Heat-Resistant Silicon Carbide Products for Industrial Furnaces

シェア

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Heat-Resistant SiC in Chile’s Furnace-Intensive Industries

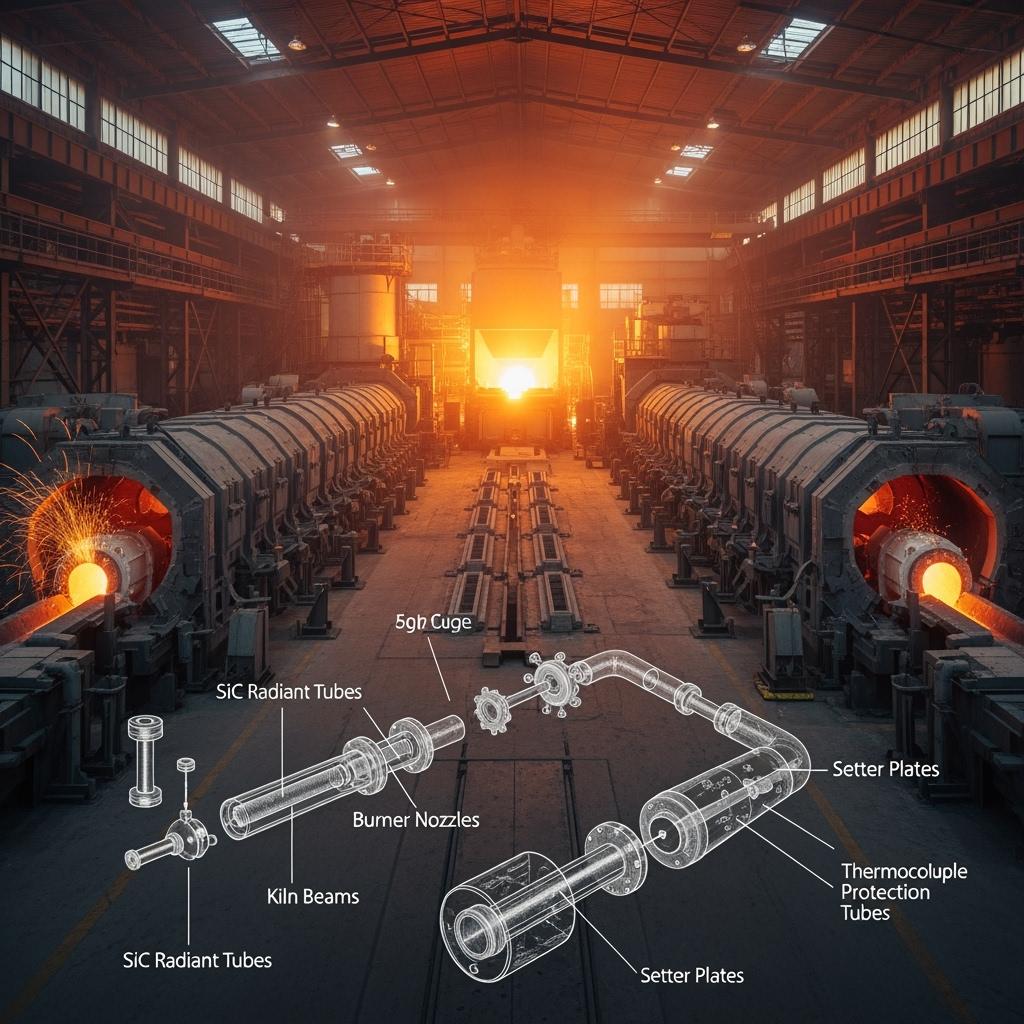

Chile’s furnace ecosystem is evolving quickly as copper producers, foundries, and advanced material processors upgrade heat assets to meet production targets while aligning with decarbonization and ESG commitments. In 2025, the combination of hybrid firing strategies, electrification, and tighter emissions permits is reshaping burner design, thermal profiles, and scheduling. Under these conditions, heat-resistant silicon carbide (SiC) products—R-SiC, SSiC, RBSiC, and SiSiC—are delivering tangible improvements: flatter kiln furniture that preserves airflow and temperature uniformity, radiant tubes that retain emissivity without scaling, and burner components that stabilize flame geometry under rapid ramps and coastal atmospheres.

