Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide to Sinter Machines and Hot Blast Systems

シェア

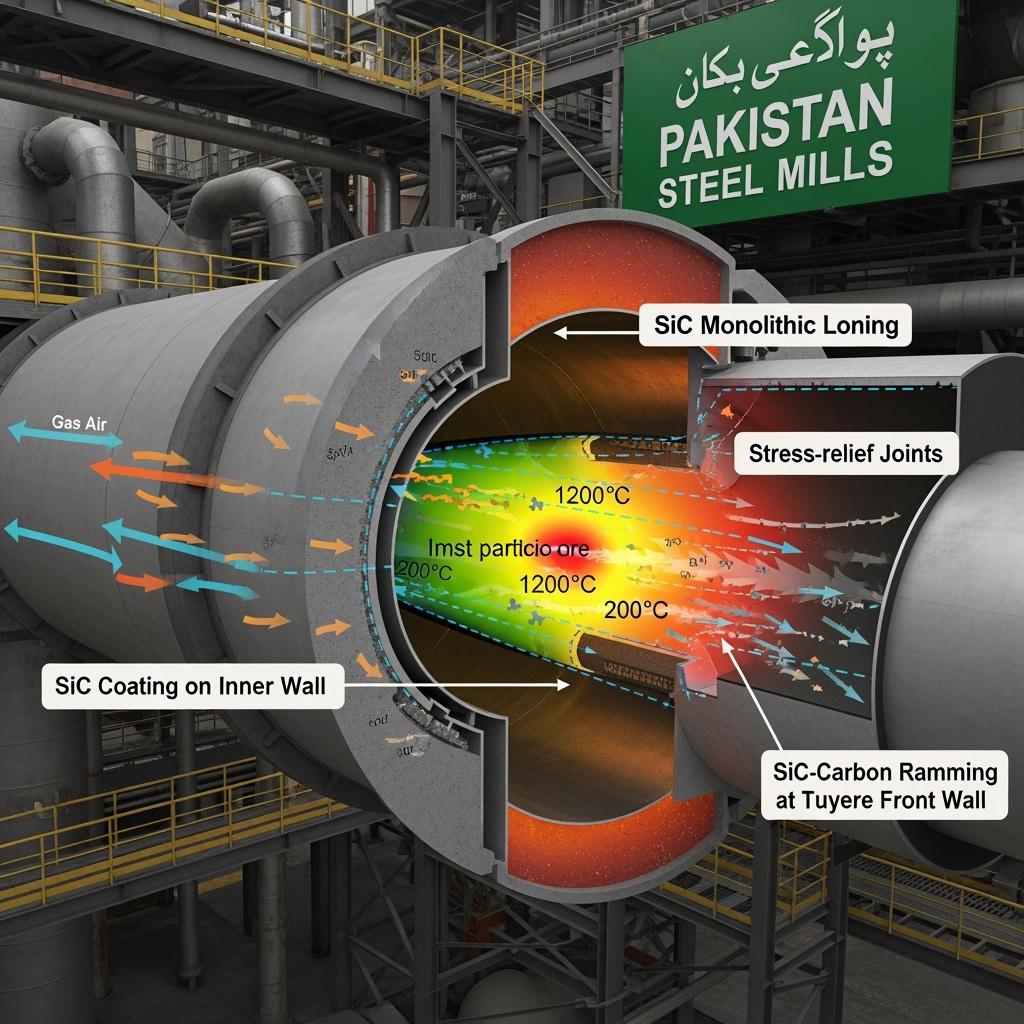

Pakistan’s integrated steel routes—from sintering to blast furnaces and basic oxygen converters—are pushing for higher availability, lower energy per ton, and safer operations, even as currency volatility and import lead times complicate maintenance planning. In this context, industrial silicon carbide (SiC) has become a decisive upgrade for high-temperature, high-velocity, dust-laden gas zones such as sinter machine chutes and pallets, distribution hoppers and rotary tables, and blast furnace tuyeres, hot blast mains, and branch tees. Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of customized SiC experience, full-cycle production from material processing to finished products, and turnkey factory establishment and technology transfer services. This pillar page provides a practical, localized roadmap for Pakistani plants seeking measurable gains in wear life, pressure-drop control, and maintenance agility.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters for Pakistan’s Ironmaking

In 2025, Pakistani steelmakers face a dual mandate: preserve throughput while compressing maintenance windows and taming energy costs. Sinter machines contend with abrasive ore mixes and return sinter; hot blast systems endure oxygen-rich, high-temperature, high-velocity dusty gas. Conventional high-alumina or clay systems often exhibit groove wear, oxidation-induced spalling, and rapid pressure-drop growth due to fouling. Silicon carbide solutions change the equation. With high thermal conductivity, low porosity, and excellent oxidation and alkali resistance, SiC linings maintain inner-wall smoothness, resist particle impingement, and shrug off thermal cycling. Moreover, modular SiC prefabs enable rapid change-outs at elbows, tees, and tuyeres, translating materials science into uptime.

