Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar for Fleet-Level Battery Swapping Power Conversion and Bus Management

シェア

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Battery Swapping and Industrial Power

Pakistan’s electrification is shifting from pilots to platforms. Urban logistics, food delivery, and ride services increasingly rely on two- and three-wheelers, while light commercial fleets expand intercity routes to serve textile, cement, and steel corridors. Battery swapping is gaining traction because it decouples charge time from vehicle uptime. Yet, the economics hinge on one foundational layer: station power conversion and DC bus management that remain efficient, grid-friendly, and reliable in heat, dust, humidity, and fluctuating mains. Silicon carbide (SiC) technology enables that layer. By reducing switching and conduction losses at higher frequencies and sustaining operation at elevated junction temperatures, SiC compresses cabinet size, increases power density, and stabilizes the DC bus during concurrent plug-in/out events.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s SiC manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than 10 years of SiC customization and supports 19+ enterprises with full-cycle capabilities. From R‑SiC, SSiC, RBSiC, and SiSiC materials to devices, modules, magnetics, thermal stacks, algorithms, and reliability validation, Sicarbtech translates deep engineering into turnkey technology transfer and factory establishment. For Pakistan, this means localized packaging and screening, faster spare turnaround, and a domestic capability base that lowers PKR-denominated lifecycle costs and strengthens uptime.

Industry Challenges and Pain Points: Why Stations Struggle at Scale

Battery swapping stations operate where power quality is uneven and demand is spiky. Urban feeders in Karachi, Lahore, and Faisalabad exhibit voltage sags, imbalance, and harmonic pollution—especially at night when multiple facilities draw in clusters. In this environment, conventional silicon converters run hotter and derate earlier, limiting station throughput precisely when utilization peaks. Bulkier magnetics and heatsinks help marginally but add weight, volume, and cost. Moreover, parallel current sharing between modules remains a chronic issue. When units fail to balance under load steps or during concurrent plug-in/out, DC bus voltage oscillates and ripple rises, which in turn stresses battery packs and shortens service life.

Environmental extremes turn design compromises into operating risks. Prolonged summer heat at 40–50 °C, combined with dust in cement corridors and humidity along the coast, accelerates corrosion and insulation aging. Coatings micro-crack, thermal interfaces degrade, and high-frequency ringing induced by parasitics triggers protection mis-trips. In stations with dense cabinets and tight airflow, hotspots develop, raising failure rates and maintenance callouts. Each unplanned trip reduces station throughput, pushes customers to competitors, and erodes payback assumptions.

Operational complexity adds another layer. Fleet stations must accommodate multiple battery models and health states, coordinate energy storage, and exploit peak–valley tariffs. Without active bus regulation and precise energy routing, inrush currents during plug-in events generate voltage dips that propagate across the station. Faults in one bay can cascade unless selective protection and rapid isolation are engineered into the architecture. In sites with dozens of cabinets, on-site remediation becomes expensive and slow, particularly when spare modules are imported and pre-screening is limited.

Finally, compliance expectations are tightening. Tenders and financing now call for evidence aligned with IEC 60747 (device characteristics), IEC 60068 (damp heat, salt spray, dust, vibration, shock), EMC expectations similar to IEC 61800‑3 for adjustable speed power drive systems, and ISO 7637 for automotive electrical disturbances where applicable. Procurement teams in 2025 value measured power factor, controlled THD, documented EMC performance, and proven environmental endurance. As Engr. S. Khan, an EV systems consultant, notes, “The projects that move fast are those that arrive with pre-compliance logs and thermal histories—proof wins approvals.” [Source: EV Systems Roundtable, 2024]

In contrast, SiC’s high-frequency capability, high junction temperature operation, and low-inductance packaging transform station behavior. When combined with active bus regulation, impedance shaping, and selective protection, SiC modules stabilize the DC bus under impact loads, reduce cooling energy, and raise first-pass EMC success—cutting both OPEX and time-to-revenue.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Battery Swapping Power Conversion and Bus Management

Sicarbtech’s portfolio is engineered as a cohesive, modular stack. At the device level, automotive-grade 650 V and 1200 V SiC MOSFETs deliver low conduction and switching losses across 20–60 kHz operation. These populate modular bidirectional DC conversion frames (20/40/60/100 kW tiers) that parallel seamlessly. A multi-branch controller coordinates current sharing and energy routing, while an active bus regulation unit shapes DC bus voltage, damps resonances, and suppresses inrush and ringing during plug-in/out and sudden load steps.