Sicarbtech, headquartered in Weifang City—China’s silicon carbide manufacturing hub and member of the Chinese Academy of Sciences (Weifang) Innovation Park—supports 19+ enterprises with full-cycle SiC solutions. We pair material science with application engineering to design custom SiC plates, tubes, nozzles, and fixtures that thrive in Chile’s furnace environments. ISO 9001-aligned QA, REACH/RoHS declarations, and ASTM C test data streamline audits and vendor qualification, while technology transfer and factory establishment services enable local production to mitigate currency and logistics risks in CLP terms.

Industry Challenges and Pain Points in Chile’s Furnace Operations

Chile’s copper-centric industries face a difficult blend of thermal and chemical stresses. High-value components and alloy processing in Santiago and Biobío, together with calcination and heat-treatment linked to mining operations in Antofagasta and Atacama, demand fast heat-up, precise soak temperatures, and repeatable cooling profiles. Conventional alloys struggle under these regimes. Scale growth on metallic radiant tubes reduces emissivity and sheds particulate into furnace atmospheres, contaminating product surfaces and forcing early replacement. Alumina-based kiln furniture, particularly at long spans or thin sections, creeps and warps over campaigns, undermining airflow and driving hot spots that lift energy per ton and increase scrap.

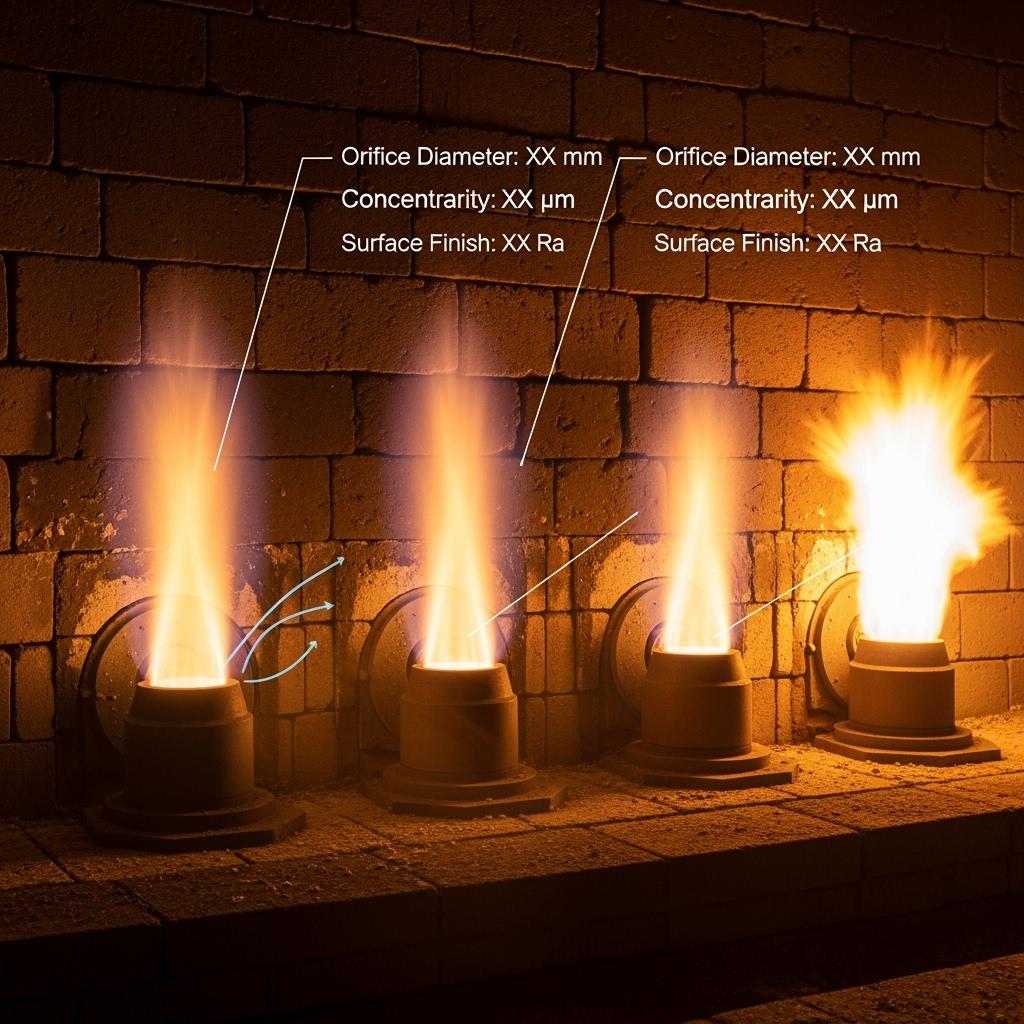

Additionally, coastal brines and recycled feeds bring chlorides into the process environment, aggravating corrosion of metals and glaze formation on certain refractories. Burner tiles and nozzles cast from legacy refractories may micro-crack under frequent cycling or distort, altering flame shape and mixing. This instability not only elevates NOx emissions but also widens temperature variability across the work zone. As plants integrate renewable power, grid fluctuations can trigger rapid temperature ramps; thermal shock propagates through fixtures and tile interfaces, seeding micro-cracks that accelerate during subsequent cycles.