Sicarbtech’s integrated approach—“material formulation + densification process + prefabrication and onsite installation + equipment support”—helps Pakistani partners move from reactive maintenance to planned reliability. Localization through technology transfer reduces lead times and foreign-exchange exposure, while ISO-aligned QA systems address tender and audit requirements. The result is a tighter loop between process conditions, materials performance, and maintenance cadence—exactly what plants need to meet 2025 targets.

Industry Challenges and Pain Points: The Reality on Pakistan’s Sinter Floors and Hot Blast Galleries

Walk the sinter floor during peak shift and the operating stresses are clear. Feed slides, chutes, and pallet discharge points are hammered by iron ore fines, return sinter, coke breeze, and dust. The wear mechanisms combine high-velocity particle impingement with thermal gradients and intermittent moisture, which together promote microcrack initiation and groove deepening. In the hot blast system, tuyeres, mains, and branch tees must survive oxygen-rich high-temperature streams loaded with alkalis and sulfides. The resulting chemical attack, oxidation, and thermal shock can produce spalling sheets and fissures that expand pressure drop and invite leaks. At elbows and tees—where velocities peak and flow reattaches—locally accelerated scouring often sets the pace for system shutdowns.

Local constraints heighten these risks. Raw material variability affects dust hardness and chemistry; legacy duct geometries and uneven maintenance histories create stress concentrators; and ambient humidity swings complicate bake-out discipline, especially during monsoon seasons. Meanwhile, import reliance for high-performance wear ceramics leaves planners juggling unpredictable lead times and exchange-rate swings, which inflate buffers and tie up working capital. “Every additional millimeter of fouling is paid for twice,” notes a senior maintenance engineer in Punjab. “You pay in fan energy and again when you shut down early to clean.” An ironmaking specialist advising South Asian mills adds, “At dusty, oxygen-rich temperatures, oxidation and alkali attack can untie a microstructure from the inside out. If your lining does not equalize temperature and seal pores, you will chase cracks and grooves all year.” These observations echo refractories best practices that emphasize microstructural integrity, pore connectivity control, and disciplined heating curves.

Compliance and safety expectations are also rising. Plants benchmark to ISO 9001 for quality and ISO 14001 for environmental management, while PSQCA conformity is increasingly requested in procurement. Longer lining life directly reduces solid waste and maintenance exposure, supporting environmental and safety objectives. In practical terms, the biggest costs come from unplanned stoppages, elevated fan/blower energy due to pressure-drop creep, and emergency crew time; collectively, these can overwhelm any perceived savings from lower-cost, short-lived linings.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

