개재물 정제 및 청정 강철 주조를 위한 탄소화규소-칼슘 복합 탈산제

공유

Pakistani steel producers are asking harder questions in 2025: how to keep silicon pickup predictable as scrap ratios rise, how to prevent alumina build-up in long casting sequences, and how to comply with cleaner shop-floor practices without sacrificing throughput. The Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean 철강 Casting answers these questions by combining the kinetic advantages of silicon carbide with the inclusion-modifying power of calcium. Sicarbtech, drawing on its Weifang manufacturing base and Chinese Academy of Sciences collaboration, designed this composite to dissolve decisively at the stream or in the early ladle stage, convert aggressive alumina clusters into softer, floatable calcium aluminates, and deliver the dual deoxidation pathway that shortens refining windows. In Pakistan’s cost and energy landscape, this is a practical lever: one material that deoxidizes, adds silicon, tunes inclusion morphology, and reduces casting risk.

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting product overview and 2025 market relevance

The priority in Pakistani EAF and converter shops is clean steel casting with fewer nozzle interventions. Energy volatility and currency effects on imported alloys put a premium on absorption and stability, while PEQS-aligned dust controls favor enclosed, low-powdering additions. The Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting was built for this environment. It starts with carbothermal reduction to produce high-activity SiC, then uses high-purity classification to cap S and P at low thresholds. A thin, engineered coating guards against moisture during Karachi-to-Punjab logistics and stabilizes dissolution once the granule hits turbulence. The integrated calcium fraction serves a precise purpose: it reacts with alumina to form deformable calcium aluminates that detach and rise, reducing clogging tendencies and smoothing sequences. As Engr. R. Khan, a Lahore-based casting metallurgist, observes, “The streamlined heats are the ones where inclusions stop behaving like glue. Calcium-enabled SiC gets you there while keeping the silicon curve on target” (Metallurgy Pakistan Review, 2024).

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting technical specifications and advanced features