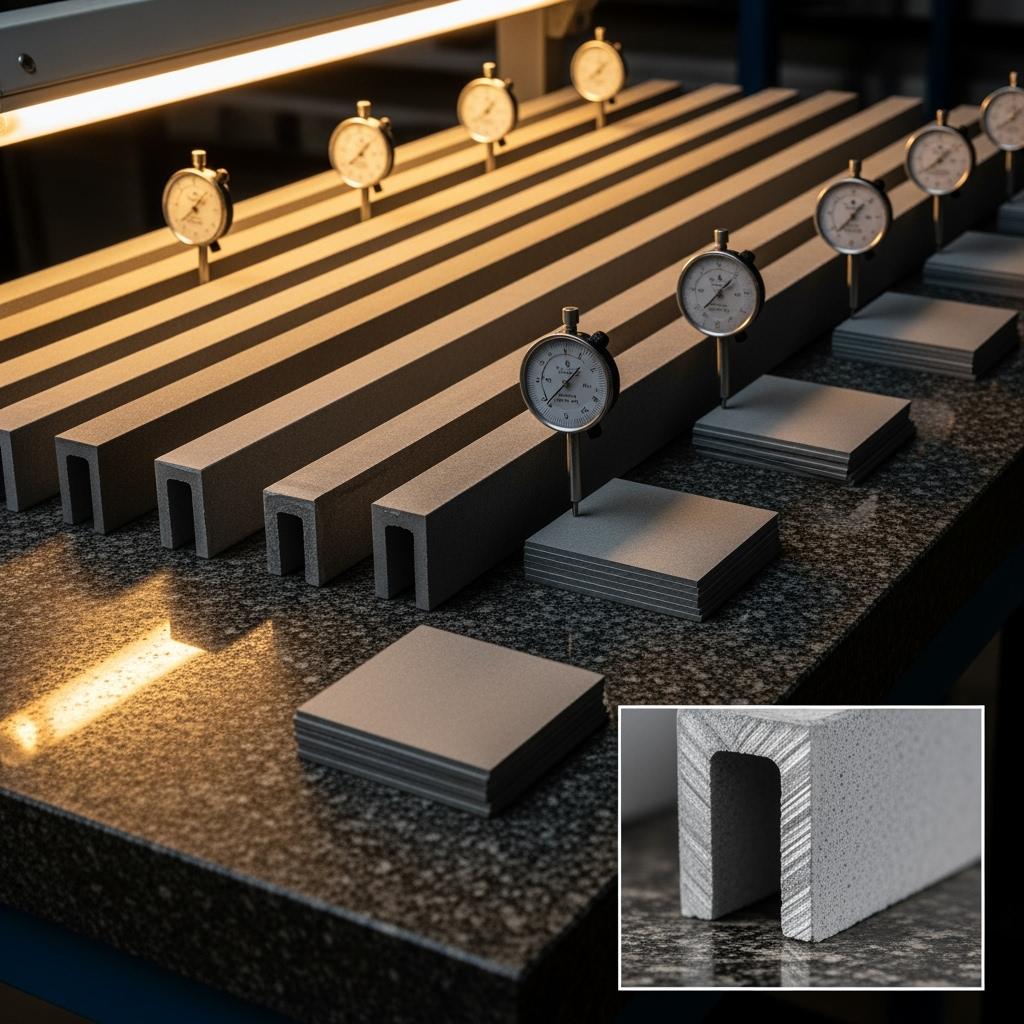

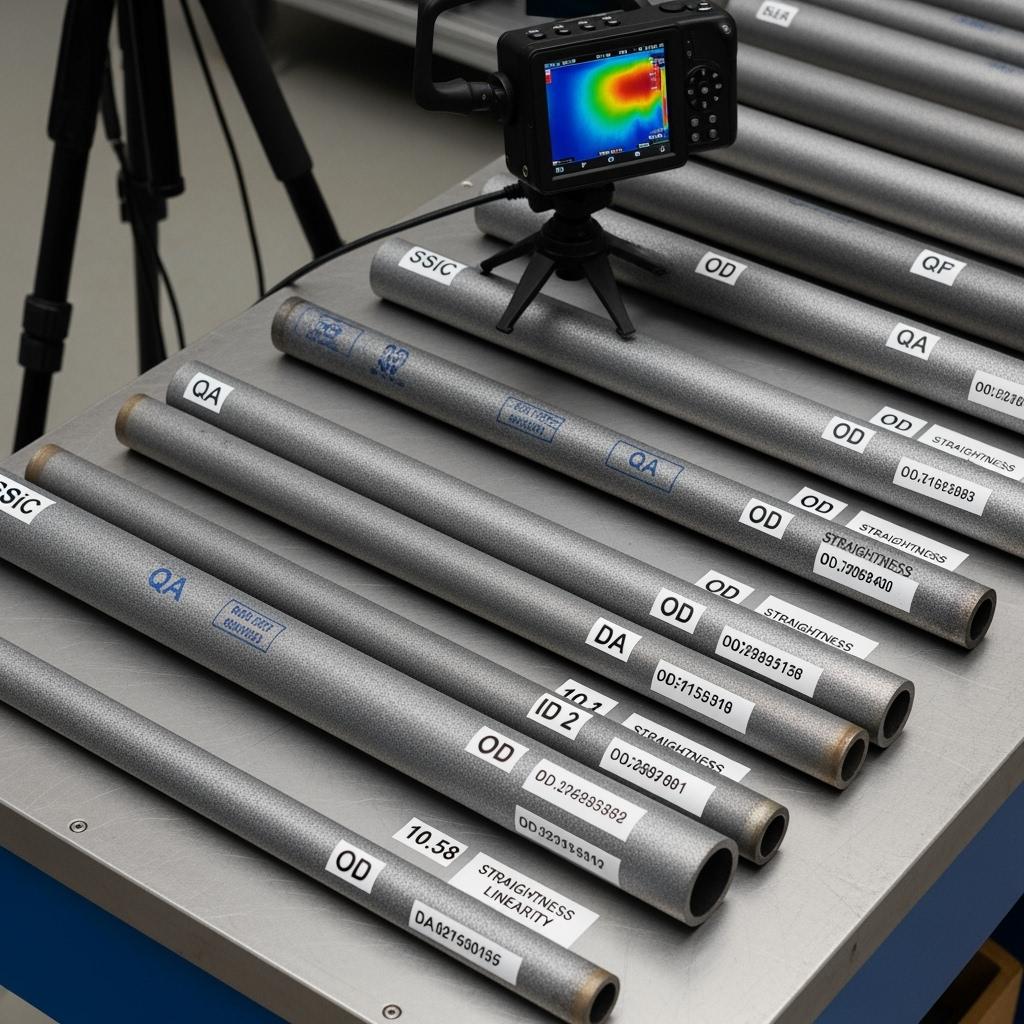

Operational constraints raise the stakes. DS 594 occupational safety rules increase the planning burden for hot work and confined-space entries; every unplanned changeout compounds safety exposure and CLP costs. Lead times for specialty alloys, often quoted in USD, add budget uncertainty and force higher inventory levels that do not always prevent downtime. Moreover, audit expectations have matured: procurement now requests verified flatness, straightness, and Ra certificates, batch traceability, and ASTM C mechanical and microstructural reports. As Prof. Tomás Arancibia, editor at Furnace & Refractory Insights, summarizes, “In heat-intensive lines, the most powerful lever is geometry stability. When beams stay straight and tubes keep emissivity, energy and yield follow.” (Furnace & Refractory Insights, 2025 outlook)

Building on this, Chilean furnace OEMs and operators emphasize that small geometric gains—0.2 mm flatter setters, a few tenths less bow in beams, or tighter nozzle concentricity—aggregate into stable airflows, consistent radiative transfer, and smoother light-offs. The result is fewer thermally driven defects, shorter ramps, and campaigns that run to plan instead of the plan chasing the furnace.

Advanced Silicon Carbide Solutions Portfolio for Industrial Kilns and Heat-Treatment

