파키스탄을 위한 산업용 탄화규소 솔루션: 2025년을 위한 고효율 전력 전자 및 첨단 세라믹

공유

요약: 탄화규소로 파키스탄의 다음 산업 도약 지원

파키스탄의 산업 부문—섬유, 시멘트, 강철, 그리고 빠르게 성장하는 재생 에너지—는 에너지 효율, 전력 품질 및 공정 신뢰성에 대한 요구가 증가하고 있습니다. 2025년에는 전기 요금 인상, 전력망 불안정, 더 엄격한 품질 기준이 산업 리더들이 차세대 전력 전자 및 첨단 세라믹을 채택하도록 밀어붙이고 있습니다. 탄화규소(SiC)는 이를 가능하게 하는 재료입니다.

중국 탄화규소 제조 허브인 웨이팡시에 위치한 Sicarb Tech는 고성능 SiC 전력 모듈 및 세라믹 기판에서 턴키 공장 설립 및 기술 이전에 이르기까지 전체 사이클 솔루션을 제공하는 탄화규소 솔루션 전문가입니다. 10년 이상의 맞춤형 경험, 중국 과학원(웨이팡) 혁신 공원 회원 자격, 19개 이상의 성공적인 기업 배치를 통해 Sicarb Tech는 파키스탄 산업 시장에 측정 가능한 ROI를 제공하는 확장 가능하고 신뢰할 수 있으며 표준을 준수하는 SiC 솔루션을 제공합니다.

주요 2025년 결과:

- 전력 시스템에서 98% 이상의 변환 효율

- SVG/STATCOM 및 APF의 10ms 미만 응답 시간

- 실리콘 기반 시스템 대비 25–35% 공간 절감

- 시스템 수명 연장(15년 이상), O&M 비용 절감

- NEPRA, NTDC 그리드 코드 및 IEC/IEEE 표준 준수

파키스탄의 산업 과제 및 문제점 (2025년 초점)

파키스탄의 산업 생태계는 강력한 전력 전자 및 고성능 세라믹 재료에 대한 필요성을 증폭시키는 고유한 제약 조건 하에서 운영됩니다.

- 전력망 불안정 및 전력 품질 문제:

- 신드 및 발루치스탄 풍력 회랑과 펀자브 중부의 태양광 클러스터에서 재생 에너지 보급이 증가함에 따라 전압 강하, 플리커 및 고조파 왜곡이 심화되고 있습니다.

- 약한 그리드 노드와 긴 피더는 시멘트 가마 및 강철 아크로에서 피크 작동 및 시동 주기 동안 그리드 코드 제한을 위반하는 무효 전력 진동을 유발합니다.

- 전기 요금 인상 및 에너지 집약도:

- 산업 요금 및 연료 가격 변동성은 에너지 집약적 부문(시멘트 클링커 라인, 재압연 공장, VFD가 많은 구동 시스템을 갖춘 대형 직조 홀)의 마진을 압박합니다.

- 비효율적인 전력 변환은 대형 공장의 경우 연간 수천만 PKR의 피할 수 없는 손실로 이어집니다.

- 장비 감량 및 열 응력:

- 45°C 이상의 주변 온도(특히 신드 및 남부 펀자브)는 실리콘 기반 전력 모듈의 감량 및 UPS/VFD 용량 감량을 강요합니다.

- 먼지, 습도 및 부식성 환경(시멘트 먼지, 해안 카라치의 염분 공기)은 장비 고장 및 유지 보수 주기를 가속화합니다.

- 규정 준수 압력 및 인증:

- NEPRA 및 NTDC의 전압 조정, 무효 전력 지원 및 고조파 제한(IEC 61000-3-6, IEEE 519에 맞춰짐) 요구 사항은 새로운 상호 연결 승인에서 강화되고 있습니다.

- 승인 지연 또는 미준수는 RE 공장 및 그리드 연결 산업 부하에 대한 감축 및 벌금의 위험을 초래합니다.

- 운영 복잡성:

- 이기종 레거시 시스템: 다양한 프로토콜(Modbus, IEC 61850, DNP3)을 사용하는 혼합 세대 VFD, 정류기, UPS 장치 및 SCADA 플랫폼.

- 숙련된 인력 부족은 고급 전력 품질 솔루션의 배포 및 유지 관리를 복잡하게 만듭니다.

- 공급망 및 리드 타임:

- 수입된 실리콘 기반 SVG/APF 시스템은 종종 긴 리드 타임과 제한된 맞춤화를 수반하여 프로젝트 일정을 지연시키고 비용을 부풀립니다.

