Industrial Silicon Carbide Composites for Extreme Thermal Shock: Sicarbtech’s 2025 Pillar Guide for Pakistan

シェア

Pakistan’s cement, 鉄鋼, glass, and adjacent sectors are heading into 2025 with a clear directive: keep heat-intensive assets on stream while fuel mixes, chemistry, and schedules grow more volatile. Nowhere is that tension sharper than at extreme thermal-shock locations—burner throats, tuyeres and secondary air-duct linings, preheater quench zones, glass regenerator switching zones, and steel furnace inlets/outlets—where start–stop cycles, severe quench/heat events, alternating oxidizing/reducing atmospheres, and dust-laden high-velocity flows converge. Traditional high-alumina or single-phase SiC often spall, crack, or erode under this combined load. Composite silicon carbide materials—SiC–silicon nitride and SiC–carbon—change the equation by pairing high thermal conductivity and low expansion with crack-deflecting, energy-dissipating toughening mechanisms. Sicarbtech, located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings 10+ years of customization, production equipment, and turnkey technology transfer to help Pakistani operators deploy these composites with confidence and speed.

Executive Summary: 2025 Outlook and Why SiC–Silicon Nitride and SiC–Carbon Composites Matter

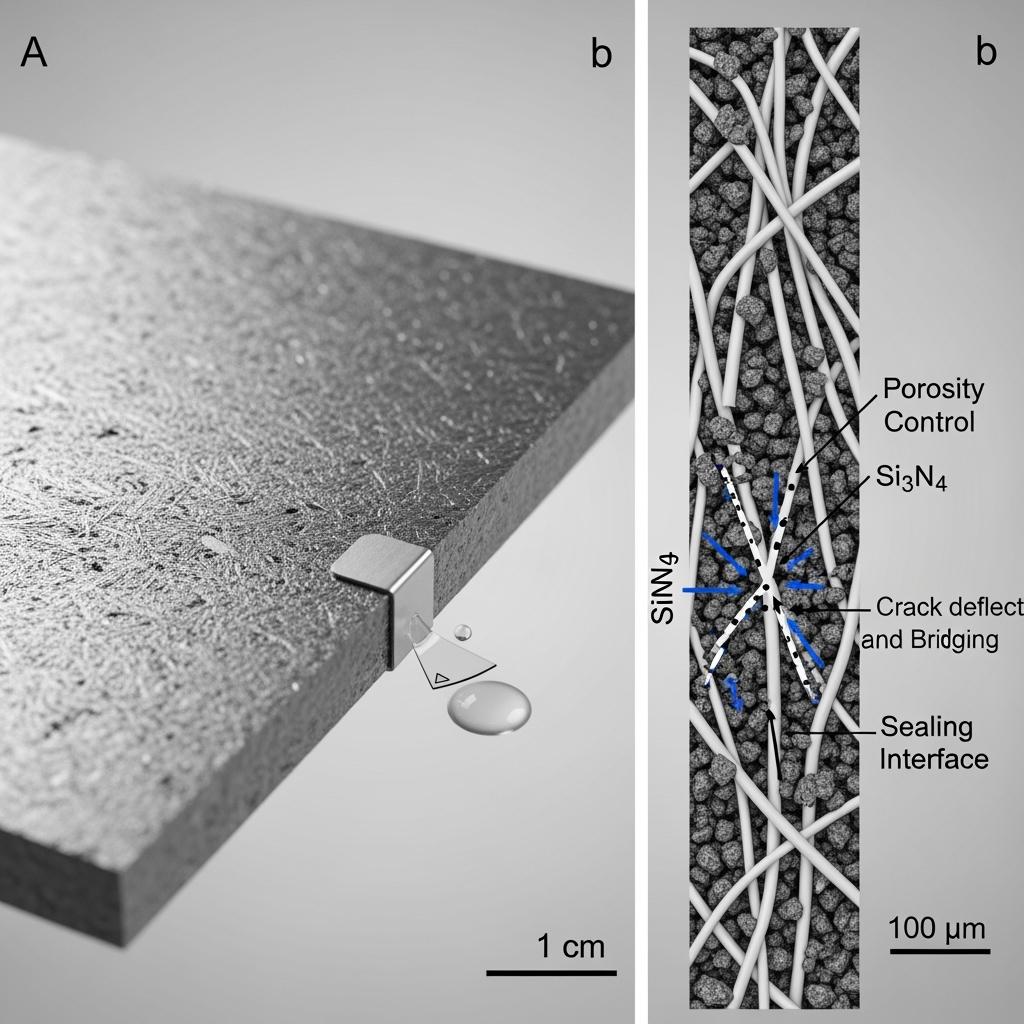

In 2025, Pakistan’s growth in clinker lines, reheating furnaces, and glass platforms coincides with wider co-firing of alternative fuels and more aggressive start–stop schedules. Extreme thermal-shock zones have therefore become the bottleneck. Composite SiC materials, engineered with silicon nitride or carbon phases (lamellae, short-cut fibers, microflakes), functionally graded structures, and low-wettability surface engineering, deliver a rare combination: high thermal conductivity to flatten temperature gradients, low CTE to reduce strain, and fracture-toughness mechanisms—crack deflection, branching, bridging, and pull-out—that curb spalling and through-cracks. Dense, fine-grained matrices, sealed interfaces, and anti-alkali/sulfur/chlorine strategies protect against chemical attack, while tailored microtextures reduce slag wetting. Sicarbtech integrates the material science with manufacturing reality—multi-zone reaction sintering/carburation, atmosphere control, impregnation densification, and digital QA—so Pakistani plants can scale from successful trials to consistent production.

Industry Challenges and Pain Points: The Reality at Pakistan’s Extreme Thermal-Shock Locations

