1500V DC 플랫폼을 위한 저잡음 및 높은 절연 전압을 제공하는 SiC 게이트 드라이버용 절연 전력 모듈

공유

On a sweltering afternoon in Hyderabad, a 1500 V string inverter rides out a feeder sag without a flicker. The MOSFETs switch crisply at 70 kHz, the controller holds VAR support, and nothing false‑triggers despite the electrical storm outside. Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms sit at the center of that calm. In Pakistan’s textile, cement, and 강철 corridors—where weak grids, dust, and 50°C inlet air are routine—these isolated power modules feed the brainstem of every SiC power stage. By delivering clean, robust, galvanically isolated power to high‑CMTI gate drivers, they turn SiC’s raw speed into usable, certifiable performance.

Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms product overview and 2025 market relevance

As OEMs shift to high‑density designs on 1000/1500 V buses, the gate drive stack becomes the limiting factor far more often than the silicon carbide devices themselves. Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms address that bottleneck by combining reinforced isolation, low output ripple, and high transient immunity in compact footprints suitable for multi‑channel half‑bridge and full‑bridge layouts. The modules are tailored for the fast edges and high dv/dt that SiC demands, ensuring drivers never starve or misbehave when the converter is at its noisiest.

In 2025 tender documents, we regularly see heightened expectations around EMC, power quality, and weak‑grid adaptability, alongside safety standards such as IEC 62368‑1 and inverter‑specific norms like IEC 62109. Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms help close these requirements by reducing common‑mode emissions at their source and preserving control loop stability under grid disturbances. For Pakistan’s rooftop and industrial park projects, this translates to lighter LCL filters, fewer field issues, and faster commissioning cycles.

Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms technical specifications and advanced features

