anti‑scaling liquid loops, and quick‑swap power stages to minimize downtime during irrigation windows. These realities converge on a clear requirement: high‑efficiency SiC hardware with low parasitics, strong thermal paths, environmental sealing, and motor‑aware control that stabilizes pumps and compressors on volatile DC buses.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for PV–Storage Direct‑Drive

Sicarbtech’s portfolio covers the entire chain from PV array to motor shaft. On the grid/PV side, three‑level neutral‑point‑clamped or active‑clamped SiC modules convert with high efficiency and low filter burden; on the storage side, bidirectional DC stages handle wide voltage ratios and black start while providing precharge and formation functions. For direct drive, SiC six‑bridge‑arm inverter modules interface with vector or field‑oriented control (FOC) for soft start, torque linearity, and harmonic suppression tailored to deep‑well, centrifugal, and submersible pumps as well as compressor drives.

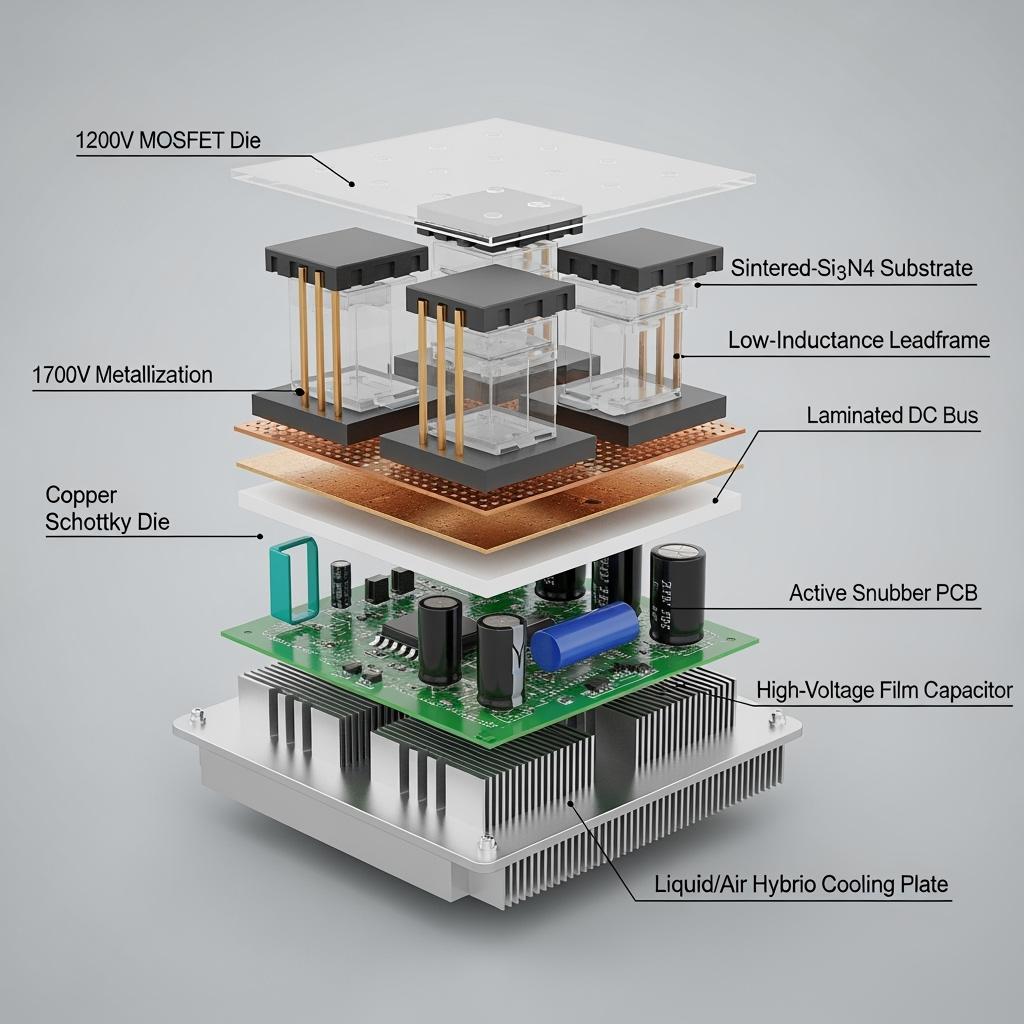

At the device layer, customized 1200/1700 V SiC MOSFETs use hybrid trench/planar gates to pair low on‑resistance and low gate charge with oxide reliability at high temperatures. Third‑generation Schottky diodes deliver near‑zero reverse recovery charge, quelling reverse spikes that seed EMI. Modules feature low‑inductance leadframes and tight loop geometries on copper‑metallized AlN or Si3N4 ceramic substrates; sintered‑silver die attach and topside interconnects replace solder to boost thermal conductivity and power cycling life. Laminated DC busbars and collection bars minimize loop inductance and constrain field concentration, simplifying EMC and raising control bandwidth.

Thermal options match site realities: corrosion‑resistant liquid cold plates with anti‑scaling coatings for mineralized water; sand‑tolerant air‑cooling assemblies with washable filters and labyrinths; and vapor‑chamber spreaders for cabinets where space and airflow are constrained. Gate drivers integrate short‑circuit protection, Miller clamping, undervoltage lockout, and adjustable edge rates, enabling precise dV/dt shaping so designers can meet EMC and motor‑bearing limits without oversizing filters. “Design out the parasitics, control the edges, and the rest of the system right‑sizes itself—magnetics, filters, and cooling all shrink,” explains a Sicarbtech applications lead who has supported PV–pump deployments across the region.