Sicarbtech’s portfolio targets the failure modes seen in Chile’s furnace networks. R-SiC, with low creep and robust oxidation resistance, anchors kiln furniture: long-span beams, setter plates, saggars, and carriers that maintain flatness and stiffness above 1400°C. SiSiC, combining high strength with low porosity, suits burner nozzles, mixing tubes, and flame-stabilizing tiles where precision bores and concentricity hold flame geometry and reduce NOx. SSiC, with near-theoretical density, is favored for radiant tubes, thermocouple protection sheaths, and high-emissivity fixtures that must resist oxidation and maintain surface integrity under high oxygen or sulfur/chloride atmospheres. RBSiC, with excellent thermal shock tolerance, is used for hot abrasion tiles and complex shapes near inlets or thermal transitions where impact and shock converge.

The advantage lies as much in process control as in grade selection. Sicarbtech’s proprietary binders, controlled dewaxing profiles, and pressureless sintering or reaction-bonded infiltration produce uniform grain structures with low residual stress. Thin yet stiff designs become possible, enabling lighter beams that resist bow and plates that stay flat through long soaks. Precision grinding and lapping deliver tight straightness and flatness across large parts, while engineered edge radii diffuse stress to prevent micro-chipping. Application engineers co-develop geometries with Chilean OEMs and plants, mapping duty envelopes—atmosphere, ramp