Walk the hot face of a burner throat after a hard restart and the signatures are familiar. Quench–heat cycles generate steep gradients that drive crack initiation in corners and edges; once a through-crack forms, spalls follow, dropping debris that damages downstream hardware or blocks gas paths. In preheater quench zones and regenerator switching regions, atmospheres swing between reducing and oxidizing, while alkali–sulfur–chlorine species volatilize and condense, infiltrating open networks and inflating porosity. Dust-laden high-velocity flows scour surfaces at elbows, throats, and reattachment points, grooving the profile and thinning the section until design geometry is lost. Traditional high-alumina and mullite refractories, while familiar and accessible, carry lower conductivity and higher CTE, making them prone to thermal-shock-driven fractures. Single-phase SiC improves conductivity and expansion, but without toughening mechanisms it can still fail by brittle spallation when cycles are severe and frequent.

Pakistan’s operating context raises the stakes. Co-firing of refuse-derived fuels, low-rank coals, and residual oils introduces uncertain ash chemistry and softening temperatures; secondary air disturbances and load trims amplify hot spots; monsoon humidity complicates installation and bake-outs; and maintenance windows tighten as plants push throughput. Supply chain variability for advanced materials prompts operators to choose “good enough” fixes, only to see spalling or erosion reappear within weeks. “We were replacing cracked throat pieces after every rough restart,” a Lahore-based kiln maintenance lead recounted in mid-2024. “The geometry stayed right for a shift or two, then the edge chips began, and we were back to patching.”

Industry advisors converge on the physics. “Thermal shock failure is about gradients and the material’s ability to dissipate energy when a crack tries to run,” notes a South Asia refractory consultant referencing standard thermal shock and fracture-toughness studies. “High conductivity flattens the gradient; low expansion reduces strain; and a toughening phase makes the crack path work harder.” Regulatory and customer expectations compound the technical demands. PSQCA conformity and ISO 9001/14001-aligned documentation and practices are increasingly referenced in tenders; safety goals penalize hot, dusty interventions and prolonged door-open time; and environmental oversight raises the bar for materials that shed debris or drive frequent cleanouts. In this climate, composite SiC solutions must deliver not only materials performance but also installation discipline, repeatable quality, and credible data for audits.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