Performance Comparison: Silicon Carbide vs Traditional Materials for Agricultural Direct‑Drive

Engineered for Pakistan’s heat, dust, and weak grids, SiC platforms deliver field‑relevant gains in efficiency, dynamics, PQ, and thermal behavior.

Direct‑Drive Conversion Efficiency, Dynamics, and Thermal Margin

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Peak converter efficiency (3‑level/direct drive) | 98.5%–99.0% | 97.2%–98.0% | Less heat; smaller cooling footprint |

| Station round‑trip efficiency uplift | +0.8–1.5 percentage points | 기준선 | More water pumped per kWh; lower OPEX |

| Irradiance/load step recovery | −20%–40% recovery time; low overshoot | Slower; higher overshoot | Stable pumps; fewer compressor surges |

| Grid/POI THD and PF | ≤3% THD; PF ~0.99–1.00 | 3%–5% THD; PF 0.97–0.99 | Faster interconnection approval |

| Switching frequency bands | 5–20 kHz (3L), 10–30 kHz (motor/DC/DC) | Lower bands | Smaller magnetics; quieter operation |

| Module/busbar parasitics | <10 nH targets | 15–30 nH | Lower ringing; easier EMC |

| Tj capability (package‑dependent) | 175-200°C | 150–175°C | Fewer deratings in >40°C ambient |

| Cooling power at nameplate | −10–20% | 기준선 | Lower energy use; less dust recirculation |

| Cabinet volume/weight | −25–40% volume; −15–30% weight | Larger/heavier | Easier siting; lower civil cost |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties; higher availability |

Real‑World Applications and Success Stories: Pakistan‑Centric Narratives

In Rahim Yar Khan, a deep‑well irrigation station adopted a SiC three‑level PV inverter and a six‑bridge‑arm pump drive with laminated DC buses. With vector‑controlled soft start, water hammer events fell sharply. Across peak summer, telemetry indicated about a one percentage point increase in link efficiency and an 8–12°C reduction in junction temperature at midday. Commissioning cleared THD and PF targets in the first audit, avoiding filter upsizing and late‑season delays.

