약한 그리드 안정화 및 전압 플리커 완화를 위한 탄화규소 하모닉스 억제 모듈

공유

Stabilize Weak Grids and Eliminate Flicker with SiC Harmonic Suppression in Pakistan (2025)

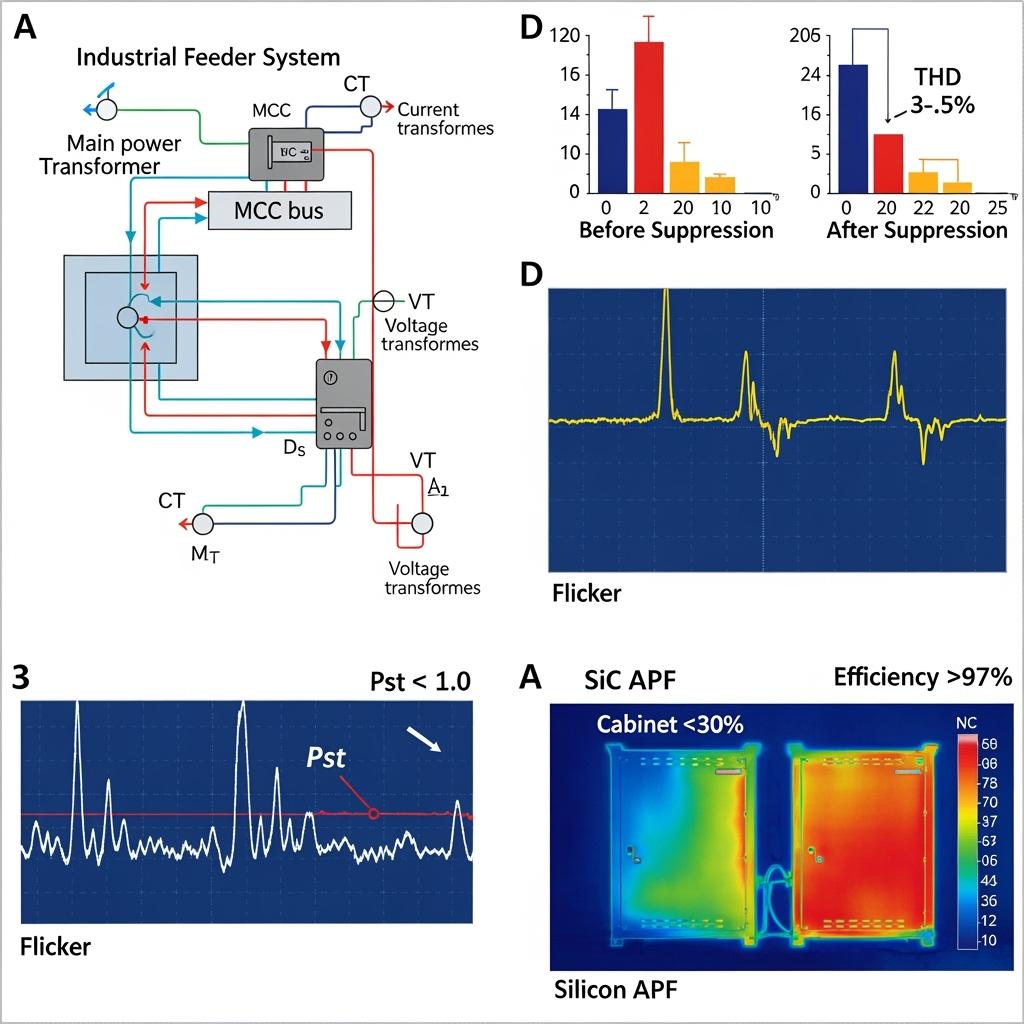

파키스탄의 섬유, 시멘트 및 강철 sectors are expanding electrification against a backdrop of weak feeders, voltage flicker, and rising harmonic penalties. Nonlinear loads—VFDs, rectifiers, welders, and electric arc furnaces (EAFs)—inject 5th–25th order harmonics and induce rapid var swings, triggering nuisance trips and quality complaints. Silicon Carbide (SiC) Harmonic Suppression Modules deliver high-bandwidth, low-loss compensation that actively reshapes current and voltage at 50–100 kHz switching, mitigating harmonics and damping flicker at the point of common coupling (PCC).