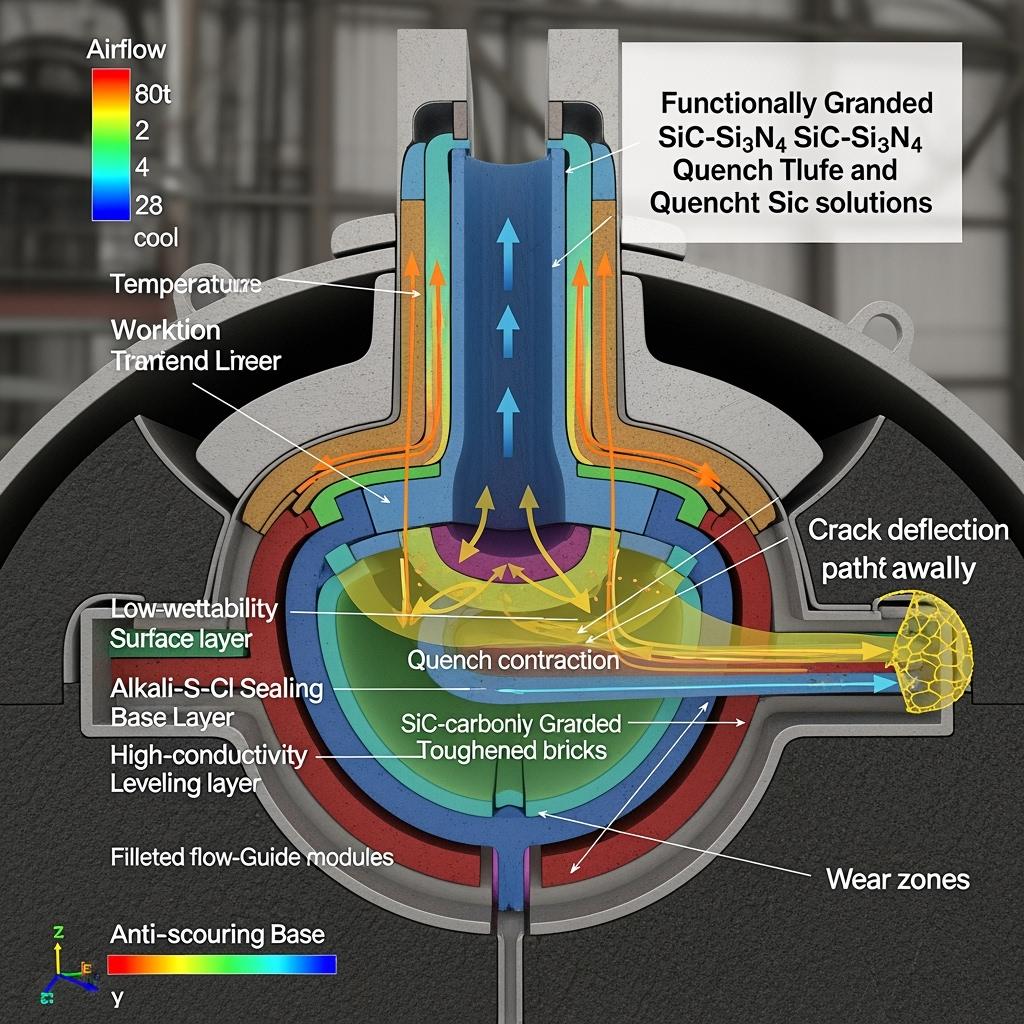

Sicarbtech’s portfolio turns composite science into field-ready systems for Pakistan’s extreme thermal-shock zones. The anchor is the SiC–silicon nitride functionally graded composite lining, with a hard, low-wettability working layer over a tough, stress-relief transition and a compliant base to balance strength and toughness. For the most violent shock sites, SiC–carbon toughened plates and bricks use short carbon fibers or microflakes to introduce crack-bridging and pull-out energy dissipation, while anti-oxidation packages and sealing strategies protect the carbon phase in oxygen-rich cycles.

Surface behavior is engineered for fouling resistance. A low-wettability anti-slag coating, combining microtexture with surface-energy tuning, suppresses adhesion and sintering of slags, salts, and alkali metals. A dual chemical barrier—an alkali–sulfur–chlorine sealing layer beneath the working face—reduces reaction pathways and porosity growth. To tame hot spots, a high-thermal-conductivity SiC heat-spreading/leveling layer smooths ΔT fields, cutting the root cause of thermal stress. Beneath the stack, a high-density anti-scouring base layer raises adhesion and load-bearing capacity where dust-laden flows run fastest.

