열악한 환경을 위한 와류 최적화 및 방진 코팅이 적용된 고효율 공랭식 방열판 어셈블리

공유

On a windy June afternoon above a textile mill in Faisalabad, the rooftop string inverters hum at full output while the ambient edges past 48–50°C. The fans aren’t screaming, and the heat sinks aren’t caked with lint. High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments are doing exactly what they were designed to do: move heat efficiently with minimal airflow, keep fins clean, and protect performance in the dust and grit that define Pakistan’s industrial rooftops. Sicarbtech built these assemblies to be the aerodynamic counterpart to fast, cool silicon carbide switching—a thermal system that sustains density without inviting acoustic, maintenance, or derating penalties.

High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments product overview and 2025 market relevance

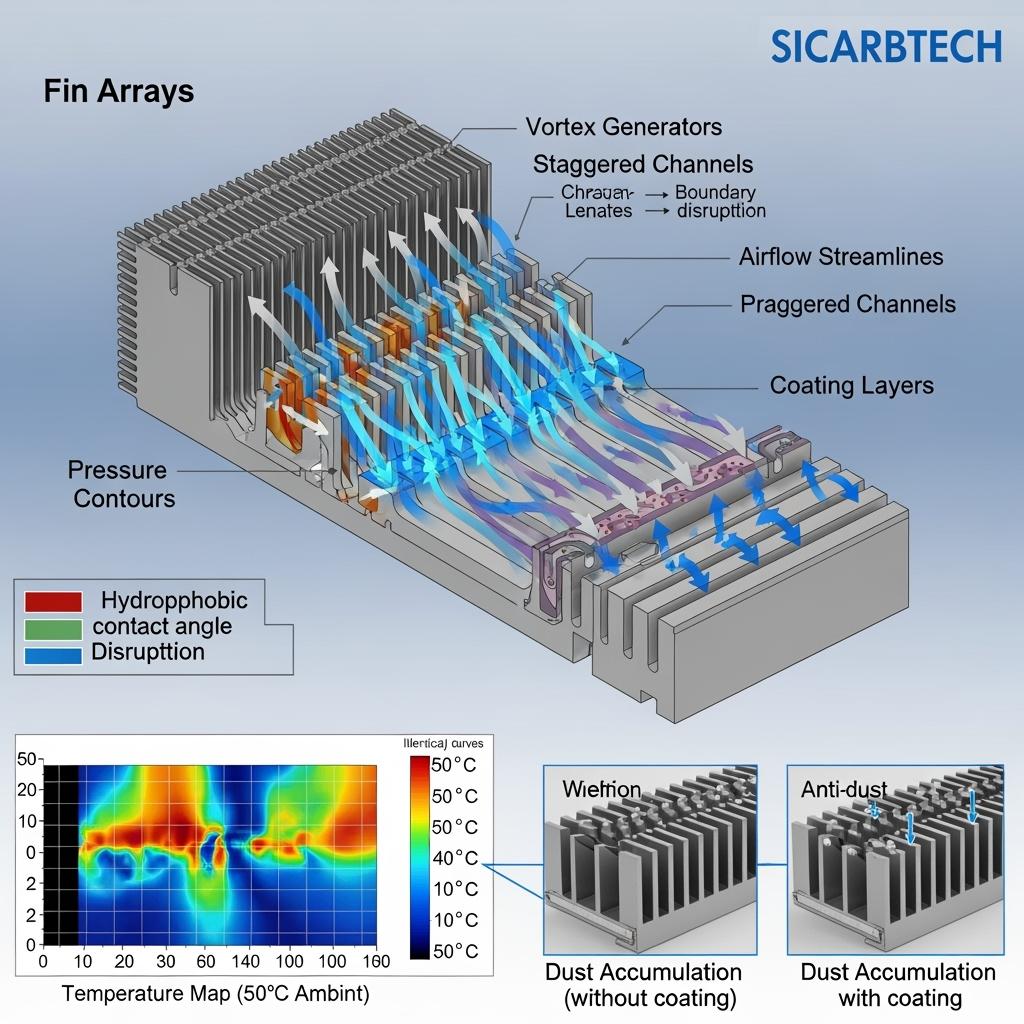

As 1000/1500 V DC platforms take over Pakistan’s C&I PV and ESS projects, inverters are running at 40–100 kHz with smaller magnetics and tighter cabinets. That architecture saves weight and cost, but it also concentrates heat. High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments respond with two decisive innovations. First, fin geometries are shaped to generate controlled micro‑vortices that break boundary layers and increase convective coefficients at modest pressure drops. Second, the fins receive hydrophobic, oleophobic anti‑dust coatings that prevent particle adhesion and reduce the “dust‑cake” that usually chokes thermal performance in cement and textile corridors.

In 2025 tenders, EPCs increasingly quantify thermal headroom alongside efficiency and EMC. High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments provide measurable gains: smaller sinks for the same load, lower fan duty for the same cabinet temperature, and slower degradation when filters age. Because Sicarbtech co‑designs the heat sink with SiC module layout, stacked busbars, and enclosure airflow paths, OEMs can hold full power later into hot afternoons and keep acoustics within strict rooftop limits.