- 예비 부품 및 애프터 서비스 지연은 핵심 공정(연속 주조, 가마 작동 일정)의 가동 시간에 영향을 미칩니다.

- 현금 흐름 및 자본 지출 제약:

- 프로젝트 자금 조달 난관, 통화 변동성(PKR 평가 절하) 및 수입 관세는 강력하고 단기적인 투자 회수를 위한 솔루션을 요구합니다.

전문가의 관점:

- "고조파 함량이 높고 간헐적인 재생 에너지가 있는 그리드의 경우 SiC 기반 컨버터는 특히 더운 기후에서 기존 실리콘이 따라갈 수 없는 빠른 동적 응답을 제공합니다." — Henry A. Toliyat 박사, 전력 전자 연구원, IEEE 펠로우 (참조: IEEE Spectrum 및 IEEE Transactions on Power Electronics 통찰력)

- "유틸리티가 전력 품질 표준을 더 엄격하게 준수하도록 추진함에 따라 SiC 기술을 사용한 효율적인 무효 전력 보상이 필수적이 되고 있습니다." — 국제 에너지 기구 전력 시스템 논평(IEA 전력 시스템 통합 보고서 참조)

무대응의 비용 영향:

- 대형 공장에서 변환 손실을 통한 2–5%의 에너지 낭비, 연간 수백만 PKR에 해당

- 열 고장 및 감량으로 인한 가동 중단 시간 증가(직조기, 가마 출력 부족으로 인한 생산 시간 손실)

- 과도한 실리콘 기반 장비 및 냉각 시스템에 대한 더 높은 자본 지출

- 그리드 연결 재생 에너지 시설의 승인 지연 및 잠재적 감축

파키스탄을 위한 첨단 실리콘 카바이드 솔루션 포트폴리오

Sicarb Tech는 산업 및 재생 에너지 애플리케이션에 맞게 조정된 포괄적인 제품군을 제공하여 전력 전자 및 첨단 세라믹을 연결합니다.