For maintenance agility, Sicarbtech supplies fast-curing composite gunning mixes for online repair of spalled zones, along with composite prefabricated modules—throats, guide blocks, filleted corner modules—that restore geometry quickly and reduce vortex-induced scouring. Ultra-low-cement composite castables, tuned to bond to the composite plates/bricks, deliver robust transitions. Microstructure stabilization additives suppress grain coarsening and high-temperature porosity growth over long campaigns, while anti-oxidation composite additives delay carbon-phase loss. Surface wear-strengthening treatments (ion/sol infiltration) add durability in the harshest streams. A suite of flow-guiding and filleted geometry optimization components reduces reattachment shear and protects edges.

The materials stack is paired with production equipment Pakistan can localize: multi-zone controlled reaction sintering and carburation kilns, atmosphere blending/recirculation systems, vacuum–inert heat-treatment furnaces, cold isostatic and die-press forming, intelligent mixing and vacuum vibration, surface modification and impregnation densification, and an online NDT and CMM/surface-energy testing suite. “Extreme zones punish shortcuts,” a Sicarbtech process lead notes. “That is why we transfer the curve, the atmosphere, the impregnation timing, and the inspection gates—so toughening shows up on the floor, not just on paper.”

Composite SiC vs Traditional Refractories: Technical Comparison for Extreme Shock

| Performance profile in extreme thermal-shock service | Composite SiC (SiC–Si3N4 / SiC–C, graded) | Single-Phase SiC (dense) | High-Alumina/Mullite |

|---|---|---|---|

| Thermal conductivity at RT (W/m·K) | 20–55 (with leveling layer options) | 20–45 | 2–6 |

| Coefficient of thermal expansion (×10⁻⁶/K) | 3.5–4.8 | ~4–5 | ~6–8 |

| Fracture toughness (MPa·m½) | 3.0–5.5 | 2.0–3.0 | 1.5–2.5 |

| Thermal-shock durability (1000°C quench, cycles) | ≥ 30–80 | 20–50 | 10–25 |

| Anti-scouring and wear | High; toughened, dense | High; brittle mode | Moderate; grooving common |

| Low-wettability/anti-slagging | High with surface engineering | 中程度 | Low–moderate |

| Chemical resistance (alkali–S–Cl) | High with sealing layer | 中・高 | 中程度 |

| Spalling tendency | Low; energy-dissipating cracks | Moderate; brittle spall risk | High under cyclic shock |

For Pakistan’s burner throats, quench zones, and switching regions, composite SiC’s conductivity, low expansion, and toughening mechanisms directly address the combined thermal, mechanical, and chemical stresses that defeat conventional materials.

Real-World Applications and Success Stories in Pakistan

On a large clinker line in central Punjab, a burner throat and quench flue suffered recurrent spalling after start–stop cycles, with debris causing secondary blockages and heat imbalance. Sicarbtech installed a functionally graded SiC–silicon nitride composite lining at the throat, added a low-wettability working layer and an alkali–sulfur–chlorine sealing layer, and replaced sharp corners with filleted flow-guide modules. In the quench flue contraction, SiC–carbon toughened bricks with anti-oxidation additives were integrated over a high-density anti-scouring base. A high-conductivity leveling layer addressed hot spots detected by IR mapping. Fast-curing composite gunning mixes enabled in-shift spot repair. Over the following campaign, thermal-shock cycle life rose by roughly 160%, spalling incidents fell by about 62%, slag thickness growth rate declined by approximately 45%, wear rate halved, unplanned downtime decreased by around 27%, and unit energy consumption dropped by roughly 3.2%. “We finally stopped chasing cracks,” the maintenance superintendent reported. “The edge chips never developed into falls.”

A steel reheating furnace in Sindh faced grooving at the secondary air-duct lining and frequent corner spalls at the furnace inlet. The retrofit applied SiC–carbon reinforced modules with microflake carbon and a low-wettability working layer, anchored to an anti-scouring base and sealed with an alkali-resistant layer. Flow guides with filleted transitions reduced shear peaks. Spall frequency dropped sharply, and inspection intervals aligned with regular maintenance, not emergency stops. Operators recorded steadier ΔP and fewer fuel trims per shift.