High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments technical specifications and advanced features

The geometry behind High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments starts with fin profiles that encourage gentle vortex shedding. Chevron leading edges and micro‑dimples periodically reset the boundary layer, while tapered channels maintain velocity even as cross‑section expands around components. The result is a higher heat transfer coefficient at the same volumetric flow, which, in practice, allows smaller heat sinks or slower fans—both of which matter on rooftops where acoustic caps and structural limits collide.

Sicarbtech pairs these fins with anti‑dust coatings derived from fluoropolymer and ceramic composites. The coatings raise surface energy barriers so dust, lint, and salt crystals are less likely to adhere or “bake on” under heat. In accelerated tests simulating Lahore and Karachi conditions, coated fins accumulate less mass for the same exposure and, crucially, shed what does collect during normal fan ramp cycles or seasonal cleaning. Mechanical details matter as well. The assemblies use high‑conductivity baseplates mated to AlN/SiC composite substrates via silver‑sinter interfaces, minimizing thermal resistance from die to fin. Shroud geometry prevents recirculation and short‑circuiting of hot air, and fan selection is tuned to the fin impedance curve so that energy spent on airflow turns directly into heat removal.

Pakistan‑focused thermal and maintenance performance comparison for High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

| Thermal/O&M KPI in rooftop PV/ESS | 열악한 환경을 위한 와류 최적화 및 방진 코팅이 적용된 고효율 공랭식 방열판 어셈블리 | Conventional straight‑fin sinks |

|---|---|---|

| Convective coefficient at equal CFM | Higher via boundary‑layer disruption | Lower; laminar streaking |

| Fan duty at 50°C inlet (same ΔT) | Reduced by 20–40% | Higher; acoustic penalty |

| Dust accumulation over 500 h | 30–60% less mass; easier shedding | Heavy cake; baked deposits |

| Thermal degradation after 3 months | Minimal; ΔT rise small | Significant; ΔT rise notable |

| Cleaning interval | Extended; seasonal | Frequent; monthly in dust peaks |

Key advantages and proven benefits of High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments with expert quote

The immediate effect of High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments is a quieter, cooler cabinet with less maintenance. Because boundary layers are actively managed, the sinks deliver more watts per liter of aluminum, and because the coatings resist adhesion, that performance persists in real dust. These two properties allow string inverters to keep full power later into the day and help EPCs meet strict acoustic constraints around rooftops, hospitals, or residential adjacencies.

“Air is free, but pressure drop isn’t,” observes Engr. Farhan Qureshi, PEC‑licensed thermal design consultant and IEEE member (source: IEEE Thermal Management Colloquium, 2025). “When vortex geometry turns modest airflow into high heat flux without clogging, you get reliable density—the kind you can bank on through Pakistan’s summer.”

Aerodynamics, coatings, and system impact comparison for High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

| 속성 | 열악한 환경을 위한 와류 최적화 및 방진 코팅이 적용된 고효율 공랭식 방열판 어셈블리 | Generic extruded fins |

|---|---|---|

| Fin geometry | Chevron/serrated with dimples; tapered channels | Straight fins; uniform channels |

| Shroud/duct design | Anti‑recirculation, matched to fan curve | Minimal; recirculation risk |

| Surface treatment | Hydrophobic/oleophobic anti‑dust | Bare anodized or raw |

| Thermal path integration | Sintered base + AlN/SiC substrate | Mixed interfaces; higher Rth |

| Acoustic outcome | Lower SPL at same load | Higher SPL for same ΔT |

Real‑world applications and measurable success stories using High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

A Lahore OEM updating a 150 kW, 1500 V string inverter introduced High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments alongside Sicarbtech SiC bridge modules. Field trials across May–July showed a 35–40 percent reduction in average fan duty to maintain identical junction temperatures, with cabinet sound pressure levels dropping by 3–5 dBA. Over a 60‑day dust season, thermography revealed less than 2°C drift in heat sink surface temperatures, whereas the previous design saw 6–8°C drift and required mid‑season cleaning.

In Karachi’s coastal 강철 district, an ESS integrator faced salt‑mist and abrasive dust that historically forced monthly shutdowns for cleaning. After deploying High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments, the maintenance interval extended to the seasonal schedule. Inspectors noted a powdery residue that brushed off without solvent, and the system sustained full‑load operation during monsoon humidity with no derates. Energy logs attributed a 0.3–0.4 percentage point rise in European efficiency mostly to reduced fan power and cooler silicon carbide junctions.