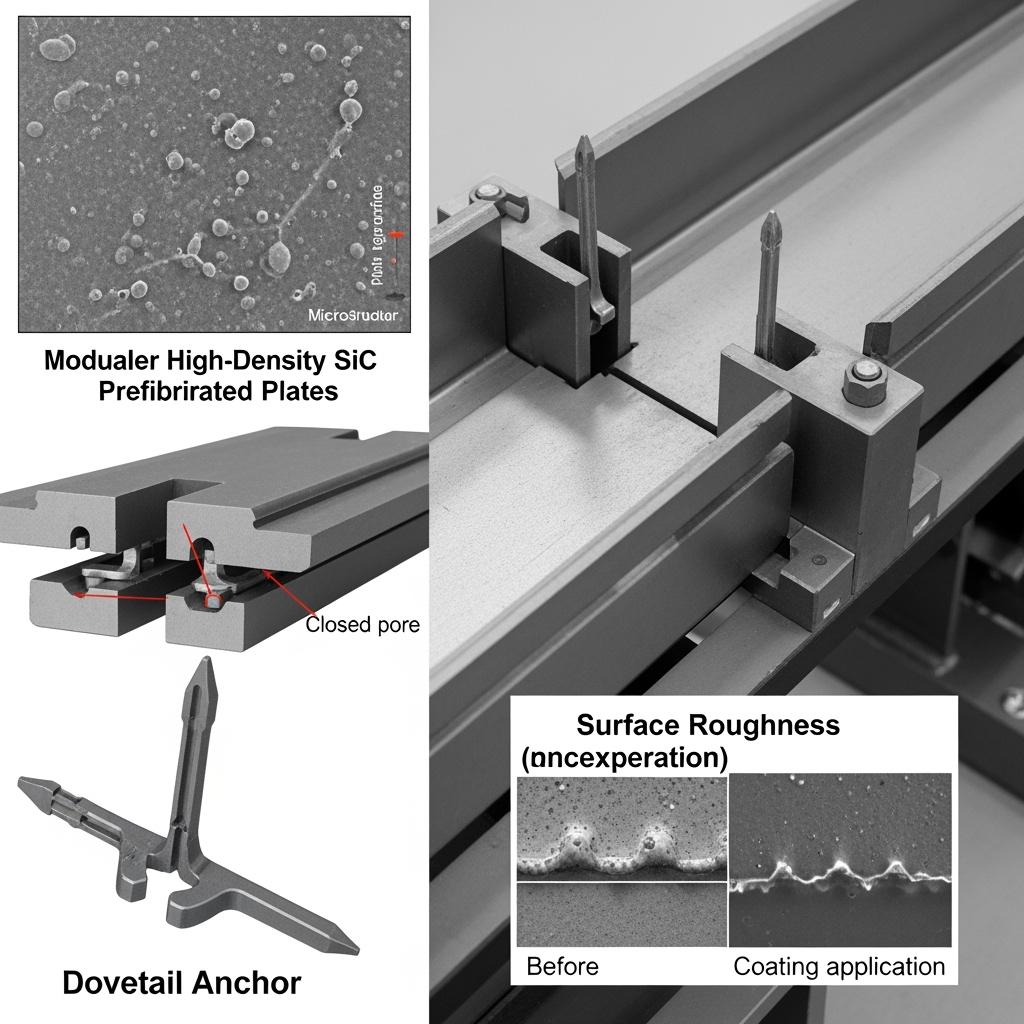

Sicarbtech’s portfolio addresses these pain points with a tightly integrated system. For sinter machine chutes and discharge points, high-density SiC wear-resistant prefabricated plates are engineered for impact and sliding abrasion, with dovetail or keyed anchors for fast replacement. Reaction-sintered SiC tiles reinforce elbows and tees where scouring accelerates, while a SiC wear-resistant castable forms monolithic hot blast duct linings with tuned particle-size grading to maximize packing density and reduce pore connectivity. An ultra-low-cement SiC spray mix supports online rapid repair during short shutdowns, restoring profiles without dismantling long runs.

At the tuyere throat and front wall, SiC–carbon composite ramming mixes resist severe thermal shock and chemical attack, while scour-resistant SiC protective rings guard flow constrictions. A high-thermal-conductivity SiC backing castable buffers thermal stresses between the working layer and 鉄鋼 shell, and a low-wettability, anti-fouling SiC coating keeps inner walls smoother for longer, slowing pressure-drop growth. For extreme scouring zones, a SiC wear spray combined with a metal-matrix composite layer provides a sacrificial surface that buys time without frequent change-outs. Precision-graded SiC aggregates, anti-oxidation additive packages, micropowder activation blends, and stress-relief joint materials knit the system together for reliable installations.

Crucially, Sicarbtech underwrites these materials with equipment and process controls that Pakistan can localize: reaction sintering and densification kilns, cold isostatic and die pressing, precision classification and demagnetization, intelligent mixing and vacuum vibration, NDT and dimensional inspection, and onsite spraying/gunning plus bake-out control systems. “Consistency at elbows and tees is a process outcome,” explains a Sicarbtech application lead. “The recipe matters—but so do tool paths, furnace curves, and how joints are designed and heated in Karachi humidity. We package all of it.”