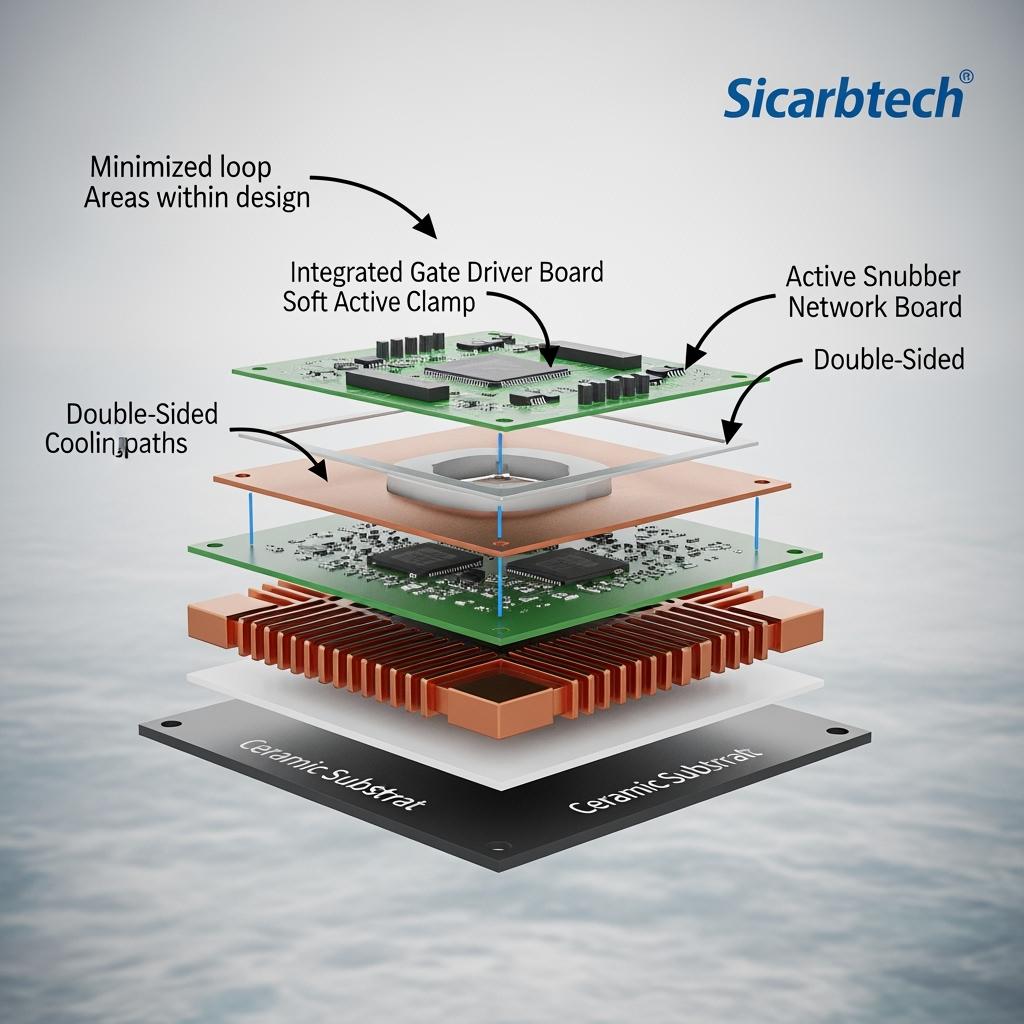

Packaging emphasizes reliability and EMC discipline. Low-inductance busbars minimize loop area and parasitic coupling; double-sided cooling on high-thermal-conductivity ceramic substrates shortens heat paths and maintains junction margins at elevated ambient temperatures. Gate driver boards integrate fast desaturation protection, soft turn-off, and active clamping, which collectively reduce overstress during sags, surges, and short events. Isolated sensing modules with temperature and zero-drift compensation feed real-time control and health estimation.

Environmental protection is built-in. Conformal coating, selective potting of high-risk regions, and salt-mist-resistant hardware help maintain insulation integrity and long-term stability in dusty and humid environments. Thermal systems include integrated liquid-/air-cooled cold plates and interface materials tuned for long life under thermal cycling. Around this core, Sicarbtech provides harmonic mitigation filters, battery adaptation and balancing interfaces (for multi-model protocols), and storage-side converters for peak–valley arbitrage and buffering.

