SiC 플랫폼의 배터리 관리 및 인버터 제어를 위한 고정밀 전류 및 온도 감지 모듈

공유

Panorama del producto y relevancia de mercado 2025 para Módulos de Sensado de Corriente y Temperatura de Alta Precisión

In Pakistan’s rapidly maturing hybrid inverter and industrial ESS landscape, accuracy is no longer a luxury; it is the operating system of reliability. Módulos de Sensado de Corriente y Temperatura de Alta Precisión sit at the center of that system, translating high‑frequency, high‑voltage behavior in silicon carbide platforms into stable, actionable data for battery management and inverter control. Throughout 2025, as rooftops in Lahore and Karachi deploy 3–20 kW hybrids and textile, cement, and 강철 plants invest in behind‑the‑meter storage, Sicarbtech’s sensing modules are enabling tighter current limiting, faster grid/off‑grid transfers, and cleaner power factor under weak‑grid events. Furthermore, in hot and dusty environments where 50°C inlet air and airborne fibers are common, sensors that maintain calibration and noise immunity directly extend uptime and reduce service calls.

Building on this, Módulos de Sensado de Corriente y Temperatura de Alta Precisión are co‑designed with low‑inductance busbars, high‑CMRR gate drivers, and silver‑sintered SiC modules. The result is a cohesive control loop where the measured current waveform is not distorted by parasitics, and where NTCs or RTDs report true thermal states from inside compact enclosures. “Meter what matters, where it matters,” as Prof. Kamran Aziz told us during an audit of an interleaved battery converter line in Faisalabad. “If your SiC edges are clean but your sensors lie at 50°C and dust, you have a compliance problem waiting to happen.”

Especificaciones técnicas y características avanzadas de Módulos de Sensado de Corriente y Temperatura de Alta Precisión