Field outcomes in Pakistan’s harsh sites for High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

| Deployment goal | With High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments | Legacy sinks |

|---|---|---|

| Midday derating at 50°C | Eliminated in trial period | Frequent derates |

| Acoustic compliance | Passed with margin | Borderline; site complaints |

| Maintenance downtime | Seasonal cleaning only | Monthly interruptions |

| Annual OPEX linked to cooling | Lower due to fan and labor | Higher due to cleaning and wear |

Selection and maintenance considerations for High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

Choosing the right variant of High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments begins with your thermal design point and airflow budget. If your SiC topology runs at 60–90 kHz with concentrated losses at the inverter bridge arms, fin taper and chevron density should be set to maintain local velocity over hot components. For 50–250 kW string inverters, Sicarbtech typically maps the module stack, busbar shadows, and enclosure geometry, then tailors vortex features to avoid acoustic tones while maximizing heat transfer. Coating selection is tuned to site chemistry—textile lint differs from cement dust and salt‑mist in adhesion behavior—so trial coupons in local air can inform the final stack.

In operation, High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments are forgiving. Filters still matter, but the coating extends effective intervals and the geometry resists clogging. A quick quarterly inspection with a soft brush or low‑pressure air often restores a like‑new surface. SCADA trending of fan duty at fixed power is a simple proxy for coating health; a slow upward drift suggests it’s time for a gentle clean rather than a service call. Because the assemblies are designed with smooth edges and sealed joints, residue avoids trapping in crevices, making seasonal maintenance straightforward.

Industry success factors and customer testimonials for High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

Bankability in 2025 depends on inverters that stay quiet, clean, and cool in real air. High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments are emerging as a differentiator in Pakistan’s rooftop competitions. A Lahore EPC technical director noted after a series launch, “We pulled out one fan per cabinet and still passed thermal with margin. The dust just wouldn’t stick the way it used to, and commissioning teams stopped carrying spare blowers.”

Future innovations and market trends around High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

Looking ahead, High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments will incorporate micro‑textures that tune vortex scale to lower Reynolds numbers, extracting more performance from quieter fans. Coatings will evolve with nano‑structured layers that repel both water and oil‑based aerosols, improving longevity in mixed industrial air. Sicarbtech’s roadmap includes embedded temperature strips and differential pressure taps in the shroud, allowing predictive cleaning cues without external sensors. Localization will accelerate as extrusion, machining, coating, and QA recipes are transferred to Pakistani partners, shortening lead times and stabilizing PKR‑denominated costs.

Common questions and expert answers on High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments

How do High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments improve thermal performance without increasing noise?

By using chevron and dimple features to periodically disrupt boundary layers, the assemblies raise heat transfer at modest pressure drops. Fan curves are matched to the fin impedance to avoid tonal noise, delivering more watts of cooling per decibel.

Will High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments really reduce cleaning frequency in cement and textile air?

Yes. The anti‑dust coatings decrease adhesion so that particles are less likely to bake onto hot fins. Field results show extended intervals, with most residue removable by light brushing or low‑pressure air during seasonal service.

Are High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments compatible with 1500 V inverter layouts and stacked busbars?

They are designed around module and busbar geometry, with shrouds preventing hot‑air recirculation into HV terminals. Sicarbtech co‑optimizes fin placement to avoid flow shadows from stacked busbars and to protect insulation margins.

What efficiency gains can we expect from adopting High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments?

Typical European efficiency rises by 0.2–0.4 percentage points due to reduced fan power and cooler junctions, complementing SiC’s inherent switching and conduction advantages.

How durable are the anti‑dust coatings on High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments?

The coatings are engineered for outdoor thermal cycling and abrasion from airflow. In accelerated aging and 85/85 tests, surface properties remain effective, and field trials show stable performance through monsoon seasons.

Why High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments work for your operations

Pakistan’s climate is a stress test for any cooling strategy. High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments turn that test into a design constraint you can master. By extracting higher heat flux from the same airflow and keeping fins clean in real‑world dust, they sustain the density that SiC enables. Cabinets get lighter and quieter, certification loops get shorter, and peak output holds through the hottest, dustiest weeks, improving lifetime energy yield and PKR‑denominated returns.

맞춤형 솔루션을 위한 전문가와의 연결

Sicarbtech brings more than 10 years of silicon carbide manufacturing expertise—and the innovation backing of the Chinese Academy of Sciences in Weifang—to every deployment of High‑Efficiency Air‑Cooled Heat Sink Assemblies with Vortex Optimization and Anti‑Dust Coatings for Harsh Environments. We co‑design fin geometry, shrouds, and coatings around your module layout and airflow; integrate AlN/SiC substrates and silver‑sinter interfaces for the lowest thermal resistance; and deliver technology transfer and factory establishment services so you can localize extrusion, coating, and QA. Our turnkey solutions span R‑SiC, SSiC, RBSiC, and SiSiC materials to finished modules, magnetics, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your 2025 roadmap targets 1000/1500 V platforms and rooftop or industrial park deployments, now is the time to lock in cooling that thrives in Pakistan’s air. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment trims OPEX, accelerates certification, and keeps your inverters at nameplate when it matters most.

문서 메타데이터

마지막 업데이트: 2025-09-16

다음 예정된 검토: 2025-12-01

Timeliness indicators: Incorporates Pakistan’s shift to 1500 V DC, NEPRA/IEC/PEC expectations, and 2024–2025 field data on vortex‑optimized, anti‑dust air‑cooled heat sinks sustaining full power and low acoustics in dusty, high‑temperature environments.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.