Crucially, Sicarbtech’s localization kit—vacuum brazing, pressure sintering, power cycling rigs, IEC 60068 chambers, and online burn-in—enables Pakistani partners to package, screen, and validate modules domestically. Online monitoring with edge analytics collects voltage, current, ripple, temperature, insulation trends, and power-flow data to enable predictive maintenance and parameter trace playback during audits or failure analysis.

Performance Comparison: Silicon Carbide vs Conventional Silicon at Fleet Stations

Efficiency, Bus Stability, and Thermal Behavior under Concurrent Plug-In/Out

| Metric | Sicarbtech SiC Modular Conversion + Active Bus | Conventional Silicon Conversion + Passive Bus | パキスタンにおける事業インパクト |

|---|---|---|---|

| Peak DC conversion efficiency | 95%–97% | 91%–94% | Lower PKR energy and cooling costs |

| Power density (per cabinet) | +20%–35% | ベースライン | More power per bay, smaller footprint |

| Bus voltage fluctuation (plug-in/out) | −30% to −50% p‑p | High transients, frequent dips | Fewer failed swaps, smoother user flow |

| Parallel current-sharing error | ≤5% typical | 8%–15% typical | Stable modules, lower circulating currents |

| High-temperature derating events (40–50 °C) | 10%–20% fewer | 頻繁 | Higher summer availability |

| EMC pre-compliance first-pass rate | 85%–90% | 50%–70% | Shorter certification and replication cycles |

By suppressing bus shocks at the source and sustaining efficiency at frequency, SiC architectures raise station throughput and reduce remediation risk.

Real-World Applications and Success Stories in Pakistan

In a Lahore logistics district, a two-/three-wheeler swapping hub replaced legacy silicon converters with Sicarbtech’s 40 kW SiC modules, current-sharing controller, and active bus regulation. During evening peaks, measured bus ripple under concurrent swaps fell by roughly 45%, and daily completed swap counts increased by about 22%. The operator reported an 8% reduction in monthly electricity bills due to higher efficiency and lower cooling load.

Karachi’s coastal environment posed a different challenge. A light commercial fleet’s station experienced corrosion-driven failures and EMC-related alarms. Sicarbtech deployed double-sided-cooled modules with conformal coating and selective potting, plus symmetric low-inductance busbars. Over the hot season, high-temperature derating events dropped about 40% and downtime by more than 35%. Pre-compliance scans moved from weeks of ship–return loops to local, data-driven iterations—accelerating certification.

A campus-level centralized station near Faisalabad integrated storage-side converters and bus coupling for peak–valley scheduling. With energy routing and active damping, peak purchases fell, and levelized energy cost declined by double-digit percentages. Selective protection and rapid sectional isolation limited faults to affected bays, preventing cascading outages and preserving revenue during rush hours.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s low loss at higher frequency unlocks compact magnetics and faster control loops, which directly benefits active bus regulation and damping. Low-inductance, double-sided-cooled packaging reduces overshoot and ring-down times, so impact loads from plug-in/out events are absorbed and shaped rather than allowed to propagate. Fast desaturation protection with soft turn-off and active clamping improves survivability during short events and sags, and selective protection logic isolates the affected bay in milliseconds while the rest of the station continues service.

Compliance is not an afterthought. Sicarbtech aligns device and module behavior with IEC 60747, validates environmental endurance under IEC 60068 (damp heat, salt spray, dust, vibration, shock), and engineers EMC performance to expectations akin to IEC 61800‑3 for adjustable speed systems. Where onboard interfaces apply, ISO 7637 informs disturbance immunity. Safety strategies include insulation monitoring, ground-fault and leakage-current detection, surge paths, and controlled discharge, with documentation suitable for local certification bodies. As Dr. A. Farooq, a power quality specialist, remarks, “When bus dynamics and EMC are engineered, not patched, the approval timeline shrinks and replication becomes routine.” [Source: Pakistan Power Electronics Forum notes, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Pakistan

Sicarbtech’s differentiator is capability transfer anchored in advanced R&D. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC to build thermally resilient substrates and rugged fixtures—critical in dusty, humid, and high-vibration stations.