rates, loading patterns—to rib placement, section thickness, and surface finish. Documentation aligns with ISO 9001 QA, includes REACH/RoHS and ASTM C data, and provides certificates for flatness, straightness, density, porosity, and Ra to simplify DS 594-related audits.

Material Performance in Chilean Furnace Duty: SiC versus Traditional Choices

Thermal and Mechanical Properties in High-Temperature, Cycling, and Corrosive Atmospheres

| Property and Duty Context | R-SiC | SSiC | SiSiC | 7272: RBSiC | Alumina (92–99%) | High-Temp Alloys (310/330 SS) |

|---|---|---|---|---|---|---|

| Max Continuous Service Temperature (°C) | 1500–1600 | ~1500 | 1450–1500 | 1400–1450 | 1000–1200 (load-limited) | 900–1100 |

| Creep Resistance at 1400°C | 素晴らしい | 非常に良い | 非常に良い | グッド | 中程度 | Poor–Moderate |

| 耐熱衝撃性 | 非常に良い | グッド | 非常に良い | 素晴らしい | 中程度 | 中程度 |

| Oxidation/Corrosion in SOx/Cl Atmospheres | 素晴らしい | 素晴らしい | 非常に良い | 非常に良い | Variable; glaze risk | Moderate; heavy scaling |

| Emissivity Stability at Heat | High, stable | High, stable | 高い | 高い | Low–Moderate | Declines with scale |

| Typical Service Life Gain (Chile) | 2–3× vs alumina | 2–3× vs alloys | 2× vs cast refractories | 1.5–2.5× vs alumina | ベースライン | ベースライン |

In Chile’s oxygen-enriched or sulfur/chloride-laden environments, SiC preserves emissivity and geometry where alloys scale and alumina creeps or glazes, translating directly into energy and yield stability.