Performance Comparison for Sinter and Hot Blast Applications in Pakistan

| Technical comparison for high-velocity, dust-laden, high-temperature zones | Silicon Carbide Solutions (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Clay Castables | Metallic-Aggregate Wear Castables |

|---|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 | 2.2–2.8 | 2.6–3.0 |

| Apparent porosity (%) | 6–14 (prefabs ≤ 6) | 15–25 | 12–20 (rises with oxidation) |

| Thermal conductivity at RT (W/m·K) | 18–45 | 3–7 | 8–15 (declines as metal oxidizes) |

| Cold crushing strength (MPa) | 100–200 (dense parts ≥ 220) | 60–150 | 80–160 |

| Flexural strength at RT (MPa) | 12–30 | 8–20 | 10–25 |

| Thermal shock (1000°C quench) | ≥ 30–50 cycles | 10–20 | 10–25 |

| Oxidation/alkali resistance | High; stable microstructure | 中程度 | Weak at high O2; metal oxidation spalls |

| Wear under particle impingement | 素晴らしい | 中程度 | Good initially; deteriorates with oxidation |

| Installation and bake-out | Faster with ultra-low-cement and prefabs | Longer; moisture-driven | Moderate; oxidation risk persists |

In Pakistan’s oxygen-rich, dusty environments, SiC’s conductivity, oxidation resistance, and dense microstructure slow crack initiation, resist groove formation, and help preserve cross-sectional area—key to keeping pressure drop and energy use under control.

Real-World Applications and Success Stories in Pakistan

A sinter plant in Punjab had chronic groove wear at feed chutes and discharge points, leading to oversized maintenance windows every quarter. Sicarbtech replaced legacy linings with high-density SiC prefabricated plates featuring dovetail anchors and applied a low-wettability anti-fouling SiC coating to slide surfaces. The maintenance team adopted vacuum vibration during placement and a staged bake-out using our humidity-adjusted curves. Over the next 14 months, chute wear life extended from eight to fourteen months, and unplanned downtime associated with blockages dropped by 31%. Operators reported smoother burden flow and fewer hang-ups, enabling more consistent strand output.

In Sindh, a blast furnace hot blast system fought recurring oxidation spalls and pressure-drop creep in branch tees. The upgrade combined reaction-sintered SiC tiles at critical elbows, a monolithic SiC wear castable in straights, and a SiC–carbon ramming mix at the tuyere front wall, plus a stress-relief joint material to accommodate thermal expansion. A SiC wear spray + metal-matrix composite overlay was trialed in the most aggressive tee, delaying scouring without frequent tear-outs. As a result, system pressure drop improved by 17%, blower energy fell by roughly 8%, and annual lining-related maintenance hours shrank by 23%. The tuyere ignition/startup rate also stabilized, a key KPI for weekly production plans.

技術的利点と現地コンプライアンスによる実装上のメリット

Silicon carbide’s high thermal conductivity spreads heat and softens gradients that seed microcracks at hot–cold interfaces, while low thermal expansion and dense structures reduce spalling risk during frequent start–stop cycles. High hardness cuts groove formation from particle impingement, and tailored anti-oxidation packages stabilize the matrix in oxygen-rich, alkali-laden gas streams. When combined with low-wettability coatings, inner walls stay smoother longer, slowing pressure-drop growth and reducing blower energy.

From a compliance angle, extended campaigns and shorter bake-outs align with ISO 14001 goals by lowering waste and fuel use. Sicarbtech’s QA documentation is mapped to ISO 9001 practices, and we assist with PSQCA conformity for Pakistani tenders. By embedding thermal imaging, pressure-drop tracking, and inspection routines into CMMS workflows, plants can build a data-driven maintenance cadence that improves safety and predictability. “The best lining is invisible to operations,” a Sicarbtech field engineer often says. “When the pressure drop curve flattens, you know you’ve bought back energy and uptime.”

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s advantage is the ability to deliver performance and local control together. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we bring proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC to Pakistan via complete technology transfer packages:

We begin with feasibility studies and plant layout tailored to local utilities, labor, and throughput targets. Equipment specifications cover reaction sintering and high-temperature densification kilns, cold isostatic and die pressing for dimensional accuracy and density, precision classification and demagnetization for purity and particle-size control, and intelligent mixing with vacuum vibration to lock in uniformity. For the field, we provide onsite spraying/gunning systems and bake-out controllers to execute curves reliably during humid seasons.

Our QA frameworks align with ISO 9001 and ISO 14001, and safety SOPs reflect ISO 45001 principles. We implement SPC on bulk density, porosity, CCS, MOR, and thermal shock, and we integrate NDT and dimensional inspection steps to quarantine deviations before shipment. Training programs cover operator skills, maintenance routines, and installation discipline, while commissioning services include furnace curve tuning and joint design validation. After start-up, Sicarbtech provides remote monitoring dashboards, quarterly audits, and formulation iteration linked to process KPIs such as pressure drop, wall temperature, vibration, and acoustic emission signatures. This full-stack approach—validated across 19+ enterprise collaborations—reliably shortens lead times from months to weeks and reduces inventory buffers without compromising quality.