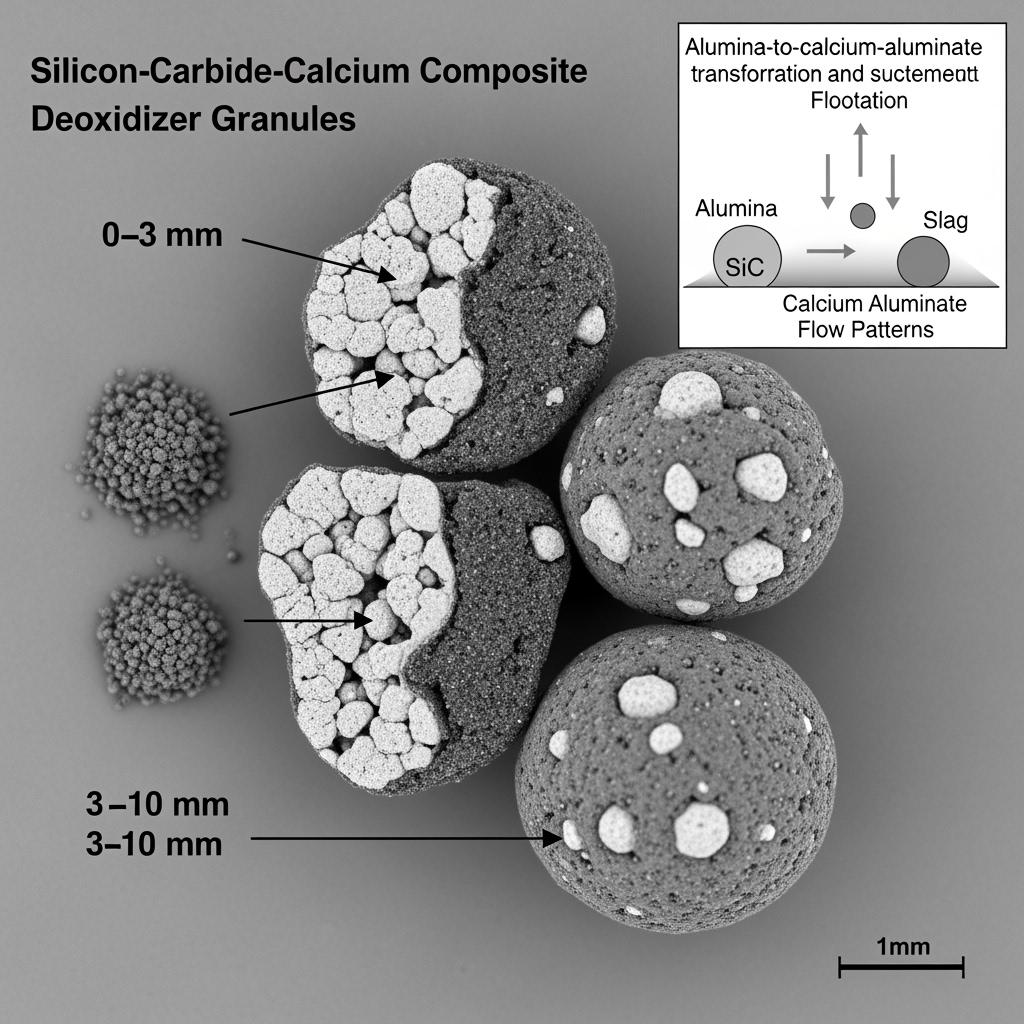

At its core, the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting maintains a high SiC content—typically between eighty-eight and ninety-five percent—supported by a calibrated free carbon range from two to six percent to reinforce the dual deoxidation mechanism. Free silicon is deliberately kept low, usually around 0.5 to 1.5 percent, to limit secondary oxidation while preserving kinetic responsiveness. The calcium content is optimized for inclusion modification without destabilizing slag chemistry; Sicarbtech typically targets a calcium fraction balanced to the expected alumina load based on your steel grades and casting practice. Particle sizing is application-led: 0–3 mm for teeming stream dissolution, and 3–10 mm for early ladle additions when residence time is slightly longer. The hydrophobic, anti-oxidation coating survives monsoon humidity and inland storage, while densified granulation enhances flowability for enclosed feeders and closed-loop dosing.

Steelmaking outcomes comparison for Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting

| Cleanliness and casting stability metrics | 개재물 정제 및 청정 강철 주조를 위한 탄소화규소-칼슘 복합 탈산제 | High-purity SiC without calcium | FeSi + aluminum wire reference |

|---|---|---|---|

| Inclusion morphology (alumina to calcium aluminate conversion) | Strong conversion; improved floatability | Partial control; alumina may persist | Al2O3-rich clusters; clogging risk |

| Continuous casting nozzle clogging incidents per 100 heats | -30–45% vs baseline | -20–35% vs baseline | Baseline reference |

| 정제 후 총 산소(ppm) | -6 to -15 ppm | -5 to -12 ppm | 가변; 알루미나 스파이크 |

| Sequence length stability | Longer, fewer tundish interventions | Improved, moderate | Variable; more interruptions |

| Silicon absorption stability (σ) | Low variability, high predictability | Low variability | Moderate variability |

Material attributes of Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting for Pakistan operations

| 속성 | 개재물 정제 및 청정 강철 주조를 위한 탄소화규소-칼슘 복합 탈산제 | Operational significance |

|---|---|---|

| SiC 콘텐츠 | 88–95% | Strong silicon source with carbon synergy |

| 무료 탄소 | 2–6% | Reinforces dual deoxidation; thermal balance |

| 무료 실리콘 | 0.5–1.5% | 2차 산화 제어 |

| Calcium modifier content | Tuned to alumina load | Inclusion purification and nozzle openness |

| S, P(각) | ≤0.02% | Clean steel and export-grade compliance |

| Particle size | 0-3mm; 3-10mm | Stream dissolution vs ladle residence |

| 코팅 | Hydrophobic, anti-oxidation | Moisture resistance and stable dosing |

| 스토리지 안정성 | ≥6개월 | Karachi-to-upcountry inventory cycles |

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting advantages and proven benefits with expert perspective

The composite nature of the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting creates a tight loop between deoxidation, silicon addition, and inclusion control. Steelmakers who struggled with alumina agglomerates and corresponding nozzle restrictions find that calcium shifts the inclusion landscape toward more deformable species. Furthermore, SiC’s high reaction activity sustains absorption even as scrap quality varies, which is increasingly relevant as Pakistan boosts EAF scrap charges. The net effect is shorter refining windows, a measurable reduction in clogging incidents, and a smoother casting cadence with fewer operator interventions. Dr. Huma Siddiqui, an inclusion metallurgy researcher, notes, “Calcium is not an afterthought—it’s a design variable. Coupled with SiC kinetics, it writes a different story in the tundish” (Journal of Steel Cleanliness, 2024).

Cost and energy impact comparison for Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting

| Economic and energy KPIs | 개재물 정제 및 청정 강철 주조를 위한 탄소화규소-칼슘 복합 탈산제 | FeSi + Al wire | Separate carburizer + Si source |

|---|---|---|---|

| 강철 톤당 합금 비용 | -1–5% vs reference | 기준선 | +0–2% volatility |

| Heat time reduction | 0.5–2% shorter | 참조 | Minor change |

| Tapping temperature drop | -2 to -6°C | 0 to -2°C | -1 to -3°C |

| Dust at addition point | Low with enclosed feeding | Wire handling dust | Higher with open charge |

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting real-world applications and measurable success stories

In a Punjab converter shop producing rebar and wire rod, the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting was introduced at early ladle addition, replacing part of FeSi and trimming aluminum wire. Over six weeks of A/B heats, total oxygen dropped by nine ppm on average, while nozzle clogging incidents per 100 heats decreased by forty-one percent. Casting sequences extended by an average of twenty minutes without increasing nozzle exchange risk, and SEM analysis showed a shift from compact Al2O3 clusters toward CA and CA2 phases with improved floatability. Meanwhile, an EAF mill near Karachi dosing at the teeming stream reported silicon absorption increasing by four to six percentage points, with heat time shortened by around one percent. The shift supervisor summarized the value succinctly: “Tundish screens stayed cleaner; the crew stopped expecting surprises.”