技術的利点と現地コンプライアンスによる実装上のメリット

Composite SiC’s advantages map cleanly onto Pakistan’s KPIs. High conductivity and low expansion reduce the gradient–strain pairing that initiates cracks, while silicon nitride and carbon toughening phases force cracks to deflect, branch, and bridge, dissipating energy and stopping spalls. Dense, fine-grain matrices with sealing layers impede alkali–sulfur–chlorine ingress that would otherwise expand pores and drop strength. Low-wettability surfaces limit slag adhesion, keeping pressure drops and cleaning frequency in check. Functionally graded architecture and high-conductivity leveling layers align stiffness and heat flow to local stress and hot-spot patterns, reducing edge chipping.

Compliance benefits follow. Fewer hot, dusty interventions and less debris support ISO 14001 goals; Sicarbtech’s QA packs align with ISO 9001 and PSQCA expectations, documenting formulation, heat-treatment curves, atmosphere profiles, adhesion tests, contact-angle results, and NDT/metrology data. Safety improves as quick-change modules and in-shift gunning reduce time-at-heat. The outcome is a credible, auditable approach that procurement and HSE teams can endorse.

Pakistan-Focused Technical Specifications and QA Guidance

| Specification ranges for composite SiC systems | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Density logs by zone (working/transition/base) |

| Apparent porosity (%) | 6–14 (working layer on lower end) | ASTM/ISO; permeability vs porosity checks |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | Coupons by location; mapping to curves |

| Flexural strength at RT (MPa) | 14–35 | 3-point bend; orientation recorded |

| Fracture toughness (MPa·m½) | 3.0–5.5 | Indentation/crack-length, SE(B) where applicable |

| CTE (×10⁻⁶/K) | 3.5–4.8 | Dilatometry; match to backing CTE |

| Thermal conductivity (W/m·K) | 20–55 | IR thermography; leveling layer validation |

| Thermal shock (1000°C quench) | ≥ 30–80 cycles | Cross-check against start–stop cadence |

| Contact angle improvement (%) | 10–30 vs oxide baselines | On-site droplets; salt/slag simulants |

| Adhesion strength (MPa) | ≥ 6–12 | Pull-off/shear tests by zone and season |

Operational Outcomes Comparison That Drive Uptime, Energy, and Safety

| Outcomes in Pakistan’s extreme shock zones | Composite SiC (graded + toughened + sealed + low-wettability) | High-Alumina/Mullite or Single-Phase SiC |

|---|---|---|

| Spalling/falling events | −40–70% | Frequent under cycling |

| Thermal shock cycle life | +50–200% | Limited; brittle failures |

| Scour/wear rate | −35–65% | Faster grooving; section loss |

| Slagging/fouling growth | −30–50% | Higher adhesion; cleanouts |

| Dimensional stability | +20–45% | Drifts with cracks/erosion |

| 計画外のダウンタイム | −20–40% | Elevated; emergency patches |

| Energy per ton | −2–6% | Higher with ΔP and leaks |

| Safety exposure at heat | Reduced via fewer hot tasks | Higher; frequent hot work |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech transforms composite SiC from a material choice into a localized capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we supply proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC, and we tailor composite-phase design—silicon nitride and carbon morphologies, ratios, and distributions—to service conditions in Pakistan.

Our turnkey stack spans:

- Forming and densification: cold isostatic/die pressing for complex shapes; reaction sintering/carburation with multi-zone temperature fields and atmosphere blending/recirculation; vacuum–inert heat treatment for stress relief and microstructure tuning.

- Surface and interface engineering: impregnation densification (sol/resin/precursor) for sealed interfaces; low-wettability, microtextured coatings; alkali–sulfur–chlorine sealing layers engineered for your chemistry indices.

- Geometry and modularity: flow-guiding ribs, fillets, and prefabricated modules for throats and corners; quick-change anchoring schemes aligned to existing frames.

