Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Ladles, EAFs, and High-Temperature Operations

シェア

Pakistan’s steel, cement, and glass industries are navigating a tightrope in 2025: deliver stable output while cutting energy use, managing currency volatility, and complying with rising quality and environmental expectations. Silicon carbide (SiC) has moved from niche to necessity because it equalizes temperature rapidly, resists slag penetration, and survives the oxidation shocks that define modern steelmaking and allied processes. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of customization experience, proprietary R-SiC, SSiC, RBSiC, and SiSiC processes, and a turnkey model that integrates materials, prefabrication, production equipment, and onsite services. This comprehensive pillar page distills how Pakistani operators can deploy SiC–carbon systems to upgrade ladle working linings and covers, EAF slag lines and splash zones, and other high-stress applications with measurable gains in life, uptime, and cost control.

Executive Summary: 2025 Outlook and Localization Imperatives for Pakistan

The 2025 market backdrop is unforgiving. Energy prices are variable, foreign exchange movements are unpredictable, and procurement teams are under pressure to reduce refractory cost per ton without compromising safety or quality. In 鉄鋼, the operational heartbeat is electric furnace–refining–continuous casting, with frequent ladle turnarounds and shifting slag regimes. Against this reality, silicon carbide’s high thermal conductivity, low open porosity, and engineered oxidation resistance offer a path to longer campaigns and fewer unplanned repairs.

Sicarbtech’s approach aligns materials science with supply chain pragmatism. Custom SiC–carbon formulations are mapped to slag chemistry, oxygen potential, and temperature–time curves, while functionally graded structures balance a high-conductivity working layer against a low-expansion, stress-buffering backing. Moreover, technology transfer—covering carburization, reaction sintering, classification, intelligent mixing, granulation, prefab pressing, and cold isostatic pressing—enables Pakistani partners to localize production, compress lead times, and dampen currency risk. The result is not simply better refractories, but a controllable system for predictable performance.

Industry Challenges and Pain Points: Ladle Linings, Ladle Covers, and EAF Hot Zones in Pakistan