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting selection and maintenance considerations

Choosing the right variant depends on your grade mix and inclusion targets. For low- and medium-carbon long products that suffer from alumina accumulation, a moderate calcium level aligned to expected oxygen pick-up will maximize inclusion modification without destabilizing slag. When continuous casting focuses on sequence length and nozzle openness, early ladle additions at 3–10 mm give calcium the residence time to engage alumina efficiently, while 0–3 mm stream dosing helps when tapping temperatures are higher and dissolution speed matters most. Storage and handling remain practical realities in Pakistan’s climate; the hydrophobic coating offers a margin of safety, yet enclosed silos, dry transfer points, and calibrated metering guard the flowability that makes dosing consistent.

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting industry success factors and customer testimonials

Across Sicarbtech’s deployments with nineteen-plus enterprises, the consistent theme is integration. Plants that pair the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting with an online feeding system linked to oxygen activity signals see the largest stability gains. A QA manager from a North Region billet caster shared a candid reflection: “Our operators talk less about the nozzle now. That silence is performance.” This aligns with Pakistan’s broader shift toward automated, traceable additions where materials and data reinforce each other.

Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting future innovations and market trends

Looking ahead, Pakistan’s mills will continue raising scrap ratios and elevating cleanliness expectations as export markets demand tighter surface quality. Inclusion engineering will therefore move upstream, with more precise calcium dosing metered against real-time oxygen and temperature curves. Sicarbtech is evolving the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting with coatings that further stabilize dissolution under variable slag basicity and with data models that match calcium load to predicted alumina formation by grade. Additionally, localized production through technology transfer will shorten lead times, giving mills a responsive lever as they iterate practices heat by heat.

자주 묻는 질문과 전문가 답변

How does the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting reduce nozzle clogging in practice?

The calcium fraction reacts with alumina inclusions to form more deformable calcium aluminates, which detach and float more readily. Coupled with SiC’s stable silicon absorption, this reduces clogging propensity and prolongs sequence stability.

Will the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting change slag basicity or volume?

When engineered to your alumina load, the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting delivers inclusion modification without destabilizing slag. Sicarbtech calibrates calcium content and coating chemistry to maintain slag behavior while improving cleanliness.

Is the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting suitable for both EAF and converter routes?

Yes. In EAF practice it excels at teeming stream additions to secure fast dissolution, while in converter routes it works well at early ladle stages where inclusion modification time is available. Dosing curves are tuned to oxygen activity and tapping temperatures in each route.

How is batch quality assured for the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting?

Sicarbtech’s in-situ quality monitoring and traceability system records SiC content, free carbon, free silicon, calcium level, moisture, particle size, and flowability for every lot, preserving batch consistency across logistics and storage.

Can the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting help us reduce aluminum wire usage?

In most trials, yes. By taking a larger share of deoxidation early and stabilizing inclusion morphology, the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting allows mills to trim aluminum wire while maintaining or improving cleanliness.

Why the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting works for your operations

Because it tackles the root causes of casting instability, not just the symptoms. The Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting delivers silicon with high absorption, uses carbon to reinforce deoxidation, and deploys calcium as an inclusion architect. In Pakistan’s mills—where energy budgets are tight, scrap feeds vary, and export customers demand cleaner surfaces—this composite reduces the need for late corrections and operator firefighting, allowing your team to plan sequences with confidence.

맞춤형 솔루션을 위한 전문가와의 연결

Sicarbtech brings more than ten years of silicon carbide manufacturing expertise—backed by the Chinese Academy of Sciences—to tailor the Silicon-Carbide–Calcium Composite Deoxidizer for Inclusion Purification and Clean Steel Casting to your exact grades and practices. The team develops custom R-SiC, SSiC, RBSiC, and SiSiC products and provides technology transfer and factory establishment services for localized production in Pakistan, from powder synthesis and classification to granulation, coating, and online feeding integration. With turnkey solutions spanning materials, equipment, and process know-how, and a track record across nineteen-plus enterprises, Sicarbtech is ready to design a no-cost pilot program that targets measurable KPIs—lower total oxygen, fewer nozzle interventions, and shorter heat times—so you can scale with certainty.

무료 상담과 데이터에 기반한 빠른 제안서를 원하시면 문의하세요:

이메일: [email protected]

전화/왓츠앱: +86 133 6536 0038

문서 메타데이터

최종 업데이트: 2025-09-15

다음 검토가 예정되어 있습니다: 2025-12-15

저자 저자: 시카브테크 애플리케이션 엔지니어링 팀

Region focus: Pakistan (EAF and converter routes; billets, bars, and wire rod)

Timeliness note: Aligned with 2025 scrap ratio trends, PEQS-aligned dust control practices, and closed-loop feeding advancements

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.