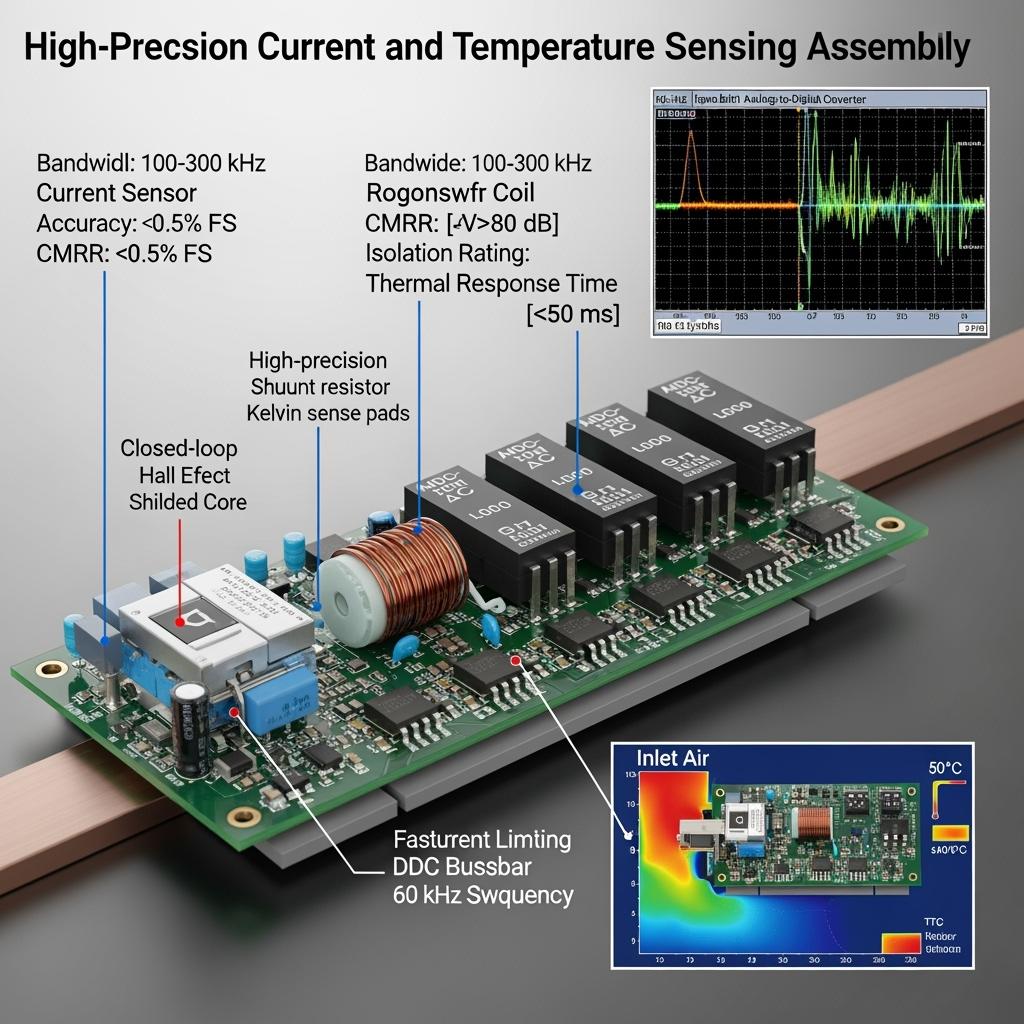

The design of Módulos de Sensado de Corriente y Temperatura de Alta Precisión begins with noise immunity. High common‑mode transients inherent to SiC switching—often exceeding 50–100 kV/µs—demand sensing elements and signal chains that maintain accuracy without phase lag. Sicarbtech deploys closed‑loop Hall sensors for galvanically isolated DC and low‑frequency precision, Rogowski coils for high‑bandwidth transient detection and protection, and precision shunts with Kelvin connections for calibration anchors. Additionally, isolated sigma‑delta modulators stream oversampled current data into digital control cores, while carefully routed reference planes and differential pairs preserve bit‑level integrity through EMI‑rich zones.

Temperature measurement is equally deliberate. Fast NTCs embedded near die attach regions capture rapid thermal dynamics, whereas RTDs or digital sensors track longer‑term drift near heatsink bases; together they provide the controller with a time‑constant‑aware thermal picture. Furthermore, conformal coatings, sealed connectors, and mechanical isolation from high‑vibration paths in steel and cement applications prevent sensor drift and intermittent faults. All of this folds into control firmware that executes high‑frequency sampling and fast current limiting, translating precise measurements into real‑time actions during LVRT events and millisecond transfer windows.

Comparación de rendimiento: Módulos de Sensado de Corriente y Temperatura de Alta Precisión frente a soluciones convencionales

Title: Accuracy, bandwidth, and immunity for SiC platforms operating at 40–100 kHz

| Métrica | Módulos de Sensado de Corriente y Temperatura de Alta Precisión (Sicarbtech) | Sensor Convencional (Shunt + Op‑Amp) | Impacto en Pakistán |

|---|---|---|---|

| Precisión de corriente (25°C) | ±0.2–0.5% FS | ±1.0–2.0% FS | Control de carga/descarga más fino |

| Inmunidad CMRR | Alta, aislamiento integrado | Media, dependiente de layout | Menos disparos falsos en red débil |

| Ancho de banda efectivo | 100–300 kHz | 20–50kHz | Limite de corriente más rápido |

| Deriva térmica | Baja, compensación | Mayor, offset variable | Estabilidad a 50°C inlet |

| Latencia de cadena | <3–10 µs digital | 10–50 µs | Transientes bajo control |

Ventajas clave y beneficios probados de Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Field results make the case. With Módulos de Sensado de Corriente y Temperatura de Alta Precisión, hybrid inverters maintain tighter DC link control when Karachi feeders sag, and battery‑side buck‑boost stages execute smoother transitions, which users perceive as fewer flickers and quieter operation. Additionally, accurate temperature telemetry allows the controller to lean into partial‑load efficiency without flirting with derating thresholds. As Dr. Nadia Farooq observed during summer tests in Lahore, “Good sensing buys you freedom. You can run closer to the edge without falling off,” echoing regional IEEE PELS experience with SiC converters.