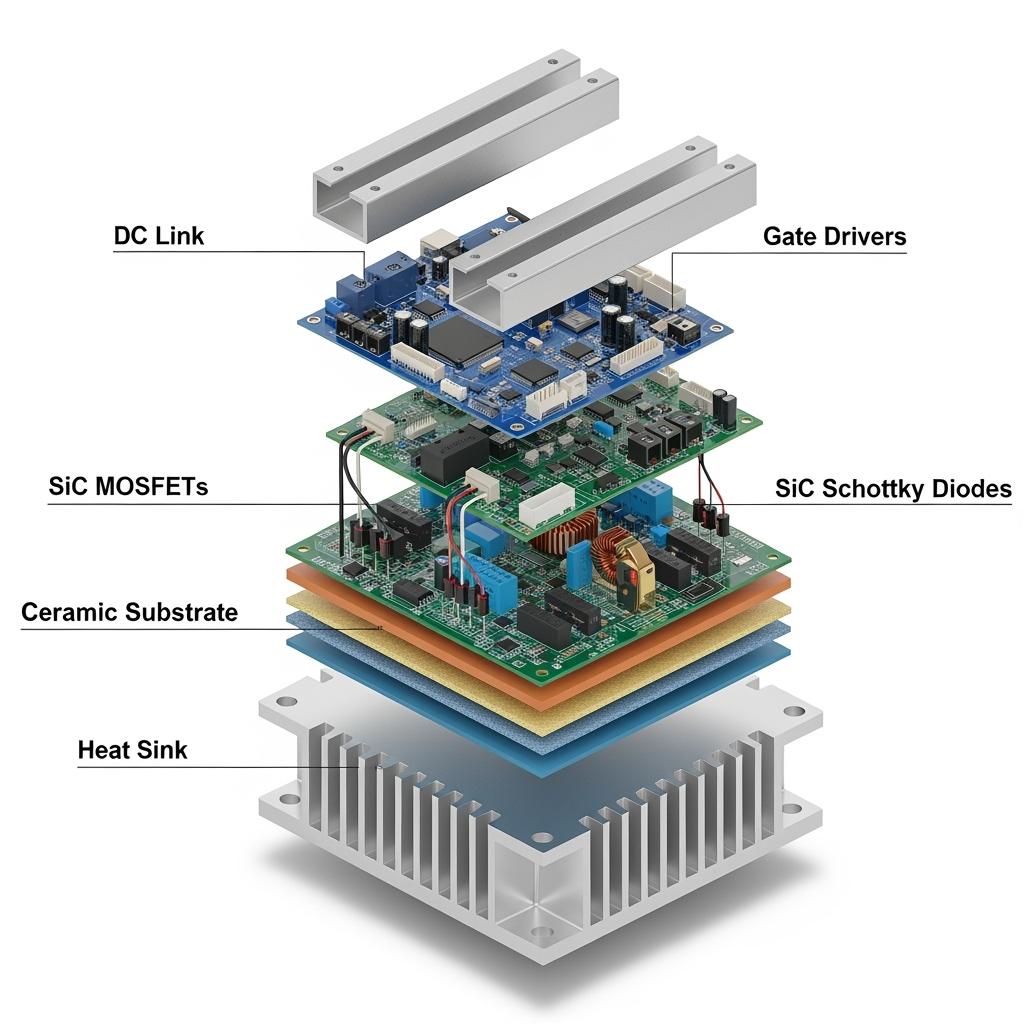

- 고주파 탄화규소 전력 모듈

- 그리드 연결 플랜트를 위한 다단계 SVG/APF 장치

- VFD 및 UPS를 위한 3단계 인버터 모듈

- 개별 SiC 장치 및 서브시스템

- SiC MOSFET(≥1700V) 및 저손실 스위칭용 쇼트키 다이오드

- 고주파, 고온 게이트 드라이버

- 고주파 절연 변압기

- 시스템 수준 솔루션

- 탄화규소 다단계 SVG 전력 장치(응답 <10ms)

- 실시간 고조파 억제(>90%) 기능을 갖춘 SiC 능동 전력 필터 모듈

- SCADA와 통합된 동적 무효 전력 보상 제어 시스템

- 고조파 억제 모듈 및 DC 버스 커패시터 통합 장치

- 지능형 모니터링 기능이 있는 메인 제어 보드

- 첨단 세라믹 부품

- 고열전도성 SiC 세라믹 기판

- 마모, 열 및 부식 저항을 위한 R-SiC, SSiC, RBSiC, SiSiC 산업 부품(노즐, 가마 가구, 씰, 베어링)

- 생산 및 테스트 장비

- SiC 장치 번인 및 자동 테스트 장비

- 현지 용량 구축을 위한 결정 성장 및 에피택시 장비

당사 포트폴리오가 파키스탄의 문제점을 해결하는 방법:

- 빠른 무효 전력 응답은 대형 모터 및 아크로의 전압 플리커를 해결합니다.

- 고온 작동은 더운 기후에서 감량을 최소화하여 성능을 유지합니다.

- 통합 제어는 NTDC/Disco SCADA 및 그리드 코드와의 원활한 호환성을 가능하게 합니다.

- 소형 모듈형 장치는 개조 공간의 공간을 줄이고 냉각 비용을 절감합니다.

- 현지화된 콘텐츠 및 교육은 서비스 리드 타임 및 수명 주기 비용을 절감합니다.