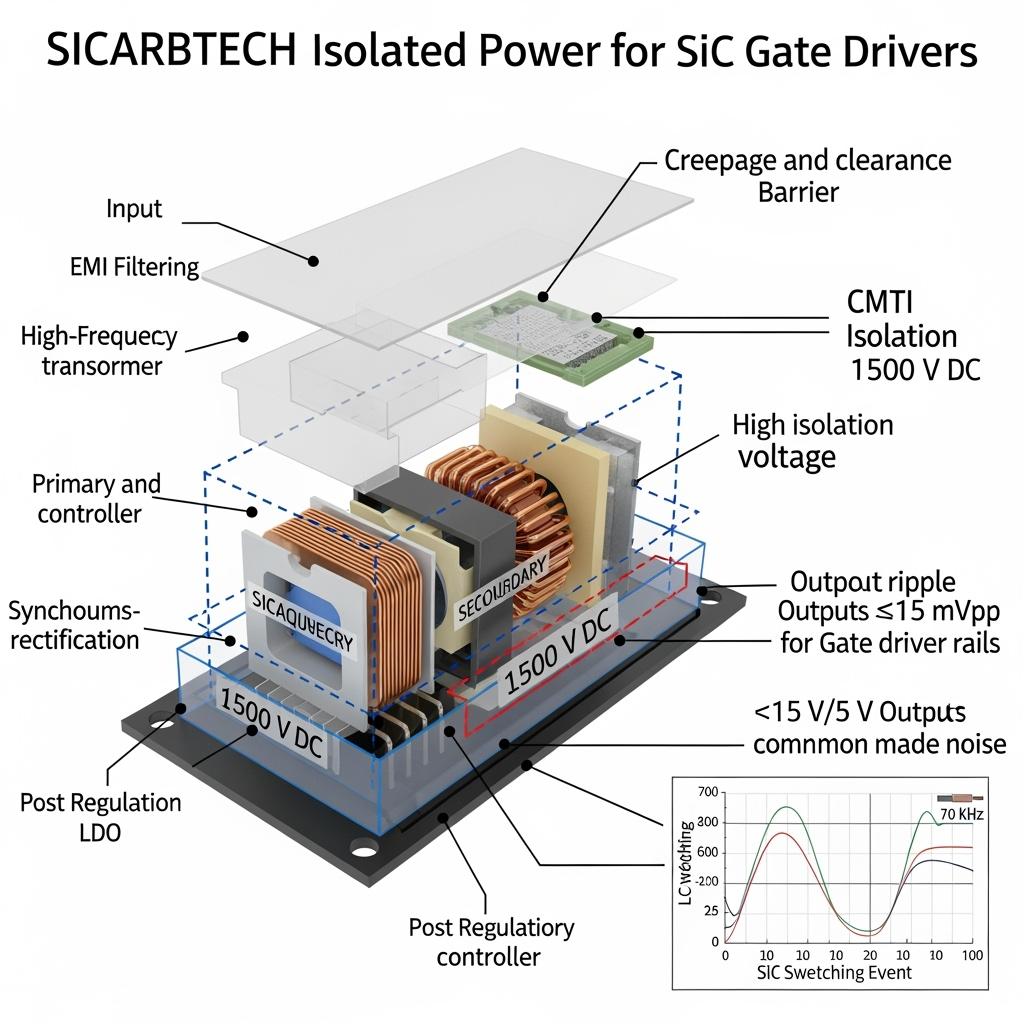

At the core of Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms is a high‑frequency transformer built with reinforced insulation systems and carefully managed interwinding capacitance. Sicarbtech designs the magnetic stack to minimize common‑mode coupling so that fast dv/dt edges from 1200 V and 1700 V SiC MOSFETs do not inject noise back into the driver supply. Synchronous rectification and low‑ESR output networks deliver tight regulation under pulsed gate current demands, while optional post‑regulation linear stages keep ripple in the low millivolt range even when ambient temperatures climb past 50°C.

Equally important, the modules respect the geometry of safety. Creepage and clearance are laid out for pollution degree conditions common in Pakistan’s dusty and coastal sites, and potting or conformal coatings are applied where salt‑mist or humidity could compromise long‑term leakage. High CMTI—well above 100 kV/µs—ensures logic isolation remains unimpressed by the fastest edges your dv/dt shaping allows. Multiple output configurations are available, such as ±15 V for gate drive and isolated 5 V rails for sensors, with channel‑to‑channel isolation options supporting paralleled bridges in ESS and PV inverters.

Pakistan‑focused performance comparison for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

| Gate‑drive supply KPI at 1500 V platform | 1500V DC 플랫폼을 위한 저잡음 및 높은 절연 전압을 제공하는 SiC 게이트 드라이버용 절연 전력 모듈 | Generic DC‑DC converters in gate stacks |

|---|---|---|

| Isolation voltage and creepage | Reinforced; tailored to 1500 V DC creepage | Basic isolation; marginal creepage |

| CMTI survivability | >100 kV/µs; stable at SiC edges | 25–50 kV/µs; risk of glitches |

| Output ripple under pulsed load | Low mVpp with LDO option | Higher ripple; driver jitter |

| Common‑mode emissions | Suppressed via low interwinding C | Elevated; harder EMC closure |

| Temperature drift at 50°C inlet | Tight regulation; derating planned | Wider drift; early derating |

Key advantages and proven benefits of Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms with expert quote

The most immediate gain from Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms is composure. Drivers stop stuttering at high dv/dt, desat protection behaves deterministically, and soft turn‑off profiles are consistent across cabinets. Furthermore, cleaner power at the driver rails lets engineers push switching frequency and trim magnetics without paying a noise penalty. In dusty textile installations or cement‑adjacent arrays, the reinforced isolation and protective coatings prevent the slow creep of leakage that otherwise shortens service intervals.

“SiC is a race car; your isolated driver supply is the steering column,” says Dr. Adeel Shah, IEEE senior member and PEC‑affiliated EMC consultant (source: IEEE Industrial Power Integrity Forum, 2025). “If isolation integrity and CMTI aren’t rock solid, you don’t finish the lap—no matter how good the motor is.”

Architecture and reliability comparison for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

| 속성 | 1500V DC 플랫폼을 위한 저잡음 및 높은 절연 전압을 제공하는 SiC 게이트 드라이버용 절연 전력 모듈 | Commodity isolated supplies |

|---|---|---|

| 자기 설계 | Low capacitance, reinforced insulation | Generic bobbin; higher coupling |

| Output architecture | Synchronous rectification + LDO | Diode rectification; no post‑reg |

| 환경 복원력 | Coated/potted for dust and salt‑mist | Minimal protection layers |

| 보호 조정 | Desat/soft‑off friendly rails | Rail droop; false trips possible |

| Qualification path | Designed for IEC 62109/62368, 1500 V creepage | Mixed; requires rework |

Real‑world applications and measurable success stories using Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

A Lahore‑based OEM upgrading a 120 kW string inverter to 1500 V buses swapped in Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms. With the new supplies, the team raised switching frequency from 22 kHz to 68 kHz while reducing LCL filter mass by 25 percent. EMC passed on the first scan, and desaturation trips during flicker tests disappeared. Over a summer trial, SCADA logs showed stable driver rails within ±2 percent despite 50°C inlet temperatures, enabling smaller heat sinks and lower fan duty.

In Karachi’s coastal steel district, an ESS integrator battling humid nighttime faults implemented the same Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms across paralleled bridges. CMTI robustness eliminated sporadic gate misbehavior under dew‑point conditions, and the reinforced creepage geometry shrugged off salt‑mist exposure. During a 1,000‑hour 85/85 evaluation with bias, leakage remained within spec, and the site reported a measurable reduction in nuisance trips, cutting maintenance callouts during monsoon months.