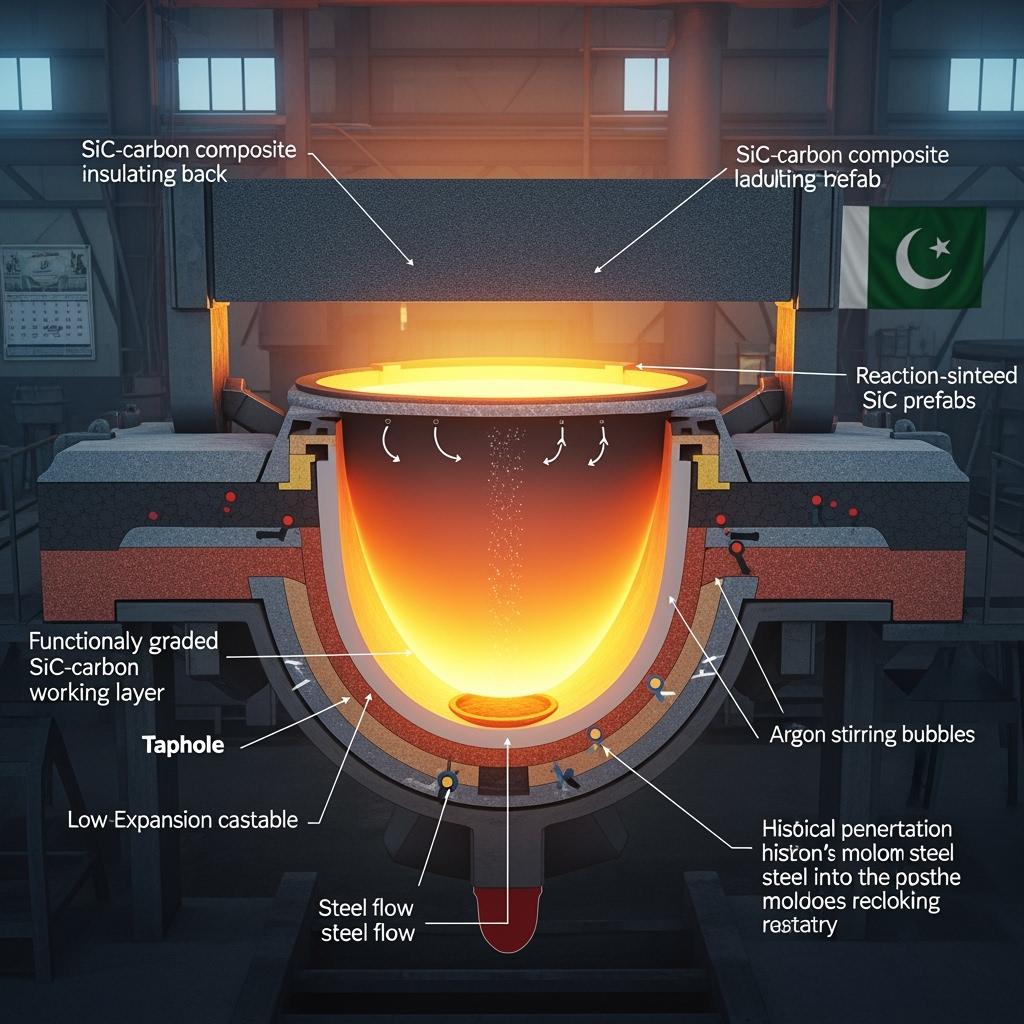

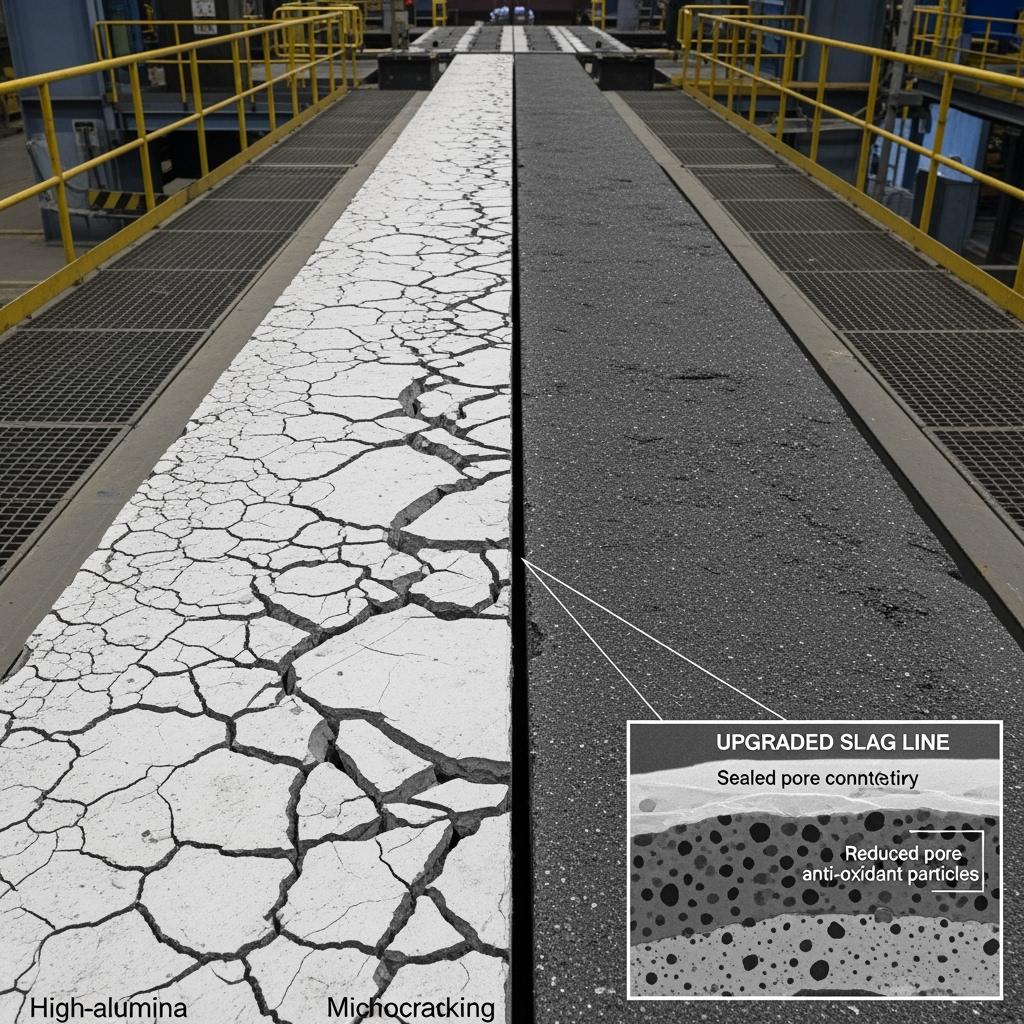

Stand at the ladle platform during a demanding sequence—argon stirring in full force, wire feeding underway, and a tight tap-to-pour cadence—and the interplay of threats becomes obvious. The working lining wrestles with high-basicity slags and oxidizing atmospheres, while hydrostatic pressure and flow scouring work at corners and impact zones. Thermal cycling is relentless, especially when casting sequences stretch and holding times vary due to grid or scrap variability. Conventional high-alumina or single magnesia-carbon systems can be caught off guard. Penetration leaves a signature of networked microcracks; spalling appears at geometric transitions; and erosion accelerates precisely where operators can least afford downtime. In continuous casting, these failings show up as larger temperature drops, unstable heats per sequence, and more inclusions—costs that echo through the entire value chain.

Pakistan’s operating context magnifies these concerns. The steel route is predominantly electric furnace to refining to continuous casting, with frequent ladle turnaround and changing slag regimes dictated by variable scrap mix and energy availability. In parallel, EAF slag lines and splash zones experience oxidizing slag attack, arc radiation, and mechanical impact during charging and oxygen blowing. Cement and glass operators face their own microstructures-first reality: abrasion and thermal gradients in preheaters and throats can punish materials designed without attention to pore connectivity and densification.

Procurement realities add pressure. The domestic base for high-performance SiC systems is still developing; import lead times and pricing can swing due to freight and FX. Plants carry larger inventory buffers, tying up working capital in materials that may not perform consistently. Local compliance is tightening as well, with PSQCA conformance and ISO 9001/14001 increasingly required in tenders and audits. “If you cannot predict lining life and bake-out times, you cannot schedule confidently,” a plant metallurgist in Punjab remarked during a 2024 technical review. “Every hour of unplanned repair adds risk to steel quality and delivery commitments.”