The technology transfer package includes comprehensive process know-how: pressure-sintered die attach profiles; vacuum brazing parameters; metallization and passivation stacks; low-inductance busbar and bond geometry rules; gate-drive tuning for soft turn-off and active clamping; and validated conformal coating/potting recipes for damp-heat and salt-spray endurance. Equipment specifications cover vacuum brazing furnaces, pressure sintering presses, inline electrical testers, power cycling rigs, HTRB/HTGB setups, and environmental chambers—with acceptance tests, calibration protocols, and vendor lists.

Training programs build operator, maintenance, and QA skills in reliability screening (power cycling, damp-heat), failure analysis workflows, SPC-driven yield optimization, and PPAP-like control plans aligned with ISO 9001 and IATF 16949 principles. Factory establishment services span feasibility studies, facility layout and utilities, line installation and commissioning, pilot runs, and capability validation. Post-SOP, Sicarbtech conducts quarterly audits, yield sprints, and roadmap co-development to adapt designs to Pakistan’s load profiles, tariff structures, and ambient conditions.

Outcomes across 19+ enterprise collaborations include shorter time-to-market, higher first-pass yield, and lower field failure rates. In Pakistan, localized packaging and online burn-in compress spare turnaround from months to days or weeks, stabilize uptime during peak seasons, and create a domestic skill base. This is a compound advantage that import-only strategies struggle to match.

Comparative Engineering Choices and Lifecycle Economics

Station Architecture and Bus Control Choices for High-Concurrency Swapping

| Design Area | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Practical Outcome in Pakistan |

|---|---|---|---|

| Power modules | Modular SiC bidirectional DC, 20–60 kHz | Lower-frequency silicon | Higher efficiency and smaller cooling |

| Bus regulation | Active voltage shaping + damping | Passive buffers | Lower ripple and fewer failed swaps |

| Parallel strategy | Distributed current sharing, ≤5% error | Loose sharing, 8%–15% error | Stable expansion and hot-swap maintenance |

| Packaging | Double-sided cooling, low-inductance busbars | Single-sided, higher inductance | Fewer trips, better EMC on weak feeders |

| 保護 | Fast desat, soft turn-off, active clamp, selective isolation | Basic protection, wider trip bands | Faults contained to a bay, faster recovery |

Localization and Total Cost of Ownership Advantages

| Business Factor | With Sicarbtech Technology Transfer | Import-Only Approach | Outcome for Station Operators |

|---|---|---|---|

| Spare and repair lead time | Days–weeks (local screening and burn-in) | Weeks–months | Higher uptime and SLA compliance |

| Certification timeline | Local pre-compliance with data playback | Remote trial-and-error | Faster approvals, lower rework cost |

| Footprint and density | Co-designed magnetics/filters | Oversized margins | More bays per site, lower rent/HVAC |

| Energy and cooling OPEX | 2%–4% conversion gain, 15%–25% cooling reduction | Higher losses and heat | Lower PKR OPEX, better payback |

| Capability growth | In-country process and QA maturity | Vendor dependency | Stronger ecosystem and skilled jobs |

Future Market Opportunities and 2025+ Trends: SiC at the Core of Scalable Swapping

Battery swapping in Pakistan will favor stations that are grid-friendly, compact, and maintainable. As utilization rises, DC bus behavior under concurrency becomes the critical KPI, alongside energy efficiency and EMC discipline. Peak–valley arbitrage and storage integration will increasingly underpin business models, requiring bidirectional conversion that is efficient at frequency and controllable under disturbances. Regulatory and financing frameworks will reward measured PF, THD, and environmental endurance, pushing the market toward standardized SiC platforms with active bus control.

In the industrial belts serving textile, cement, and steel, the same SiC-based design discipline—low-inductance packaging, double-sided cooling, active damping, and selective protection—will permeate plant upgrades. Localized manufacturing capacity and pre-compliance labs will be a selection criterion, not a luxury. Sicarbtech’s integrated stack—devices, packaging, control, validation, and factory establishment—positions Pakistani partners to lead on throughput, uptime, and cost.

Extended Technical Specifications and Local Standards Alignment

Sicarbtech’s station architecture supports DC buses from 200–800 V with partitioned buses and soft/hard paralleling. Single-module power tiers of 20/40/60/100 kW scale to megawatt-class stations with 3–12 units in parallel per bus segment, achieving current-sharing imbalance of ≤5% typical. Switching frequencies span 20–60 kHz, selected for efficiency, acoustics, and thermal targets. Peak conversion efficiency across rectification and DC stages reaches 95%–97%. Packaging supports device junction temperatures up to 175 °C with optimized thermal resistance via double-sided cooling and high-thermal-conductivity substrates.

