전력 모듈 열 확산을 위한 고열 전도성 절연 세라믹 기판 AlN/SiC 복합재

공유

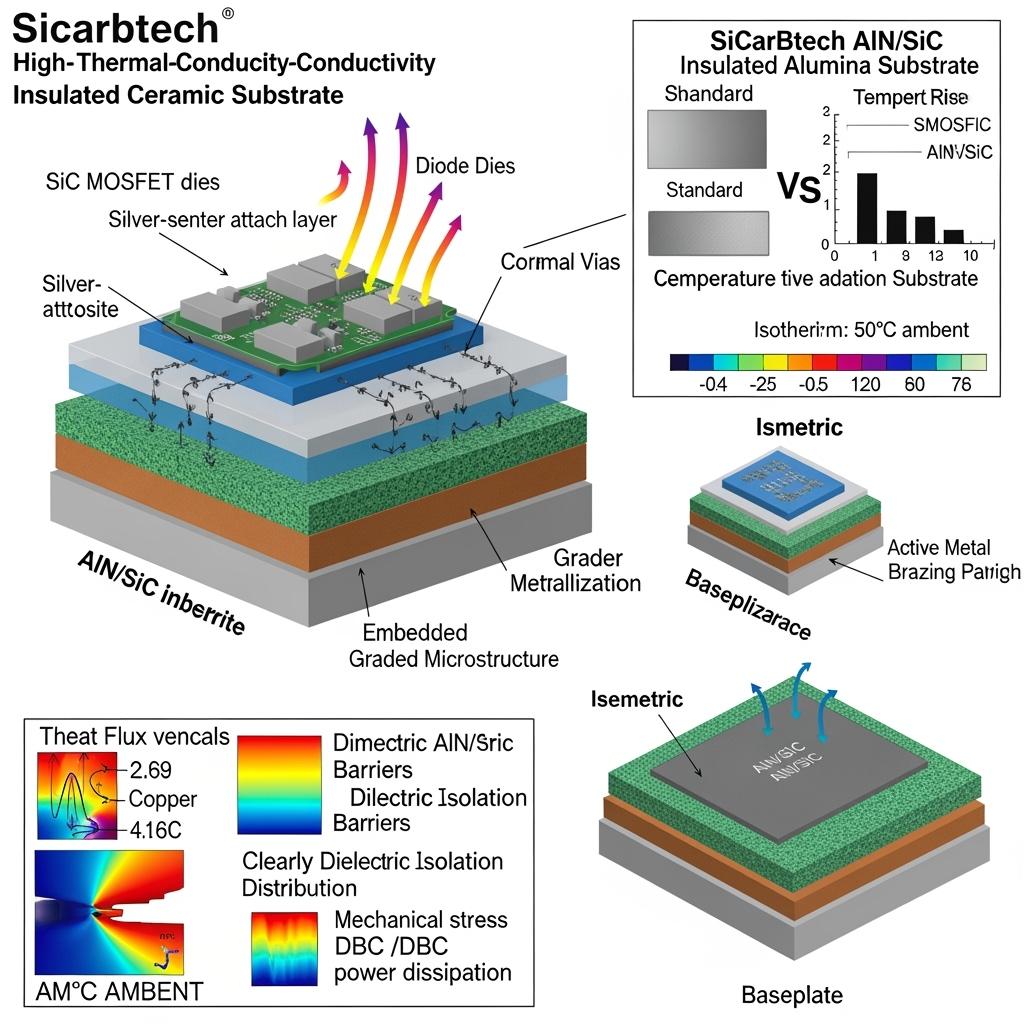

On a rooftop in Faisalabad, a string inverter pushes full power through a dusty, 50°C afternoon. The fans run slower than you’d expect, and the cabinet stays quiet. The unseen hero is the thermal backbone beneath each module: High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading. In Pakistan’s textile, cement, and 강철 corridors, where ambient heat and particulate stress conspire against electronics, Sicarbtech’s composite substrates spread heat rapidly while holding high isolation voltage, making high‑density SiC practical without a penalty in reliability.

High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading product overview and 2025 market relevance

As the market moves decisively to 1000/1500 V DC platforms, inverter designers in Pakistan are asked to fit more power into smaller, outdoor‑rated enclosures. High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading address that requirement by combining aluminum nitride’s conductivity with silicon carbide’s mechanical robustness. The composite conducts heat away from SiC dies quickly, reduces hot‑spot gradients under pulsed loads, and maintains dielectric strength under humidity and dust exposure. For string inverters between 50 and 250 kW, this translates into smaller heat sinks, fewer fans, lower acoustics, and steadier thermal margins when the grid flickers.