- Digital QA: ultrasonic/acoustic emission for internal defects and crack onset; IR thermography for hot spot mapping; coordinate metrology for dimensional control; contact-angle testing for surface performance; and adhesion pull-off/shear testing by zone.

We embed quality systems from day one—ISO 9001-aligned QC, ISO 14001 environmental practices, and safety SOPs aligned with ISO 45001 principles. Training covers atmosphere–temperature–time profiling, impregnation timing, surface prep and adhesion, staged bake-out and soak protocols, in-shift gunning and patching, and seasonal adjustments for humidity. Commissioning uses DOE trials to lock in recipes per geometry and thickness, followed by quarterly audits and iterative tuning tied to site KPIs—spall rate, wear slope, contact-angle retention, ΔP trend, IR hot-spot suppression, and repair frequency.

Across 19+ enterprise collaborations, this “materials + equipment + process + training” approach has consistently shortened ramp-to-rate, stabilized batch quality through weather swings, and reduced FX-exposed imports. As a Sicarbtech technical director puts it, “Owning a composite is not about buying a brick. It’s about owning the curve, the atmosphere, the interface—and the proof.”

Composite Architecture and Design Elements: Why This System Works

| Design element | Sicarbtech Composite SiC Approach | Conventional Approach |

|---|---|---|

| Architecture | Functionally graded (working/transition/base) | Monolithic or simple bilayer |

| Toughening phase | Silicon nitride lamellae + carbon microflakes/short fibers | None or un-optimized additions |

| Surface engineering | Low-wettability microtexture + sealing layer | Generic coating; no energy tuning |

| Heat leveling | Optional high-conductivity equalizing layer | Typically absent |

| Geometry optimization | Filleted modules, guide ribs at scour zones | Sharp corners; high shear |

| Interface control | Impregnation densification; adhesion tested | Basic bonding; limited QA |

| Digital QA | NDT + IR + CMM + contact angle + adhesion | Visual checks; limited testing |

Innovation That Matters: Toughening Mechanisms, Sealed Interfaces, and Low-Wettability Surfaces

Sicarbtech’s R&D focuses on three leverage points. First, composite toughening uses silicon nitride lamellae and carbon microstructures to force crack deflection and bridging. This multiplies the energy required for a crack to run, turning brittle failure into manageable microcrack networks. Second, sealed interfaces—via impregnation densification and dual-layer chemical barriers—cut off alkali–sulfur–chlorine pathways and stabilize microstructures across redox cycles. Third, low-wettability microtextures tune surface energy so slags and salts struggle to anchor, flattening fouling curves and reducing cleaning. These are reinforced by hot-spot equalization layers and geometry optimization—practical tools that translate to fewer spalls, less grooving, and steadier pressure drops.

Future Market Opportunities and 2025+ Trends in Pakistan

Three forces will shape adoption in Pakistan. Energy and emissions pressures will favor materials that maintain geometry and low fouling under cycling; composite SiC’s conductivity and toughening are built for this. Alternative fuels and chemistry volatility will push plants toward sealed, low-wettability systems that blunt alkali–sulfur–chlorine attack. Localization will accelerate as producers seek to control lead time and budget variance; staged technology transfer—forming, reaction sintering/carburation, impregnation, and digital QA—will turn promising pilots into reliable programs.

In scale terms, a 5,000–8,000 t/d clinker line or a medium-to-large steel/glass unit typically consumes 50–150 tons per year of composites for extreme zones, depending on section thickness and intervals. Nationally, Pakistan’s retrofit and expansion pipeline implies kiloton-scale annual demand; including prefabs, coatings, and online gunning services, the addressable market sits in the tens to hundreds of millions of Pakistani Rupees. Providers who align proven composite-phase design with local manufacturing, fast delivery, digital traceability, and quantifiable lifecycle savings will set the pace. Sicarbtech’s integrated platform is built for exactly this transition.

As one regional furnace technologist observed in a 2025 briefing, “When cracks deflect and deposits don’t stick, your maintenance calendar suddenly matches your production plan—and that’s the definition of control.”

よくある質問

Which composite should we choose for burner throats vs quench flues?