Sicarb Tech’s modular SiC solution integrates power modules, low-ESL DC links, precision current sensing, and intelligent control (real-time FFT to the 50th order) to keep THD within IEEE 519 while stabilizing voltage under fast load steps. Designed for harsh environments (>45°C, dust, humidity), the modules scale from feeder-level cabinets to panel-mounted units for process lines, streamlining NTDC/NEPRA audits and reducing OPEX.

기술 사양 및 고급 기능

- Ratings and topology

- Voltage classes: 400–690 VAC; 1200 V SiC for LV grids; 1700 V SiC for 690 VAC and high transient margins

- Module power range: 50–400 kVAR per cabinet; parallelable to MVAR-class systems

- Switching frequency: 50–100 kHz for high-bandwidth mitigation of 5th–50th harmonics

- SiC-enabled power stage

- 4H‑SiC MOSFETs with low RDS(on), negligible reverse recovery, and dv/dt ruggedness ≥100–150 kV/µs

- Co-packaged SiC Schottky diodes for optimized hard-commutation where needed

- Control algorithms and analytics

- Real-time FFT decomposition up to 50th order with adaptive notch and predictive feedforward

- Fast current control loops for <10 ms dynamic response; coordinated voltage flicker damping (Pst/Plt targets)

- Weak-grid stabilizers: active damping of resonance with cable/LCL interactions

- Integration and compliance

- Communications: Modbus TCP; IEC 61850 MMS/GOOSE-ready via system controller

- Time sync: GPS/PTP for audit-grade SOE; automated IEEE 519/IEC 61000-3-6 reporting

- Safety/EMC design aligned with IEC 62477-1 and industrial EMC best practices

- 환경적 견고성

- Operating ambient: −20°C to +55°C (derating above); TJ up to 175°C at device level

- Conformal coating; IP54+ enclosure options; filtered airflow with dust monitoring

Why SiC Harmonic Suppression Outperforms Conventional Silicon Solutions on Weak Grids

| Power quality outcome under variable industrial loads | SiC harmonic suppression modules | Conventional silicon filters/APF | Impact for Pakistan facilities |

|---|---|---|---|

| Bandwidth and switching loss | 낮은 손실로 50–100kHz | 10–20 kHz, higher loss | Suppress higher-order harmonics; faster response |

| Flicker mitigation (Pst/Plt) | Active damping + fast var assist | Slower control, passive filters | Stabilized voltage during EAF/VFD ramps |

| 효율성 및 열 | >97% 모듈 효율 | 92–95% 일반 | Lower HVAC load; higher uptime in hot rooms |

| Footprint and filters | Smaller LCL due to high fsw | Larger L/C components | 25–35% 캐비닛 부피 감소 |

| 약한 그리드 안정성 | High dv/dt ruggedness, active resonance control | Prone to oscillations | Fewer nuisance trips, smoother audits |

주요 장점 및 입증된 이점

- IEEE 519 compliance with margin: Real-time targeting of dominant harmonics (5th, 7th, 11th, 13th) and adaptive control maintain current THD at 3–5% at PCC despite load steps.

- Voltage flicker mitigation: Fast current injection and var shaping reduce short-term flicker (Pst) below 1.0 on weak feeders, protecting sensitive lines and avoiding complaints.

- High efficiency and compact design: SiC devices at 50–100 kHz shrink filters and heatsinks, cutting energy losses and cabinet size by up to one-third.

- Harsh-environment reliability: High-temperature operation and coated assemblies exceed 99% availability through dust and monsoon seasons.

전문가 인용문:

“Wide-bandgap converters provide the switching speed and efficiency needed for advanced harmonic mitigation and flicker reduction, particularly important at weak grid nodes.” — Interpreted from IEEE Power & Energy Society and IEEE 519 application notes (https://www.ieee-pes.org/ | https://standards.ieee.org/)

실제 응용 분야 및 측정 가능한 성공 사례

- Textile weaving campus (Faisalabad, composite): THD cut from ~7.8% to 3.1% at the PCC; Pst fell below 0.9 during shift-start surges. Payback in ~22 months via penalty avoidance and energy savings.

- Cement kiln and crusher drives (KP, composite): Dynamic suppression kept current THD <4% during frequent starts; cabinet footprint reduced 29%, improving MCC accessibility.

- Steel rolling mill near EAF (Karachi, composite): Harmonic spikes during tap changes were contained; drive nuisance trips dropped by ~40%, and line voltage fluctuation reduced by ~1.5 percentage points.