Independent experts echo these observations. “Thermal conductivity and controlled microstructure are decisive in limiting crack initiation under oxidation and rapid cycling,” notes a South Asia–focused refractory advisor referencing established refractory handbooks and field best practices. “If pore connectivity grows, penetration follows; if carbon phases are not stabilized, oxidation strips away the very properties you paid for.” The implication for Pakistan’s plants is clear: materials must reduce gradient-driven stress, resist slag chemistries, and preserve microstructure across start–stop cycles—while the supply chain must deliver quickly and consistently.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio is built specifically to resolve these pain points in Pakistan’s operating window. For ladle working linings, high-density SiC–carbon castables are tuned to your slag basicity and oxygen potential, leveraging multi-component anti-oxidant packages and an activation blend for SiC micropowders to preserve strength and thermal conductivity across cycles. Reaction-sintered dense SiC bricks reinforce tapholes and impact zones, where flow transitions and mechanical shock concentrate damage. In ultra-high basicity or particularly oxidizing regimes, SiC–magnesia-carbon composite bricks balance chemical compatibility with thermal shock resistance.

Ladle covers benefit from SiC–carbon composite insulation boards that pair a high-conductivity face for rapid equalization with an insulating back to minimize temperature loss and condensation. Around the nozzle and in slag-prone corners, functionally graded prefabs standardize geometry and density for faster, more predictable replacements. To seal the system, a SiC anti-penetration agent provides secondary densification after installation, while a low-expansion backing castable buffers stress between layers. For maintenance, a SiC composite gunning mix supports online hot repairs; for the permeable brick zone, an SiC–carbon upper sheath offers erosion resistance during argon stirring.

Underpinning the materials is an equipment roadmap that can be localized. Carburization and reaction sintering furnaces, high-temperature energy-saving kilns (continuous or intermittent), precision classification and demagnetization systems, intelligent mixing and granulation, and prefab mold pressing with cold isostatic pressing provide the manufacturing backbone. Bake-out control systems and gunning equipment complete the loop for installation and maintenance discipline. “We do not ship a bag and wish you luck,” a Sicarbtech applications engineer explains. “We define the recipe and the routine—so Pakistani teams can hit their KPIs with confidence.”