성능 비교: 산업용 전력 시스템을 위한 탄화규소 대 기존 실리콘

파키스탄 운영 조건 하에서의 기술적 성능

| 속성 | SiC 기반 솔루션 | 기존 실리콘 기반 솔루션 | 파키스탄 운영에 미치는 영향 |

|---|---|---|---|

| 응답 시간(SVG/APF) | <10ms | 25–40ms | 약한 피더를 안정화하고 모터 시동 시 플리커를 줄입니다. |

| 효율성(시스템) | >98% | 92–95% | 고부하 플랜트에서 5–7%의 에너지 절약 |

| 스위칭 주파수 | 50–100 kHz | 10–20 kHz | 더 작은 자성체, 더 조용한 작동 |

| 작동 접합 온도 | -55~175°C | -40~125°C | 더운 기후에서 감량 문제 감소 |

| 전력 밀도 | >8kW/L | 3–5kW/L | 25–35% 공간 절감 |

| 고조파 억제 | >90% | 70–80% | IEEE 519/IEC 제한을 안정적으로 충족합니다. |

| 냉각 요구 사항 | 낮음 | 높음 | 낮은 OPEX 및 유지 보수 |

| 예상 수명 | >15년 | 8–10년 | 더 긴 정비 간격 |

| 그리드 코드 준수 | 빠른 역학으로 용이하게 처리 | 약한 노드에서 어려움 | 더 쉬운 상호 연결 승인 |

가혹한 산업 환경을 위한 재료 및 세라믹 부품 특성

| 속성 | SSiC/RBSiC 부품 | 기존 알루미나/강철 | 시멘트/강철/섬유에 대한 이점 |

|---|---|---|---|

| 열 전도성 | 높음(SiC 기판의 경우 120–200W/m·K) | 낮음–중간 | 더 나은 열 확산, 핫스팟 고장 감소 |

| 내마모성 | 우수 | 보통 | 가마 가구, 노즐의 수명 연장 |

| 내식성 | 우수(산/알칼리) | 변수 | 부식성 환경에서 가동 중단 시간 감소 |

| 최대 서비스 온도 | >1600°C(세라믹) | <1200°C 일반 | 더 높은 공정 안정성 |

| 밀도 | 낮음 | 더 높음 | 더 가벼운 구조, 움직이는 부품의 에너지 절약 |

실제 응용 분야 및 성공 사례

- 재생 에너지 플랜트(신드, 펀자브)

- SiC 모듈이 있는 SVG/STATCOM 및 APF는 PV 및 풍력 발전소 상호 연결을 안정화했습니다.

- 결과: 그리드 전압 변동은 ±2% 이내로 유지; 시스템 효율은 최대 98.5%; NTDC 지침에 따라 빠른 시운전.

- 결과: 일반 액세스 인증 획득; 감축 감소 및 더 부드러운 램프 속도.

- 강철 재압연 공장 전력 품질 업그레이드

- 문제: EAF 및 대형 드라이브로 인한 고조파 및 플리커로 인해 벌금 및 생산 변동성이 발생합니다.

- 솔루션: SiC 다단계 APF + 동적 무효 전력 보상; IEC 61850을 통해 기존 SCADA와 통합.

- 영향: THD가 IEEE 519 제한 미만으로 감소; 4.8% 에너지 절약; 유지 보수 간격이 30% 연장되었습니다.

- 시멘트 공장 가마 라인 최적화

- 문제: 기존 부품 및 드라이브의 열 응력 및 먼지로 인한 고장.

- 솔루션: SiC 기반 고주파 드라이브 및 열 충격 저항성이 향상된 SSiC 가마 가구.

- 영향: 2% 처리량 증가; 계획되지 않은 가동 중단 시간 20% 감소; >45°C 주변 온도에서 안정적인 작동.

- 섬유 공장 VFD 플릿 현대화(직조 및 방적)

- 문제: 빈번한 전압 강하로 인한 직조기 트립; 냉각에 대한 높은 에너지 소비.

- 솔루션: 통합 DC 버스 커패시터 장치 및 고열전도성 기판이 있는 SiC 3단계 인버터 모듈.

- 영향: 불필요한 트립 60% 감소; 에너지 비용 6% 절감; 작업 현장에서 더 조용한 작동.

기술적 장점 및 현지 규정 준수 구현 이점

- 그리드 코드 정렬:

- 무효 전력 및 전압 조정을 위한 NTDC 그리드 코드 지원; IEEE 519 및 IEC 61000-3-6에 따른 고조파.

- 통신 호환성: 로컬 SCADA/DCS 시스템에 통합하기 위한 IEC 61850, Modbus TCP, DNP3.

- 환경을 위한 설계:

- 시멘트 및 강철 환경을 위한 45°C, 방진 설계, 컨포멀 코팅 및 IP 등급 인클로저.

- 파키스탄 기후대에 맞게 조정된 감량 프로필; 검증된 열 모델.

- 제어 인텔리전스:

- 적응형 필터링을 통한

- 자체 진단 및 원격 유지 보수가 현지 4G/5G 산업용 라우터 및 VPN 정책과 호환됩니다.

- 안전 및 표준:

- 수출 지향 공장에 필요한 IEC 62477-1(전력 전자 변환기 시스템), IEC 62109(PV용) 및 UL/CE 경로를 목표로 합니다.

- 산업 단지에서 흔히 사용되는 중전압 상호 연결을 위해 설계된 전기적 여유/누설 거리.

구현 이점:

- 더 빠른 상호 연결 승인 및 더 적은 그리드 페널티

- 냉각 시스템에 대한 더 낮은 자본 지출 및 더 작은 전기실

- 모듈식 핫 스왑 가능 장치를 통해 MTTR 감소

- 상태 기반 유지 보수를 통한 예측 가능한 수명 주기 비용

맞춤형 제조 및 기술 이전 서비스

Sicarb Tech의 차별점은 제품뿐만 아니라 현지 역량과 노하우를 제공하는 완벽한 엔드 투 엔드 기능입니다.