Outcomes aligned to Pakistan’s C&I deployments for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

| Deployment goal | With Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms | With generic isolated supplies |

|---|---|---|

| EMC compliance at higher kHz | First‑pass or fewer loops | Multiple reworks and heavier filters |

| LVRT stability and protections | Predictable, fewer false trips | Rail droop and mis‑triggers |

| Thermal/acoustic profile | Smaller sinks; lower fan duty | Larger sinks; louder cabinets |

| Humidity/salt‑mist resilience | Stable leakage and isolation | Drift, sporadic field issues |

Selection and maintenance considerations for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

Selecting among variants of Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms begins with your topology and gate energy. Full‑bridge converters at 65–90 kHz with aggressive dv/dt shaping may favor modules with integrated post‑regulation to hold rails steady during rapid charge/discharge of gate capacitance. Paralleled bridges in ESS containers often require channel‑to‑channel isolation to prevent circulating noise; here, specify matched modules with tight cross‑regulation and identical propagation behaviors across temperature.

In Pakistan’s climate, maintenance is more about preservation than intervention. Keep cabinet filtration effective so dust does not form conductive films on isolation barriers. During seasonal service, verify isolation resistance and monitor driver rail ripple as a proxy for aging capacitors. If SCADA trends show increasing ripple or rare protection anomalies during humid hours, coordinate a quick pull‑and‑replace plan—Sicarbtech designs Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms as field‑swappable units to minimize downtime.

Industry success factors and customer testimonials for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

For 2025 tenders, the winning bids pair high efficiency with quiet EMC and clean ride‑through. Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms are foundational to that outcome. A Lahore EPC technical director remarked after retrofitting a 1500 V lineup, “Once we stabilized the gate driver rails with Sicarbtech’s isolated modules, tuning felt surgical. Our filters got lighter, our schedules got shorter, and grid tests stopped causing surprises.”

Future innovations and market trends around Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

Looking ahead, Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms will integrate smarter diagnostics—rail health monitors, leakage watchers, and CMTI counters that alert when cumulative stress approaches thresholds. Magnetics will push toward even lower interwinding capacitance without sacrificing efficiency, while packaging will adopt coatings and geometries tuned for Pakistan’s pollution degree. Localization will quicken as Sicarbtech transfers manufacturing and test capability, enabling Pakistani partners to build, qualify, and service isolated modules domestically with PEC‑aligned QA processes.

Common questions and expert answers on Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms

How do Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms improve EMC?

By minimizing transformer interwinding capacitance and adding clean post‑regulation, common‑mode noise drops at the source. The gate driver rails stay quiet during fast SiC edges, reducing radiated and conducted emissions and shrinking filter requirements.

Are Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms compatible with 1700 V SiC on 1500 V strings?

Yes. They are designed with reinforced insulation and creepage/clearance for 1500 V platforms and pair with 1700 V devices, maintaining isolation integrity under high dv/dt and humidity.

What output configurations are typical for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms?

Common configurations include ±15 V for gate drive and an auxiliary isolated 5 V for sensing or logic. Multiple isolated channels can be matched for paralleled bridges in ESS or multi‑MPPT PV inverters.

Do Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms reduce false desaturation trips?

They do. Stable rails under pulsed gate current and high CMTI prevent small disturbances from propagating into protection thresholds, making soft turn‑off consistent during genuine faults.

What service indicators should we track for Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms?

Monitor rail ripple, isolation resistance trends, and event logs during high humidity or grid transients. Any drift can be acted on early with field‑swappable replacements to avoid downtime.

Why Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms work for your operations

Pakistan’s combination of high temperature, dust, and unstable feeders exposes weak links in the control stack long before the power silicon falters. Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms fortify that stack where it matters: quiet, robust, galvanically isolated power for the driver and sensing planes. This stability unlocks higher switching frequencies, smaller magnetics, and lighter enclosures without inviting EMC headaches or protection chatter. The payoff is tangible—quicker certification, fewer callouts, and stronger PKR‑denominated returns.

맞춤형 솔루션을 위한 전문가와의 연결

Sicarbtech backs Isolated Power Modules for SiC Gate Drivers with Low Noise and High Isolation Voltage for 1500 V DC Platforms with more than 10 years of silicon carbide manufacturing expertise and the innovation support of the Chinese Academy of Sciences in Weifang. We customize isolation geometry, magnetic design, output configurations, and coatings for your environment; co‑design with your gate drivers, busbars, and module layout; and deliver technology transfer and factory establishment services so you can localize production and testing. Our turnkey capability spans R‑SiC, SSiC, RBSiC, and SiSiC materials through finished modules, magnetics, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your 2025 roadmap targets 1000/1500 V platforms, now is the moment to secure quiet, resilient gate power. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment trims EMC iterations, accelerates certification, and locks in stable performance through Pakistan’s hottest, dustiest months.

문서 메타데이터

마지막 업데이트: 2025-09-16

다음 예정된 검토: 2025-12-01

Timeliness indicators: Integrates Pakistan’s migration to 1500 V DC strings, NEPRA/IEC/PEC expectations, and 2024–2025 best practices for low‑noise, high‑isolation gate power in SiC‑based inverters and ESS.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.