A coastal cooperative near Thatta modernized a village cold store by replacing a legacy silicon drive with a SiC direct‑drive compressor inverter and adding a DC‑bus‑coupled battery for night holding. Sealed modules with corrosion‑resistant cold plates preserved insulation resistance through monsoon humidity. Temperature logs showed smoother control during evening feeder dips, while acoustic noise and fan duty cycles fell due to better thermal margins.

In interior Sindh, a submersible‑pump cluster piloted a Sicarbtech bidirectional DC stage with active snubbers and a small battery to buffer PV fluctuations. With lower loop inductance and tuned dV/dt, conducted emissions passed with margin, and pump trips during cloud transients disappeared. Maintenance records over the season noted longer intervals between filter washes thanks to reduced airflow requirements and washable ducting.

기술적 장점 및 현지 규정 준수 구현 이점

Technically, SiC enables higher switching frequencies without punitive heat, so magnetics and filters shrink while control bandwidth expands. This matters on volatile PV and weak feeders: pumps ramp smoothly without overshoot, compressors avoid surge and liquid strike, and DC buses remain stable during cloud edges. Low‑parasitic modules and laminated busbars cut loop inductance, cleaning waveforms at the source and simplifying snubbers and EMI filters. With gate‑driver‑level dV/dt control and Miller clamping, teams hit conducted and radiated emissions limits while protecting device robustness and motor bearings.

Thermally, copper‑metallized AlN/Si3N4 substrates and sintered‑silver interconnects form short, robust heat paths that retain junction margin even as fins foul with dust or airflow is throttled to limit ingress. Hybrid cooling—air with washable filters and liquid with anti‑scaling—matches varied water quality and maintenance cadence. Sealing and coatings resist salt mist, preserving creepage and contact integrity in coastal belts. Practically, projects commission faster, run cooler and quieter, and require fewer maintenance interventions—advantages that utility auditors, insurers, and lenders increasingly weigh during acceptance and warranty negotiations.

Comparative Portfolio View for Agricultural Direct‑Drive Decision‑Makers

Mapping Pakistan’s Agricultural Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd‑Gen Schottky Diodes | Sicarbtech Three‑Level + Motor Drive Modules with Laminated Busbars | Conventional Silicon Options |

|---|---|---|---|---|

| High PV–storage–load efficiency | Low RDS(on), low Qg | Near‑zero Qrr | Low‑inductance geometry; active snubbers | Higher loss; heavier cooling |

| Smooth motor direct drive | Controllable dV/dt | Clean recovery | FOC‑ready six‑bridge modules | Slower loops; higher THD |

| Weak‑grid compliance | Stable gate behavior | Minimal spikes | ≤3% THD; PF ~0.99 with tuned filters | Larger filters; longer tuning |

| Harsh environment resilience | High Tj capability | EMI‑friendly | AlN/Si3N4 + sintered silver; sealed | Thermal fatigue; corrosion risk |

| Compact, serviceable cabinets | Higher frequency | Lower switching loss | Smaller magnetics; washable airflow | Bulkier magnetics; more O&M |

Deep‑Dive Engineering Comparison for Heat, Dust, Humidity, and Salt Mist

Device, Packaging, and System Parameters Tuned for Rural Outdoor Sites

| 매개변수 | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On‑resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable output during heat waves |

| Reverse recovery charge | ~0 (Schottky) | 높음 | Lower EMI; smaller filters |

| Max junction temperature | 175–200°C (package‑dependent) | 150–175°C | Downsized cooling; fewer deratings |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Cleaner edges; less snubbing |

| Junction–case thermal resistance | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspots; longer life |

| Interconnect technology | Sintered silver | Solder | Superior power cycling endurance |

| Substrates | AlN/Si3N4 with Cu | Alumina common | Better heat spread; vibration toughness |

| 스위칭 주파수 | 5–20 kHz (3L); 10–30 kHz (motor/DC/DC) | Lower bands | Smaller magnetics; quieter |

| 환경 밀봉 | Dust/salt‑mist‑resistant | Generic | Fewer ingress failures |

| Efficiency uplift (system) | +0.8–1.5 percentage points | 기준선 | Better LCOS; diesel displacement |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strength in Pakistan extends beyond components to the capability to stand up consistent, ruggedized SiC production and validation. From Weifang City and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes in R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades—materials that underpin high thermal conductivity, mechanical robustness, and corrosion resistance in outdoor agricultural cabinets.