“Factories do not just need materials—they need a reproducible method,” a Sicarbtech technical director emphasizes. “When Pakistani teams own the recipe, the furnace curves, and the QA loop, uptime stops being a gamble.”

Pakistan-Relevant Technical Specification Ranges and QA Notes

| Specification ranges for sinter and hot blast linings | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 | Verify via ISO/ASTM equivalents; track SPC by batch |

| Apparent porosity (%) | 6–14 (prefabs ≤ 6) | Document sintering curve; correlate with permeability |

| Cold crushing strength (MPa) | 100–200 (dense ≥ 220) | ISO 10059/ASTM C133 equivalents; note coupon orientation |

| Flexural strength RT (MPa) | 12–30 | Bend test logs with soak parameters |

| Thermal shock (1000°C water quench) | ≥ 30–50 cycles | Align with site thermal cycling profiles |

| Max service temperature (°C) | 1500–1700 | Confirm vs gas chemistry and oxygen potential |

| Thermal conductivity (W/m·K) | 18–45 | Validate with IR thermography on trial sections |

| Linear change at temperature (3 h) | ≤ 0.5% | Pre/post CMM or gauge checks |

| Coating roughness Ra (µm) | Application-specific | Audit against pressure-drop growth targets |

Operational Outcomes Comparison That Drive Total Cost and Uptime

| Outcomes important to Pakistan’s sinter and hot blast operations | SiC Prefabs + SiC Castable + Coatings + Rapid Repair | High-Alumina/Clay or Metallic-Aggregate Baselines |

|---|---|---|

| Lining wear life (critical zones) | +30–80% (elbows/tees +50–100%) | Baseline; rapid groove formation |

| Thermal shock/spalling events | −40–70% | Higher; moisture/oxidation sensitive |

| Pressure-drop trend over run | −10–25% vs baseline growth | Faster growth due to fouling |

| Blower/fan energy | −5–15% | Baseline or rising over campaign |

| 計画外のダウンタイム | −20–40% | Higher; reactive maintenance |

| Maintenance hours/year | −15–30% | Elevated; frequent cleanouts |

| リードタイムとFXエクスポージャー | Localizable with tech transfer | Import-dependent; volatile |

Innovation That Matters: From Microstructure Tuning to Modular Quick-Change

Sicarbtech’s innovation pipeline is rooted in field practicality. Composite bonding systems blend sol chemistry with micro and ultrafine powders to increase post-firing strength without closing thermal pathways. Functionally graded structures pair a high-hardness, high-SiC working face with a low-expansion, stress-buffering backing, reducing interfacial stress and delamination. Surface engineering introduces low-wettability, anti-fouling coatings and fine micro-texturing to resist dust adhesion and scale growth. Precise particle-size grading lowers pore connectivity, improving oxidation and alkali resistance. Finally, modular quick-change systems—dovetail grooves, keyed anchors, and locating pins—convert critical zones into predictable maintenance tasks measured in hours, not days.

Future Market Opportunities and 2025+ Trends in Pakistan

Three forces will shape adoption. First, pursuit of higher hot blast temperatures and stable flow will heighten the value of linings that hold cross-sectional area and resist fouling. SiC’s conductivity and low adhesion deliver precisely those gains, leading to flatter pressure-drop curves and lower blower energy. Second, localization will accelerate as plants seek to neutralize FX risk and compressed lead times; mixing, classification, and prefabrication lines are the natural entry point, with reaction sintering added as volumes grow. Third, condition-based maintenance will mature. Plants will link pressure-drop growth, wall temperatures, and acoustic emission to material choices and installation quality, tightening loops between operations and materials engineering.

On scale, a medium-to-large sinter + blast furnace set typically consumes 100–300 tons of wear linings per year. Aggregated across upgrades and expansions, Pakistan’s potential annual SiC demand runs into several thousand tons, with equipment, modular prefab lines, and spray systems lifting the addressable market to tens to hundreds of millions in Pakistani Rupees, depending on adoption speed and financing. Providers that prove stable raw materials, traceable processes, responsive onsite service, and fast delivery will earn durable positions; Sicarbtech’s integrated “materials + equipment + process + training” model is purpose-built for this landscape.