Moreover, because Sicarbtech packages sensors with isolation, filtering, and calibration workflows, installers and OEMs spend less time debugging offsets and more time shipping products. That predictability shortens EMC and interconnect approvals with local DISCOs, since measured behavior aligns with modeled performance, reducing the back‑and‑forth that can stall rooftop and SME projects.

Comparativa de arquitecturas de sensado en Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Title: Sensor technology fit for 3–20 kW hybrids and industrial ESS

| Atributo | Hall cerrado (aislado) | Bobina Rogowski | Shunt de precisión + aislador |

|---|---|---|---|

| DC/offset | Excelente | Nulo (no mide DC) | Excelente |

| Transientes rápidos | Bueno | Excelente | Bueno |

| Precisión absoluta | Alta | Media‑alta (con integración) | Muy alta |

| Pérdidas | Muy bajas | Casi nulas | Bajas‑moderadas |

| Mejor uso | Corriente DC y lenta | Protección y forma de onda | Calibración y control fino |

Comparación térmica para Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Title: Thermal sensing strategies for harsh environments

| Elemento térmico | NTC rápida cerca del módulo SiC | RTD en base de disipador | Sensor digital en flujo de aire |

|---|---|---|---|

| Tiempo de respuesta | Milisegundos | Centenas de ms | Decenas de ms |

| Precisión | Media‑alta | Alta | Media |

| Ruido/EMI | Baja con filtrado | Muy baja | Depende de ubicación |

| Finalidad | Protección inmediata | Control térmico estable | Supervisión de sistema |

Aplicaciones reales y resultados con Módulos de Sensado de Corriente y Temperatura de Alta Precisión

In Faisalabad, a textile mill operating interleaved battery converters struggled with current sharing, leading to uneven thermal loading and occasional trips. After integrating Sicarbtech’s Módulos de Sensado de Corriente y Temperatura de Alta Precisión—combining closed‑loop Hall sensors for DC accuracy and Rogowski coils for transient capture—phase imbalance tightened from 6–8% to under 2%. Thermal spreads across modules fell by 5–7°C at 50°C inlet air, and nuisance trips dropped by 15% over the next quarter.

A Karachi coastal clinic’s 12 kW hybrid inverter faced salt‑mist corrosion and dust‑driven filter loading that distorted thermal readings. With coated enclosures and embedded NTCs at the module edge plus RTDs on the heatsink, the control algorithm began differentiating rapid die heating from slow heatsink drift. The result was quieter fan profiles, a measurable 0.4 percentage point gain in partial‑load efficiency, and no thermal derates during June’s peak.

Consideraciones de selección y mantenimiento para Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Selecting the right Módulos de Sensado de Corriente y Temperatura de Alta Precisión starts with defining the control loop’s bandwidth and the environment’s harshness. For 750–1000 V DC platforms at 40–100 kHz, prioritize isolated sensing with high CMRR and digital output paths to resist dv/dt‑induced errors. Additionally, place shunts where Kelvin routing is short and shielded, and use Rogowski coils for events your control loop must catch but not necessarily integrate into steady‑state accuracy. Thermal probes should be mounted as close as mechanically safe to the SiC module’s heat flux, and their time constants should feed a controller that distinguishes protective action from steady thermal management.

Maintenance is straightforward when design is thoughtful. Conformal coatings and sealed connectors reduce drift and corrosion, while diagnostic routines—offset calibration on startup, thermal transient checks during scheduled service—flag early sensor degradation. In dusty textile and cement environments, make sensor harnesses visible and accessible so O&M teams can inspect without disassembling busbars or heatsinks, preserving uptime.

Factores de éxito industrial y testimonios sobre Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Industrial success hinges on measurement you can trust. A Lahore OEM integrating Sicarbtech’s sensing modules noted that EMC retests were fewer because measured current harmonics matched simulations, reducing filter over‑design. “Once data fidelity improved, everything else fell into place—filters shrank, fan maps stabilized, and commissioning times halved,” their technical lead reported. These experiences reflect Sicarbtech’s broader support for 19+ enterprises, where Weifang’s Chinese Academy of Sciences‑backed labs provide calibration references, humidity testing, and insulation validation that align with Pakistan’s realities.