- 중국 과학 아카데미 파트너십의 지원을 받는 고급 R&D

- 고주파 제어 알고리즘, 게이트 드라이버 최적화 및 열 인터페이스 재료의 공동 개발.

- 가속화된 검증을 위한 웨이팡 혁신 공원 테스트 시설에 대한 접근.

- R-SiC, SSiC, RBSiC, SiSiC를 위한 독점 제조 공정

- 우수한 밀도, 열 전도율 및 내마모성을 제공하는 최적화된 소결, 반응 결합 및 함침 공정.

- 전력 모듈 조립을 위한 엄격한 공차 제어를 통한 고수율 세라믹 기판 생산.

- 완벽한 기술 이전 패키지

- 공정 노하우: SOP, 레시피 매개변수, QA 계획 및 수율 개선 방법론.

- 장비 사양: 결정 성장, 에피택시 및 패키징 라인에 대한 BOM, 레이아웃 도면, 유틸리티 및 EHS 요구 사항.

- 인력 교육: 공정 엔지니어, 유지 보수 팀 및 QA 직원을 위한 여러 주 모듈; 현장 및 원격 옵션.

- 공장 설립 서비스

- 타당성 조사(시장, 자본 지출/운영 지출, PKR 대 USD 위험 시나리오).

- 시설 설계, 조달 지원, 설치, 시운전 및 파일럿 생산 램프.

- 파키스탄 공급업체 및 유통업체를 위한 현지화 전략.

- 품질 관리 및 인증 지원

- 통계적 공정 관리(SPC), 신뢰성 테스트(HTRB, HTGB, 전력 사이클링) 및 번인 워크플로우.

- IEC, IEEE 및 ISO 9001/14001 인증 지원; 그리드 프로젝트에서 NEPRA/NTDC 제출을 위한 문서.

- 지속적인 기술 지원 및 최적화

- 원격 진단, 펌웨어 업데이트 및 분기별 성능 감사.

- 에너지 KPI 및 가동 시간 SLA에 연결된 지속적인 개선 프로그램.

19개 이상의 기업 파트너와 입증된 결과:

- 평균 5–7% 시스템 에너지 개선 및 25–35% 공간 절감

- SiC 기반 열 설계를 통해 유지 보수 주기 연장 >25%

- 고부하 애플리케이션에서 빠른 ROI(종종 <24개월)

미래 시장 기회와 2025년 이상의 트렌드

- 성장하는 재생 에너지 및 하이브리드화

- 파키스탄의 재생 에너지 설치는 1.5GW를 초과했으며, 단기적으로 >2GW가 예상됩니다. 하이브리드 PV-풍력-저장 노드는 더 빠르고 효율적인 그리드 컨버터를 요구할 것입니다.

- 필수적인 전력 품질 관리

- 상호 연결 계약에서 고조파 및 무효 전력 제한의 시행 증가; SiC는 향후 조임에 대한 여유 공간으로 규정 준수를 가능하게 합니다.

- 공정 열 및 모터의 전력화

- 고효율 SiC 드라이브는 강철, 시멘트 및 섬유 라인에서 확장되어 에너지 강도와 열 손실을 줄입니다.

- 현지 제조 잠재력

- 전력 모듈 및 세라믹의 합작 투자 및 현지 조립은 리드 타임을 단축하고 FX 위험을 헤지할 수 있습니다.

- 디지털 O&M

- AI 기반 모니터링은 더 높은 스위칭 주파수에서 SiC 시스템의 더 풍부한 센서 데이터를 활용하여 예측 유지 보수를 수행합니다.

업계 관점:

- "SiC와 같은 광대역 갭 반도체는 더 높은 효율성과 더 높은 온도 작동을 가능하게 하여 산업 전력 시스템의 탈탄소화에 중심적인 역할을 합니다." — 국제 재생 에너지 기구(IRENA) 기술 브리핑

- "2025년까지 SiC 장치는 입증된 신뢰성과 비용 성숙도로 인해 중전압 드라이브 및 그리드 컨버터에서 가속화된 채택을 보게 될 것입니다." — IEEE 전력 전자 학회 패널 및 로드맵

자주 묻는 질문

- SiC 시스템이 파키스탄의 그리드 코드 요구 사항을 충족합니까?

- 예. Sicarb Tech SVG/APF 및 인버터 솔루션은 NTDC/NEPRA 상호 연결 기준을 충족하고 IEEE 519, IEC 61000-3-6 및 IEC 61850 통신을 준수하도록 설계되었습니다.