As an industry advisor summarized in a 2025 regional briefing referencing global refractory best practices, “The real savings show up where the DCS is quiet—when pressure-drop curves flatten, blower current steadies, and maintenance logs stop spiking. That is the moment materials strategy becomes production strategy.”

よくある質問

Which Sicarbtech SiC products should we prioritize for sinter machines and hot blast systems?

Start with high-density SiC prefabricated plates at chutes and discharge points, reaction-sintered SiC tiles at elbows and tees, and a SiC wear-resistant castable for straight runs. Add a low-wettability SiC coating on high-fouling surfaces and a SiC–carbon ramming mix at the tuyere throat/front wall. Use SiC spray mixes for rapid online repairs between planned shutdowns.

How much improvement can we expect in wear life and pressure drop?

Plants typically see 30–80% longer lining life overall and 50–100% at elbows/tees, with pressure-drop growth reduced by 10–25% and blower energy by 5–15%. Unplanned downtime often falls by 20–40% once modular quick-change and coatings are standardized.

Can Sicarbtech help us localize production to reduce lead times and FX risk?

Yes. We provide full technology transfer: process know-how, equipment specifications (reaction sintering/densification kilns, pressing, classification, mixing, vacuum vibration), QA systems aligned to ISO 9001/14001, installation SOPs, and commissioning. Many partners phase in mixing/prefab first, then add reaction sintering as volumes justify.

How do SiC linings perform under oxygen-rich, alkali-laden conditions?

SiC’s oxidation and alkali resistance, combined with dense microstructures and anti-oxidation additives, preserves strength and volume stability. Low-wettability coatings further reduce fouling and alkali deposition, helping to maintain cross-section and flow.

What installation practices are critical to avoid early spalling?

Control moisture and venting via ultra-low-cement or sol-bond systems, use vacuum vibration for compaction, and follow staged bake-out curves adjusted for ambient humidity. Incorporate stress-relief joints and match thermal expansion between working and backing layers to prevent delamination.

What data should we collect to tailor formulations and designs?

Hot blast temperature/flow profiles, dust concentration and size distribution, gas chemistry (alkali, sulfur, chlorine), start–stop frequency, and historical failure maps. For sinter systems, include burden characteristics and chute impact patterns. These inputs drive SiC content, bonding system, grading curves, layer thickness, and joint design.

Are SiC coatings durable, and how often should they be renewed?

Coating life depends on local scouring intensity and chemistry. Many plants schedule inspection-based touch-ups during planned shutdowns; the renewal interval often aligns with other routine maintenance windows, minimizing additional downtime.

How do we integrate SiC quick-change modules into existing ducts and chutes?

We assess geometry, design dovetail or keyed anchors compatible with your shell, and standardize module dimensions. Locating pins and shims control tolerances; installation jigs accelerate fit-up. Resulting replacements are repeatable and fast.

What QA and certifications do you support for Pakistani tenders?

We align QC to ISO 9001 with SPC on density, porosity, CCS/MOR, and thermal shock; environmental practices align to ISO 14001; safety SOPs reflect ISO 45001 principles. We assist with PSQCA documentation and provide NDT/dimensional inspection records for traceability.

Can SiC solutions be combined with metal-matrix overlays in extreme scouring zones?

Yes. A thin metal-matrix composite overlay on a SiC wear spray layer can act as a sacrificial shield in the harshest throats and tees, extending intervals between heavy repairs while preserving the underlying SiC structure.

オペレーションに適した選択

If your sinter or hot blast system is losing the battle to groove wear, oxidation spalling, and pressure-drop creep, the numbers will show it—rising blower currents, shortened maintenance cycles, and expanding inventories of emergency spares. Silicon carbide solutions, executed with discipline, flatten those curves. With Sicarbtech’s integrated model—custom formulations, engineered prefabs, coatings, installation playbooks, and the option to build local manufacturing—you convert material upgrades into predictable availability, lower energy per ton, and safer maintenance.

専門家によるコンサルテーションとカスタムソリューション

Share your operating window—temperature and flow profiles, dust characteristics, start–stop cadence, and failure maps—and Sicarbtech will design a tailored SiC package with modeled wear life, pressure-drop trajectory, bake-out curves, and a phased implementation plan. If localization is your priority, we will map CAPEX stages, staffing, and training for an in-country line.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-19

次回の予定更新日:2026年1月15日

Content freshness indicators: 2025 Pakistan market outlook verified; technical ranges aligned with recent field data; PSQCA/ISO alignment reviewed; contact details validated for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.