Performance Comparison for Pakistan’s Ladle and EAF Applications

| Technical performance profile relevant to Pakistan’s ladles and EAFs | SiC–Carbon Systems (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Clay-Based | Ordinary Magnesia-Carbon |

|---|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 (prefabs ≤ 7% porosity) | 2.2–2.8 | 2.8–3.1 |

| Apparent porosity (%) | 7–14 (dense parts ≤ 7) | 15–25 | 10–18 (rises with oxidation) |

| Thermal conductivity at RT (W/m·K) | 12–35 (tunable by grading and C) | 3–7 | 6–12 (degrades as C burns out) |

| Thermal shock (1000°C water quench) | ≥ 25–45 cycles | 10–20 | 15–30 |

| Slag/steel penetration resistance | High; sealed and dense | Moderate; prone to infiltration | Moderate; oxidation weakens matrix |

| Gas permeability (relative) | 20–40% lower vs baseline | ベースライン | Higher after oxidation cycles |

| Max service temperature (°C) | 1500–1700 | 1400–1600 | 1600–1750 |

| Bake-out and restart | Shorter with ultra-low-cement | Longer; higher moisture | Moderate; bricklaying dependent |

| Life uplift in Pakistan use cases | +30–60% typical | ベースライン | +10–25% if oxidation is low |

In Pakistan’s ladle and EAF environments—where oxidation, thermal cycling, and variable slags dominate—SiC–carbon’s combination of conductivity, density control, and stabilized carbon phases consistently narrows temperature swings and curbs spalling.

Real-World Applications and Success Stories in Pakistan

A representative steel plant in Punjab moved from high-alumina working linings to a high-density SiC–carbon castable, added reaction-sintered SiC prefabs at the taphole and corners, and installed SiC–carbon composite boards on the ladle cover with a sealing-edge wear strip to reduce air ingress. Post-installation, a SiC anti-penetration sealing agent was applied to the hot face. Over a four-month evaluation, working-layer life increased from roughly 80 heats to 128 heats; ladle cover maintenance intervals extended by 35%; refractory consumption per ton fell by 16%; average molten steel temperature drop improved by about 3.5°C; and overall downtime losses declined by roughly 22%. Continuous casting stability improved notably, with fewer sequence interruptions tied to temperature variability.

In Sindh, an EAF operator confronting chronic splash zone erosion introduced a combination of ultra-low-cement SiC castable at the slag line, reaction-sintered SiC corner protectors, and an SiC wear-resistant spray coating for online reinforcement between heats. Unplanned gunning events fell by 29%, and tapping temperature fluctuation bands narrowed sufficiently to improve downstream inclusion control. A glass plant that adopted dense SSiC flow-guiding components at the throat reported less fouling and a steadier pull rate, outcomes attributed to more uniform thermal fields and chemical resistance.

技術的利点と現地コンプライアンスによる実装上のメリット

The physics of SiC–carbon map cleanly to Pakistan’s operating and compliance priorities. High thermal conductivity spreads heat, softening gradients that seed cracks; high hardness resists scouring; and composite bonding systems—sol plus micro and ultrafine powders—drive densification while preserving thermal pathways. Multi-component anti-oxidant packages stabilize carbon phases against start–stop oxidation, and secondary densification via anti-penetration sealing further suppresses infiltration.

From a regulatory standpoint, fewer relines and shorter bake-outs support ISO 14001 goals through reduced fuel use and waste. PSQCA-aligned documentation and ISO 9001-compatible QA (with SPC on bulk density, porosity, CCS, MOR, thermal shock) facilitate vendor qualification and tender compliance. Plants that integrate thermal imaging into weekly routines can correlate surface temperature distribution with wear, gradually tightening process windows and tapping temperature control. The result is consistent heats per sequence, improved cleanliness, and fewer production plan disruptions.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s edge in Pakistan is comprehensive capability transfer—giving partners materials performance with process control. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D portfolio spans proprietary R-SiC, SSiC, RBSiC, and SiSiC process windows with documented inputs, cycle parameters, and QA checkpoints. We convert this into implementable packages:

We start with feasibility and layout, balancing throughput, utilities, and staffing. Equipment specifications cover carburization and reaction sintering furnaces fit for pilot or production scales; high-temperature energy-saving kilns (continuous or intermittent); precision classification and demagnetization for stable purity and particle size; intelligent mixing and granulation to ensure flow and homogeneity; and prefab mold pressing plus cold isostatic pressing to lock in dimensional accuracy and density. For the field, we add gunning kits and bake-out control systems to manage curves with repeatability.

Training programs cover operator safety, maintenance, and QA routines consistent with ISO 9001, ISO 14001, and ISO 45001 principles where applicable. Statistical process control is embedded—from incoming raw material checks to final CCS/MOR and thermal shock tests—while documentation templates streamline PSQCA submissions. Post-commissioning, Sicarbtech provides remote monitoring, periodic onsite audits, and formulation iteration based on plant data trends (slag chemistry, oxygen potential, thermal profiles). This end-to-end framework has supported more than 19 enterprise collaborations, repeatedly compressing lead times from months to weeks and lowering inventory buffers, even as batch-to-batch consistency improves.