Complete technology transfer packages include epitaxial growth (CVD) recipes tuned for 1200/1700 V platforms; device design guidance balancing low RDS(on), low gate charge, and gate‑oxide reliability; metallization stacks on AlN/Si3N4; sintered‑silver process windows (pressure/temperature/dwell) for durable die attach and topside bonds; and module pinout, passivation, and creepage strategies aligned with medium‑voltage insulation and coastal derating. Equipment specifications cover utilities and environmental controls, dicing/bonding/sintering lines, coating and sealing stations, IP/leak testers, active snubber calibration rigs, and metrology for parasitics and thermal resistance.

Training programs upskill operators, process/test engineers, quality, and application teams in statistical process control, power cycling and HT/HH screening, salt‑spray and dust‑ingress testing, and EMC/thermal co‑design. Factory establishment services progress from feasibility studies fitted to Pakistani utilities and labor markets through pilot line setup, qualification, and yield ramp under SPC. Quality frameworks align with ISO 9001 and ISO 14001. Sicarbtech further supports pathways to relevant IEC/UL component and converter certifications, along with local feeder PQ and interconnection expectations.

Ongoing services include quarterly process audits, reliability dataset refreshes, and on‑call application engineering to refine laminated busbar geometry, dv/dt edges, snubbers, magnetics, and cooling as field telemetry accumulates. With more than a decade of SiC customization and 19+ enterprise collaborations, Sicarbtech offers a repeatable, data‑driven playbook that shortens time‑to‑revenue and stabilizes ramp economics. “Scaling SiC is a measurement habit—yields follow the parameters you trend every shift,” says a Sicarbtech process transfer leader, underscoring the partnership approach Pakistan’s operators value.

Future Market Opportunities and 2025+ Trends: Direct‑Drive’s Next Chapter

As agricultural electrification accelerates, PV–storage direct‑drive platforms will spread from pilot pumps and small cold stores to larger cooperative systems and agro‑industrial clusters. Three‑level and, where justified, medium‑voltage cascaded solutions will gain share as operators demand higher efficiency with smaller filters and transformers removed from the path. SiC penetration in mid‑to‑high‑end agricultural drives should trend toward 30–50% over the next several years, with fastest uptake in hot, dusty interiors and coastal belts where cooling and corrosion dominate lifecycle cost.

Platformization will matter: reusable SiC building blocks across pump sizes and compressor capacities will compress engineering cycles and simplify spares. Integration with agricultural IoT—flow, pressure, temperature, and vibration telemetry—will enable predictive maintenance and performance‑based O&M. On the financing side, lenders will increasingly require local‑condition reliability datasets—power cycling at elevated Tj, damp‑heat, salt‑spray, dust ingress—before underwriting extended warranties. Vendors that combine materials–devices–modules–equipment integration with authentic technology transfer and responsive local service will enjoy a structural advantage, enabling partial localization that reduces FX exposure and spares lead times.

자주 묻는 질문

What efficiency gains are realistic for PV–storage direct‑drive irrigation and cold storage?

Most projects realize 0.8–1.5 percentage points improvement in round‑trip efficiency and 98.5–99.0% peak converter efficiency in three‑level stages. Gains are largest in hot months when cooling overhead and irradiance variability are highest.

How does Sicarbtech protect systems from dust and salt mist common in Pakistan?