In 2025 tenders, EPCs increasingly value thermal evidence alongside efficiency and EMC. High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading provide that evidence through lower junction‑to‑sink resistance and improved power cycling life—two metrics that determine whether a plant derates in June or holds its rating until sunset. Because Sicarbtech pairs materials with process know‑how—silver sintering, vacuum brazing, and terminal passivation—Pakistani OEMs can localize module builds while maintaining bankable reliability.

High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading technical specifications and advanced features

The foundation of High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading is a ceramic architecture that prioritizes heat flow without compromising insulation. Sicarbtech’s AlN/SiC composites routinely deliver thermal conductivity in the 170–220 W/m·K class, with dielectric strength engineered for 1000/1500 V DC isolation needs. The composite’s coefficient of thermal expansion is tuned to sit between copper and SiC, reducing thermo‑mechanical stress at die attach interfaces during power cycling. Metallization options include DBC and AMB copper, enabling low‑resistance current spread while preserving robust adhesion through humidity and salt‑mist exposure.

On the process side, High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading are paired with silver sintering to minimize voiding and thermal resistance. Surface treatments enhance wetting and bondline integrity; controlled roughness supports reliable sinter interfaces at production scale. For Pakistan’s harsh sites, conformal coatings and edge passivation on the ceramic/metallization stack maintain leakage stability under 85/85 stress and salt‑fog. The result is a substrate that not only spreads heat efficiently, but also remains electrically quiet and mechanically resilient over years of dust‑laden operation.

Thermal and mechanical performance comparison for High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

| Substrate KPI in SiC modules | 전력 모듈 열 확산을 위한 고열 전도성 절연 세라믹 기판 AlN/SiC 복합재 | Standard Al2O3 DBC | Pure AlN DBC |

|---|---|---|---|

| Thermal conductivity (W/m·K) | 170–220 (application dependent) | 20–30 | 150–180 |

| CTE alignment to SiC/Cu | Tuned composite; reduced stress | Mismatch higher | Good, but brittle |

| Dielectric strength | High; 1000/1500 V isolation | 높음 | 높음 |

| 전력 사이클링 견고성 | Excellent with sinter attach | 보통 | Good but brittle fracture risk |

| Cost/performance ratio | Optimized for PV/ESS | Lowest cost, lowest thermal | Higher cost, high thermal |

Key advantages and proven benefits of High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading with expert quote

The first‑order benefit of High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading is cooler junctions at the same output—or the same junctions at higher density. Because the composite spreads heat efficiently, hot spots are tamed and airflow demands fall, letting designers reduce fan count and heat sink volume. Additionally, the composite’s mechanical behavior under cycling reduces microcrack propagation, extending module life in rooftop cabinets where day‑night swings are steep.

“Thermal pathways decide whether your inverter is a midday sprinter or an all‑day runner,” explains Dr. Huma Rashid, a PEC‑licensed materials specialist and IEEE member (source: PEC Thermal Materials Clinic, 2025). “AlN/SiC composites give you AlN‑class conductivity with friendlier mechanics, which is exactly what high‑density SiC needs in outdoor enclosures.”

Heat spreading and system impact comparison for High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

| System outcome | 전력 모듈 열 확산을 위한 고열 전도성 절연 세라믹 기판 AlN/SiC 복합재 | Conventional Al2O3 |

|---|---|---|

| Junction‑to‑sink thermal resistance | Lower; tighter ΔTj under load | Higher; larger ΔTj |

| Heat sink and fan sizing | 30–50% reduction feasible | Larger sinks; higher airflow |

| Acoustic/emissions side‑effects | Quieter; fewer fan harmonics | Louder cabinets |

| Power cycling life | Longer due to reduced stress | Shorter; bond fatigue risk |

| Summer derating in Pakistan | Reduced or eliminated | Frequent at midday |

Real‑world applications and measurable success stories using High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

A Lahore OEM shifted a 150 kW inverter to High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading alongside silver‑sinter die attach. Thermal models predicted a 10–15°C junction temperature drop at full load; field data matched within a degree. The design team removed one fan per cabinet and trimmed the heat sink by 38 percent, which in turn reduced rooftop acoustics below site thresholds. European efficiency nudged up by 0.4 percentage points, driven by lower fan power and improved switching loss at cooler junctions, while midday derating vanished during a two‑month heat wave.

In southern Punjab, an ESS integrator battling night‑day cycling stress adopted High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading across paralleled inverters. Power cycling tests showed a 2× improvement in cycles to specified ΔTj compared to alumina‑based builds. Maintenance teams reported extended filter cleaning intervals because slower fans pulled less dust through the cabinet, and the lower thermal gradient reduced dust‑bake on fins, making seasonal cleaning more effective.