For burner throats with severe cyclic shock and oxidation, SiC–silicon nitride graded linings with a low-wettability working layer and a sealing barrier offer excellent stability. In quench flues and contractions where shock is violent and scouring is severe, SiC–carbon toughened bricks with anti-oxidation packages perform well, especially when combined with flow-guide fillets and a high-density anti-scouring base.

How much improvement can we expect in spalling and wear?

Field results typically show 50–200% gains in thermal-shock cycle life, 40–70% fewer spalling events, and 35–65% lower wear rates. Slagging growth rates usually fall by 30–50%, and many lines report 20–40% fewer unplanned hot interventions.

Will carbon phases oxidize and weaken in oxygen-rich cycles?

We use coordinated anti-oxidation additives, sealed interfaces, and graded architecture to protect carbon-phase contributions. In zones with persistent high oxygen activity, SiC–silicon nitride composites or hybrid stacks are recommended; our application engineers select phase ratios and barriers by zone chemistry.

Can we retrofit composite modules into existing frames and anchors?

Yes. We adapt module geometries, add quick-change locking and shimming schemes, and supply transition layers to achieve fit, sealing pressure, and CTE compatibility. Dimensional templates and CMM checks ensure repeatable installation.

What installation practices prevent early spalls?

Surface preparation and roughness control, moisture and venting management, and staged bake-out/soak are decisive. We specify adhesion pull-off tests, contact-angle checks, and IR baselines by zone before return-to-service. Fillets at corners and flow guides at reattachment zones reduce stress and shear peaks.

How do we verify performance during operation?

Monitor spall and wear maps, ΔP and fan current, IR hot-spot distribution, fouling thickness, and repair frequency. We help correlate these KPIs with materials and installation data to fine-tune recipes and geometry.

Can Sicarbtech localize manufacturing and repair workflows in Pakistan?

Yes. We deliver equipment specifications and process packages for reaction sintering/carburation, atmosphere control, impregnation densification, and digital QA. Training covers forming, curves, coating/sealing, in-shift gunning, and seasonal adjustments. Most partners start with prefab modules and onsite coatings, then add sintering capacity.

How do composites impact energy and safety?

Lower fouling and steadier geometry flatten ΔP growth and reduce fuel trims, delivering 2–6% energy savings in typical cases. Fewer hot cleanouts and quick-change modules shorten exposure at heat, improving safety and compliance.

What documentation supports tenders and audits in Pakistan?

We provide ISO 9001-aligned QC packs, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, and PSQCA conformity documentation. Packs include formulation records, furnace/atmosphere curves, adhesion and contact-angle results, NDT/IR/CMM data, and acceptance criteria.

What is a realistic roadmap to deploy composites across multiple zones?

Phase 1: apply composite modules and coatings in the worst shock/scour zones; lock SOPs and QA. Phase 2: extend to adjacent zones with geometry optimization and equalization layers. Phase 3: localize production—sintering/carburation and impregnation—supported by digital QA and remote diagnostics.

オペレーションに適した選択

If cracked throats, chipped corners, and emergency cleanouts are dictating your shifts, materials are managing your plant. Composite silicon carbide puts you back in control. High conductivity and low expansion attack the gradient–strain root cause; toughening phases convert brittle failure into tolerable microcrack energy dissipation; sealed, low-wettability surfaces blunt chemistry and fouling. Sicarbtech’s integrated model—materials, equipment, curves, surface engineering, geometry, installation playbooks, and localizable QA—turns proven science into predictable performance that Pakistan’s teams can run and audit.

専門家によるコンサルテーションとカスタムソリューション

Share your zone maps—start–stop cadence, ΔT and IR hot spots, atmosphere indices (alkali/sulfur/chlorine), flow velocities and dust loading, wear and spall histories—and Sicarbtech will design a tailored composite SiC package. We will specify graded architecture, toughening phase ratios, sealing and surface-energy targets, geometry optimizations, and staged bake-out protocols. If localization is a priority, we will outline a phased technology transfer—equipment, recipes, QA, and training—to bring capability onshore.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-19

次回の予定更新日:2026年1月15日

Content freshness indicators: 2025 Pakistan cement/steel/glass outlook validated; composite SiC technical ranges aligned with current field deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.