We pair sealed modules and gasketed enclosures with moisture‑resistant encapsulants, anti‑corrosion coatings, and protected fasteners. Copper‑on‑AlN/Si3N4 substrates and sintered‑silver interconnects maintain thermal and mechanical integrity when airflow is throttled to limit dust ingress.

Can SiC platforms satisfy rural feeder PQ and utility interconnection limits?

Yes. With <10 nH loops, clean Schottky recovery, tuned dV/dt, and right‑sized filters, ≤3% THD and PF near unity are typical. Faster dynamics also reduce flicker during cloud edges and load steps.

Which device voltages and topologies should we choose for pumps and compressors?

1200/1700 V devices suit 750–1000 V DC buses and three‑level converters. Motor drives use SiC six‑bridge modules for FOC/vector control. Medium‑voltage cascaded stages are considered when cable runs, insulation, or power class justify them.

Why are sintered silver and AlN/Si3N4 ceramics essential in hot, dusty environments?

They provide high thermal conductivity and fatigue resistance, extending power cycling life and preserving junction margin under thermal pulsing, fouled fins, and vibration—key to long warranties and fewer service calls.

Will higher switching frequencies make EMC more difficult?

Not when parasitics are minimized. Laminated busbars, compact loop geometries, and adjustable edge rates with Miller clamping suppress ringing at the source, allowing smaller filters and quicker compliance.

Can Sicarbtech support local assembly, screening, and service in Pakistan?

Yes. We offer technology transfer, equipment specs, operator/engineer training, ISO‑aligned quality frameworks, commissioning, and ongoing audits. Phased localization reduces FX risk and spare‑part lead times.

What reliability tests are available for Pakistan‑specific stressors?

Power cycling, temperature cycling, high‑temperature/high‑humidity, neutral salt spray, dust‑ingress cycles, and online screening. We share acceleration models and co‑author validation plans that underpin extended warranties.

How quickly can pilots be deployed and evaluated?

Pilots can be executed within weeks to a few months, depending on scope. We recommend A/B trials tracking weighted efficiency, THD/PF, step‑response, black start success, thermal maps, and maintenance intervals.

What total cost of ownership improvements are typical?

Despite higher device costs, gains in efficiency, reduced cooling energy, fewer diesel hours, smaller cabinets, and fewer maintenance interventions deliver lower TCO over 10–15 years, with stronger bankability.

운영에 적합한 선택하기

Start by mapping the realities of your site: water depth and pump curve, compressor duty cycles, ambient heat and dust, salt‑mist exposure, feeder stiffness, space and cooling constraints, and maintenance cadence. When Sicarbtech co‑designs from epitaxy and gate‑oxide reliability through module parasitics, laminated busbar geometry, active snubbers, magnetics, thermal stack, and dV/dt control, the benefits compound—higher efficiency, smoother starts, cooler and quieter operation, faster commissioning, and stronger compliance and warranty narratives. For farms, cooperatives, and agro‑industrial parks across Pakistan, SiC‑driven direct drive turns grid uncertainty into a durable productivity advantage.

전문가 상담 및 맞춤형 솔루션 받기

Whether you are specifying a new PV–storage direct‑drive system, retrofitting pump and compressor drives, or exploring localized assembly and reliability screening, Sicarbtech will translate your KPIs into a data‑backed plan with milestones for performance, compliance, and ramp. Contact our engineering team at [email protected] or +86 133 6536 0038.

문서 메타데이터

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: 2025 Pakistan agricultural electrification outlook; SiC 1200/1700 V devices; three‑level and motor direct‑drive architectures; sintered‑silver and AlN/Si3N4 substrates; laminated low‑parasitic busbars; ≤3% THD and millisecond step‑response targets; HT/HH, salt‑spray, and dust reliability; localization and technology transfer pathways; case narratives from Rahim Yar Khan, Thatta, and interior Sindh.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full‑cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.