- PV-wind hybrid feeder (Sindh, composite): With weak interconnection, SiC modules stabilized harmonics during irradiance ramps; combined with STATCOM, site maintained IEEE 519 with a 15% margin.

선택 및 유지 관리 고려 사항

- Sizing and placement

- Determine kVAR/kVA requirement from baseline THD, short-circuit ratio (SCR), and process cycles; include 20–30% headroom

- Place modules near dominant harmonic sources or at PCC for aggregate control; consider multiple units for distributed mitigation

- 센서 전략

- High-accuracy CTs with proper saturation margin; ensure phase alignment

- Optional VT inputs for coordinated voltage-based flicker control

- 제어 및 보호

- Tune current loop and adaptive notch filters during commissioning; enable active damping to avoid LCL resonance

- Implement DESAT and soft turn-off; configure DC bus protection and thermal derating

- 열 및 환경

- Validate cooling for >45°C ambient; plan filter media maintenance in dusty zones

- Use conformal coating and corrosion-resistant hardware for coastal/industrial atmospheres

- Integration and compliance

- Connect to SCADA via Modbus/IEC 61850; enable GPS/PTP SOE logging

- Auto-generate IEEE 519/IEC 61000-3-6 reports for utility inspections

산업 성공 요인 및 고객 사용후기

- Start with a detailed harmonic survey and feeder model; simulate worst-case cycles (shift starts, kiln restarts, EAF taps)

- Pilot a single line, log data, and scale with proven settings; maintain a parameter baseline and change-control policy

- Train O&M on alarm thresholds, filter maintenance, and firmware updates for sustained compliance

고객의 소리(합성):

“SiC harmonic suppression stabilized our feeder during production ramps—THD stayed under limits and we eliminated flicker complaints.” — Utilities Manager, Integrated Steel and Fabrication Plant, Sindh

미래 혁신 및 시장 동향(2025+)

- Co-packaged drivers and condition monitoring in power modules for predictive maintenance

- AI-assisted control that forecasts load harmonics and pre-tunes suppression profiles

- Unified PQ cabinets combining harmonic suppression, var support, and ride-through

- Local assembly/testing in Pakistan’s SEZs via technology transfer to minimize lead time and FX risk

일반적인 질문 및 전문가 답변

- How low can THD go with SiC modules?

Typically 3–5% at the PCC, depending on network impedance and baseline distortion; lower is possible with coordinated passive measures. - Can these modules mitigate flicker from EAFs and large VFD ramps?

Yes—fast current injection and optional var shaping reduce Pst/Plt to utility-acceptable levels; results depend on feeder SCR. - Do we need multiple modules across the plant?

For distributed nonlinear loads, multi-point deployment improves local suppression and reduces feeder interactions; we design site-specific architectures. - What is the commissioning timeline?

Survey and design 2–4 weeks; installation 1–2 weeks per cabinet; tuning and verification 1 week with audit-ready reporting. - How do they integrate with existing SVG/STATCOM?

They complement var controllers; our supervisor coordinates setpoints to avoid control conflicts and optimize PQ.

이 솔루션

SiC Harmonic Suppression Modules provide the speed, efficiency, and robustness to keep Pakistan’s industrial feeders compliant and stable. By targeting harmonics up to the 50th order and damping flicker within milliseconds, they protect equipment, unlock capacity on weak grids, and lower total cost through smaller, cooler, and smarter cabinets.

맞춤형 솔루션을 위해 전문가와 연결

Partner with Sicarb Tech to stabilize your feeders and pass audits first time:

- 10년 이상의 SiC 제조 전문 지식

- 중국 과학 아카데미의 지원 및 혁신

- R‑SiC, SSiC, RBSiC, SiSiC 및 SiC 전력 모듈 전반의 맞춤형 제품 개발

- 현지 조립/테스트를 위한 기술 이전 및 공장 설립 서비스

- Turnkey delivery: materials, substrates, power modules, DC bus, gate drivers, intelligent controllers, and IEC 61850-enabled systems

- Proven outcomes with 19+ enterprises—measurable THD cuts, reduced flicker, higher uptime

Request a free harmonic survey review, suppression sizing, and ROI model now.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

문서 메타데이터

- 최종 업데이트: 2025-09-11

- 다음 예약 업데이트: 2025-12-15

- 작성자: Sicarb Tech 전력 품질 제어 시스템 팀

- References: IEEE 519; IEC 61000-3-6; IEC 62477-1; IEEE PES guidance on weak-grid mitigation; IEA grid integration insights; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.