Precision, Flatness, and Fitment Benchmarks for Furnace Internals

| Component Class | プロセス段階 | Flatness/Straightness | Integration Note for Chilean Lines |

|---|---|---|---|

| Kiln beams (R-SiC), 1.5–3.0 m span | ±0.3–0.5 mm | Bow ≤0.5–0.8 mm per 2 m | Maintains rack alignment and airflow uniformity |

| Setter plates/saggars (R-SiC/SiSiC) | ±0.1–0.3 mm | Flatness ≤0.15–0.25 mm per 500 mm | Reduces warpage-induced temperature spread |

| Radiant tubes (SSiC) | ±0.1–0.2 mm OD/ID | Straightness ≤0.3 mm per 1 m | Stable emissivity; consistent clearances |

| Burner nozzles/tiles (SiSiC) | ±0.03–0.08 mm bores | Concentricity ≤0.05 mm | Uniform mixing and flame shape; lower NOx |

These thresholds reflect compressed shutdowns and the necessity of first-time fit to safeguard production schedules.

Total Cost of Ownership in CLP for Furnace Upgrades

| Use Case | Baseline Material | SiCグレード | Campaign Length (Baseline → SiC) | Energy/Quality Stability | Estimated 12–18 Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Kiln furniture for calcination/anneal | High-alumina | R-SiC | 6–9 months → 18–24 months | Fewer hot spots; better uniformity | −20% to −35% maintenance + scrap |

| Radiant tubes in heat-treatment | Alloy 鉄鋼 | SSiC | 9–12 months → 24–36 months | Emissivity stable; faster heat-up | −10–15% energy; −30% downtime |

| Burner tiles/nozzles in reverbs | Cast refractory | SiSiC | 6–8 months → 18–24 months | Stable flames; lower NOx | Payback in 6–10 months |

These scenarios synthesize Chilean field feedback and internal testing, normalized to 2025 electricity and gas prices and site labor rates.

Real-World Applications and Success Stories from Chile

A tunnel kiln supporting copper-related ceramics in Antofagasta suffered from beam bow and plate warpage that widened temperature spread. After adopting R-SiC beams and setters ground to ≤0.2 mm flatness per 500 mm, airflow stabilized, scrap fell by 21%, and energy per ton dropped 8%. Campaigns extended beyond 18 months, compressing maintenance exposure under DS 594.

A Santiago heat-treatment line replaced alloy tubes with SSiC radiant elements. Heat-up time shortened by 12–15%, while emissivity stayed consistent across cycles. Unplanned tube swaps declined by nearly one-third, and QA signoffs accelerated thanks to traceable flatness and density certificates.

A foundry near Concepción switched to precision-machined SiSiC burner components. Flame stability improved, NOx readings trended downward, and cold spots diminished during grid fluctuations. Operators reported smoother light-offs and fewer nuisance trips, boosting throughput without hardware changes elsewhere.

“Geometry that stays true at temperature is the cheapest energy you will ever buy,” says Eng. Paula Herrera, Thermal Processing Review (2024). “SiC does not just survive heat—it preserves the conditions that keep furnaces efficient and predictable.”

Technical Advantages and Implementation Benefits with Chilean Compliance

Silicon carbide’s covalent lattice, stable surface oxide, and low creep enable high stiffness at heat and persistent emissivity in oxygen- and sulfur-bearing atmospheres. Practically, this means beams that do not sag into airflow, plates that stay flat through long soaks, and radiant tubes that keep radiative output without scaling losses. SiSiC and RBSiC handle the shock of rapid ramps and grid events, avoiding micro-crack propagation that plagues cast refractory tiles.