- 일반적인 투자 회수 기간은 얼마입니까?

- 대형 섬유, 강철 또는 시멘트 공장의 경우 에너지 절약과 페널티 회피 및 냉각 감소를 통해 종종 18–30개월의 투자 회수가 발생합니다. 재생 에너지 공장은 감축 위험 감소의 이점을 누릴 수 있습니다.

- Sicarb Tech는 기존 VFD 및 SCADA와 통합할 수 있습니까?

- 예. Modbus TCP, IEC 61850, DNP3 및 레거시 시스템을 위한 맞춤형 게이트웨이를 지원합니다. 당사 엔지니어는 현장 통합 및 시운전을 제공합니다.

- SiC 시스템은 고온 및 먼지 환경에서 어떻게 작동합니까?

- SiC의 높은 접합 온도와 당사의 열 설계는 디레이팅을 최소화합니다. IP 등급 인클로저, 필터링된 기류 및 컨포멀 코팅은 먼지 또는 습한 환경에서 내구성을 향상시킵니다.

- 어떤 현지 인증이 필요합니까?

- 그리드 연결 시스템의 경우: NTDC 코드 및 유틸리티 승인 준수; 산업 장비의 경우: IEC 표준 및 현지 EHS 요구 사항 준수. 당사는 문서 및 테스트 보고서를 제공합니다.

- 파키스탄에서 현지 제조 또는 조립을 지원할 수 있습니까?

- 예. 기술 이전, 장비 사양 및 교육을 통해 전력 모듈 및 세라믹 부품의 현지 조립 라인을 설정하여 리드 타임과 수입 비용을 줄이는 데 도움을 드립니다.

- 파일럿 테스트를 제공합니까?

- 특정 환경에서 절감 및 규정 준수를 검증하기 위해 성능 보증과 함께 파일럿 배포를 권장합니다.

- SiC 세라믹 기판은 애플리케이션에 어떻게 도움이 됩니까?

- 더 높은 열 전도율과 기계적 강도는 핫 스폿을 줄이고 모듈 수명을 연장합니다. 특히 고부하 사이클에서 그렇습니다.

- 어떤 금융 또는 통화 고려 사항이 적용됩니까?

- 당사는 이정표에 연결된 단계별 지불로 제안을 구성하고, FX 위험을 헤지하기 위해 가격 지수 옵션을 제공하며, 프로젝트 자금 조달을 위해 EPC 및 금융 파트너와 협력할 수 있습니다.

운영에 적합한 선택하기

공장이 더 높은 가동 시간, 더 낮은 에너지 비용 및 확실한 규정 준수를 목표로 하는 경우 SiC 솔루션은 강력하고 미래 지향적인 경로를 제공합니다. Sicarb Tech는 고급 재료 전문 지식(R-SiC, SSiC, RBSiC, SiSiC), 고성능 전력 전자 장치 및 턴키 기술 이전을 결합하여 파키스탄의 가장 시급한 산업 과제를 해결합니다. 10년 이상의 실적과 19개 이상의 성공적인 배포는 측정 가능한 결과를 강조합니다. 즉, 더 빠른 응답, 더 높은 효율성 및 장기적인 신뢰성입니다.

전문가 상담 및 맞춤형 솔루션 받기

Faisalabad의 섬유 복합 단지, Khyber Pakhtunkhwa의 시멘트 공장, Karachi의 제철소 또는 Sindh의 태양광/풍력 사이트를 운영하든 관계없이 귀하의 시설에 맞는 맞춤형 평가, ROI 모델 및 규정 준수 로드맵을 위해 당사 애플리케이션 엔지니어에게 문의하십시오.

Sicarb Tech - 실리콘 카바이드 솔루션 전문가

- 이메일: [email protected]

- 전화/왓츠앱: +86 133 6536 0038

- 위치: 중국 웨이팡시(중국 과학 아카데미 혁신 공원 회원)

문서 메타데이터

- 최종 업데이트: 2025-09-11

- 다음 예약 업데이트: 2025-12-15

- 작성자: Sicarb Tech 산업 솔루션 팀

- 참고 자료:

- SiC 장치에 대한 IEEE 전력 전자 및 IEEE 스펙트럼 기사(일반 산업 출처)

- IEEE 519, IEC 61000-3-6, IEC 61850 표준 지침

- 그리드 통합 및 광대역 갭 반도체에 대한 국제 에너지 기구 및 IRENA 기술 브리핑

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.