“Localization is not just substitution; it is ownership of outcomes,” says a Sicarbtech technical director. “When Pakistani teams control the recipe, the furnace curves, and the QA loop, performance becomes predictable—and costs become controllable.”

Pakistan-Focused Technical Specification Ranges and QA Notes

| Specification ranges aligned to Pakistan’s QA practices | Typical SiC–Carbon Targets | Local testing and acceptance guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 | Verify via ISO/ASTM equivalents; track SPC bands per batch |

| Apparent porosity (%) | 7–14 (prefabs ≤ 7) | Stricter limits for taphole/impact zones; document soak parameters |

| Cold crushing strength (MPa) | 90–170 (dense parts ≥ 180) | ISO 10059/ASTM C133 equivalents; record temperature and dwell |

| Flexural strength at RT (MPa) | 12–28 | Bend tests with traceable coupons; trend across seasons |

| Thermal shock (1000°C water quench) | ≥ 25–45 cycles | Correlate with plant thermography during trials |

| Max service temperature (°C) | 1500–1700 | Confirm vs slag chemistry and oxygen potential |

| Thermal conductivity at RT (W/m·K) | 12–35 | Tune via grading and carbon; validate with in-situ thermal mapping |

| Gas permeability (relative) | 20–40% lower than baseline | Assess via cup tests and penetration depth post-trial |

Operational Outcomes Comparison for Ladles and EAFs in Pakistan

| Outcomes that drive cost and uptime | SiC–Carbon Working Layer + Dense SiC Prefabs + Sealing | High-Alumina or Single Magnesia-Carbon Baselines |

|---|---|---|

| Working-layer life (heats) | +30–60% uplift; stable corners and taphole | Frequent spalling and corner erosion |

| Ladle cover heat loss | Lower; conductive face with insulating back | Higher; uneven thermal fields, condensation risk |

| Unplanned hot repairs | −20–35%; predictable gunning windows | Higher; driven by penetration and microcracks |

| Molten steel temperature drop | −2 to −6°C typical | Larger drops; wider tapping variance |

| Inclusion/cleanliness impact | Reduced penetration; cleaner sequences | More variability; inclusion excursions |

| リードタイムとFXエクスポージャー | Localizable via tech transfer | Import-dependent; volatile timelines |

Innovation That Matters in Pakistan’s Conditions

Sicarbtech’s innovations are practical and field-proven. Composite bonding systems use sol chemistry to uniformly distribute micro and ultrafine powders, raising post-firing strength without sacrificing thermal pathways. Functionally graded structures place high-SiC, high-conductivity material at the hot face and low-expansion buffering behind it, mitigating thermal stress accumulation. Anti-oxidation packages stabilize carbon and slow oxygen ingress, and microstructure tuning—spheroidized micropowders, precision grading—reduces pore connectivity and blocks penetration routes. Modular prefabs paired with online gunning institutionalize a “fast repair + precise replacement” rhythm, preserving on-stream factor during peak demand.

Future Market Opportunities and 2025+ Trends in Pakistan

As EAF capacity rises and continuous casting cadence tightens, Pakistan’s demand for high-performance, low-consumption refractories will accelerate. Plants will prioritize maintenance strategies that compress bake-out and return-to-service times, making ultra-low-cement SiC castables and prefabs the default in critical zones. A second structural trend is localization: to tame FX risk and freight uncertainty, operators will increasingly invest in local mixing, classification, and prefabrication, with selected partners adding reaction sintering for dense components. Third, data-driven maintenance will mature, with thermal imaging, temperature logging, and wear mapping feeding formulation iteration—closing the loop between process conditions and material design.

Market sizing suggests that medium-to-large ladles (80–160 tons) typically consume 50–150 tons of working lining and cover refractories annually, and EAF slag line and splash zone needs for comparable scale often reach 60–180 tons per furnace. Taken together, potential demand for SiC–carbon solutions in Pakistan sits in the several-thousand-ton range, with equipment and prefab lines lifting the addressable market into tens to hundreds of millions of Pakistani Rupees, depending on adoption speed and financing. Competitive advantage will accrue to suppliers who prove raw material stability, process traceability, on-site technical strength, and short lead times—areas where Sicarbtech has built a repeatable playbook.