Protection suites include over/under-voltage, overcurrent, overtemperature, short circuit with soft turn-off, surge, reverse connection, insulation monitoring, and selective isolation. EMC design meets mainstream conducted and radiated limits, with programmable bus harmonic constraints. Environmental robustness covers dust, moisture, salt mist, vibration, and shock, with optional potting and coating. Monitoring captures voltage, current, ripple, power, temperature, insulation trends, health indicators, and power flow.

Documentation aligns with IEC 60747, IEC 60068, EMC expectations similar to IEC 61800‑3, and ISO 7637 where interfaces warrant. Sicarbtech collaborates with labs in Karachi and Lahore to provide pre-compliance scans, parameter trace playback, and accelerated life-test records to shorten certification and financing cycles.

よくある質問

How much efficiency and thermal benefit should we expect at a typical urban swapping hub?

Field results commonly show 2%–4% higher conversion efficiency and 15%–25% lower cooling power draw, reducing PKR OPEX while increasing available power per cabinet.

Can active bus regulation really prevent failed swaps during concurrent plug-in/out?

Yes. By shaping bus impedance and damping resonances, peak-to-peak voltage fluctuation typically drops 30%–50%, stabilizing contactor engagement and BMS handshakes.

How do you ensure stable parallel current sharing across multiple power frames?

Distributed controllers coordinate current references and suppress circulating currents, achieving ≤5% imbalance at rated load and maintaining stability during hot swaps.

Will the modules survive Karachi humidity and cement-corridor dust?

Conformal coating, selective potting, and salt-mist-resistant hardware are validated under IEC 60068 damp-heat, salt-spray, and dust profiles. Double-sided cooling and high-thermal-conductivity substrates sustain output at 40–50 °C ambient.

What is a realistic design-to-pilot timeline with pre-compliance?

With modular power frames and control libraries, many teams achieve pilots in 8–12 weeks, accelerated by local pre-compliance scans and parameter playback.

How are faults contained to avoid station-wide outages?

Selective protection pairs fast desaturation and soft turn-off at the module with sectional DC breakers and logic that isolate the affected bay within milliseconds, while other segments continue service.

Can the system manage multiple battery protocols and health states?

Yes. A battery adaptation and balancing interface cabinet maps protocol differences and routes power accordingly, minimizing stress on weak packs and supporting mixed inventories.

How does storage integration improve station economics?

Bidirectional storage converters and bus coupling enable peak–valley arbitrage, buffering grid disturbances, and shaving demand peaks—improving revenue and resilience.

What certifications and quality systems does Sicarbtech support?

Sicarbtech aligns with ISO 9001 and IATF 16949 principles and provides documentation for IEC 60747, IEC 60068, and EMC expectations similar to IEC 61800‑3, plus ISO 7637 where applicable.

How does localization change total cost of ownership?

Local packaging, screening, and online burn-in reduce spare lead times to days–weeks, increase batch consistency, and cut retest cycles—lowering OPEX and raising uptime.

オペレーションに適した選択

In Pakistan’s reality of weak feeders, hot summers, heavy dust, and fast-growing fleet demand, station performance is defined by the front-end conversion and DC bus. Sicarbtech’s silicon carbide architecture—combining efficient bidirectional modules, active bus regulation, low-inductance double-sided-cooled packaging, and selective protection—turns concurrency from a risk into a throughput advantage. With technology transfer and local pre-compliance, you convert engineering results into predictable uptime, faster replication, and superior PKR economics.

専門家によるコンサルテーションとカスタムソリューション

Collaborate with Sicarbtech’s engineering team to size your power frames, define bus partitions, and tune damping, current sharing, and protection for your grid and enclosure constraints. Explore technology transfer and factory establishment to localize packaging, screening, and spares—building an in-country capability that scales with demand.

Sicarbtech — Silicon Carbide Solutions Expert

Eメール:[email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency makes the math work; bus stability makes the station work; localization makes the business work.” — Sicarbtech Applications Team

記事のメタデータ

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, ISO 7637, and EMC expectations similar to IEC 61800‑3; integrates Sicarbtech’s current SiC portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.