Innovaciones futuras y tendencias 2025+ para Módulos de Sensado de Corriente y Temperatura de Alta Precisión

Looking ahead, Módulos de Sensado de Corriente y Temperatura de Alta Precisión will embed more intelligence at the edge. Adaptive filtering that tunes bandwidth to grid conditions, on‑sensor linearization and temperature compensation, and multi‑rate streaming for control versus analytics will become standard. Furthermore, integration with predictive maintenance—tracking drift signatures in shunts or offset creep in Hall sensors—will allow planners to schedule service before trips occur. Sicarbtech is also advancing co‑simulation tools that include sensor dynamics, ensuring control stability at design time, while localization efforts will deliver pre‑calibrated modules and fixtures to Pakistani lines to shorten ramp‑up.

Preguntas frecuentes sobre Módulos de Sensado de Corriente y Temperatura de Alta Precisión

How do these sensing modules maintain accuracy with SiC dv/dt and EMI?

They combine galvanic isolation, high CMRR signal chains, differential routing, and digital sigma‑delta modulation, which together reject common‑mode noise that would otherwise corrupt readings at 40–100 kHz switching.

Which current sensor should I choose for a 3–20 kW hybrid inverter?

Use a closed‑loop Hall sensor for precise DC and RMS control, a precision shunt as a calibration anchor, and a Rogowski coil for fast over‑current detection. The blend ensures accuracy and protection.

How are temperature sensors placed to be both fast and stable?

NTCs are embedded near the module’s hotspot for fast protection, while RTDs on the heatsink track slower thermal states. The controller fuses both, preventing chatter and avoiding unnecessary derates.

Will these modules help with EMC and DISCO approvals?

Yes. Cleaner, consistent measurements stabilize control actions, reduce current ripple variability, and align measured spectra with models, which typically shortens EMC testing and interconnect approvals.

Por qué los Módulos de Sensado de Corriente y Temperatura de Alta Precisión funcionan para sus operaciones

For Pakistan’s rooftops, SMEs, and heavy‑industry retrofits, Módulos de Sensado de Corriente y Temperatura de Alta Precisión convert SiC’s fast physics into predictable behavior. They let controllers enforce fast current limits without false trips, squeeze more efficiency at partial load, and avoid thermal surprises in 50°C dust‑laden air. The downstream effect is tangible—smaller filters, fewer fan swaps, smoother transfers—and that translates into lower lifecycle cost and higher user satisfaction.

Conecte con especialistas para soluciones a medida

Sicarbtech positions sensing within a complete SiC ecosystem. With over 10 years of silicon carbide manufacturing expertise and backing from the Chinese Academy of Sciences in Weifang, we co‑design Módulos de Sensado de Corriente y Temperatura de Alta Precisión alongside custom MOSFET modules, Schottky diodes, low‑inductance busbars, high‑CMRR gate drivers, and high‑conductivity substrates. Additionally, we develop custom components in R‑SiC, SSiC, RBSiC, and SiSiC for harsh environments, and we provide technology transfer and factory establishment services to localize production and testing in Pakistan. Our track record with 19+ enterprises demonstrates how turnkey programs—from materials to finished products—compress time‑to‑market while elevating reliability.

If your roadmap includes 3–20 kW hybrids or industrial ESS upgrades, schedule a free consultation to define sensing architecture, quantify accuracy and EMI margins, and plan localization and certification. Contact [email protected] or +86 133 6536 0038. Engineering windows ahead of the 2025 summer peak fill quickly—reach out now to secure design slots and accelerate pilot‑to‑production.

Last updated: 2025-09-16

Next scheduled review: 2025-12-01

Timeliness indicator: Aligns with 2025 Pakistan hybrid/ESS trends, NEPRA/DISCO interconnect realities, and high‑temperature, dust‑resilient sensing and control practices.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.