As an industry advisor summarized in a 2025 regional briefing (general references: WorldSteel perspectives and refractory best-practice digests), “The next productivity wave will come from refractories treated as engineered systems, not consumables, with localization and data feedback completing the loop.”

よくある質問

Which SiC grades are best for ladle working linings and covers in Pakistan?

High-density SiC–carbon castables are the primary choice for the working layer, complemented by reaction-sintered dense SiC prefabs at the taphole and corners. For high-basicity slags under strong oxidation, SiC–magnesia-carbon composites add chemical compatibility. Ladle covers benefit from SiC–carbon composite boards with a conductive face and insulating back.

How much life improvement and temperature stability can we realistically expect?

Plants typically see 30–60% longer working-layer life, 20–35% lower unplanned hot repairs, and a 2–6°C reduction in molten steel temperature drop. Tapping temperature fluctuation bands commonly narrow by 15–25% when installation discipline and bake-out control are followed.

Can Sicarbtech help us localize production to reduce lead times and FX risk?

Yes. We provide full technology transfer: process recipes, equipment specifications, plant layout, operator training, QA frameworks (ISO 9001/14001 aligned), and commissioning. Partners can localize classification, mixing, granulation, prefab pressing, cold isostatic pressing, and—where feasible—reaction sintering.

What standards and certifications are supported for Pakistani tenders?

We align QC with ISO 9001 and environmental management with ISO 14001, and we support test method equivalence (e.g., ISO 10059/ASTM C133). We assist with PSQCA documentation packs and batch traceability to streamline vendor qualification.

How do SiC–carbon systems resist penetration and oxidation during long sequences?

Dense microstructures, stabilized carbon sources, multi-component anti-oxidant packages, and post-installation anti-penetration sealing work together to reduce pore connectivity and oxygen ingress, preserving strength and conductivity across cycles.

What does installation and bake-out look like for ultra-low-cement SiC systems?

Moisture is lower and early strength is higher than conventional systems, enabling shorter, staged bake-out curves. We provide site-specific heating and soaking profiles, venting strategies, and checklists to prevent explosive spalling and early microcracking.

Are there fast-repair options compatible with Pakistan’s production cadence?

Yes. SiC composite gunning mixes support online hot repairs, while functionally graded prefabs allow quick replacement in critical zones. These approaches shrink downtime windows and protect casting cadence.

What plant data should we share to customize formulations effectively?

Slag chemistry trends, temperature–time curves, holding and turnaround times, argon-stirring intensity, wire-feeding practices, and historical wear/penetration maps. With these, we tune SiC content, carbon sources, particle grading, bonding systems, and anti-oxidant packages.

How do you ensure steady quality amid seasonal and scrap variability?

We combine stable raw material sourcing, precision classification/demagnetization, intelligent mixing and granulation, SPC-based QC for density/porosity/strength, and periodic onsite audits. Formulations are iterated based on your process data to keep performance in range.

Can SiC solutions integrate with our CMMS and thermal monitoring tools?

Yes. Sicarbtech provides installation SOPs, bake-out schedules, inspection and thermography checklists, and data templates designed to plug into common CMMS platforms, enabling condition-based maintenance and continuous improvement.

オペレーションに適した選択

Choosing silicon carbide for Pakistan’s ladles and EAFs is an engineering decision grounded in life, uptime, and energy math. When spalling, penetration, and oxidation-induced dusting disrupt schedules, SiC–carbon systems restore predictability by lowering thermal stress, sealing microstructures, and stabilizing carbon phases. With Sicarbtech’s integrated model—custom materials, prefabs, equipment, QA, training, and ongoing support—you do not just buy refractories; you establish a controllable performance system that aligns with quality, environmental, and financial objectives.

専門家によるコンサルテーションとカスタムソリューション

Talk to Sicarbtech’s application engineers about your operating window. Share your slag data, thermal profiles, and maintenance constraints, and we will propose a tailored SiC–carbon package with modeled life improvement, bake-out curves, and a phased implementation plan—plus a localization roadmap if you want to build capability in-country.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Eメール:[email protected]

電話/WhatsApp:+86 133 6536 0038

記事のメタデータ

Last updated: 2025-09-19

次回の予定更新日:2026年1月15日

Content freshness indicators: 2025 Pakistan market outlook reviewed; technical ranges aligned with recent field data; PSQCA/ISO references validated; contact details and service scope confirmed for Pakistan.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.