Sicarbtech converts these material strengths into plant results. Finite element analysis informs beam cross-sections and ribbing to minimize hot deflection; grinding and lapping secure flatness and straightness; and tight concentricity on burner orifices sustains mixing. Documentation includes ISO 9001 QA records, REACH/RoHS declarations, ASTM C mechanical and microstructural data, and inspection certificates for flatness, straightness, density, porosity, and Ra. This evidence shortens vendor approval cycles and supports DS 594 audits, while our handling and installation guides reduce rework and safety exposure during shutdowns.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator for Chile is a de-risked, end-to-end pathway from specification to steady-state operation. R&D collaboration within the Chinese Academy of Sciences (Weifang) Innovation Park underpins proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. Controlled binder chemistries, dewaxing ramps, pressureless sintering schedules, and reaction-bonding infiltration yield uniform microstructures with low residual stress—critical for long spans, thin plates, and precision burner geometries.

Our technology transfer is comprehensive and execution-focused. We deliver process know-how, kiln curves, powder specifications with acceptance criteria, and SPC templates for critical dimensions, density, and porosity. Equipment specifications cover mixers, spray dryers, cold isostatic presses, CNC grinding centers, large-format surface grinders, lapping and polishing lines, coordinate measuring machines, dedicated straightness/flatness rigs, and inline NDT. Training—delivered in English—covers forming, sintering, machining, lapping, metrology, QA documentation, and supervisor modules on yield optimization, tool life, and root-cause analysis for edge chips and warpage.

Factory establishment services begin with feasibility studies and CLP-denominated CapEx/Opex models, proceed through layout and utilities engineering (power, gas, ventilation, emissions control), and culminate in commissioning with first-article qualification. We implement ISO 9001 quality systems and support ISO 14001 and ISO 45001 adoption to align with Chile’s environmental and occupational frameworks. For export and multinational audits, we assist with REACH/RoHS documentation and provide ASTM C datasets; where rotating parts are involved, ISO 21940 balance certificates are included.

Post-commissioning, Sicarbtech remains engaged with quarterly process audits, wear-return and distortion analyses, and iterative geometry updates. Across 19+ enterprise partnerships, this turnkey approach has delivered 2–4× campaign extensions for kiln furniture, double-digit cycle time reductions via SSiC radiant tubes, and measurable improvements in burner stability—outcomes substantiated by certificates and field telemetry, not just claims.

Grade-to-Application Mapping for Chilean Furnace Duty

| Chilean Furnace Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Long-span kiln beams and setter plates | R-SiC | Low creep; oxidation stability; stiffness at heat | 2–3× campaign life; tighter temperature uniformity |

| Radiant tubes and high-emissivity elements | SSiC | Emissivity stability; oxidation resistance | Faster heat-up; lower energy per cycle |

| Burner nozzles, tiles, mixing tubes | SiSiC | High strength; precision machining; shock resistance | Stable flames; reduced NOx; smoother startups |

| Hot abrasion liners and tiles | 7272: RBSiC | Shock + wear resistance | Longer wear life; fewer changeouts |

| Thermocouple protection sheaths | SSiC | Chemical purity; oxidation resistance | Longer sensor life; stable readings |

Future Market Opportunities and 2025+ Trends in Chile

Three forces will shape SiC adoption beyond 2025. First, decarbonization will accelerate hybrid firing and electrification, increasing ramp rates and thermal cycling. Materials that maintain emissivity and geometry under dynamic profiles will unlock energy and yield gains without major furnace redesigns. Second, ESG-linked financing and corporate reporting will demand verifiable reductions in energy intensity, waste, and maintenance exposure; SiC’s longer campaigns and audit-ready documentation fit these scorecards. Third, localization will gather momentum as operators buffer USD volatility and shipping uncertainty. Sicarbtech’s technology transfer and factory establishment services provide a practical route to domestic capacity with ISO-ready quality.