Deployment outcomes for Pakistan’s PV/ESS using High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

| Deployment goal | With High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading | With Al2O3 substrates |

|---|---|---|

| Midday power at 50°C inlet | Sustained at nameplate | Periodic derating |

| Cabinet mass and logistics | Lighter; fewer fans, smaller sinks | Heavier; more hardware |

| O&M effort | Lower; longer intervals | Higher; frequent fan/filter work |

| Warranty risk | Reduced via cooler junctions | Higher due to thermal stress |

Selection and maintenance considerations for High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

Selecting among High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading begins with your thermal budget and switching strategy. For 1500 V rooftop platforms running 50–80 kHz, the composite’s conductivity allows you to prioritize smaller magnetics without overtaxing airflow. Align substrate thickness and copper weight to balance current distribution with mechanical compliance; Sicarbtech typically recommends AMB copper for heavier current spreads in 200+ kW cabinets, while DBC suits compact bridge‑arm modules where low profile is vital. Integrating silver sintering under SiC dies closes the loop, minimizing bondline resistance and enhancing cycling life.

From a maintenance standpoint, the substrate itself is passive, but its benefits amplify when the enclosure stays clean. High‑protection‑level airflow designs keep dust off fins, preserving the temperature headroom the composite creates. Annual thermography should verify uniform heat spreading; any emerging hotspots can signal TIM aging or fan degradation long before performance drops. In coastal and cement corridors, periodic checks of conformal coating integrity along substrate edges help maintain leakage stability throughout monsoon humidity.

Industry success factors and customer testimonials for High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

Bankability in 2025 Pakistan hinges on inverters that do not flinch in summer. High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading enable exactly that. A Karachi EPC technical manager captured the shift after a platform refresh: “We cut a third of the heat sink and lost a fan, then sailed through thermal and acoustic tests. The field stayed quiet through monsoon—no surprise trips, no hot cabinets.”

Future innovations and market trends around High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

Looking ahead, High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading will evolve toward even higher thermal conductivity with micro‑architectures that steer heat laterally toward baseplate edges. Expect tougher metallization systems that resist corrosion in salt‑mist and alkaline dust, along with embedded temperature sensing layers for tighter control. Sicarbtech’s roadmap includes localized manufacturing kits—ceramic prep, copper bonding, sinter profiles, and PD screening—so Pakistani partners can build and qualify substrates domestically with PEC‑aligned QA, reducing lead times and currency risk.

Common questions and expert answers on High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading

How do High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading reduce derating?

By lowering thermal resistance and spreading heat laterally, the composite keeps junction temperature below protection thresholds at high ambient, allowing full‑power operation longer into hot afternoons.

Are High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading compatible with silver sintering?

Yes. Surface chemistry and roughness are tailored for sinter attach, reducing voids and improving cycling life, especially critical for SiC modules on 1500 V platforms.

What isolation and creepage options exist for High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading?

Thickness and edge passivation can be specified to meet 1000/1500 V DC requirements under Pakistan’s pollution degrees, with conformal coatings to stabilize leakage in humidity and dust.

Do High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading help with acoustics?

Indirectly, yes. Cooler modules need less airflow, allowing lower fan speeds and quieter rooftops, which eases industrial site constraints.

How do these substrates compare economically to pure AlN?

They offer AlN‑class thermal performance with improved mechanical resilience and a more favorable cost/performance balance for PV and ESS applications.

Why High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading work for your operations

Pakistan’s climate punishes any thermal weakness. High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading neutralize that risk by pulling heat away from SiC dies efficiently and evenly, enabling smaller heat sinks and lower fan duty without sacrificing insulation or reliability. The practical outcomes—lower cabinet weight, quieter operation, fewer derates, and faster certification—compound into stronger PKR‑denominated returns for EPCs and OEMs alike.

맞춤형 솔루션을 위한 전문가와의 연결

Sicarbtech delivers High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading with over 10 years of silicon carbide manufacturing expertise and the innovation backing of the Chinese Academy of Sciences in Weifang. We co‑design the substrate stack, copper bonding, and sinter interfaces; integrate with your module geometry and busbars; and transfer the full process through technology transfer and factory establishment services. Our turnkey scope spans R‑SiC, SSiC, RBSiC, and SiSiC materials to finished modules, magnetics, and production‑line reliability equipment, validated with 19+ enterprise collaborations.

If your 2025 roadmap targets 1000/1500 V platforms, now is the time to anchor thermal performance with High‑Thermal‑Conductivity Insulated Ceramic Substrates AlN/SiC Composites for Power Module Heat Spreading. Arrange a free consultation at [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment shortens certification, trims O&M, and secures stable output through Pakistan’s hottest, dustiest months.

문서 메타데이터

마지막 업데이트: 2025-09-16

다음 예정된 검토: 2025-12-01

Timeliness indicators: Reflects Pakistan’s migration to 1500 V DC strings, NEPRA/IEC/PEC expectations, and 2024–2025 field data linking AlN/SiC composite substrates to reduced derating, lighter thermal hardware, and improved cycling life in PV and ESS inverters.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.