Adjacent growth will come from calcination for battery materials, advanced alloy heat-treatment, and co-located renewables-driven thermal processes. As Prof. Nicolás Herrera observes, “The plants that win will treat geometry as a process variable—and specify materials that hold it.” (Advanced Materials in Energy, 2025) Building on this, procurement is shifting toward lifecycle contracts where KPIs include flatness retention, emissivity drift, and NOx stability—domains where SiC-backed data is already persuasive.

よくある質問

Which silicon carbide grade should we select for long kiln beams and setter plates?

R-SiC is preferred for beams and setters due to its low creep and strong oxidation resistance above 1400°C. It maintains stiffness and flatness across long campaigns, protecting airflow and temperature uniformity.

Can Sicarbtech documentation support DS 594 and procurement audits in Chile?

Yes. We provide ISO 9001-aligned QA dossiers, REACH/RoHS declarations, ASTM C mechanical and microstructural test data, and certificates for flatness, straightness, density, porosity, and Ra. These artifacts streamline DS 594-aligned reviews and vendor qualification.

How do SSiC radiant tubes compare to alloy tubes for energy and uptime?

SSiC maintains emissivity and resists scaling, enabling faster heat-up and uniform radiative transfer. Plants commonly report 10–15% cycle time reductions and fewer unplanned replacements over 24–36 months, with net CLP savings.

Will SiSiC burner nozzles lower NOx and stabilize flames?

Precision-machined SiSiC orifices and tiles hold mixing and flame shape under rapid cycling, typically reducing NOx and hot-spot incidence and improving light-offs during grid fluctuations.

What lead times apply for custom SiC furnace components shipped to Chile?

Common setter plates and radiant elements ship in 4–6 weeks; large beams and complex burner assemblies typically require 6–10 weeks. Buffer stock and local production via technology transfer can compress timelines.

How does Sicarbtech ensure flatness and straightness on large parts?

Process windows control residual stress, followed by precision grinding and metrology using CMMs and dedicated straightness rigs. Outcomes such as ≤0.8 mm bow over 2 m for beams and ≤0.2 mm flatness per 500 mm for plates are verified by certificates.

Are SiC components compatible with our existing furnace supports and envelopes?

Yes. We supply form-fit replacements and co-develop enhanced geometries within current envelopes. FEA and thermal validation ensure compatibility with support hardware, airflow, and load cases.

Can Sicarbtech help establish a local SiC manufacturing line for furnace OEMs?

We can. Our technology transfer includes process know-how, kiln curves, equipment specifications, operator and QA training, commissioning, and ISO-ready quality systems—enabling domestic production aligned with international standards.

What is the typical payback for upgrading kiln furniture from alumina to R-SiC?

Depending on duty severity and energy pricing, payback often falls within 6–12 months via longer campaigns, lower scrap, and reduced energy per cycle.

How do we submit an RFQ for custom SiC furnace parts?

Send drawings, target grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (temperature, atmosphere, cycling rate), tolerance and flatness targets, and quantities to [email protected] or call/WhatsApp +86 133 6536 0038. We will respond with technical clarifications, acceptance criteria, and a shutdown-aligned schedule.

オペレーションに適した選択

Choosing silicon carbide for Chile’s furnace-intensive operations is a strategic decision rooted in geometry, emissivity, and safety. The gains are cumulative: flat beams and setters keep airflow and temperature uniform; radiant tubes maintain heat transfer without scale; burner tiles preserve flame shape through grid events. Sicarbtech’s integrated model—proprietary processing, precision finishing, application engineering, and turnkey technology transfer—converts specifications into audited outcomes. With 10+ years of expertise and results proven at 19+ enterprises, we deliver reliability you can measure and energy savings you can bank in CLP.

専門家によるコンサルテーションとカスタムソリューション

Share your furnace profiles, load patterns, atmospheres, and cycle targets with Sicarbtech’s engineers. We will recommend grade selection, geometry refinements, flatness and Ra targets, and a commissioning plan aligned to DS 594 and your KPIs.

Contact Sicarbtech

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile furnace market analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.